Abstract

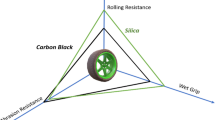

It is essential to keep the balance among rolling resistance, wet skid resistance and wear resistance (the so-called devil's triangle) of tire treads so as to ensure the reliability and safety of the vehicles. For this purpose, hexamethyl-disiloxane (HMDS) and carboxylated polyethylene vinyl acetate copolymer (EVA, emulsion polymer latex) were used to modify nanosilica by in situ surface-modification method, thereby obtaining surface-capped nanosilica possessing good compatibility and strong interfacial interactions with rubber matrix. The surface-capped nanosilica of the above both modifications were introduced into the blend of solution polymerized styrene butadiene rubber (SSBR) and butadiene rubber (BR), and its effect on the mechanical properties and wear resistance of the SSBR/BR-matrix nanocomposites was investigated. The results indicated that both HMDS and EVA contribute to enhancing the compatibility and interfacial interactions of nanosilica with the rubber matrix, which is favorable for improving the mechanical properties and wear resistance of SSBR/BR-matrix nanocomposites. Particularly, HMDS can endow the rubber-matrix nanocomposites with increased wet skid resistance, and EVA can ensure the low rolling resistance of the nanocomposites. Therefore, the SSBR/BR blend filled with HMDS–SiO2–EVA possesses the desired mechanical properties and wear resistance and shows promising prospective as a candidate material for fabricating high-performance tire tread.

Similar content being viewed by others

References

Poompradub S, Tosaka M, Kohjiya S, Ikeda Y, Toki S, Sics I, Hsiao BS (2005) Mechanism of strain-induced crystallization in filled and unfilled natural rubber vulcanizates. J Appl Phys 97:103529

Delgado E, Espitia A, Aperador W (2020) Comparative evaluation of Clusia multiflora wood flour, against mineral fillers, as reinforcement in SBR rubber composites. Iran Polym J 29:13–23

Wu X, Liao Y, Meng G, Tang L, Zhou Z, Li Q, Huang W (2019) SiO2/carbon fiber-reinforced polypropylene-thermoplastic polyurethane composites: electrical conductivity and mechanical and thermal properties. Iran Polym J 28:527–537

Huang C, Dang X, Bei R, Zhao Y, Li C, Chen Q, Wang S (2019) Effect of SiOx layer on preventing the migration of plasticizer and antioxidant from polyethylene terephthalate films. Iran Polym J 28:173–182

WangYX WuYP, Li WJ, Zhang LQ (2011) Influence of filler type on wet skid resistance of SSBR/BR composites: effects from roughness and micro-hardness of rubber surface. Appl Surf Sci 257:2058–2065

Bragaglia M, Cacciotti I, Cherubini V, Nanni F (2019) Influence of organic modified silica coatings on the tribological properties of elastomeric compounds. Wear 434:202987

Tian Q, Tang Y, Ding T, Li X, Zhang Z (2018) Effect of nano-silica surface-capped by bis[3-(triethoxysilyl)propyl] tetrasulfide on the mechanical properties of styrene-butadiene rubber/butadiene rubber nanocomposites. Compos Commun 10:190–193

Xia L, Song J, Wang H, Kan Z (2019) Silica nanoparticles reinforced natural rubber latex composites: the effects of silica dimension and polydispersity on performance. J Appl Polym Sci 136:47449

Xiao L, Zhao S (2008) Study on structure and properties of SSBR/SiO2 co-coagulated rubber and SSBR filled with nanosilica composites. J Appl Polym Sci 109:3900–3907

Stöckelhuber KW, Das A, Jurk R, Heinrich G (2010) Contribution of physico-chemical properties of interfaces on dispersity, adhesion and flocculation of filler particles in rubber. Polymer 51:1954–1963

Yoshikawa C, Qiu J, Shimizu Y, Huang CF, Gelling OJ, van den Bosch E (2017) Concentrated polymer brush-modified silica particle coating confers biofouling-resistance on modified materials. Mater Sci Eng C70:272–277

