Abstract

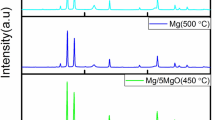

In this work, in situ oxidation and particle-dispersed methods are successfully used to prepare novel oxide/Mg composites with ultra-high damping capacity starting from pure Mg as the matrix. Successful incorporation of the MgO particles into the Mg matrix is experimentally demonstrated, and the role of the oxide in enhancing the damping capacities of the composites is examined in detail. The increased damping capacity of the composites with respect to the pure magnesium is attributed to an increased dislocation density and the introduction of interface damping. In the temperature-dependent damping tests, two damping peaks P1 and P2 were found. The P1 peak is considered to be related to the interaction between dislocations and impurity atoms or vacancies. The P2 peak is considered to be caused by the grain boundaries sliding.

Graphic Abstract

Similar content being viewed by others

References

J.Y. Zhai, X.Y. Song, A.Y. Xu, Y.G. Chen, Q.K. Han, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00566-y

V.V. Ramalingam, P. Ramasamy, M.D. Kovukkal, G. Myilsamy, Met. Mater. Int. 26, 409–430 (2020). https://doi.org/10.1007/s12540-019-00346-8

S.R. Agnew, J.F. Nie, Scripta Mater. 63(7), 671–673 (2010). https://doi.org/10.1016/j.scriptamat.2010.06.029

Y.J. Cui, Y.P. Li, S.H. Sun, H.K. Bian, H. Huang, Z.C. Wang, Y. Koizumi, A. Chiba, Scripta Mater. 101, 8–11 (2015). https://doi.org/10.1016/j.scriptamat.2015.01.002

Z.S. Wu, J.F. Wang, H.B. Wang, S. Ma, S. Huang, S. li, F.S. Pan, J. Mater. Sci. Technol., 33(9) (2017), pp. 941–946. https://doi.org/10.1016/j.jmst.2016.06.027

J.F. Wang, Z.S. Wu, S. Gao, R.P. Lu, D.Z. Qin, W.X. Yang, F.S. Pan, J. Magnes. Alloy. 3(1), 79–85 (2015). https://doi.org/10.1016/j.jma.2015.02.001

N. Srikanth, X.L. Zhong, M. Gupta, Mater. Lett. 59(29–30), 3851–3855 (2005). https://doi.org/10.1016/j.matlet.2005.07.029

W. Cao, C. Zhang, T. Fan, D. Zhang, Mater. Sci. Eng. A. 496(1–2), 242–246 (2008). https://doi.org/10.1016/j.msea.2008.06.032

H. Abdizadeh, R. Ebrahimifard, M.A. Baghchesara, Compos. Part. B Eng. 56, 217–221 (2014). https://doi.org/10.1016/j.compositesb.2013.08.023

C.S. Goh, M. Gupta, J. Wei, L.C. Lee, J. Compos. Mater. 41(19), 2325–2335 (2007). https://doi.org/10.1177/0021998307075445

S.L. Zhang, Y.T. Zhao, G. Chen, T. Nonferr, Metal. Soc. 20, 2096–2099 (2010). https://doi.org/10.1016/S1003-6326(09)60424-6

Z.Y. Zhang, Y.H. Guo, Y.T. Zhao, G. Chen, J.L. Wu, M.P. Liu, Mater. Charact. 150, 229–235 (2019). https://doi.org/10.1016/j.matchar.2019.02.024

X. Wang, W. Wu, Y. Tang, X. Zeng, S. Yao, J. Alloy. Compd. 474, 499–504 (2009). https://doi.org/10.1016/j.jallcom.2008.06.122

M. Zhang, Y. Yang, D. Wang, C. Song, J. Chen, Mater. Des. 165, 107583 (2019). https://doi.org/10.1016/j.matdes.2019.107583

D. Chen, S. Kitipornchai, J. Yang, Mater. Des. 140, 473–487 (2018). https://doi.org/10.1016/j.matdes.2017.12.019

A. Granato, K. Lücke, J. Appl. Phys. 27(6), 583–593 (1956). https://doi.org/10.1063/1.1722436

A. Granato, K. Lücke, J. Appl. Phys. 27(7), 789–805 (1956). https://doi.org/10.1063/1.1722485

X. Zhang, L. Liao, N. Ma, H. Wang, Compos. Part. A 37, 2011–2016 (2006). https://doi.org/10.1016/j.compositesa.2005.12.007

