Abstract

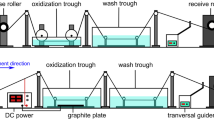

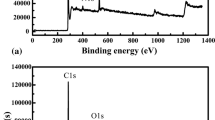

In this study, nitric acid oxidation with varied treatment temperature and time was conducted on the surfaces of polyacrylonitrile-based ultrahigh modulus carbon fibers. Scanning electron microscopy, X-ray photoelectron spectroscopy, Raman spectroscopy and surface tension/dynamic contact angle instruments were used to investigate changes in surface topography and chemical functionality before and after surface treatment. Results showed that the nitric acid oxidation of ultrahigh modulus carbon fibers resulted in decreases in the values of the crystallite thickness Lc and graphitization degree. Meanwhile, increased treating temperature and time made the decreases more obviously. The surfaces of ultrahigh modulus carbon fibers became much more activity and functionality after surface oxidation, e.g., the total surface energy of oxidized samples at 80 °C for 1 h increased by 27.7% compared with untreated fibers. Effects of surface nitric acid oxidation on the mechanical properties of ultrahigh modulus carbon fibers and its reinforced epoxy composites were also researched. Significant decreases happened to the tensile modulus of fibers due to decreased Lc value after the nitric acid oxidation. However, surface treatment had little effect on the tensile strength even as the treating temperature and processing time increased. The highest interfacial shear strength of ultrahigh modulus carbon fibers/epoxy composites increased by 25.7% after the nitric acid oxidation. In the final, surface oxidative mechanism of ultrahigh modulus carbon fibers in the nitric acid oxidation was studied. Different trends of the tensile strength and tensile modulus of fibers in the nitric acid oxidation resulted from the typical skin–core structure.

Similar content being viewed by others

References

Sharma M, Gao S, Mäder E et al (2014) Carbon fiber surfaces and composite interphases. Compos Sci Technol 102:35–50

Raphael N, Namratha K, Chandrashekar BN et al (2018) Surface modification and grafting of carbon fibers: a route to better interface. Prog Cryst Growth Charact Mater 64:75–101

Kim KW, Jeong JS, An KH et al (2019) A study on the microstructural changes and mechanical behaviors of carbon fibers induced by optimized electrochemical etching. Compos Part B Eng 165:764–771

Werken N, Reese MS, Taha MR et al (2019) Investigating the effects of fiber surface treatment and alignment on mechanical properties of recycled carbon fiber composites. Compos Part A Appl Sci Manuf 119:38–47

Zhang RL, Huang YD, Liu L et al (2011) Effect of the molecular weight of sizing agent on the surface of carbon fibres and interface of its composites. Appl Surf Sci 257:1840–1844

Lissek F, Haeger A, Knoblauch V et al (2018) Acoustic emission for interlaminar toughness testing of CFRP: evaluation of the crack growth due to burst analysis. Compos Part B Eng 136:55–62

Liu L, Jia C, He J et al (2015) Interfacial characterization, control and modification of carbon fiber reinforced polymer composites. Compos Sci Technol 121:56–72

Newcomb BA (2016) Processing, structure, and properties of carbon fibers. Compos Part A Appl Sci Manuf 91:262–282

Yue Z, Vakili A, Duran MP (2017) Surface treatments of solvated mesophase pitch-based carbon fibers. J Mater Sci 52:10250–10260

Wen Z, Xu C, Qian X et al (2019) A two-step carbon fiber surface treatment and its effect on the interfacial properties of CF/EP composites: the electrochemical oxidation followed by grafting of silane coupling agent. Appl Surf Sci 486:546–554

Zhang Y, Choi JR, Park SJ (2018) Enhancing the heat and load transfer efficiency by optimizing the interface of hexagonal boron nitride/elastomer nanocomposites for thermal management applications. Polymer 143:1–9

Sun T, Li M, Zhou S et al (2020) Multi-scale structure construction of carbon fiber surface by electrophoretic deposition and electropolymerization to enhance the interfacial strength of epoxy resin composites. Appl Surf Sci 499:143929

Wen Z, Qian X, Zhang Y et al (2019) Electrochemical polymerization of carbon fibers and its effect on the interfacial properties of carbon reinforced epoxy resin composites. Compos Part A Appl Sci Manuf 119:21–29

Du X, Xu F, Liu HY et al (2016) Improving the electrical conductivity and interface properties of carbon fiber/epoxy composites by low temperature flame growth of carbon nanotubes. RSC Adv 6:48896–48904

