Abstract

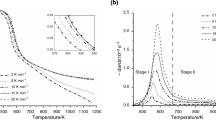

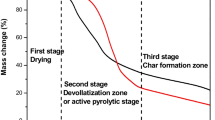

The novelty of this study is that it presents the first in-depth evaluation of the kinetic triplet and thermodynamic parameters from the pyrolysis of açaí seed (Euterpe oleracea), which is the main biowaste from the açaí fruit processing industry. First, the physicochemical characteristics of the açaí seed, i.e., the proximate analysis, ultimate analysis, energy content, bulk density, and bioenergy density, were determined. Thermogravimetric experiments were then conducted to evaluate the pyrolysis characteristics of the açaí seed, the kinetic triplet (Ea, A, and f(α)), and the thermodynamic parameters (ΔH, ΔS, and ΔG). Three pseudo-components were distinguished from the açai seed pyrolysis profile using the asymmetric double sigmoidal (Asym2sig) function, which was described by the reaction model for the first order, third order, and eighth order, respectively. The Vyazovkin isoconversional method showed values of Ea ranging from 103 to 346 kJ mol−1 for açaí seed pyrolysis. The kinetic expression was applied to reconstruct the experimental data used (R2 > 0.9210) for the kinetic study and validated with a different experimental condition. The statistical test indicated no significant difference between experimental and calculated curves; therefore, the kinetic parameters are applicable to different thermal conditions. Physicochemical properties and thermodynamic parameters suggested that the açaí seed is a good candidate for bioenergy conversion through pyrolysis. Açaí seed is a promising feedstock for bioenergy production, as demonstrated by the kinetic and thermodynamic findings, and this information is important for advancing the design and scale-up of an açai seed pyrolysis process.

Similar content being viewed by others

References

Pessôa TS, de Lima Ferreira LE, da Silva MP et al (2019) Açaí waste beneficing by gasification process and its employment in the treatment of synthetic and raw textile wastewater. J Clean Prod 240:118047. https://doi.org/10.1016/j.jclepro.2019.118047

IBGE (2019) Production of vegetable extraction and silviculture - quantity produced and value of production in plant extraction, by type of extractive product (in Portuguese). In: SIDRA. https://sidra.ibge.gov.br/tabela/289. Accessed 12 Jan 2019

de Sousa Ribeiro LA, Thim GP, Alvarez-Mendez MO, dos Reis Coutinho A, de Moraes NP, Rodrigues LA (2018) Preparation, characterization, and application of low-cost açaí seed-based activated carbon for phenol adsorption. Int J Environ Res 12:755–764. https://doi.org/10.1007/s41742-018-0128-5

Itai Y, Santos R, Branquinho M, Malico I, Ghesti GF, Brasil AM (2014) Numerical and experimental assessment of a downdraft gasifier for electric power in Amazon using açaí seed (Euterpe oleracea Mart.) as a fuel. Renew Energy 66:662–669. https://doi.org/10.1016/j.renene.2014.01.007

Teixeira MA, Escobar Palacio JC, Sotomonte CR, Silva Lora EE, Venturini OJ, Aßmann D (2013) Assaí - an energy view on an Amazon residue. Biomass Bioenergy 58:76–86. https://doi.org/10.1016/j.biombioe.2013.08.007

da Silva JCG, Alves JLF, Galdino WV d A et al (2018) Pyrolysis kinetic evaluation by single-step for waste wood from reforestation. Waste Manag 72:265–273. https://doi.org/10.1016/j.wasman.2017.11.034

Tahir MH, Çakman G, Goldfarb JL, Topcu Y, Naqvi SR, Ceylan S (2019) Demonstrating the suitability of canola residue biomass to biofuel conversion via pyrolysis through reaction kinetics, thermodynamics and evolved gas analyses. Bioresour Technol 279:67–73. https://doi.org/10.1016/j.biortech.2019.01.106

Alves JLF, Da Silva JCG, Filho VF d S et al (2019) Bioenergy potential of red macroalgae Gelidium floridanum by pyrolysis: evaluation of kinetic triplet and thermodynamics parameters. Bioresour Technol 291:121892. https://doi.org/10.1016/j.biortech.2019.121892

