Abstract

Purpose

A close form solution was developed in this paper to find the nonlinear tuning parameters of symmetric/asymmetric rotor—Squeeze film damper system.

Methods

Initially, close form solution was developed to find the optimum tuning criteria using linear models. Later, it has been extended to nonlinear unbalanced rotor damper system using circular centre orbit condition. Analytical modeling of Squeeze film damper forces is carried out considering viscous, inertial and temporal contributions under laminar and turbulent conditions. Modified Reynolds equation with short damper approximation is used to derive the SFD forces for 2π-film. The solution of the system of equations helped to predict optimum tuning parameters, such as cross-over frequency and maximum possible amplitudes. Contributions of various governing parameters are discussed.

Conclusion

Mass ratio of damper-to-rotor mass and nonlinear radial/tangential damper forces play an important role in finding the tuning parameters of symmetric system. Additional shaft parameter, fp, plays an important role in getting the optimum tuning parameters of asymmetric system as compared to symmetric system.

Similar content being viewed by others

Abbreviations

- M s :

-

Mass of rotor and disc system, Kg, Ms = M for asymmetric system, Ms = M/2 for symmetric system

- M s :

-

M/2 for symmetric system

- M :

-

Mass of disc, kg

- M d :

-

Mass of damper, kg

- K1:

-

Shaft stiffness of top half-length of shaft, N/m

- K2:

-

Shaft stiffness of bottom half-length of shaft, N/m

- K3:

-

Stiffness of retainer spring, N/m

- K s :

-

Stiffness of the shaft, N/m Ks = K1 + K2 for asymmetric system Ks = (K1 + K2)/2

- u :

-

Unbalance eccentricity, m

- U :

-

Unbalance parameter, \(\frac{u}{c}\)

- ωn :

-

Natural frequency of rotor, \(\sqrt {\frac{{K_{\text{s}} }}{{M_{\text{s}} }}}\), Hz

- ωd :

-

Natural frequency of damper, \(\sqrt {\frac{{K_{3} }}{{M_{\text{d}} }}}\), Hz

- ωp :

-

Natural frequency of bottom half of the shaft, \(\sqrt {\frac{{K_{2} }}{{M_{\text{s}} }}}\), Hz

- n :

-

Stiffness ratios of top and bottom half of the shaft, \(\frac{{K_{2} }}{{K_{1} }}\)

- f :

-

Frequency ratio of damper vs rotor, \(\frac{{\omega _{{\text{s}}} }}{{\omega _{n} }}\)

- f p :

-

Frequency ratio of half of the shaft connected at damper end, \(\frac{{\omega_{\text{p}} }}{{\omega_{n} }}\)

- α :

-

Mass ratio of damper to rotor, \(\frac{{M_{{\text{d}}} }}{{M_{{\text{s}}} }}\)

- ω :

-

Rotational speed, rad/s

- Ω :

-

Frequency ratio, ω/ωn

- Cd:

-

Damping coefficient of damper, \(2\xi M_{\text{d}} \omega_{\text{d}}\), N-s/m

- CC:

-

Critical damping, 2Md ωd

- ξ :

-

Damping ratio, Cd/Cc

- \(x_{\text{s}}\),\(y_{\text{s}}\), \(x_{\text{d}}\),\(y_{\text{d}}\) :

-

Rotor and damper Displacements in Cartesian coordinates, m

- \(\bar{x}_{\text{s}} ,\bar{y}_{\text{s}}\), \(\bar{x}_{\text{d}} ,\bar{y}_{\text{d}}\) :

-

Non-dimensional rotor and damper displacement in Cartesian coordinates, \(\bar{x}_{\text{s}} = \frac{{x_{\text{s}} }}{c}\), \(\bar{y}_{\text{s}} = \frac{{y_{\text{s}} }}{c}\), \(\bar{x}_{\text{d}} = \frac{{x_{\text{d}} }}{c}\),\(\bar{y}_{\text{d}} = \frac{{y_{\text{d}} }}{c}\)

- \({\mathbf{x}}_{s}\),\({\mathbf{x}}_{d}\) :

-

Rotor and damper displacement vector, i.e.,\({\bar{\mathbf{x}}}_{s} = \bar{x}_{s} + i\bar{y}_{s} = \varepsilon_{s} e^{{i\varphi_{s} }}\) and \({\mathbf{x}}_{d} = x_{d} + iy_{d} = e_{d} e^{{i\varphi _{d} }}\)

- \({\mathbf{\bar{X}}}_{s}\), \({\bar{\mathbf{X}}}_{d}\) :

