Abstract

Poly(N,N-bis(2-methoxyethyl)acrylamide) (PbMOEAm) featuring two classical chemical motifs from non-ionic water-soluble polymers, namely, the amide and ethyleneglycolether moieties, was synthesized by reversible addition fragmentation transfer (RAFT) polymerization. This tertiary polyacrylamide is thermoresponsive exhibiting a lower critical solution temperature (LCST)–type phase transition. A series of homo- and block copolymers with varying molar masses but low dispersities and different end groups were prepared. Their thermoresponsive behavior in aqueous solution was analyzed via turbidimetry and dynamic light scattering (DLS). The cloud points (CP) increased with increasing molar masses, converging to 46 °C for 1 wt% solutions. This rise is attributed to the polymers’ hydrophobic end groups incorporated via the RAFT agents. When a surfactant-like strongly hydrophobic end group was attached using a functional RAFT agent, CP was lowered to 42 °C, i.e., closer to human body temperature. Also, the effect of added salts, in particular, the role of the Hofmeister series, on the phase transition of PbMOEAm was investigated, exemplified for the kosmotropic fluoride, intermediate chloride, and chaotropic thiocyanate anions. A pronounced shift of the cloud point of about 10 °C to lower or higher temperatures was observed for 0.2 M fluoride and thiocyanate, respectively. When PbMOEAm was attached to a long hydrophilic block of poly(N,N-dimethylacrylamide) (PDMAm), the cloud points of these block copolymers were strongly shifted towards higher temperatures. While no phase transition was observed for PDMAm-b-pbMOEAm with short thermoresponsive blocks, block copolymers with about equally sized PbMOEAm and PDMAm blocks underwent the coil-to-globule transition around 60 °C.

Similar content being viewed by others

Introduction

Many non-ionic polymers in aqueous solution are thermoresponsive featuring a lower critical solution temperature (LCST), i.e., they are water-soluble or highly swollen below a characteristic transition temperature but are water-insoluble and collapsed above. Apart from the basic scientific interest in this behavior, its use for a plethora of possible “smart” applications has been discussed [1,2,3]. While many different polymer chemistries are known to exhibit LCST behavior in aqueous media [4, 5], two major chemical motifs prevail. Water solubility is implemented either via amide moieties or via ethyleneglycol ether groups, as exemplified by the two arguably most studied thermoresponsive polymer systems, namely, poly(N-isopropyl acrylamide) (PNIPAm) [6] and polymers based on poly (ethyleneglycol) (PEG) [7, 8]. The specific LCST is mainly determined by the polymer composition, i.e., in the case of homopolymers, by the chemical structure of the underlying monomer. Typically, small chemical changes of the monomer’s molecular structure result in big changes of the LCST [4], whereat in particular for low-to-moderate molar masses, the precise value can be adjusted to a certain extent by incorporating functional end groups [9,10,11] or by the precise molar mass itself [4]. A more flexible control over the LCST value is achieved by using statistical copolymers. They can be either obtained by direct copolymerization of appropriate monomers in suitable amounts [12,13,14,15,16,17] or by partial chemical modification [18,19,20,21], and enable the fine-tuning of the LCST value. Yet, except for the rare case of ideal azeotropic copolymerizations (i.e., all copolymerization reactivity ratios are close to unity) [22,23,24,25,26,27], this gives rise to product mixtures that risk blurring the transition. In any case, the chemical complexity of such thermoresponsive copolymers is increased, which tends to render their chemical analysis as well as the interpretation of experimental findings complicated. This is particularly problematic when additional structural features are to be implemented into thermoresponsive polymers, such as blocky structures or complex functional moieties [28,29,30,31,32]. Therefore, there is a continuous quest for new monomers that yield thermoresponsive homopolymers.

In this general context, we have synthesized and explored polymers of N,N-bis(2-methoxyethyl)acrylamide 1 (Fig. 1) with respect to their thermosensitive behavior in aqueous solution. Monomer 1 combines the two dominating chemical motifs of non-ionic thermoresponsive polymers within the same molecule, the amide and ethyleneglycolether moieties, which has been rarely done [33,34,35,36,37,38,39]. The monomer does not contain hydrolytically fragile groups such as esters, and its molar mass is rather small compared with the frequently used (oligoethyleneoxide) acrylates and methacrylates [7, 26, 40, 41], which often have the character of macromonomers. Moreover, its chemical structure is close to the ones of the well-established monomers N,N-diethylacrylamide (DEAm) and (methoxy diethylene glycol acrylate) (MDEGA), which represent the pure amide and ethyleneglycolether structures. Their polymers exhibit LCSTs in water in the physiologically particularly attractive temperature region of ± 10 °C around human body temperature of 37 °C [23, 42,43,44,45,46]. The thermoresponsivity of the polymers of 1 was mentioned already in the early 1990s [33], but apart from patent claims, polymer P1 has been hardly studied, and the few data on the aqueous phase behavior are conflicting [36, 47, 48]. Yet, statistical copolymers of N,N-dimethylacrylamide and 2-methoxyethylacrylate, which structurally are quite similar to P1, have been reported to be both thermosensitive and highly biocompatible [13, 14, 49, 50]. Therefore, we have now explored the use of reversible fragmentation addition chain transfer (RAFT) radical polymerization, to prepare homopolymers of 1 of targeted molar masses. We also synthesized diblock copolymers of 1 with the strongly hydrophilic comonomer N,N-dimethylacrylamide 2 (Fig. 1) and investigated the thermoresponsive behavior of the various polymers in dilute aqueous solution.

Experimental

Materials

Acetone-d6 (≥ 99.5 atom% D, Armar Chemicals (Europa), Leipzig, Germany), acryloyl chloride (≥ 96.0%, stabilized with phenothiazine, Merck), allyltrimethylsilane (98%, abcr, Karlsruhe, Germany), aluminum oxide (Al2O3 activated basic, Brockmann I, Sigma–Aldrich), benzene (99.5%, Carl Roth GmbH, Karlsruhe, Germany), benzyl bromide (99%, Alfa Aesar), N,N-bis(2-methoxyethyl) amine (> 98.0%, TCI Deutschland GmbH, Eschborn, Germany) carbon disulfide (≥ 99.9%, Merck), chloroform (≥ 99.5%, stabilized with amylene, Th. Geyer, Renningen, Germany), chloroform-d (99.8 atom% D, Armar Chemicals), 4-chloromethylbenzoyl chloride (> 98%, TCI), deuterium oxide (99.8 atom% D, Armar Chemicals), dichloromethane (≥ 99.8%, stabilized with amylene, Th. Geyer), diethylether (≥ 99.5%, Th. Geyer), n-dodecyl-1-amine (97%, Alfa Aesar, ethanol, (abs, Merck)), ethyl acetate (99.9%, VWR International GmbH, Darmstadt, Germany), n-hexane, (99.0%, Th. Geyer), aqueous hydrochloric acid (HCl, 1 M, Th. Geyer), magnesium sulfate (anhydrous ≥ 99.5%, Alfa Aesar), methanol (technical grade, Merck), methanol (for spectroscopy, Uvasol grade, Merck), petrol ether (b.p. 60–80 °C, analytical grade, Th. Geyer), propane-1-thiol (98%, Alfa Aesar), pyridine (anhydrous > 99.0%, Alfa Aesar), pyrrolidine (99%, Merck), sodium hydroxide (≥ 98.8%, Th. Geyer), tetrahydrofuran (≥ 99.9%, stabilized with 2,6-di-t-butylbutyl-p-cresol “BHT”, Th. Geyer), thioacetic acid (≥ 98%, Merck), and triethylamine (99%, Acros Organics/Fisher Scientific GmbH, Schwerte, Germany) were used as received. 1,1′-Azobis (cyclohexanecarbonitrile) V-40 (98%, Sigma–Aldrich) and 2,2′-Azobis(2-methylpropionitrile) AIBN (98%, Sigma–Aldrich) were crystallized from chloroform (V-40) or n-hexane (AIBN) prior to use. N,N-dimethylacrylamide (DMAm 2, ≥ 99.0%, stabilized with 4-methoxyphenol “MEHQ”) was distilled prior to use. Deionized water was used for synthesis. For measurements, deionized water was further purified by a Millipore Milli-Q Plus water purification system (Merck Millipore, Darmstadt, Germany), resistivity 18 mΩ cm−1. Column chromatography was performed on Silica Gel 60 (0.063–0.200 mm, 230–400 mesh ASTM, Merck).

Chain transfer agent (CTA) benzylpropylcarbonotrithioate (BPTC, 3) was prepared from 1-propanethiol, CS2, and benzylbromide, adapting reported procedures [51, 52]. The raw product was purified by column chromatography on silica gel using the mixture petroleum ether:ethyl acetate 40:1 (v/v). The analytical data agreed with the reported ones [52, 53].