Yao Z, Xiong J, Yu S et al (2020) Kinetic study on the slow pyrolysis of nonmetal fraction of waste printed circuit boards (NMF-WPCBs). Waste Manag Res. https://doi.org/10.1177/0734242X19896630

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520:1–19. https://doi.org/10.1016/j.tca.2011.03.034

Boubacar Laougé Z, Merdun H (2020) Pyrolysis and combustion kinetics of Sida cordifolia L. using thermogravimetric analysis. Bioresour Technol 299:122602. https://doi.org/10.1016/j.biortech.2019.122602

Lopez-Velazquez MA, Santes V, Balmaseda J, Torres-Garcia E (2013) Pyrolysis of orange waste: a thermo-kinetic study. J Anal Appl Pyrolysis 99:170–177. https://doi.org/10.1016/j.jaap.2012.09.016

García-Garrido C, Pérez-Maqueda LA, Criado JM, Sánchez-Jiménez PE (2018) Combined kinetic analysis of multistep processes of thermal decomposition of polydimethylsiloxane silicone. Polymer (Guildf) 153:558–564. https://doi.org/10.1016/j.polymer.2018.08.045

da Silva JCG, de Albuquerque JG, Galdino WV d A et al (2020) Single-step and multi-step thermokinetic study – deconvolution method as a simple pathway for describe properly the biomass pyrolysis for energy conversion. Energy Convers Manag 209:112653. https://doi.org/10.1016/j.enconman.2020.112653

Alves JLF, Da Silva JCG, da Silva Filho VF et al (2019) Determination of the bioenergy potential of Brazilian pine-fruit shell via pyrolysis kinetics, thermodynamic study, and evolved gas analysis. BioEnergy Res 12:168–183. https://doi.org/10.1007/s12155-019-9964-1

Sharma P, Pandey OP, Diwan PK (2019) Non-isothermal kinetics of pseudo-components of waste biomass. Fuel 253:1149–1161. https://doi.org/10.1016/j.fuel.2019.05.093

Chen C, Miao W, Zhou C, Wu H (2017) Thermogravimetric pyrolysis kinetics of bamboo waste via asymmetric double sigmoidal (Asym2sig) function deconvolution. Bioresour Technol 225:48–57. https://doi.org/10.1016/j.biortech.2016.11.013

CEN (2011) BS EN 14780:2011 - solid biofuels - sample preparation. British Standards Institution, London, pp 1–28

ASTM (2016) D5373-08: standard test methods for instrumental determination of carbon, hydrogen, and nitrogen in laboratory samples of coal and coke. In: Annual book of ASTM standards. ASTM International, West Conshohocken, p 1–4

ASTM (2017) D4239-17: standard test method for sulfur in the analysis sample of coal and coke using high-temperature tube furnace combustion. In: Annual book of ASTM standards. ASTM International, West Conshohocken, p 1–7

ASTM (2013) D5865-13: standard test method for gross calorific value of coal and coke. In: Annual book of ASTM standards. ASTM International, West Conshohocken, pp 1-19

ASTM (2019) E873-82: standard test method for bulk density of densified particulate biomass fuels. In: Annual book of ASTM standards. West Conshohocken , pp 1–2

TAPPI (2002) T 212 om-02: test methods for one percent sodium hydroxide solubility of wood and pulp. In: TAPPI Standards & Methods. Technical Association of the Pulp and Paper Industry, Atlanta, pp 1–4

TAPPI (1999) T 203 cm-99: test methods for alpha-, beta- and gamma-cellulose in pulp. In: TAPPI Standards & Methods. Technical Association of the Pulp and Paper Industry, Atlanta, pp 1–5

TAPPI (2002) T 222 om-02: test methods for acid-insoluble lignin in wood and pulp. In: TAPPI Standards & Methods. Technical Association of the Pulp and Paper Industry, Atlanta, pp 1–5

ASTM (2017) E2550-17: standard test method for thermal stability by thermogravimetry. In: Annual book of ASTM standards. ASTM International, West Conshohocken, pp. 1–5

Van de Velden M, Baeyens J, Boukis I (2008) Modeling CFB biomass pyrolysis reactors. Biomass Bioenergy 32:128–139. https://doi.org/10.1016/j.biombioe.2007.08.001