Lutz V, Duchet-Rumeau J, Godin N et al (2018) Ex-PAN carbon fibers vs carbon nanotubes fibers: from conventional epoxy based composites to multiscale composites. Eur Polym J 106:9–18

Barzoki PK, Rezadoust AM, Latifi M et al (2018) The experimental and numerical study on the effect of PVB nanofiber mat thickness on interlaminar fracture toughness of glass/phenolic composites. Eng Fract Mech 194:145–153

Xiao C, Tan Y, Wang X et al (2018) Study on interfacial and mechanical improvement of carbon fiber/epoxy composites by depositing multi-walled carbon nanotubes on fibers. Chem Phys Lett 703:8–16

Chang H, Luo J, Liu HC et al (2019) Carbon fibers from polyacrylonitrile/cellulose nanocrystal nanocomposite fibers. Carbon 145:764–771

Rostamiyan Y, Youseftabar H, Azadi R (2018) Experimental study on the effect of nano zirconia on mechanical strength and microstructure of damaged epoxy-nanocomposites. Mater Res Express 6:025046

Qian X, Wang X, OuYang Q et al (2012) Surface structural evolvement in electrochemical oxidation and sizing and its effect on carbon fiber/epoxy composites properties. J Reinf Plast Compos 31:999–1008

Qian X, Zhi J, Chen L et al (2013) Effect of low current density electrochemical oxidation on the properties of carbon fiber-reinforced epoxy resin composites. Surf Interface Anal 45:937–942

Zhang G, Sun S, Yang D et al (2008) The surface analytical characterization of carbon fibers functionalized by H2SO4/HNO3 treatment. Carbon 46:196–205

Paredes JI, Martinez-Alonso A, Tascon JMD (2003) Atomic-scale scanning tunneling microscopy study of plasma-oxidized ultrahigh-modulus carbon fiber surfaces. J Colloid Interface Sci 258:276–282

Lee ES, Lee CH, Chun YS et al (2017) Effect of hydrogen plasma-mediated surface modification of carbon fibers on the mechanical properties of carbon-fiber-reinforced polyetherimide composites. Compos Part B Eng 116:451–458

Moosburger-Will J, Lachner E, Löffler M et al (2018) Adhesion of carbon fibers to amine hardened epoxy resin: influence of ammonia plasma functionalization of carbon fibers. Appl Surf Sci 453:141–152

Yuan JM, Fan ZF, Yang QC et al (2018) Surface modification of carbon fibers by microwave etching for epoxy resin composite. Compos Sci Technol 164:222–228

Woodhead AL, Souza ML, Church JS (2017) An investigation into the surface heterogeneity of nitric acid oxidized carbon fiber. Appl Surf Sci 401:79–88

Chae HG, Newcomb B, Gulgunje PV et al (2015) High strength and high modulus carbon fibers. Carbon 93:81–87

Qian X, Zhi J, Chen L et al (2018) Evolution of microstructure and electrical property in the conversion of high strength carbon fiber to high modulus and ultrahigh modulus carbon fiber. Compos Part A Appl S 112:111–118

Qian X, Zhong J, Zhi J et al (2019) Electrochemical surface modification of polyacrylonitrile-based ultrahigh modulus carbon fibers and its effect on the interfacial properties of UHMCF/EP composites. Compos Part B Eng 164:476–484

Kiuchi N, Sohda Y, Arai Y et al (2000) Unique low modulus carbon fibers for hybrid materials with excellent impact resistance. In: SAMPE 2000: 45 th International SAMPE Symposium and Exhibition 330–341

Anikin VA, Andrianova NN, Borisov AM et al (2017) Physical and mechanical properties of high-modulus carbon fiber crimped by ion irradiation. J Phys Conf Ser 941:102029

Xu P, Yu Y, Liu D et al (2018) Enhanced interfacial and mechanical properties of high-modulus carbon fiber composites: establishing modulus intermediate layer between fiber and matrix based on tailored-modulus epoxy. Compos Sci Technol 163:26–33

Makeev A, Ghaffari S, Seon G (2019) Improving compressive strength of high modulus carbon-fiber reinforced polymeric composites through fiber hybridization. Int J Eng Sci 142:145–157

Zhao XJ, Qin W, Wang BL (2007) Effect of ozone treatment on the interfacial properties of high modulus carbon fiber/epoxy composites. Mater Sci Forum 546–549:1547–1550