Synthesis of N,N-bis(2-methoxyethyl)acrylamide (bMOEAm, 1)

A solution of acryloyl chloride (11.3 mL, 12.6 g, 0.139 mol, 1.1 eq.) in CH2Cl2 (40 mL) was dropped over 3 h into a stirred solution of bis(2-methoxyethyl) amine (18.7 mL, 16.8 g, 0.127 mol) and triethylamine (26.5 mL, 19.3 g, 0.191 mol, 1.51 eq.) in CH2Cl2 (350 mL) at 0 °C. The reaction mixture was allowed to warm up to ambient temperature and continued to be stirred overnight. The precipitated triethylammonium hydrochloride was filtered off and washed with CH2Cl2 (100 mL). The combined organic solutions were extracted subsequently with 1 m HCl (3 × 50 mL), water (50 mL), and brine (100 mL). The organic layer was dried over anhydrous MgSO4 and the solvent removed under reduced pressure. The raw product was purified by vacuum distillation to give a viscous liquid (n20D = 1.4722). Yield: 14.5 g (61%)

1H-NMR (300 MHz in CDCl3, δ in ppm): δ = 3.11 (s, 6H, CH3, 3.27–3.43 (m, 6H, N-CH2-CH2-O), 5.44 (dd, 1H, CHE = C-CO), 6.09 (dd, 1H, CHZ = C-CO), 6.46 (dd, 1H, =CH-C=O)

13C-NMR (75 MHz in CDCl3, δ in ppm): δ = 46.45 (N-CH2), 48.33 (N-CH2), 58.16 (O-CH3), 58.43 (O-CH3), 70.53 (CH2-O), 126.93 (CH2-CH), 127.71 (CH-CO), 166.11 (CO)

Elemental analysis, calculated: C9H17NO3: C 57.7%, H 9.2%, N 7.5%, found: C 56.7%, H 10.9%, N 7.4%

Mass spectrometry: calculated mass Mr: 188.1287 g/mol, found mass: 188.1291 g/mol

FTIR (selected bands cm−1): 2982, 2929, 2883, 2821, 1647, 1610, 1443, 1363, 1189, 1111, 1012, 978, 960, 795

Synthesis of 4-chloromethyl-N-n-dodecylbenzamide

4-Chloromethylbenzoyl chloride (25.5 g, 0.135 mol) was dissolved in CHCl3 (20 mL) and cooled down to 0 °C. Pyridine (21.5 mL, 21.0 g, 0.266 mol, 1.97 eq.) was added. Subsequently, dodecylamine (25.1 g, 0.136 mol, 1.1 eq.) was added slowly. The mixture was stirred at room temperature overnight. Then, CHCl3 (150 mL) was added, the mixture was extracted with 1 m aqueous HCl (100 mL), and the aqueous phase was re-extracted with CHCl3 (3 × 50 mL). The combined organic phases were washed with 1 m HCl (100 mL) and distilled water (100 mL). The resulting emulsion was split by adding NaOH (23.3 g). The combined organic phases were washed with brine (500 mL). After drying over MgSO4, the solvent was removed under reduced pressure. The residue was crystallized twice from MeOH and twice from ethyl acetate and dried in vacuo to yield a colorless solid (16.05 g, 35%).

1H-NMR (300 MHz in CDCl3, δ in ppm): δ = 0.88 (t, 3H, CH3), 1.26–1.33 (m, 18H, -(CH2)9, 1.61 (m, 2H, N-C-CH2), 3.44 (dt, 2H, N-CH2), 4.60 (s, 2H, C-CH2-S), 6.14 (broad t, 1H, N-H), 7.44 (d, 2H, ArH2,6), 7.75 (d, 2H, ArH3,5)

Synthesis of 3-(trimethylsilyl)propane-1-thiol

Adapting a literature procedure [54], allyltrimethylsilane (33.5 mL, 24.1 g, 211 mmol) was dissolved in THF (120 mL). Thioacetic acid (29.0 mL, 26.9 g, 353 mmol, 1.67 eq.) and AIBN (0.273 g, 1.66 mmol, 0.01 eq.) were added and the solution was refluxed under inert gas for 23 h. After cooling, 10 wt% aqueous NaOH (100 mL) was added at 0 °C while stirring. The organic solvent was removed under reduced pressure and the residue was dissolved in ethyl acetate (100 mL). The organic phase was washed with 10 wt% NaOH (3 × 100 mL, 3 × 50 mL) and distilled water (100 mL). The combined aqueous phases were extracted with ethyl acetate (100 mL). The combined organic phases were washed with distilled water (100 mL) and brine (100 mL) and dried over MgSO4. Afterwards, the solvent was removed under reduced pressure to give S-(4-(trimethylsilyl)propyl) ethanethioate as colorless liquid (38.7 g, 0.203 mol, 94%).

1H-NMR (300 MHz in CDCl3, δ in ppm): δ = − 0.02 (s, 9H, Si-CH3), 0.56 (mc, 2H, Si-CH2), 1.61–1.50 (m, 2H, CH2-CH2), 2.32 (s, 3H, CO-CH3), 2.87 (t, 2H, CH2-S)

The so obtained intermediate thioester (41.3 g, 0.217 mol) was dissolved in ethanol and cooled to 0 °C. A 25 wt% NaOH solution (1.5 eq.) was added and the reaction mixture was stirred overnight. Thin layer chromatography (TLC) showed completely consumption of the educt. The reaction mixture was neutralized with conc. HCl, and extracted twice with CH2Cl2 (100 mL, 40 mL). The combined organic phases were washed with distilled water (3 × 100 mL), 10 wt% NaOH (3 × 50 mL), distilled water (100 mL), and brine (100 mL). After drying over MgSO4, the solvent was removed under reduced pressure. The residue was distilled in vacuo to give 3-(trimethylsilyl)propane-1-thiol as colorless liquid (12.4 g, 83.7 mmol, 66%).

1H-NMR (300 MHz in CDCl3, δ in ppm): δ = − 0.01 (s, 9H, Si-CH3), 0.58 (mc, 2H, Si-CH2), 1.34 (t, 1H, S-H), -), 1.65–1.55 (m, 2H, CH2-CH2), 2.52 (dt, 2H, CH2-S)

Synthesis of 4-(dodecylcarbamoyl)benzyl-3-(trimethylsilyl)propyl) carbonotrithioate (4dBtmsPTC, 4)

S-(4-(Trimethylsilyl)propyl) ethanethiol (8.22 g, 55.4 mol) and CS2 (3.35 ml, 4.22 g, 55.4 mmol, 1.00 eq.) were dissolved in dry CH2Cl2 (20 mL) and stirred at room temperature. Triethylamine (7.90 mL, 5.77 g, 57.1 mmol, 1.03 eq.) was added dropwise, while keeping the reaction at room temperature. The orange solution formed was stirred for 30 min. 4-Chloromethyl-N-dodecylbenzamide (17.79 g, 52.64 mmol, 0.95 eq.) was slowly added, and the reaction was stirred overnight. After dilution with more CH2Cl2 (40 mL), the solution was washed with water (3 × 100 mL), the collected aqueous phases re-extracted with CH2Cl2 (20 mL), and the combined organic phases finally washed with brine and dried over MgSO4. The organic solvent was removed under reduced pressure, and the raw product purified by two subsequent column chromatographies on silica gel using petrol ether:ethyl acetate (first with gradient: 10:1 (v/v) increasing to 10:4 (v/v); second with a fixed ratio of 20:1 (v/v)). Yield: 9.67 g, 18.4 mmol (39%), yellow wax

1H-NMR (300 MHz in CDCl3, δ in ppm): δ = − 0.01 (s, 9H, Si-(CH3)3), 0.61 (mc, 2H, Si-CH2), 0.88 (t, 3H, CH3), 1.25–1.32 (m, 18H, CH3-(CH2)9), 1.57–1.70 (m, 4H, N-CH2-CH2 & S-CH2-CH2), 3.35–3.46 (m, 4H, N-CH2 & S-CH2-CH2), 4.63 (s, 2H, C-H2-S), 6.12 (br. t, 1H, N-H), 7.39 (d, 2H, ArH2,6), 7.70 (d, 2H, ArH3,5)

13C-NMR (75 MHz in CDCl3, δ in ppm): δ = − 1.63 (Si-CH3), 14.21 (CH3-CH2), 16.69 (Si-CH2), 22.81 (CH3-CH2), 23.15 (Si-CH2-CH2), 27.15 (N-(CH2)2-CH2), 29.47–29.84 (N-(CH2)2-CH2-(CH2)6), 32.05 (CH3-CH2-CH2), 40.29 (S-CH2-CH2), 40.68 (N-CH2), 40.81 (Ar-CH2), 127.33 (ArC3,5), 129.51 (ArC2,6), 134.44 (ArC4), 139.09 (ArC1), 167.10 (CO), 223.39 (CS)

Elemental analysis, calculated: C27H47NOS3Si: C 61.7%, H 9.0%, N 2.7%, S 18.3% found: C 61.5%, H 9.0%, N 2.6%, S 17.6

Electron ionization mass spectrometry: C27H48NOS3Si: calculated mass Mr: 526.2662 g/mol, found: m/z: 526.2663 g/mol

FTIR (selected bands cm−1): 2953, 2920, 2850, 1632, 1533, 1504, 1468, 410, 1300, 1248, 1061, 949, 860, 831, 808, 719, 688

Homopolymerization of N,N-bis(2-methoxyethyl)acrylamide (P1)

In a typical procedure, monomer 1 (1.00 g, 5.34 mmol, 25 eq.) and CTA 3 (51.19 mg, 0.2112 mmol) were dissolved in benzene (2.00 mL) at ambient temperature. 2.57 mL of a stock solution of V-40 in benzene (2.00 mg mL−1) equivalent to 0.0212 mmol of initiator was added, and the homogenous reaction mixture were purged with N2 for 45 min. The mixture was immersed into an oil bath preheated to 90 °C and stirred. After 5 h, the polymerization was quenched by opening the flask to the air and cooling the mixture with an isopropanol/dry ice bath. After warming to room temperature, 5 mL of THF were added, and the polymer was isolated by precipitation into diethylether. After drying in the vacuum oven (40 °C, 1 mbar), the polymer was dissolved in water and lyophilized to obtain a viscous, yellowish mass. Yield: 0.82 g (78%)

Various homopolymer samples were prepared by varying the relative amounts of monomer 1, CTA, and initiator V-40 (series P1), or by substituting CTA 3 by CTA 4 (series P1/HE), while maintaining throughout a 10:1 M ratio of CTA:initiator.