Vyazovkin S, Chrissafis K, Di Lorenzo ML et al (2014) ICTAC Kinetics Committee recommendations for collecting experimental thermal analysis data for kinetic computations. Thermochim Acta 590:1–23. https://doi.org/10.1016/j.tca.2014.05.036

Vyazovkin S, Dollimore D (1996) Linear and nonlinear procedures in isoconversional computations of the activation energy of nonisothermal reactions in solids. J Chem Inf Comput Sci 36:42–45. https://doi.org/10.1021/ci950062m

Khawam A, Flanagan DR (2006) Solid-state kinetic models: basics and mathematical fundamentals. J Phys Chem B 110:17315–17328. https://doi.org/10.1021/jp062746a

Montgomery DC, Runger GC (2018) Applied statistics and probability for engineers, 7th ed. Wiley

Ding Y, Zhang Y, Zhang J, Zhou R, Ren Z, Guo H (2019) Kinetic parameters estimation of Pinus sylvestris pyrolysis by Kissinger-Kai method coupled with particle swarm optimization and global sensitivity analysis. Bioresour Technol 293:122079. https://doi.org/10.1016/j.biortech.2019.122079

Lilliefors HW (1969) On the Kolmogorov-Smirnov test for the exponential distribution with mean unknown. J Am Stat Assoc 64:387–389. https://doi.org/10.1080/01621459.1969.10500983

Yang YB, Ryu C, Khor A et al (2005) Effect of fuel properties on biomass combustion. Part II Modelling approach—identification of the controlling factors. Fuel 84:2116–2130. https://doi.org/10.1016/j.fuel.2005.04.023

Kalkreuth W, Holz M, Kern M, Machado G, Mexias A, Silva MB, Willett J, Finkelman R, Burger H (2006) Petrology and chemistry of Permian coals from the Paraná Basin: 1. Santa Terezinha, Leão-Butiá and Candiota coalfields, Rio Grande do Sul, Brazil. Int J Coal Geol 68:79–116. https://doi.org/10.1016/j.coal.2005.10.006

Vassilev SV, Baxter D, Andersen LK, Vassileva CG (2010) An overview of the chemical composition of biomass. Fuel 89:913–933. https://doi.org/10.1016/j.fuel.2009.10.022

Alves J, da Trindade E, da Silva J et al (2020) Lignocellulosic residues from the Brazilian juice processing industry as novel sustainable sources for bioenergy production: preliminary assessment using physicochemical characteristics. J Braz Chem Soc. https://doi.org/10.21577/0103-5053.20200094

Rambo MKD, Schmidt FL, Ferreira MMC (2015) Analysis of the lignocellulosic components of biomass residues for biorefinery opportunities. Talanta 144:696–703. https://doi.org/10.1016/j.talanta.2015.06.045

Monteiro AF, Miguez IS, Silva JPRB, Silva AS d (2019) High concentration and yield production of mannose from açaí (Euterpe oleracea Mart.) seeds via mannanase-catalyzed hydrolysis. Sci Rep 9:10939. https://doi.org/10.1038/s41598-019-47401-3

Sunphorka S, Chalermsinsuwan B, Piumsomboon P (2017) Artificial neural network model for the prediction of kinetic parameters of biomass pyrolysis from its constituents. Fuel 193:142–158. https://doi.org/10.1016/j.fuel.2016.12.046

García R, Pizarro C, Lavín AG, Bueno JL (2014) Spanish biofuels heating value estimation. Part II: Proximate analysis data. Fuel 117:1139–1147. https://doi.org/10.1016/j.fuel.2013.08.049

Protásio TDP, Bufalino L, Tonoli GHD et al (2013) Brazilian lignocellulosic wastes for bioenergy production: characterization and comparison with fossil fuels. BioResources 8:1166–1185

Filipe dos Santos Viana H, Martins Rodrigues A, Godina R et al (2018) Evaluation of the physical, chemical and thermal properties of Portuguese maritime pine biomass. Sustainability 10:2877. https://doi.org/10.3390/su10082877

Collard F-X, Blin J (2014) A review on pyrolysis of biomass constituents: mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sust Energ Rev 38:594–608. https://doi.org/10.1016/j.rser.2014.06.013

