Abstract

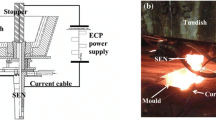

Clogging behavior has been investigated by applying a direct current on a submerged entry nozzle (SEN). The relevant experimental results verify that the high-speed friction acting on the SEN not only leads to charging of the inclusions, but also inhibits the clogging behavior and improves the quality of the steel. After DC treatment, the formation of clogging in the SEN decelerates and the stability improves, such that the density of clogging increases and the porosity of clogging decreases significantly. Meanwhile, after applying a DC electric field, the overall quality of steel is also improved.

Similar content being viewed by others

References

Z.G. Yan: Doctoral thesis, Northeastern University, Shenyang, China, 2011.

2. E. Gutierrez, S. Garcia-Hernandez, and J. D. Barreto: ISIJ Int, 2016, vol.56(8), pp.1394-1403.

3. X. S. Yu, K. Shen, X. L. Liao, and H. Ma: SPECIAL STEEL, 2014, vol.35(6), pp.32-34.

4. T. B. Braun, J. F. Elliott, and M. C. Flemings: Metall. Mater.Trans. B, 1979, vol.10, pp.171-184.

5. S. N. Singh: Metall Trans, 1974, vol.5(10), pp.2165-2178.

6. N. Kojola, S. Ekerot, M. Andersson, and P. G. Jönsson: Ironmak. Steelmak, 2011, vol.38(1), pp.1-11.

7. Z. Y. Deng, M. Y. Zhu, B. J. Zhong, and S. C. Du: ISIJ Int, 2014, vol.54(12), pp.2813-2820.

8. T. Komai, K. Miyamura, M. Oosaki, A. Kusano, S. Yamada, I. Shimazu, N. Sato, and T. Yamamoto: Tetsu-to-Hagane, 2009, vol.67(8), pp.1152-1161.

9. Y. Ren, Y. F. Wang, S. S. Li, L. F. Zhang, X. J. Zuo, S. N. Lekakh, and K. Peaslee: Metall. Mater. Trans. B, 2014, vol.45(4), pp.1291-1303.

10. B. G. Thomas and H. Bai: Steelmaking Conf. Proc, 2001, vol.84, pp.895-912.

11. C. Wang, N. Verma, Y. Kwon, W. Tiekink, N. Kikuchi, and S. Sridhar: ISIJ Int, 2011, vol.51(3), 375-381.

12. L. F. Zhang and B. G. Thomas: Metall. Mater. Trans. B, 2006, vol.37(5), pp.733-761.

13. R. B. Tuttle, J. D. Smith, and K. D. Peaslee: Metall. Mater. Trans. B, 2007, vol.38(1), pp.101-108.

14. Y. Tsukaguchi, H. Hayashi, H. Kurimoto, S. Yokoya, K. Marukawa, and T. Tanaka: Tetsu-to-Hagane, 2010, vol.50(5), pp.721-729.

15. H. Cui, Y. P. Bao, M. Wang, and W. S. Wu: Int J Miner. Metall. Mater, 2010, vol.17(2), pp.154-158.

16. Y. Vermeulen, B. Coletti, B. Blanpain, P. Wollants, and J. Vleugels: ISIJ Int, 2002, vol.42(11), pp.1234-1240.

17. S. Basu, S. K. Choudhary, and N. U. Girase: ISIJ Int, 2004, vol.44(10), pp.1653-1660.

18. A. Memarpour, V. Brabie, and P. Jönsson: Ironmak. Steelmak, 2013, vol.38(3), pp.229-39.

19. J. K. S Svensson, A. Memarpour, S. Ekerot, V. Brabie, and P. Jönsson: Ironmak. Steelmak, 2017, vol.44(2), pp.117-127.

20. X. D. Zou, D. P. Zhao, J. C. Sun, C. Wang, and H. Matsuura: Metall. Mater. Trans. B, 2018, vol.49, pp.481-489.

21. J. H. Lee, M. H. Kang, S. K. Kim, J. Kim, M. S. Kim, and Y. B. Kang: ISIJ Int, 2019, vol.59(5), pp.749-758.

22. Y. H. Paik, H. C. Shin, and J. M. Lee: Metals. Mater. Int, 1998, vol. 4(5), pp.995-1000.

J.H. Kim, J.M. Lee, HC Shin, et al. Separation of oxide inclusions from liquid metal in an applied electrostatic field. Metals. Mater. Int, 2003, vol 9(6), pp. 593-597.