Homopolymerization of N,N-dimethylacrylamide (P2/HE)

Monomer 2 (17.5 mL, 16.9 g, 0.170 mol, 202 eq.), CTA 4 (442.6 mg, 0.8415 mmol, 1 eq.), and V-40 (20.6 mg, 0.0843 mmol, 0.1 eq.) in benzene (76 mL) were purged with N2 for 45 min. The mixture was placed into a preheated oil bath at 90 °C and stirred for 3 h. Then, the polymerization was quenched by opening the flask to the air and rapid cooling. The polymer was isolated and purified by precipitating twice into diethylether. The collected polymer P2/HE was dried in the vacuum oven, dissolved in water, and lyophilized. Yield: 10.98 g (63%) hygroscopic yellow powder

Synthesis of block copolymers P2-1/HE

In a typical procedure, monomer 1 (1.02 g, 5.44 mmol, 100 eq.) and macroCTA P2/HE (0.87 g, 0.054 mmol) were dissolved in benzene (17.0 mL) at ambient temperature. 0.67 mL of a stock solution of V-40 in benzene (2 mg mL−1) equivalent to 0.0055 mmol were added. The solution was purged with N2 for 45 min and placed into a preheated oil bath with a temperature of 90 °C. After stirring for 3 h, the reaction was stopped by opening the flask to the air and cooling the flask with liquid nitrogen. The polymer P2-1b/HE was isolated and purified by twice repeated precipitations into diethylether. The polymer was dried in the vacuum oven, dissolved in water, and lyophilized. Yield: 1.34 g (71%), hygroscopic yellow powder

Methods and instrumentation

Elemental analysis was performed with a Vario ELIII microanalyzer (Elentar Analysensysteme, Hanau, Germany). Refractive indexes were determined with a NAR-3T refractometer (ATAGO CO., LTD., Tokyo, Japan) equipped with a DTM-3 thermostat. NMR spectra were recorded using a Bruker Avance 300 NMR spectrometer operating at 300 MHz for 1H measurements and 75 MHz for 13C measurements. Chemical shifts δ are given in ppm referring to the respective solvent peaks at δ (1H) 7.26 ppm and δ (13C) 77.16 ppm for CDCl3, and at δ (1H) 4.79 ppm for D2O. Fourier-transform infrared spectroscopy (FTIR) spectra were recorded using a Nicolet Avatar 370 FTIR spectrometer (Thermo Fisher Scientific) equipped with an ATR Smart Performer element and AMTIR crystal.

Polymers were analyzed by size exclusion chromatography (SEC) in NMP + 0.1% LiBr with simultaneous UV and RI detection at room temperature (flow rate 0.5 mL min−1). The stationary phase used was a 300 × 8 mm2 PSS GRAM linear M column (7 μm particle size). Samples were filtered through 0.45-μm filters and the injected volume was 100 μL. Narrowly distributed polystyrene standards (PSS, Mainz, Germany) were used for calibration.

UV/Vis spectra were recorded on a PerkinElmer Lambda 25 UVVis Spectrometer, using quartz sample cells with 1 cm path length. Number average molar masses MnUV were calculated by end group analysis, using the extinction E at 309 nm of the π-π* transition of the trithiocarbonate chromophore in methanol. Values were calculated according to MnUV = ε∙c∙d∙E−1 where ε (L mol−1 cm−1) is the extinction coefficient, c (g L−1) is the concentration of the polymer in solution, and d (cm) is the optical path length. The molar extinction coefficient ε of the trithiocarbonate chromophore was assumed to be 15,800 L mol−1 cm−1 at 309 nm in methanol, due to the structural similarity of the polymer bound trithiocarbonate end groups with the references 2-(((butylthio)carbonothioyl)thio) propanoic acid and N,N-dimethyl-2-(((butylthio)carbonothioyl)thio) propionamide [55].

Thermogravimetric analysis (TGA) was conducted under N2 purged atmosphere using an apparatus SDTA851e (Mettler-Toledo, Giessen, Germany), in the temperature range from 25 to 900 °C with a heating rate of 10 K min−1. Differential scanning calorimetry (DSC) was performed with an apparatus DSC822e (Mettler-Toledo, Giessen, Germany), applying heating and cooling rates of 10 K min−1 for the first and second, and 30 K min−1 for the third and fourth heating and cooling cycles. Glass transition temperatures Tg were taken from the second heating cycle that used a heating rate of 10 K min−1 via the midpoint method [56].

Dynamic light scattering (DLS) was carried out with a high-performance particle sizer (HPPS-5001, Malvern Instrument, Malvern, UK) using a He-Ne laser beam and a thermoelectric Peltier element to control the temperature of the sample cell. The backscattering mode was used at a scattering angle of Θ = 173°. Samples were prepared by dilution with Millipore water to the desired concentration, and measured in heating runs by raising the temperature in steps of 1 °C equilibrating the sample for 120 s prior to each measurement. Temperature-dependent turbidimetry measurements were performed with a Cary 5000 (Varian) spectrometer with heating and cooling rates of 0.5 K min−1. Temperatures are precise within 0.5 K.

Results and discussion

Monomer N,N-bis(2-methoxyethyl)acrylamide 1 was synthesized by the straightforward reaction of the amine with acryloylchloride, adapting previous procedures [33, 47], and the so far scarce molecular analytical data available were completed. Figure 2 displays the 1H and 13C NMR spectra in CDCl3. The duplication of methylene signal characteristic for the 2-methyoxyethyl substituents on the amide nitrogen between 3.4 and 3.7 ppm is caused by the ambient temperature still relatively slow exchange (compared with the NMR frequency) between the trans- and cis-positions of the amide substituents, so that the respective signal groups do not completely coalesce.

Initially, monomer 1 was homopolymerized by radical polymerization employing the RAFT method to control molar masses and minimize the polymers’ dispersities, Ð. For preparing a series of increasing molar masses of P1, the established RAFT agent S-benzyl-S′-propyl trithiocarbonate 3 was employed as CTA [52, 53]. The polymerization recipes are compiled in Table 1, and the key characteristics of the obtained polymers in Table 2. The resulting general structure is displayed in Fig. 1, and a typical 1H NMR spectrum in Fig. 2(c). In analogy to statistical copolymers of 2-methoxyethylacrylate and N,N-dimethylacrylamide 2 [14], all polymers P1 were soluble in a large variety of solvents of strongly differing polarities, such as cold water, methanol, ethanol, trifluoroethanol, hexafluoroisopropanol, acetonitrile, N-methylpyrrolidone (NMP), dimethylsulfoxide (DMSO), ethyl acetate, acetone, α,α,α-trifluorotoluene, dioxane, tetrahydrofuran (THF), chloroform, dichloromethane, and benzene. Only diethylether and plain hydrocarbons such as pentane and hexane were found to be nonsolvents.

Due to the low molar mass of the sample P1b shown (Fig. 2(c)), characteristic signals of both end groups can be easily distinguished in the spectrum, namely, of the phenyl moiety originating from the R-group of CTA 3 at 7.1 to 7.3 ppm, and of the methyl moiety of the n-propyl residue originating from the Z-group at about 0.9 ppm. These signals enable the calculation of the number average molar mass Mn using either of the two end groups (denoted MnNMR-R and MnNMR-Z). However, the accuracy inevitably decreases rapidly with increasing molar masses. Additionally, the thiocarbonyl moiety of the Z-group is a strong UV-chromophore with an absorbance maximum in the range of 305–310 nm and an extinction coefficient ε in the order of 104 L mol−1 cm−1. This allows for a rather sensitive determination of the polymer’s Z-group content even for high molar masses when the value of ε is known, and, thus, also to derive a number average molar mass value, denoted MnUV [55]. Moreover, assuming ideal conditions for the RAFT polymerization process, the theoretically expected number average molar mass Mntheo can be calculated from the molar ratio of the monomer to the RAFT agent employed that is corrected by the monomer conversion. Furthermore, size exclusion chromatography (SEC) was used to analyze the molar mass distribution, and to calculate therefrom apparent number average molar masses Mnapp (calibrated to polystyrene) and the dispersities Ð. Altogether, the comparison of the various analytical molar mass data allows judging the controlled character of the polymerization, and, in particular, to estimate the degree of Z-group fidelity, i.e., the percentage of the polymer chains that bear an active end group. This is a crucial information for successful further chain extension as in the synthesis of block copolymers.