-

Non-dimensional rotor and damper displacement vector

- P :

-

Gauge pressure in the damper, N/m2

- m :

-

Dynamic viscosity of damper oil, N-s/m2

- ρ :

-

Density of damper oil, kg/m3

- h :

-

Thickness of the film, m

- θ :

-

Angular coordinate measured from the position of maximum film thickness in the direction of rotor angular speed, rad

- t :

-

Time, s

- R :

-

Radius of damper, m

- L :

-

Length of the damper, m

- z :

-

Axial coordinate in length direction

- φs :

-

Angle of rotor from positive-x axis of the Cartesian coordinate system

- φd :

-

Angle of damper from positive -x axis of the Cartesian coordinate system

- c :

-

Initial radial clearance in the damper, m

- btt:

-

Tangential damping coefficient, N-s/m

- mr cen:

-

Mixed temporal and convective origin in radial direction

- \(\varepsilon _{d} \dot{\varphi }_{d}\) :

-

Tangential velocity, rad/s

- \(\varepsilon _{d} \dot{\varphi }{}_{d}^{2}\) :

-

Centripetal acceleration, rad/s2

- \(\left( {\varepsilon _{d} \dot{\varphi }_{d} } \right)^{2}\) :

-

Nonlinear tangential acceleration, rad/s2

- F r, F t :

-

Damper oil film forces in radial and tangential direction, N

- F dx, F dx :

-

Damper oil film forces in x- and y-direction, N

- \(\bar{F}_{r}\), \(\bar{F}_{t}\) :

-

Non-dimensional radial and tangential forces

- \({\bar{\mathbf{F}}}_{d}\) :

-

Non-dimensional force vector, \(\bar{F}_{{{\text{d}}x}} + j\bar{F}_{{{\text{d}}y}}\)

- B :

-

Damper viscous parameters, \(\frac{{4\mu RL^{3} }}{{M_{s} c^{3} \omega _{n} }}\)

- B1:

-

Damper inertial parameters, \(\frac{{4\rho RL^{3} }}{{M_{s} c}}\)

- (.):

-

Denotes differentiation with respect to ‘t’

- O g :

-

Mass center of disc

- O s :

-

Geometric center of disc

- O d :

-

Geometric center of damper

- O b :

-

Bearing center

- X-, Y-:

-

Stationary Cartesian coordinate system with origin at the damper geometric center

- r-, t-:

-

Rotating coordinate system with origin at the damper geometric center

- S :

-

Rotor

- d :

-

Damper

- r :

-

Radial

- t :

-

Tangential

- P, Q :

-

Cross-over points in frequency domain

References

Den Hartog JP (1985) Mechanical vibrations, 4th edn. Dover, New York

Randall SE, Halsted DM, Taylor DL (1981) Optimal vibration absorbers for linear damper systems. J Mech Design 103:908–913

Liu K, Liu J (2005) The damped dynamic vibration absorbers: revisited and new result. J Sound Vibrat 284:1181–1189

Febbo M, Vera SA (2008) Optimization of a two degree of freedom system acting as a dynamic vibration absorber. J Vibrat Acoust 130:1–11

Gunter EJ (1970) Influence of flexibly mounted rolling element bearings on rotor response, part I linear analysis. J Lubricat Technol 92:59–69

Kirk RG, Gunter EJ (1972) The effect of support flexibility and damping on the synchronous response of single mass flexible rotor. J Eng Ind 94(1):221–232

Cunningham RE, Cunningham DP, Gunter EJ (1975) Design of a squeeze-film dampers for a multi-mass flexible rotor. J Eng Ind 97(4):1383–1389

Pilkey WD, Wang BP, Vannoy D (1976) Efficient optimal design of suspension systems for rotating shafts. J Eng Ind 98(3):1026–1029

Jawaid II-H (2005) Bifurcations of a flexible rotor response in squeeze-film dampers without centering springs. Chaos Sol Fract 24:583–596

Jawaid II-H (2009) Bifurcations in the response of a flexible rotor in squeeze-film dampers with retainer springs. Chaos Sol Fract 39:519–532

Rao JS (2018) Rotor dynamics, 3rd edn. New age International publications, Bengaluru

Rabinowitz MD, and Hahn EJ (1977) Steady state performance of squeeze film damper supported flexible rotors. J Eng Power 552–558

Rabinowitz MD, Hahn EJ (1983) Optimal design of squeeze film supports for flexible rotors. J Eng Power 105:487–494

Rabinowitz MD, Hahn EJ (1983) Experimental evaluation of squeeze film supported flexible rotors. J Eng Power 105:495–503