Zhang T, Qi L, Li S et al (2019) Evaluation of the effect of PyC coating thickness on the mechanical properties of T700 carbon fiber tows. Appl Surf Sci 463:310–321

Ma L, Li N, Wu G et al (2018) Interfacial enhancement of carbon fiber composites by growing TiO2 nanowires onto amine-based functionalized carbon fiber surface in supercritical water. Appl Surf Sci 433:560–567

Jiang D, Xing L, Liu L et al (2015) Enhanced mechanical properties and anti-hydrothermal ageing behaviors of unsaturated polyester composites by carbon fibers interfaced with POSS. Compos Sci Technol 117:168–175

Li WW, Kang HL, Xu J et al (2018) Microstructures of high-strength high-modulus carbon fibers and high-modulus carbon fibers. Acta Polym Sin 49:380–388

Chen X, Zha L, Zhu Y (2010) Microstructure of high tensile strength and high tensile modulus PAN-based carbon fibers determined by X-ray diffraction. New Chem Mater 38:85–88

Hao W, Wang Z, Zhang X et al (2018) Transforming of high-strength-medium-modulus into high-modulus carbon fiber. New Chem Mater 46:70

Qian X, Wang X, Zheng K et al (2019) Relationship between micro-structure and macro-properties during the formation of PAN-based high modulus carbon fibers. Chem Ind Eng Prog 38:2276–2283

Melanitis N, Tetlow PL, Galiotis C (1996) Characterization of PAN-based carbon fibres with laser Raman spectroscopy. 1. Effect of processing variables on Raman band profiles. J Mater Sci 31:851–860

Moosburger-Will J, Jan J, Strauch J et al (2016) Interphase formation and fiber matrix adhesion in carbon fiber reinforced epoxy resin: influence of carbon fiber surface chemistry. Compos Interfaces 24:1–20

Ren GZ, Chen CJ, Deng LH et al (2015) Microstructural heterogeneity on the cylindrical surface of carbon fibers analyzed by Raman spectroscopy. New Carbon Mater 30:476–480

Qian X, Wang X, Zhong J et al (2019) Effect of fiber microstructure studied by Raman spectroscopy upon the mechanical properties of carbon fibers. J Raman Spectrosc 50:665–673

Fu Y, Lu Y, You T et al (2019) Study on multistage anodization for high-modulus carbon fiber. Surf Interface Anal 51:798–808

Paiva MC, Bernardo CA, Nardin M (2000) Mechanical, surface and interfacial characterisation of pitch and PAN-based carbon fibres. Carbon 38:1323–1337

Liu X, Yang C, Lu Y (2012) Contrastive study of anodic oxidation on carbon fibers and graphite fibers. Appl Surf Sci 258:4268–4275

Wang B, Duan Y, Zhang J et al (2016) Microwave radiation effects on carbon fibres interfacial performance. Compos Part B Eng 99:398–406

Qian X, Chen L, Huang J et al (2013) Effect of carbon fiber surface chemistry on the interfacial properties of carbon fibers/epoxy resin composites. J Reinf Plast Compos 32:393–401

Guigon M, Oberlin A, Desarmot G (1984) Microtexture and structure of some high-modulus, PAN-base carbon fibres. Fibre Sci Technol 20:177–198

Guigon M, Oberlin A, Desarmot G (1984) Microtexture and structure of some high tensile strength, PAN-base carbon fibres. Fibre Sci Technol 20:55–72

Peebles LH (1994) Carbon fibres: structure and mechanical properties. Int Mater Rev 39:75–92

Zhang T, Cheng Q, Xu Z et al (2019) Improved interfacial property of carbon fiber composites with carbon nanotube and graphene oxide as multi-scale synergetic reinforcements. Compos Part A Appl Sci Manuf 125:105573

Acknowledgements

The authors would like to acknowledge the financial supports from Equipment Development Fund in The Field of Key Projects (no. 6140922010103), the Strategic Priority Research of Programme of Chinese Academy of Sciences (No. XDA17020405), Natural Science Foundation of Zhejiang Province (no. LY18E080037), and the “Science and Technology Innovation 2025” Major Project of Ningbo of China (no. 2019B10091).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, X., Qian, X., Zhang, Y. et al. Surface oxidation of PAN-based ultrahigh modulus carbon fibers (UHMCFs) and its effect on the properties of UHMCF/EP composites. Carbon Lett. 31, 449–461 (2021). https://doi.org/10.1007/s42823-020-00173-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-020-00173-7