Analyzing the data for P1a–P1f, we note in general relatively low dispersities Ð of 1.2–1.3, and good agreement of Mntheo and MnNMR-R. This suggests that the RAFT polymerization of 1 is well controlled. We note that the Mnapp values derived from SEC systematically underestimate the molar masses of the P1 samples, i.e., the calibration using polystyrene standards is not optimal. Furthermore, we find that the MnNMR-Z and MnUV values agree reasonably well with the values of Mntheo and MnNMR-R, indicating good preservation of the RAFT-active trithiocarbonate end group. Still, it appears that the MnNMR-Z and in particular the MnUV values tend to become higher than the MnNMR-R values with increasing molar masses, pointing to an increasing loss of active end groups. To a certain extent, such a loss is inevitable due to the inherent RAFT mechanism [57]. Moreover, the ether functions of 1 that are prone to radical side reactions via hydrogen abstraction might contribute to the loss. In any case, if molar masses up to 20,000 are aspired, the data demonstrate that RAFT polymerization of 1 proceeds smoothly. Even for higher molar masses, the extent of polymerization control is still reasonably good.

Additionally, we undertook preliminary experiments exploring the use of functionalized RAFT agent 4 for the polymerization of 1, in the perspective of synthesizing thermoresponsive polymeric surfactants. The mixed aliphatic-aromatic N-dodecylbenzamide moiety of the R-group of 4 will confer the needed segmental hydrophobic character to polymers of structure P1/HE (see Fig. 1). Importantly, the use of CTA 4 albeit somewhat cumbersome to synthesize attaches the hydrophobic end groups by hydrolytically inert C-C bonds to such polymeric surfactants. This is an important advantage over most reported hydrophobized RAFT agents, where the hydrophobe is placed in the so-called Z-group that is inherently sensitive to hydrolysis [58,59,60,61,62,63,64]. Moreover, the particular choice of the various building blocks of CTA 4 was aimed at supporting polymer end group analysis by 1H NMR, as they simplify the identification and quantification of both the R- and Z-groups attached to the polymers in the spectra [65,66,67]. For instance, the signals of the aryl protons in ortho position to the carboxyl moiety of the R-group appear close to 8 ppm, while the signal of the trimethylsilyl groups of the Z-group is positioned close to 0 ppm, i.e., in regions that are devoid of signals for most polymers and solvents used in NMR analysis. This allows not only the determination of the true number average molar masses Mn but enables also the first-hand estimation of the RAFT-active end group fidelity by comparing the integrated signals specific to the R- and Z-groups. Both informations are generally difficult to obtain, especially in the case of amphiphilic polymers which, e.g., often tend to interact either with SEC column material, and/or to associate in the eluent.

In a second stage, we explored the use of monomer 1 for constructing thermoresponsive block copolymers. For this purpose, we first polymerized monomer 2, N,N-dimethylacrylamide (DMAm), to produce a polymer that is water-soluble over the full temperature range between 0 and 100 °C [23, 68], using the RAFT agent 4. Subsequently, we employed this homopolymer P2/HE as macroCTA for the chain extension with monomer 1. This yields block copolymers with a permanently hydrophobic end group at one terminus of the polymer chain (due to the use of CTA 4), and a hydrophilic-to-hydrophobic reversibly “switchable” end block made of the polymer of 1 on the opposite terminus (see Fig. 1). This design results in a polymer surfactant architecture which can be thermally switched between the structure of classical polymeric surfactants with one hydrophobic end group (similar to fatty alcohol ethoxylates) and the one of associative telechelics that dispose of two, here nonsymmetrical, hydrophobic end groups [69]. Key molecular data of the various polymers prepared with CTA 4 are listed in Table 2. For homopolymers P1/HE and P2/HE, we note good agreement not only between the Mntheo and MnNMR-R values, but also with the respective values MnNMR-Z. This finding, together with the low dispersities Ð of 1.2 for P2/HE, suggests that the RAFT polymerization using CTA 4 is also well controlled. Still, notwithstanding the good agreement of the values for Mntheo, MnNMR-R and MnNMR-Z, sample P1/HE presents a relatively high dispersity of 1.4–1.5 in the SEC analysis. Also, the Mnapp value even more underestimates the true molar mass of P1/HE than we noted for the series of samples P1a–P1f prepared using CTA 3. These apparently inconsistent findings might be due to some weak interaction of the end-functionalized polymer P1/HE with the column material, thus provoking a tailing of the elugram towards longer elution times, which consequently reduces Mnapp but increases Ð. In any case, the analytical data show that the trithiocarbonate group is largely preserved, and sample P2/HE represented a good macroCTA for the chain extension with monomer 1. The data in Tables 1 and 2 also demonstrate the successful chain extension up to high conversions to produce the block copolymers P2-1a/HE and P2-1b/HE. Still, the analytical data indicate that the RAFT-active trithiocarbonate group was largely lost at the end of the chain extension step, despite the low values of about 1.2 for Ð.

Thermal analysis showed that the polymers were thermally stable up to at least 200 °C according to thermogravimetric analysis TGA (Fig. 3(a)), when presumably the decomposition of the trithiocarbonate end groups sets in [70, 71]. Notable mass loss took only place at temperatures beyond 300 °C. Differential scanning calorimetry showed (compared with most reported polyacrylamides) a rather low glass transition for polymers P1 (Fig. 3(b)), which approaches about 10 °C for high molar masses (Fig. 4), indicating an intramolecular plasticizer effect of the methoxyethyl groups. This value compares surprisingly well with the reported glass transition of about 5 °C for the 1:2 statistical copolymer of dimethylacrylamide 2 and 2-methoxyethylacrylate [14]. In contrast, sample P2/HE displayed a glass transition at about 115–120 °C, in agreement with the literature on P2 [14, 72, 73]. Polymers P1/HE and P2/HE showed an additional small transition at about 40 °C, which is attributed to the alkyl chain terminus (Fig. 3(c)). Noteworthy, the block copolymers P2-1a/HE (Tg = 80 °C) and P2-1b/HE (Tg = 58 °C) (Fig. 3(d)) did only show one glass transition, which is located between those of the respective homopolymers and decreases with an increasing share of P1 in the block copolymers. This suggests that the two different polyacrylamide blocks are compatible in the bulk phase.

Behavior in aqueous solution

The thermoresponsive behavior of the polymers P1 in aqueous solution was investigated by temperature-dependent turbidimetry (see Fig. 5).

Turbidimetry studies (at λ = 600 nm) of homopolymers of 1: (a) temperature-dependent transmission for different concentrations of P1c, heating cycles are shown by full symbols, cooling cycles by open symbols; (b) concentration dependence of the cloud points of homopolymers P1 having various molar masses and/or end groups. The lines are meant as guide to the eye

The transmission of the solutions showed a sharp transition from clear to opaque for the heating, and vice versa for the cooling runs (Fig. 5(a)). These transitions were fully reversible. The hysteresis between cooling and heating runs was very small indicating a relatively quick rehydration and resolubilization of the collapsed polymer coils. This behavior is similar to the one of PDEAm [74,75,76], but contrasts with the one of PNIPAm [74, 76, 77]. The different transition behaviors were attributed to the N-H group of the secondary amide moiety specific for PNIPAm, which is assumed to enable interchain hydrogen bonds that act as “cross-linking points” inside the swollen polymer chain and delay the diffusion of water into the dense aggregates [74,75,76,77], but other kinetic effects seem also responsible [78,79,80]. Furthermore, the two methoxyethyl groups attached to the amide moiety of P1 might facilitate the diffusion of water because they provide additional hydrophilicity in analogy to poly((meth)acrylate)s that bear oligo (ethylene oxide) side chains [24, 46]. Up to 10 g L−1, the cloud points shift towards lower temperatures with increasing concentration. Except for the oligomeric sample of P1a with a molar mass of 1.9 kg mol−1, the phase transitions of all samples slowly approached a temperature minimum with increasing concentration (Fig. 5(b)). To investigate the influence of the molar mass, homopolymers P1a–f were synthesized with molar masses varying from about 2 to 100 kg mol−1 using CTA 3. This CTA was chosen to introduce only rather small propyl and benzyl end groups into the polymers, in order to minimize end group effects on the LCST. Figure 5 (b) illustrates that with increasing molar mass, the cloud points are initially increasing. Only when the molar mass becomes sufficiently high at around 10 kg mol−1 (P1c), the cloud point at 10 g L−1 seems to approach a maximum temperature, reaching a plateau value of around 46 °C. This trend does not follow the classical Flory–Huggins theory, according to which polymers become less soluble with growing molar mass as the combinatorial entropy term of mixing becomes less favorable [81, 82]. We explain this behavior by the sensitivity of the coil-to-globule transition of P1 to the presence of even small hydrophobic end groups, as known for other thermoresponsive polyacrylamides as, e.g., PNIPAm [9, 82] or poly(N-acryloyl pyrrolidine) PNAP [83]. With increasing length of the polymer chain, the polymer’s inherent hydrophilicity can increasingly outweigh the hydrophobic contribution of the end groups, so that the cloud point approaches an upper limiting value.