X. Zhang, H. Wang, L. Liao, N. Ma, Compos. Sci. Technol. 67(3–4), 720–727 (2007). https://doi.org/10.1016/j.compscitech.2006.04.010

L. Liao, X. Zhang, X. Li, H. Wang, N. Ma, Mater. Lett. 61(1), 231–234 (2007). https://doi.org/10.1016/j.matlet.2006.04.038

Z. Trojanová, Z. Drozd, P. Minárik, P. Lukáč, A. Kasakewitsch, Thermochim. Acta 644, 69–75 (2016). https://doi.org/10.1016/j.tca.2016.10.010

L.P. Fu, H.Z. Gu, A. Huang, M.J. Zhang, J.F. Wu, Ceram. Int. 46, 959–967 (2020). https://doi.org/10.1016/j.ceramint.2019.09.057

J. Zhang, R. Perez, C. Wong, E.J. Lavernia, Mater. Sci. Eng. R 13(8), 325–389 (1994). https://doi.org/10.1016/0927-796x(94)90010-8

C.F. Zhang, T.X. Fan, W. Cao, D. Zhang, Mater. Sci. Eng. A 508(1–2), 190–194 (2009). https://doi.org/10.1016/j.msea.2009.01.060

Y.J. Zhang, N.H. Ma, H.W. Wang, Mater. Lett. 61(14–15), 3273–3275 (2007). https://doi.org/10.1016/j.matlet.2006.11.052

G. Schoeck, Phys. Status Solidi B 32(2), 651–658 (1969). https://doi.org/10.1002/pssb.19690320216

G. Schoeck, E. Bisogni, Phys. Status. Solidi B 32(1), 31–40 (1969). https://doi.org/10.1002/pssb.19690320104

Z.K. Xie, M. Tane, S.K. Hyun, Y. Okuda, H. Nakajima, Mater. Sci. Eng. A 417, 129–133 (2006). https://doi.org/10.1016/j.msea.2005.10.061

I.S. Golovin, H.R. Sinning, Mater. Sci. Eng. A 370, 504–511 (2004). https://doi.org/10.1016/j.msea.2003.08.083

I.S. Golovin, H.R. Sinning, I.K. Arhipov, S.A. Golvin, M. Bram, Mater. Sci. Eng. A 370, 531–536 (2004). https://doi.org/10.1016/j.msea.2003.08.089

Q. Li, G. Jiang, J. Dong, J.W. Hou, G. He, J. Alloy. Compd. 680, 522–530 (2016). https://doi.org/10.1016/j.jallcom.2016.04.101

X.S. Hu, Y.K. Zhang, M.Y. Zheng, K. Wu, Scripta Mater. 52, 1141–1145 (2005). https://doi.org/10.1016/j.scriptamat.2005.01.048

X.S. Hu, X.J. Wang, X.D. He, K. Wu, M.Y. Zheng, T. Nonferr, Met. Soc. 22, 1907–1911 (2012). https://doi.org/10.1016/s1003-6326(11)61406-4

D.Q. Wan, J.C. Wang, Rare Met. Mater. Eng. 10, 2790–2793 (2017). https://doi.org/10.1016/S1875-5372(18)30008-0

T.S. Kê, Phys. Rev. 71, 533–546 (1947). https://doi.org/10.1103/PhysRev.71.533

Y.T. Tang, C. Zhang, L.B. Ren, W. Yang, D.D. Yin, G.H. Huang, H. Zhou, Y.B. Zhang, J. Magnes. Alloy. 7(3), 522–528 (2019). https://doi.org/10.1016/j.jma.2019.05.003

Funding

This work was supported by the National Natural Science Foundation of China [Grant Number 51665012]; the Jiangxi province Science Foundation for Outstanding Scholarship [Grant Number 20171BCB23061, 2018ACB21020]; and the Primary Research & Development Plan of Jiang Xi Province [Grant Number 2019BBEL50019].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wan, D., Hu, J., Wang, H. et al. Ultra-High Damping Capacity of Oxide Reinforced Magnesium Matrix Composites by In Situ Synthesis. Met. Mater. Int. 27, 5399–5406 (2021). https://doi.org/10.1007/s12540-020-00834-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00834-2