Dhyani V, Bhaskar T (2018) A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew Energy 129:695–716. https://doi.org/10.1016/j.renene.2017.04.035

Wang S, Lin H, Ru B, Dai G, Wang X, Xiao G, Luo Z (2016) Kinetic modeling of biomass components pyrolysis using a sequential and coupling method. Fuel 185:763–771. https://doi.org/10.1016/j.fuel.2016.08.037

Vyazovkin S (2015) Isoconversional kinetics of thermally stimulated processes, 1st edn. Springer International Publishing, Cham

Mehmood MA, Ahmad MS, Liu Q, Liu CG, Tahir MH, Aloqbi AA, Tarbiah NI, Alsufiani HM, Gull M (2019) Helianthus tuberosus as a promising feedstock for bioenergy and chemicals appraised through pyrolysis, kinetics, and TG-FTIR-MS based study. Energy Convers Manag 194:37–45. https://doi.org/10.1016/j.enconman.2019.04.076

Yao Z, Yu S, Su W, Wu W, Tang J, Qi W (2020) Kinetic studies on the pyrolysis of plastic waste using a combination of model-fitting and model-free methods. Waste Manag Res 38:77–85. https://doi.org/10.1177/0734242X19897814

Yao Z, Yu S, Su W, Wu W, Tang J, Qi W (2020) Comparative study on the pyrolysis kinetics of polyurethane foam from waste refrigerators. Waste Manag Res 38:271–278. https://doi.org/10.1177/0734242X19877682

Shahid A, Ishfaq M, Ahmad MS, Malik S, Farooq M, Hui Z, Batawi AH, Shafi ME, Aloqbi AA, Gull M, Mehmood MA (2019) Bioenergy potential of the residual microalgal biomass produced in city wastewater assessed through pyrolysis, kinetics and thermodynamics study to design algal biorefinery. Bioresour Technol 289:121701. https://doi.org/10.1016/j.biortech.2019.121701

Hu M, Wang X, Chen J, Yang P, Liu C, Xiao B, Guo D (2017) Kinetic study and syngas production from pyrolysis of forestry waste. Energy Convers Manag 135:453–462. https://doi.org/10.1016/j.enconman.2016.12.086

Chong CT, Mong GR, Ng JH, Chong WWF, Ani FN, Lam SS, Ong HC (2019) Pyrolysis characteristics and kinetic studies of horse manure using thermogravimetric analysis. Energy Convers Manag 180:1260–1267. https://doi.org/10.1016/j.enconman.2018.11.071

Yeo JY, Chin BLF, Tan JK, Loh YS (2017) Comparative studies on the pyrolysis of cellulose, hemicellulose, and lignin based on combined kinetics. J Energy Inst 92:27–37. https://doi.org/10.1016/j.joei.2017.12.003

Kumar M, Mishra PK, Upadhyay SN (2020) Thermal degradation of rice husk: effect of pre-treatment on kinetic and thermodynamic parameters. Fuel 268:117164. https://doi.org/10.1016/j.fuel.2020.117164

Acknowledgments

The authors are grateful for the financial support given by the Brazilian Council for Scientific and Technological Development (CNPq/Brazil Process 423869/2016-7) and Brazilian Coordination for the Improvement of Higher Education Personnel (CAPES/Brazil Finance Code 001). The authors would also like to acknowledge LCA/UFPB and LabMaq/UFPB for providing the infrastructure that was required to carry out this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Açaí seed is an abundant (193 kt year−1) and underutilized residual biomass in Brazil.

• First detailed attempt to evaluate the açaí seed’s feasibility as feedstock for pyrolysis.

• Açaí seed has a remarkable bioenergy potential due to its physicochemical properties.

• Deconvolution was successfully applied for kinetic evaluation of açaí seed pyrolysis.

• The endothermic and favorable natures for bioenergy were observed by thermodynamic analysis.

Rights and permissions

About this article

Cite this article

Alves, J.L.F., Da Silva, J.C.G., Di Domenico, M. et al. Exploring Açaí Seed (Euterpe oleracea) Pyrolysis Using Multi-component Kinetics and Thermodynamics Assessment Towards Its Bioenergy Potential. Bioenerg. Res. 14, 209–225 (2021). https://doi.org/10.1007/s12155-020-10175-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10175-y