To gain a better understanding of how hydrophobic end groups influence the phase behavior of P1, we studied also the homopolymer P1/HE bearing a marked hydrophobic end group incorporating the hydrophobic dodecyl chain. Having a molar mass of around 30 kg mol−1, P1/HE is well comparable to P1d, their main difference being the hydrophobicity of the end groups. For P1/HE, the cloud points are notably lowered to the temperature of about 42 °C compared with the cloud point of P1d of around 46 °C. This indicates a higher solubility for the polymer with the less hydrophobic end groups. This marked influence of the hydrophobic end group is in agreement with the explanation proposed above for the observed increase of the cloud points with increasing molar masses up to 10 kg mol−1.

We note that the limiting cloud point values of our samples approached the range between 42 and 46 °C with increasing molar masses, which is above the originally reported value of 41.5 °C by Ito [33], but lower than the values of 49.5 °C reported by Yamazaki et al. [47] and of 58.4 °C reported by Hidaka et al. [36]. These differences might be due to differing molar masses, dispersities, and/or end groups of these samples, which were synthesized by classical free radical polymerization. Also, different tacticities might be responsible taking the reports for other polyacrylamides including PDEAm into account [42, 84,85,86]. However, the scarce analytical data reported preclude from a more thorough discussion.

In most cases, thermoresponsive polymers are not employed in pure water, but their applications include solution additives such as salts. In addition to the effect of ionic strength, ion specific effects on the LCST have been reported, which follow the so-called Hofmeister series [87]. This series empirically describes the ability of salts to precipitate proteins from aqueous solution. This phenomenon is more pronounced for anions than for cations following the typical order:

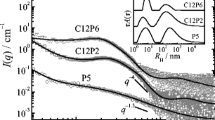

The anions on the left side of the series are referred to as kosmotropes, originally supposed to “structure” bulk water, while those on the right side are called chaotropes originally supposed to “break” bulk water structure. Several ionic properties such as size, polarizability, hydration energetics, and the partition coefficient influence their precipitation. The presence of such anions can also influence the phase transition behavior of thermoresponsive polymers such as PNIPAm [42, 88,89,90,91] or PDEAm [42, 92]. Consequently, we explored the effect of representative sodium salts on the cloud point of P1 using sample P1f via DLS, employing the fluoride F− that is regarded to be highly kosmotropic, the thiocyanate SCN− that is regarded to be highly chaotropic, and the chloride Cl− designating the dividing line between those two types (Fig. 6).

At temperatures well below the phase transition, P1f has a hydrodynamic diameter of ~ 25 nm which is comparable with the values reported for single PDEAM chains of similar molar mass [93]. Within the precision of the measurement, the hydrodynamic diameter seems to be unchanged upon the addition of the salts. In pure water, the cloud point of P1f is 45 °C. When NaCl is added, the cloud point shifts slightly towards lower temperatures. The observed rather weak salting-out effect of Cl− was similar not only to other polyacrylamides such as PNIPAm [88, 94], PDEAm [42, 92], or PNAP [83] but also to polymethacrylates bearing oligo (ethyleneglycolether) side chains [83]. The ability to lower the phase transition temperature becomes more pronounced when NaF is added. The strongly hydrated F− induces a marked salting-out effect, decreasing the cloud point of P1f to 34 °C. Contrariwise, the addition of NaSCN raises the cloud point to 52 °C, clearly showing the salting-in effect of the weakly hydrated and highly polarizable SCN− anion. The kosmotropic and chaotropic nature of F− and SCN−, respectively, with the corresponding salting-out and salting-in effects was also demonstrated on low dispersity PNIPAm of similar [94] and other molar masses [88, 95]. However, the influence on the phase transition temperature of PNIPAm was less pronounced than for P1f revealing the higher ion specific response of polymers of bMOEAm 1 to such salts.

It is interesting to note that P1f produced rather long-lived colloidal aggregates in pure aqueous solution above the cloud point. Such aggregates are often referred to as mesoglobules, the precise reasons for their formation still being under discussion [4, 6, 96]. Such a behavior seems typical for PNIPAm in dilute aqueous solution, for which it has been intensely studied, but has been also described occasionally for other non-ionic thermoresponsive polymers [4, 6]. Mesoglobules were reported to be destabilized when inorganic salts, typically chlorides, were added, resulting in macroscopic phase separation [6]. Figure 6 shows that this was also the case for P1f in the presence of NaCl or NaF, but not when adding NaSCN. On the basis of our limited experiments, it could only be speculated whether and how the sensitivity of mesoglobules to electrolytes is correlated to the kosmotropic and chaotropic nature of their anions, but this may be a point worth to be addressed in future studies for refining the understanding of the mesoglobule phenomenon.

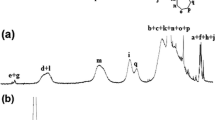

In addition to the homopolymers, we explored the thermoresponsive behavior of the block copolymers P2-1a/HE and P2-1b/HE as potentially “smart” surfactants by DLS and turbidimetry (Fig. 7).

Both block copolymers have a hydrodynamic diameter of ~ 10 nm at temperatures well below the phase transition. This is similar to homopolymer samples P1c-d with comparable chain lengths as the thermoresponsive block of the copolymers has, but lower than the hydrodynamic diameter observed for the high molar mass polymers P1e-f. This points to a marked influence of the thermoresponsive block on the coil size in water (Fig. 7(b)), possibly due to the compatibility of the P1 and P2 blocks as indicated in the DSC thermograms.

Noteworthy, for P2-1a/HE bearing a short P1 block with around 40 repeating units of bMOEAm, no phase transition occurred up to a concentration of 5 g L−1. In contrast, when a longer thermoresponsive block of around 100 repeat units was incorporated as in P2-1b/HE, we observed a fully reversible phase transition with a very small hysteresis analogously to the behavior of the homopolymers. Still, the phase transition temperature increased markedly compared with the homopolymers. As demonstrated, the water solubility of polymers P1 is strongly affected by hydrophobic end groups. Obviously, this is also the case for hydrophilic groups attached to P1, such as the P2 block (PDMAm). The enhanced solubility in water increases the cloud point and shifts the phase transition to around 60 °C, which is almost 15 °C higher than for the P1 homopolymers. Most likely, enhanced solubility accounts also for the lacking phase transition of P2-1a/HE in the studied temperature range, as the thermoresponsive P1 block is apparently too short to counterbalance the effect of the strongly hydrophilic P2 block attached. We note that structurally similar block copolymers of P2 and PDEAm (PDMAm-b-PDEAm) showed only slightly higher phase transition temperatures compared with PDEAm homopolymers [97]. This is also the case for block copolymers of P2 and PNIPAm [98, 99]. Accordingly, the additional ethyleneglycolether motifs in the analogous tertiary polyacrylamide P1, PbMOEAm, render the phase transition considerably more sensitive to attached hydrophilic blocks.

Conclusion

Homo- and block copolymers based on bMOEAm 1, which bears both the amide and ethyleneglycolether motifs, with varying molar mass and low dispersities were synthesized by RAFT polymerization. The thermoresponsive behavior of the polymers P1 in aqueous solution was investigated by DLS and turbidimetry as a function of the polymer concentration, molar mass, and end groups. The cloud points were found to approach a limiting value of around 46 °C with increasing concentration and molar mass. The phase transitions were fully reversible showing a very small hysteresis only, similar to PDEAm and PEG-derived vinyl polymers. The observed increase of the cloud point with increasing molar mass, which is apparently in conflict with the classical Flory–Huggins theory, is explained by the hydrophobicity of the end groups introduced by the RAFT process. Those effects are only gradually overcome with growing polymer chain length. The thermoresponsive behavior of the polymers is also influenced by the concentration of added salts and by the specific nature of their anions, following the Hofmeister series. A kosmotropic anion such as fluoride markedly decreased the cloud point, while the chaotropic thiocyanate markedly increased it. The cloud points of P1 were stronger affected by F− and SCN− anions than reported for PNIPAm, whereas Cl− showed as little effect as on other polyacrylamides. Homopolymers of bMOEAm 1 bearing a strongly hydrophobic end group implemented through the CTA, as well as block copolymers containing additionally a long hydrophilic PDMAm block, were studied as potential switchable surfactants. The former design provides successfully a responsive macrosurfactant with a transition from an amphiphilic to a water-insoluble state and a transition temperature around 42 °C, i.e., in the interesting window around human body temperature. However, for the latter block copolymer design, the phase transition temperature of PbMOEAm P1 is strongly increased when an additional hydrophilic block enhances the water solubility of the polymer. Consequently, for the block copolymer bearing a rather short block of PbMOEAm P1, no phase transition occurred which would convert the double hydrophilic copolymer into an amphiphilic one. Even when a rather long block of P1 is incorporated so that a phase transition is imposed, nevertheless, the transition is shifted to an often unpractically high temperature of 60 °C. Accordingly, PbMOEAm P1 seems not the obvious choice for constructing this type of switchable block copolymer surfactants for medical or cosmetic applications, but are interesting for applications where 'switching' is aspired at elevated temperatures. Nonetheless, double hydrophilic block copolymers containing PbMOEAm P1 as well as the pure homopolymers represent a useful complement to established thermosensitive polymers for applications in material science and biotechnology at elevated temperatures, due to their straightforward monomer synthesis and good polymerizability, as well as their tunable phase transition temperature.