McLean LJ, Hahn EJ (1983) Unbalance behavior of squeeze film damped multi-mass flexible rotor bearing systems. J Lubricat Technol 105:22–27

McLean LJ, Hahn EJ (1985) Stability of squeeze film damped multi-mass flexible rotor bearing systems. J Tribol 107:402–409

Chen WJ, Rajan M, Rajan SD, Nelson HD (1988) The optimal design of squeeze film dampers for flexible rotor systems. J Mech Trans Automat Design 110:166–174

Zhu CS, Robb DA, Ewins DJ (2002) Analysis of the multiple-solution response of a flexible rotor supported on non-linear squeeze film dampers. J Sound Vibrat 252(3):389–408

EI-Shafei A, Yakoub RYK (2002) Optimum design of squeeze film dampers supporting multiple mode rotors. J Eng Gas Turb Power 124:992–1001

Pietra LD, Adiletta G (2002) The squeeze film damper over four decades of investigations. Part I: characteristics and operating features. Shock Vibr Dig 34:3–26

Adiletta G, Pietra LD (2002) The squeeze film damper over four decades of investigations. Part II: rotor dynamic analyses with rigid and flexible rotors. Shock Vibr Dig 34:97–126

Qingchang T, Chang Y, Wang L (1997) Effect of a circumferential feeding groove on fluid force in short squeeze film dampers. Tribol Int 30:409–416

Qingchang T, Xiaohua L (1999) Analytical study on effect of a circumferential feeding groove on unbalance response of a flexible rotor in squeeze film damper. Tribol Int 32:559–566

Rezvani MA, Hahn EJ (1996) An experimental evaluation of squeeze film dampers without centralizing springs. Tribol Int 29(1):51–59

Rezvani MA, Hahn EJ (2000) Floating ring squeeze film damper: theoretical analysis. Tribol Int 33:249–258

Hai-Lun Z, Gui-Huo L, Guo C, Fei W (2013) Analysis of the nonlinear dynamic response of a rotor supported on ball bearings with floating-ring squeeze film dampers. Mech Mach Theory 59:65–77

Giovanni A (2015) Bifurcating behaviour of a rotor on two-lobe wave squeeze film damper. Tribol Int 92:72–83

Wang J, Feng N, Meng G, Hahn EJ (2006) Vibration control of rotor by squeeze film damper with magnetorheological fluid. J Intell Mater Syst Struct 17:353–357

Jaroslav Z, Petr F, Paola F (2017) A new mathematical model of a short magnetorheological squeeze film damper for rotordynamic applications based on a bilinear oil representation—derivation of the governing equations. Appl Math Model 52:558–575

Siva Srinivas R, Tiwari R, Kannababu Ch (2018) Application of active magnetic bearings in flexible rotordynamic systems—a state-of-the-art review. Mech Syst Signal Process 106:537–572

Heidari HR, Safarpour P (2016) Design and modeling of a novel active squeeze film damper. Mech Mach Theory 105:235–243

Zhifei H, Qian D, Wei Z (2019) Dynamical analysis of an elastic ring squeeze film damper-rotor system. Mech Mach Theory 131:406–419

Wei Z, Bingbing H, Xiang L, Jianqiao S, Qian D (2019) Multiple-objective design optimization of squirrel cage for squeeze film damper by using cell mapping method and experimental validation. Mech Mach Theory 132:66–79

Muszynska A (1986) Whirl and whip rotor/bearing stability problems. J Sound Vibrat 110(3):443–462

Zhang J, Ellis J, Roberts JB (1993) Observations on the nonlinear fluid forces in short cylindrical squeeze film dampers. ASME J Tribol 115:692–698

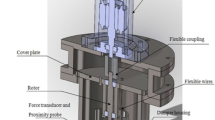

Shaik K, Dutta BK, Gouthaman G (2019) Experimental and analytical investigation of short squeeze-film damper (SFD) under circular-centered orbit (CCO) motion. J Vibrat Eng Technol. https://doi.org/10.1007/s42417-019-00100-9

Ku C-P, Tichy JA (1987) Application of the k − ϵ turbulence model to the squeeze film damper. ASME J Tribol 109:164–168

Booker JF (1965) A table of the journal bearing integral. ASME J Basic Eng 1965:533–535

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shaik, K., Dutta, B.K. Tuning Criteria of Nonlinear Flexible Rotor Mounted on Squeeze Film Damper Using Analytical Approach. J. Vib. Eng. Technol. 9, 325–339 (2021). https://doi.org/10.1007/s42417-020-00229-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-020-00229-y