YH Paik, JH Pan, WJ Yoon: J. Colloid. Interface Sci, 2001, vol 244(2), pp. 444-446.

YH Paik, WJ Yoon, and HC Shin: J. Colloid. Interface Sci, 2004, vol. 269(2), pp. 354-57.

26. X. Yang, J. K. Yu, Z. Y. Liu, X. H. Hou, and B. Y. Ma: Ceram. Int, 2017, vol.43, pp.2881-2883.

27. J. K. Yu, X. Yang, Z. Y. Liu, X. H. Hou, and Z. K. Yin: Ceram. Int, 2017, vol.43, pp.13025-13029.

28. X. Yang, Z. Y. Liu, and J. K. Yu: J. Mater. Process. Tech, 2018, vol.259, pp.341-345.

29. C. Tian, J. K. Yu, E. D. Jin, T. P. Wen, D. B. Jia, L. Yuan: J. Alloys. Compd, 2019, vol.809, pp.151825.

30. W. B. Dai, J. K. Yu, C. M. Du, L. Zhang, and X. L. Wang: Mater. Sci. Tech, 2015, vol.31(13), pp.1555-1559.

31. Y.Tsukaguchi, T.Kato,S.Watanabe, S.Ooga, and T.Tanaka : Materia Japan, 2011, vol.50, pp.27-29

32. T.Kato, Y.Tsukaguchi, M.Kawamoto, A.Muto, and K.Oota: CAMP-ISIJ, 2009, vol.22, pp.125.

33. C. Tian, J. K. Yu, E. D. Jin, T. P. Wen, D. B. Jia, Z. L. Liu, P. X. Fu, L. Yuan: J. Alloys. Compd, 2019, vol.792, pp.1-7.

34. J. H. Shin, and J. H. Park: Metall. Mater. Trans. B, 2017, vol.48, pp.2820-2825.

35. Brabie and Voicu: Steel Res, 1997, vol.68(2), pp.54-60.

36. Brabie and Voicu: ISIJ Int, 1996, vol.36, pp.S109-S112.

37. A. H. Bui, S. C. Park, I. S. Chung, and H. G. Lee: Metal and Mater Int, 2006, vol.12(5), pp.435-440.

A. Memarpour: Doctoral thesis, KTH Royal Institute of Technology, Sweden, 2011.

39. Q. F. Shu, Y. F. Wang, J. L. Li, Y. Liu, P. F. Li, and K. Chou: ISIJ Int, 2015, vol.55(11), pp.2297-2303.

40. M. Suzuki and E. Jak: Metall. Mater. Trans. B, 2013, vol.44(6), pp.1451-1465.

41. L. X. Kong, J. Bai, W. Li, X. D. Wen, X. M. Li, Z. Q. Bai, Z. X. Guo, and H. Z. Li: Fuel, 2016, vol.179, pp.10-16.

42. K. Wang, C. H. Li, Y. H. Gao, X. G Lu, and W. Z. Ding: J Am Ceram Soc, 2009, vol.92(5), pp.1098-1104.

43. C. Liu, S. F. Yang, J. S. Li, L. B. Zhu, and X. G. Li: Metall. Mater. Trans. B, 2016, vol.47(3), pp.1882-1892.

44. P. L. Harrison and R. A. Farrar: J Mater. Sci, 1981, vol.16(8), pp.2218-2226.

45. D. S. Sarma, A. V. Karasev, and P. Jönsson: ISIJ Int, 2009, vol.49(7), pp.1063-1074.

46. L. Cheng and K. M. Wu: Acta Mater, 2009, vol.57(13), pp.3754-3762.

47. Y. Yu, J. L. Gu, F. L. Shou, L. Xu, B. Z. Bai and Y. B. Liu: Int J Fatig, 2011, vol.33(3), pp.500-506.

Acknowledgments

The authors express their gratitude for the financial support from the National Natural Science Foundation of China (Grant Nos. 51974074, 51874083), the State Key Program of National Natural Science Foundation of China (Grant No. 51932008) and the Fundamental Research Funds for the Central Universities (Grant N2025036, N182504009).

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 31, 2020.

Rights and permissions

About this article

Cite this article

Tian, C., Yuan, L., Yu, J. et al. Effect of External Electric Field Application on the Clogging Behavior of Submerged Entry Nozzles During Aluminum-Killed Steel Casting. Metall Mater Trans B 51, 2095–2106 (2020). https://doi.org/10.1007/s11663-020-01926-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-020-01926-5