References

Cohen Stuart MA, Huck WTS, Genzer J, Müller M, Ober C, Stamm M, Sukhorukov GB, Szleifer I, Tsukruk VV, Urban M, Winnik F, Zauscher S, Luzinov I, Minko S (2010) Emerging applications of stimuli-responsive polymer materials. Nat Mater 9:101–113. https://doi.org/10.1038/nmat2614

Hu L, Zhang Q, Li X, Serpe MJ (2019) Stimuli-responsive polymers for sensing and actuation. Mater Horiz 6:1774–1793. https://doi.org/10.1039/c9mh00490d

Doberenz F, Zeng K, Willems C, Zhang K, Groth T (2020) Thermoresponsive polymers and their biomedical application in tissue engineering—a review. J Mater Chem B 8:607–628. https://doi.org/10.1039/c9tb02052g

Aseyev V, Tenhu H, Winnik F (2011) Non-ionic thermoresponsive polymers in water. Adv Polym Sci 242:29–89. https://doi.org/10.1007/12_2010_57

Roy D, Brooks WLA, Sumerlin BS (2013) New directions in thermoresponsive polymers. Chem Soc Rev 42:7214–7243. https://doi.org/10.1039/c3cs35499g

Halperin A, Kröger M, Winnik FM (2015) Poly(N-isopropylacrylamide) phase diagrams: fifty years of research. Angew Chem Int Ed 54:15342–15367. https://doi.org/10.1002/anie.201506663

Lutz J-F (2008) Polymerization of oligo (ethylene glycol) (meth)acrylates: toward a new generation of smart biocompatible materials. J Polym Sci Part A Polym Chem 46:3459–3470

Badi N (2017) Non-linear PEG-based thermoresponsive polymer systems. Prog Polym Sci 66:54–79. https://doi.org/10.1016/j.progpolymsci.2016.12.006

Furyk S, Zhang Y, Ortiz-Acosta D, Cremer PS, Bergbreiter DE (2006) Effects of end group polarity and molecular weight on the lower critical solution temperature of poly(N-isopropylacrylamide). J Polym Sci Part A Polym Chem 44:1492–1501. https://doi.org/10.1002/pola.21256

Roth PJ, Jochum FD, Forst FR, Zentel R, Theato P (2010) Influence of end groups on the stimulus-responsive behavior of poly [oligo (ethylene glycol) methacrylate] in water. Macromolecules 43:4638–4645. https://doi.org/10.1021/ma1005759

Xia Y, Burke NAD, Stöver HDH (2006) End group effect on the thermal response of narrow-disperse poly(N-isopropylacrylamide) prepared by atom transfer radical polymerization. Macromolecules 39:2275–2283

Nord FF, Bier M, Timasheff SN (1951) Investigations on proteins and polymers. IV Critical phenomena in polyvinyl alcohol-acetate copolymer solutions. J Am Chem Soc 73:289–293

Mueller KF (1992) Thermotropic aqueous gels and solutions of N,N-dimethylacrylamide-acrylate copolymers. Polymer 33:3470–3476. https://doi.org/10.1016/0032-3861(92)91105-B

El-Ejmi AAS, Huglin MB (1996) Characterization of N,N-dimethylacrylamide/2-methoxyethylacrylate copolymers and phase behaviour of their thermotropic aqueous solutions. Polym Int 39:113–119. https://doi.org/10.1002/(sici)1097-0126(199602)39:2<113::Aid-pi476>3.0.Co;2-c

Chytrý V, Netopilík M, Bohdanecký M, Ulbrich K (1997) Phase transition parameters of potential thermosensitive drug release systems based on polymers of N-alkylmethacrylamides. J Biomater Sci Polym Ed 8:817–824. https://doi.org/10.1163/156856297x00010

Liu R, Fraylich M, Saunders BR (2009) Thermoresponsive copolymers: from fundamental studies to applications. Colloid Polym Sci 287:627–643. https://doi.org/10.1007/s00396-009-2028-x

Kokufuta MK, Sato S, Kokufuta E (2012) LCST behavior of copolymers of N-isopropylacrylamide and N-isopropylmethacrylamide in water. Colloid Polym Sci 290:1671–1681. https://doi.org/10.1007/s00396-012-2706-y

Ritter H, Stock A (1994) Synthesis of thermoreversible polymers by aminolysis of poly (methyl 2-(N-acryloylamino)-2-methoxyacetate): correlations of the lower critical solution temperatures (LCST) with the side group structures and the salt concentration in aqueous systems. Macromol Rapid Commun 15:271–277. https://doi.org/10.1002/marc.1994.030150314

Laschewsky A, Rekai ED, Wischerhoff E (2001) Tailoring of stimuli-responsive water-soluble acrylamide and methacrylamide polymers. Macromol Chem Phys 202:276–286. https://doi.org/10.1002/1521-3935(20010101)202:2<276::AID-MACP276>3.0.CO;2-1

Jochum FD, Theato P (2009) Temperature- and light-responsive polyacrylamides prepared by a double polymer analogous reaction of activated ester polymers. Macromolecules 42:5941–5945. https://doi.org/10.1021/ma900945s

Zhu Y, Batchelor R, Lowe AB, Roth PJ (2016) Design of thermoresponsive polymers with aqueous LCST, UCST, or both: modification of a reactive poly(2-vinyl-4,4-dimethylazlactone) scaffold. Macromolecules 49:672–680. https://doi.org/10.1021/acs.macromol.5b02056

Priest JH, Murray SL, Nelson RJ, Hoffman AS (1987) Lower critical solution temperatures of aqueous copolymers of N-isopropylacrylamide and other N-substituted acrylamides. ACS Symp Ser 350:255–264

Liu HY, Zhu XX (1999) Lower critical solution temperatures of N-substituted acrylamide copolymers in aqueous solutions. Polymer 40:6985–6990. https://doi.org/10.1016/S0032-3861(98)00858-1

Lutz J-F, Akdemir Ö, Hoth A (2006) Point by point comparison of two thermosensitive polymers exhibiting a similar LCST: is the age of poly (NIPAM) Over? J Am Chem Soc 128:13046–13047

Keerl M, Richtering W (2007) Synergistic depression of volume phase transition temperature in copolymer microgels. Colloid Polym Sci 285:471–474

Weiss J, Li A, Wischerhoff E, Laschewsky A (2012) Water-soluble random and alternating copolymers of styrene monomers with adjustable lower critical solution temperature. Polym Chem 3:352–361. https://doi.org/10.1039/c1py00422k

Kermagoret A, Fustin C-A, Bourguignon M, Detrembleur C, Jerome C, Debuigne A (2013) One-pot controlled synthesis of double thermoresponsive N-vinylcaprolactam-based copolymers with tunable LCSTs. Polym Chem 4:2575–2583. https://doi.org/10.1039/c3py00134b

Buller J, Laschewsky A, Lutz J-F, Wischerhoff E (2011) Tuning the lower critical solution temperature of thermoresponsive polymers by biospecific recognition. Polym Chem 2:1486–1489. https://doi.org/10.1039/c1py00001b

Couturier J-P, Sütterlin M, Laschewsky A, Hettrich C, Wischerhoff E (2015) Responsive inverse opal hydrogels for the sensing of macromolecules. Angew Chem Int Ed 54:6641–6644. https://doi.org/10.1002/anie.201500674

Eggers S, Eckert T, Abetz V (2018) Double thermoresponsive block–random copolymers with adjustable phase transition temperatures: from block-like to gradient-like behavior. J Polym Sci Part A Polym Chem 56:399–411. https://doi.org/10.1002/pola.28906

Kudo Y, Mori H, Kotsuchibashi Y (2018) Preparation of an ethylene glycol-based block copolymer consisting of six different temperature-responsive blocks. Polym J (Jpn) 50:1013–1020. https://doi.org/10.1038/s41428-018-0091-1

Yamano T, Higashi N, Koga T (2020) Precisely synthesized sequence-controlled amino acid–derived vinyl polymers: new insights into thermo-responsive polymer design. Macromol Rapid Commun 41(1900550):1900551–1900558. https://doi.org/10.1002/marc.201900550

Ito S (1990) Phase transition of aqueous solutions of poly(N-alkoxyalkylacrylamide) derivatives. Effects of side chain structure. Kobunshi Ronbunshu 47:467–474. https://doi.org/10.1295/koron.47.467

Terada T, Inaba T, Kitano H, Maeda Y, Tsukida N (1994) Raman spectroscopic study on water in aqueous solutions of temperature-responsive polymers: poly(N-isopropylacrylamide) and poly [N-(3-ethoxypropyl)acrylamide]. Makromol Chem 195:3261–3270. https://doi.org/10.1002/macp.1994.021950922

Chua GBH, Roth PJ, Duong HTT, Davis TP, Lowe AB (2012) Synthesis and thermoresponsive solution properties of poly [oligo (ethylene glycol) (meth)acrylamide]s: biocompatible PEG analogues. Macromolecules 45:1362–1374. https://doi.org/10.1021/ma202700y

Hidaka T, Sugihara S, Maeda Y (2013) Infrared spectroscopic study on LCST behavior of poly(N,N-bis(2-methoxyethyl)acrylamide). Eur Polym J 49:675–681. https://doi.org/10.1016/j.eurpolymj.2013.01.002