Liu H, Liu T, Takafuji M, Qiu H, Ihara H (2017) Monodisperse core-shell melamine-formaldehyde polymer-modified silica microspheres prepared using a facile microwave-assisted method. New J Chem 41:11517–11520

Liu Y, Liu Q, Yu H, Sun S, Xue Y, Wang Y, Qu Q, Yan C (2017) Polymer-modified fibrous mesoporous silica nanoparticles as coating material for open-tubular capillary electrochromatography. J Chromatogr A 1499:196–202

Wang L, Zhao S, Li A, Zhang X (2010) Study on the structure and properties of SSBR with large-volume functional groups at the end of chains. Polymer 51:2084–2090

Wang Z, Lai X, Zhang M, Yang W, Yang M (2017) Synthesis of an efficient processing modifier silica-g-poly (lactic acid)/poly (propylene carbonate) and its behavior for poly (lactic acid)/poly (propylene carbonate) blends. Ind Eng Chem Res 56:14704–14715

Liu J, Tian XH, Sun JY, Wang SY, Duan JC (2016) Mechanical properties and thermal resistance of natural rubber nanocomposite reinforced with quaternized polyvinyl alcohol/silica nanoclusters. J Nano Res 43:46–56

Gao W, Lu J, Song W, Hu J, Han B (2019) Solution mechanochemical approach for preparing high-dispersion SiO2-g-SSBR and the performance of modified silica/SSBRcomposites. Ind Eng Chem Res 58:7146–7155

Zhang C, Tang Z, Guo B, Zhang L (2019) Concurrently improved dispersion and interfacial interaction in rubber/nanosilica composites via efficient hydrosilane functionalization. Compos Sci Technol 169:217–223

Khabibullin A, Kopeć M, Matyjaszewski K (2016) Modification of silica nanoparticles with miktoarm polymer brushes via ATRP. J Inorg Organomet P26:1292–1300

Nie H, Zhang C, Liu Y, He A (2016) Synthesis of Janus rubber hybrid particles and interfacial behavior. Macromolecules 49:2238–2244

Boonmahitthisud A, Chuayjuljit S (2012) Effects of nanosized polystyrene and polystyrene-encapsulated nanosilica on physical properties of natural rubber/styrene butadiene rubber nanocomposites. Polym Plast Technol 51:311–316

Khalifeh S, Tavakoli M (2019) Styrene butadiene rubber/epoxidized natural rubber/carbon filler nanocomposites: microstructural development and cure characterization. Iran Polym J 28:1023–1033

Zhang Z J, Li X H, Liu K (2011) Method for preparing hydrophobic nano silica. Chinese Patent: CN102502663A

Sing KS (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl Chem 57:603–619

Grosch KA (1974) In: Hays DF, Browne AL (eds) The physics of tire traction. Springer, Boston

Zhang X, Cui H, Song L, Ren H, Wang R, He A (2018) Elastomer nanocomposites with superior dynamic mechanical properties via trans-1,4-poly (butadiene-co-isoprene) incorporation. Compos Sci Technol 158:156–163

Cao L, Sinha TK, Tao L, Li H, Zong C, Kim JK (2019) Synergistic reinforcement of silanized silica-graphene oxide hybrid in natural rubber for tire-tread fabrication: a latex based facile approach. Compos B 161:667–676

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant no. 51803048), Henan Science and Technology Project (Grant no. 192102210190), Jiyuan City Science and Technology Projects (Grant no. 19022015), the Graduate Education Innovation and Quality Improvement Program of Henan University (Grant no. SYL18060147), and Double First-Class Discipline Cultivation Project of Henan University (Grant no. 2018YLZDCG04).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Tang, Y., Tian, Qf., Liu, Yl. et al. Application of carboxylated ethylene/vinyl acetate copolymer-modified nanosilica in tire tread rubber. Iran Polym J 29, 853–864 (2020). https://doi.org/10.1007/s13726-020-00843-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00843-3