Kawatani R, Kawata Y, S-i Y, Kelland MA, Ajiro H (2018) Synthesis of thermosensitive poly(N-vinylamide) derivatives bearing oligo ethylene glycol chain for kinetic hydrate inhibitor. Macromolecules 51:7845–7852. https://doi.org/10.1021/acs.macromol.8b01573

Sedlacek O, Bera D, Hoogenboom R (2019) Poly(2-amino-2-oxazoline)s: a new class of thermoresponsive polymers. Polym Chem 10:4683–4689. https://doi.org/10.1039/C9PY00943D

Quek JY, Zhu Y, Roth PJ, Davis TP, Lowe AB (2013) RAFT Synthesis and aqueous solution behavior of novel pH- and thermo-responsive (co) polymers derived from reactive poly(2-vinyl-4,4-dimethylazlactone) scaffolds. Macromolecules 46:7290–7302. https://doi.org/10.1021/ma4013187

Trzebicka B, Szweda D, Rangelov S, Kowalczuk A, Mendrek B, Utrata-Wesołek A, Dworak A (2013) (Co) polymers of oligo (ethylene glycol) methacrylates—temperature-induced aggregation in aqueous solution. J Polym Sci Part A Polym Chem 51:614–623. https://doi.org/10.1002/pola.26410

Vancoillie G, Frank D, Hoogenboom R (2014) Thermoresponsive poly (oligo ethylene glycol acrylates). Progr Polym Sci 39:1074–1095. https://doi.org/10.1016/j.progpolymsci.2014.02.005

Baltes T, Garret-Flaudy F, Freitag R (1999) Investigation of the LCST of polyacrylamides as a function of molecular parameters and the solvent composition. J Polym Sci Part A Polym Chem 37:2977–2989. https://doi.org/10.1002/(SICI)1099-0518(19990801)37:15<2977::AID-POLA31>3.0.CO;2-I

Plamper FA, Steinschulte AA, Hofmann CH, Drude N, Mergel O, Herbert C, Erberich M, Schulte B, Winter R, Richtering W (2012) Toward copolymers with ideal thermosensitivity: solution properties of linear, well-defined polymers of N-isopropyl acrylamide and N,N-diethyl acrylamide. Macromolecules 45:8021–8026. https://doi.org/10.1021/ma301606c

Watanabe R, Takaseki K, Katsumata M, Matsushita D, Ida D, Osa M (2016) Characterization of poly(N,N-diethylacrylamide) and cloud points in its aqueous solutions. Polym J (Jpn) 48:621–628. https://doi.org/10.1038/pj.2015.120

Hua F, Jiang X, Li D, Zhao B (2006) Well-defined thermosensitive, water-soluble polyacrylates and polystyrenics with short pendant oligo (ethylene glycol) groups synthesized by nitroxide-mediated radical polymerization. J Polym Sci Part A Polym Chem 44:2454–2467

Miasnikova A, Laschewsky A (2012) Influencing the phase transition temperature of poly (methoxy diethylene glycol acrylate) by molar mass, end groups, and polymer architecture. J Polym Sci Part A Polym Chem 50:3313–3323. https://doi.org/10.1002/pola.26116

Yamazaki A, Song JM, Winnik FM, Brash JL (1998) Synthesis and solution properties of fluorescently labeled amphiphilic (N-alkylacrylamide) oligomers. Macromolecules 31:109–115. https://doi.org/10.1021/ma971111u

Yamazaki A, Winnik FM, Cornelius RM, Brash JL (1999) Modification of liposomes with N-substituted polyacrylamides: identification of proteins adsorbed from plasma. Biochim Biophys Acta Biomembr 1421:103–115. https://doi.org/10.1016/S0005-2736(99)00117-0

El-Ejmi AAS, Huglin MB (1997) Behaviour of poly(N,N-dimethylacrylamide-co-2-methoxyethylacrylate) in non-aqueous solution and LCST behaviour in water. Eur Polym J 33:1281–1284. https://doi.org/10.1016/S0014-3057(96)00272-8

Haraguchi K, Kubota K, Takada T, Mahara S (2014) Highly protein-resistant coatings and suspension cell culture thereon from amphiphilic block copolymers prepared by RAFT polymerization. Biomacromolecules 15:1992–2003. https://doi.org/10.1021/bm401914c

Bivigou-Koumba AM, Kristen J, Laschewsky A, Müller-Buschbaum P, Papadakis CM (2009) Synthesis of symmetrical triblock copolymers of styrene and N-isopropylacrylamide using bifunctional bis (trithiocarbonate) s as RAFT agents. Macromol Chem Phys 210:565–578. https://doi.org/10.1002/macp.200800575

Schweizerhof S, Demco DE, Mourran A, Keul H, Fechete R, Möller M (2017) Temperature-induced phase transition characterization of responsive polymer brushes grafted onto nanoparticles. Macromol Chem Phys 218(1600495):1600491–1600411. https://doi.org/10.1002/macp.201600495

Zhao Y, Perrier S (2007) Reversible addition-fragmentation chain transfer graft polymerization mediated by fumed silica supported chain transfer agents. Macromolecules 40:9116–9124. https://doi.org/10.1021/ma0716783

Roth M, Oesterreicher A, Mostegel FH, Moser A, Pinter G, Edler M, Piock R, Griesser T (2016) Silicon-based mercaptans: high-performance monomers for thiol-ene photopolymerization. J Polym Sci Part A Polym Chem 54:418–424. https://doi.org/10.1002/pola.27792

Skrabania K, Miasnikova A, Bivigou-Koumba AM, Zehm D, Laschewsky A (2011) Examining the UV-vis absorption of RAFT chain transfer agents, and their use for polymer analysis. Polym Chem 2:2074–2083. https://doi.org/10.1039/c1py00173f

Flynn JH (1974) Thermodynamic properties from differential scanning calorimetry by calorimetric methods. Thermochim Acta 8:69–81. https://doi.org/10.1016/0040-6031(74)85073-2

Moad G, Rizzardo E, Thang SH (2008) Toward living radical polymerization. Acc Chem Res 41:1133–1142. https://doi.org/10.1021/ar800075n

Lai JT, Filla D, Shea R (2002) Functional polymers from novel carboxyl-terminated trithiocarbonates as highly efficient RAFT agents. Macromolecules 35:6754–6756. https://doi.org/10.1021/ma020362m

Ganeva DE, Sprong E, Hd B, Warr GG, Such CH, Hawkett BS (2007) Particle formation in ab initio RAFT mediated emulsion polymerization systems. Macromolecules 40:6181–6189

Samakande A, Chaghi R, Derrien G, Charnay C, Hartmann PC (2008) Aqueous behaviour of cationic surfactants containing a cleavable group. J Colloid Interface Sci 320:315–320. https://doi.org/10.1016/j.jcis.2008.01.022

Rieger J, Osterwinter G, Bui C, Stoffelbach F, Charleux B (2009) Surfactant-free controlled/living radical emulsion (Co) polymerization of n-butyl acrylate and methyl methacrylate via RAFT using amphiphilic poly (ethylene oxide)-based trithiocarbonate chain transfer agents. Macromolecules 42:5518–5525. https://doi.org/10.1021/ma9008803

Herfurth C, Malo de Molina P, Wieland C, Rogers SH, Gradzielski M, Laschewsky A (2012) One-step RAFT synthesis of well-defined amphiphilic star polymers and their self-assembly in aqueous solution. Polym Chem 3:1606–1617. https://doi.org/10.1039/c2py20126g

Ren H, Qiu X-P, Shi Y, Yang P, Winnik FM (2019) pH-dependent morphology and photoresponse of azopyridine-terminated poly(N-isopropylacrylamide) nanoparticles in water. Macromolecules 52:2939–2948. https://doi.org/10.1021/acs.macromol.9b00193

Ohnsorg ML, Ting JM, Jones SD, Jung S, Bates FS, Reineke TM (2019) Tuning PNIPAm self-assembly and thermoresponse: roles of hydrophobic end-groups and hydrophilic comonomer. Polym Chem 10:3469–3479. https://doi.org/10.1039/C9PY00180H

Päch M, Zehm D, Lange M, Dambowsky I, Weiss J, Laschewsky A (2010) Universal polymer analysis by 1H NMR using complementary trimethylsilyl end groups. J Am Chem Soc 132:8757–8765. https://doi.org/10.1021/ja102096u

Weiss J, Laschewsky A (2011) Temperature induced self-assembly of triple responsive triblock copolymers in aqueous solutions. Langmuir 27:4465–4473. https://doi.org/10.1021/la200115p

Marsat J-N, Heydenreich M, Kleinpeter E, Laschewsky A, von Berlepsch H, Böttcher C (2011) Self-assembly into multicompartment micelles, and selective solubilization by hydrophilic-lipophilic-fluorophilic block copolymers. Macromolecules 44:2092–2105. https://doi.org/10.1021/ma200032j

Fischer F, Zufferey D, Tahoces R (2011) Lower critical solution temperature in superheated water: the highest in the poly(N,N-dialkylacrylamide) series. Polym Int 60:1259–1262. https://doi.org/10.1002/pi.3071

Laschewsky A, Herfurth C, Miasnikova A, Stahlhut F, Weiss J, Wieland C, Wischerhoff E, Gradzielski M, Malo de Molina P (2013) Stars and blocks: tailoring polymeric rheology modifiers for aqueous media by controlled free radical polymerization. ACS Symp Ser 1148:125–143. https://doi.org/10.1021/bk-2009-1023.ch013

Moad G, Chong YK, Postma A, Rizzardo E, Thang SH (2005) Advances in RAFT polymerization: the synthesis of polymers with defined end-groups. Polymer 46:8458–8468. https://doi.org/10.1016/j.polymer.2004.12.061

Laschewsky A, Pound G, Skrabania K, Holdt HJ, Teller J (2007) Unsymmetrical bifunctional trithiocarbonate as unexpected by-product in the synthesis of a dithioester RAFT-agent. Colloid Polym Sci 285:947–952. https://doi.org/10.1007/s00396-007-1653-5

Köberle P, Laschewsky A, van den Boogaard D (1992) Self-organization of hydrophobized polyzwitterions. Polymer 33:4029–4039. https://doi.org/10.1016/0032-3861(92)90601-r

Bennour S, Louzri F (2014) Study of swelling properties and thermal behavior of poly(N,N-dimethylacrylamide-co-maleic acid) based hydrogels. Adv Chem 147398:147391–147310. https://doi.org/10.1155/2104/147398

Zhou K, Lu Y, Li J, Shen L, Zhang G, Xie Z, Wu C (2008) The coil-to-globule-to-coil transition of linear polymer chains in dilute aqueous solutions: effect of intrachain hydrogen bonding. Macromolecules 41:8927–8931. https://doi.org/10.1021/ma8019128

Lu Y, Zhou K, Ding Y, Zhang G, Wu C (2010) Origin of hysteresis observed in association and dissociation of polymer chains in water. Phys Chem Chem Phys 12:3188–3194. https://doi.org/10.1039/b918969f

Pühse M, Keerl M, Scherzinger C, Richtering W, Winter R (2010) Influence of pressure on the state of poly(N-isopropylacrylamide) and poly(N,N-diethylacrylamide) derived polymers in aqueous solution as probed by FTIR-spectroscopy. Polymer 51:3653–3659. https://doi.org/10.1016/j.polymer.2010.06.011

Cheng H, Shen L, Wu C (2006) LLS and FTIR studies on the hysteresis in association and dissociation of poly(N-isopropylacrylamide) chains in water. Macromolecules 39:2325–2329. https://doi.org/10.1021/ma052561m

Meier-Koll A, Pipich V, Busch P, Papadakis CM, Müller-Buschbaum P (2012) Phase separation in semidilute aqueous poly(N-isopropylacrylamide) solutions. Langmuir 28:8791–8798. https://doi.org/10.1021/la3015332

Philipp M, Kyriakos K, Silvi L, Lohstroh W, Petry W, Krüger JK, Papadakis CM, Müller-Buschbaum P (2014) From molecular dehydration to excess volumes of phase-separating PNIPAM solutions. J Phys Chem B 118:4253–4260. https://doi.org/10.1021/jp501539z

Futscher MH, Philipp M, Müller-Buschbaum P, Schulte A (2017) The role of backbone hydration of poly(N-isopropyl acrylamide) across the volume phase transition compared to its monomer. Sci Rep 7(17012):17011–17010. https://doi.org/10.1038/s41598-017-17272-7

Dormidontova EE (2002) Role of competitive PEO−water and water−water hydrogen bonding in aqueous solution PEO behavior. Macromolecules 35:987–1001. https://doi.org/10.1021/ma010804e

Xia Y, Yin X, Burke NAD, Stöver HDH (2005) Thermal response of narrow-disperse poly(N-isopropylacrylamide) prepared by atom transfer radical polymerization. Macromolecules 38:5937–5943. https://doi.org/10.1021/ma050261z

Skrabania K, Kristen J, Laschewsky A, Akdemir Ö, Hoth A, Lutz J-F (2007) Design, synthesis, and aqueous aggregation behavior of nonionic single and multiple thermoresponsive polymers. Langmuir 23:84–93. https://doi.org/10.1021/la061509w

Katsumoto Y, Etoh Y, Shimoda N (2010) Phase diagrams of stereocontrolled poly(N,N-diethylacrylamide) in water. Macromolecules 43:3120–3121. https://doi.org/10.1021/ma902673z

Munk T, Baldursdottir S, Hietala S, Rades T, Nuopponen M, Kalliomäki K, Tenhu H, Rantanen J, Strachan CJ (2013) Investigation of the phase separation of PNIPAM using infrared spectroscopy together with multivariate data analysis. Polymer 54:6947–6953. https://doi.org/10.1016/j.polymer.2013.10.033

Biswas CS, Hazer B (2015) Synthesis and characterization of stereoregular poly(N-ethylacrylamide) hydrogel by using Y (OTf)3 Lewis acid. Colloid Polym Sci 293:143–152. https://doi.org/10.1007/s00396-014-3399-1

Salis A, Ninham BW (2014) Models and mechanisms of Hofmeister effects in electrolyte solutions, and colloid and protein systems revisited. Chem Soc Rev 43:7358–7377. https://doi.org/10.1039/c4cs00144c

Zhang Y, Furyk S, Bergbreiter DE, Cremer PS (2005) Specific ion effects on the water solubility of macromolecules: PNIPAM and the Hofmeister series. J Am Chem Soc 127:14505–14510. https://doi.org/10.1021/ja0546424

Du H, Wickramasinghe R, Qian X (2010) Effects of salt on the lower critical solution temperature of poly(N-Isopropylacrylamide). J Phys Chem B 114:16594–16604. https://doi.org/10.1021/jp105652c

Maeda Y, Nakamura T, Ikeda I (2001) Changes in the hydration states of poly(N-alkylacrylamide) s during their phase transitions in water observed by FTIR spectroscopy. Macromolecules 34:1391–1399. https://doi.org/10.1021/ma001306t

Bruce EE, Bui PT, Rogers BA, Cremer PS, van der Vegt NFA (2019) Nonadditive ion effects drive both collapse and swelling of thermoresponsive polymers in water. J Am Chem Soc 141:6609–6616. https://doi.org/10.1021/jacs.9b00295

Idziak I, Avoce D, Lessard D, Gravel D, Zhu XX (1999) Thermosensitivity of aqueous solutions of poly(N,N-diethylacrylamide). Macromolecules 32:1260–1263. https://doi.org/10.1021/ma981171f

Lessard DG, Ousalem M, Zhu XX, Eisenberg A, Carreau PJ (2003) Study of the phase transition of poly(N,N-diethylacrylamide) in water by rheology and dynamic light scattering. J Polym Sci B Polym Phys 41:1627–1637. https://doi.org/10.1002/polb.10517

Suwa K, Yamamoto K, Akashi M, Takano K, Tanaka N, Kunugi S (1998) Effects of salt on the temperature- and pressure-responsive properties of poly(N-vinylisobutyramide) aqueous solutions. Colloid Polym Sci 276:529–533. https://doi.org/10.1007/s003960050276

Zajforoushan Moghaddam S, Thormann E (2017) Hofmeister effect on PNIPAM in bulk and at an interface: surface partitioning of weakly hydrated anions. Langmuir 33:4806–4815. https://doi.org/10.1021/acs.langmuir.7b00953

Niebuur B-J, Chiappisi L, Jung F, Zhang X, Schulte A, Papadakis CM (2019) Kinetics of mesoglobule formation and growth in aqueous poly(N-isopropylacrylamide) solutions: pressure jumps at low and at high pressure. Macromolecules 52:6416–6427. https://doi.org/10.1021/acs.macromol.9b00937

Herfurth C, Laschewsky A, Noirez L, von Lospichl B, Gradzielski M (2016) Thermoresponsive (star) block copolymers from one-pot sequential RAFT polymerizations and their self-assembly in aqueous solution. Polymer 107:422–433. https://doi.org/10.1016/j.polymer.2016.09.089

Convertine AJ, Lokitz BS, Vasileva Y, Myrick LJ, Scales CW, Lowe AB, McCormick CL (2006) Direct synthesis of thermally responsive DMA/NIPAM diblock and DMA/NIPAM/DMA triblock copolymers via aqueous, room temperature RAFT polymerization. Macromolecules 39:1724–1730. https://doi.org/10.1021/ma0523419

Skrabania K, Li W, Laschewsky A (2008) Synthesis of double-hydrophilic BAB triblock copolymers via RAFT polymerisation and their thermoresponsive self-assembly in water. Macromol Chem Phys 209:1389–1403. https://doi.org/10.1002/macp.200800108

Acknowledgments

The authors gratefully acknowledge SEC support by S. Prenzel and H. Schlaad, and assistance for thermal analysis by D. Schanzenbach (Universität Potsdam). We thank Dr. Makoto Uyama (Shiseido Co.) for translating reference [33] from Japanese to English.

Funding

Open Access funding provided by Projekt DEAL. This work was supported by Deutsche Forschungsgemeinschaft (DFG), grants GR 1030/22-1 and LA 611/17-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hechenbichler, M., Laschewsky, A. & Gradzielski, M. Poly(N,N-bis(2-methoxyethyl)acrylamide), a thermoresponsive non-ionic polymer combining the amide and the ethyleneglycolether motifs. Colloid Polym Sci 299, 205–219 (2021). https://doi.org/10.1007/s00396-020-04701-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-020-04701-9