Abstract

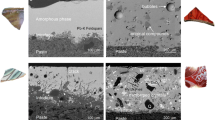

Surface treatment techniques, that is, smoothing and burnishing, help to define the cultural, traditional, and economical state of an ancient society. They prove artistic feelings combined with practical skills were used to obtain more attractive and highly functional objects. This paper aims to prepare the reader to investigate ceramic surfaces and discern between different treatments. Interpretation of the finishing techniques is based mainly on a wide variety of surface topography. Both treatments plastically deform the surface and tend to diminish its roughness, but the results are strikingly different. A smoothed surface has still large irregularities and a dull or matte appearance due to the diffuse reflection of light. A burnished surface has only small-sized irregularities and is glossy/lustrous due to specular reflection of light. Smoothing slightly aligns the platy minerals only at the very surface, whereas, burnishing may create two separate individual levels: A burnish peel and a subsurface layer. The differences are evidenced by all applied analytical methods, such as macroscopy, optical microscopy, electron microprobe, scanning electron microscopy, and vertical scanning interferometry.

Similar content being viewed by others

Notes

Coordinates: 36° 30′ 14.4′′ N, 39° 5′ 34.8′′ E; ~ 80 km N of Raqqa, in northern Syria.

Not to be confused with the same term applied to the wheel-forming technique (for details, see Thér et al. 2017).

For detailed description of burnishing techniques, see von Dassow (2009)

A hand loupe and a Nikon H600L stereoscopic microscope equipped with a digital camera were used in this study.

The thin sections were investigated with a Zeiss Axio Imager-type petrographic microscope. The images were captured with a Zen 2011 Axio ICc5 digital video camera, working at 5 Mega pixel resolution.

Polished thin sections, coated with carbon under vacuum, were analyzed with a JXA Superprobe8600 electron microprobe (Salzburg University), at an accelerating voltage of 15 kV and ~ 3-μm diameter of electron-beam. For high-quality back scattered images, the beam current intensity was 10–15 nA.

Small chips of CAP and MBC samples were coated with a 10-nm thick PdPt film and investigated with a Hitachi 8230 equipment (National Institute for Research and Development of Isotopic and Molecular Technologies, Cluj-Napoca) that enables to visualize components around 10 nm in size. The equipment worked at 30 kV acceleration voltage.

Modern MBC pottery has been analyzed by VSI using a ZemetricsZeMapper instrument equipped with a CCD camera. The surface topography of the sample was obtained at high vertical (~ 1 nm, white light mode) and lateral (minimum ~ 50-nm virtual pixel diameter) resolution.

References

WEB PAGES:

Adrimi-Sismani V (2006) The palace of Iolkos and its end. In: Deger-Jalkotzy S, Lemos IS (eds) Ancient Greece: from the Mycenaean palaces to the age of Homer. Edinburgh University Press, Edinburgh, pp 465–481

Allen JRL (1986) On the curl of dessication polygons. Sediment Geol 46(1–2):23–31. https://doi.org/10.1016/0037-0738(86)90003-5

Aloupi-Siotis E (2020) Ceramic technology. How to characterise black Fe-based glass-ceramic coatings. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01134-x

Anderson WP (1990) The beginnings of Phoenician pottery: vessel shape, style, and ceramic technology in the early phases of the Phoenician Iron Age. Bull Am Sch Orient Res 279:35–54. https://doi.org/10.2307/1357207

Bankoff A, Meyer N, Stefanovich M (1996) Handmade burnished ware and the Late Bronze Age of the Balkans. J Mediterr Archaeol 9(2):193–209. https://doi.org/10.1558/jmea.v9i2.193

Banning EB (2000) The archaeologist’s laboratory. The analysis of archaeological data. Chapter Analysing Pottery 161–186. https://doi.org/10.1007/b110579

Ben-Shlomo D, Uziel J, Maeir AM (2009) Pottery production at Tell es-Safi/Gath: a Longue Durée perspective. J Archaeol Sci 36(10):2258–2273. https://doi.org/10.1016/j.jas.2009.06.011

Berg I (2008) Looking through pots: recent advances in ceramics X-radiography. J Archaeol Sci 35(5):1177–1188. https://doi.org/10.1016/j.jas.2007.08.006

Berlo JC, Phillips RB (2015) Native North American art. Oxford University Press, Oxford

Birney K (2008) Tracking the cooking pot à la stéatite: signs of Cyprus in Iron Age Syria. Am J Archaeol 112(4):565–580. https://doi.org/10.3764/aja.112.4.565

Black AJ, Kopalinski EM, Oxley PLB (1997) Analysis and experimental investigation of a simplified burnishing process. Int J Mech Sci 39(6):629–641. https://doi.org/10.1016/S0020-7403(96)00068-9

Boileau M-C, Badre L, Capet E, Jung R, Mommsen H (2010) Foreign ceramic tradition, local clays: the handmade burnished Ware of Tell Kazel (Syria). J Archaeol Sci 37(7):1678–1689. https://doi.org/10.1016/j.jas.2010.01.028

Brelstaff G, Blake A (1988) Detecting specular reflections using Lambertian constraints. Proceedings of the 2nd International Conference on Computer Vision 297–302

Buxeda I Garrigós J, Jones RE, Kilikoglou V, Levi ST, Maniatis Y, Mitchell J, Vagnetti L, Wardle KA, Andreou S (2003) Technology transfer at the periphery of the Mycenaean world: the cases of Mycenaean pottery found in central Macedonia (Greece) and the Plain of Sybaris (Italy). Archaeometry 45(2):263–284. https://doi.org/10.1111/1475-4754.00108

Catling HW, Catling EA (1981) ‘Barbarian’ pottery from the Mycenaean settlement at the Menelaion, Sparta. Annu Br Sch Athens 76:71–82

Clarke C (2012) Minoan metal vessel manufacturing: techniques and technology. Chronika 2:11–21

Courty MA, Roux V (1995) Identification of wheel throwing on the basis of ceramic surface features and microfabrics. J Archaeol Sci 22:17–50. https://doi.org/10.1016/S0305-4403(95)80161-8

Crandell O, Ionescu C, Mirea P (2016) Neolithic and Chalcolithic stone tools used in ceramics production: examples from the south of Romania. J Lithic Stud 3(1):241–258. https://doi.org/10.2218/jls.v3i1.1134

Culican W (1973) The graves at Tell er-Reqeish. Aust J Bibl Archaeol 2:66–105

Cuyler Young T Jr (1965) A comparative ceramic chronology for western Iran, 1500-500 BC. Iran 3:53–85. https://doi.org/10.1080/05786967.1965.11834401

de Lapérouse J-F (2020) Ceramic musealisation: how ceramics are conserved and the implications for research. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01139-6

de Niederhãusen S, Bondi M, Bondioli F (2013) Self-cleaning and antibacteric ceramic tile surface. Int J Appl Ceram Technol 10:949–956. https://doi.org/10.1111/j.1744-7402.2012.02801.x

Deal M (1988) An ethnoarchaeological approach to the identification of Maya domestic pottery production. In: Kolb C (ed), Ceramic ecology revisited, 1987: the technology and socioeconomics of pottery. BAR International Series 436:111–142, Oxford. https://doi.org/10.1017/laq.2016

Dickinson O (2006) The aegean from bronze age to iron age. Continuity and change between the twelfth and eighth centuries BC. Taylor & Frances Group Routledge, London New York. https://doi.org/10.4324/9780203968369

El-Axir MH, Othman OM, Abodiena AM (2008) Improvements in out-of-roundness and microhardness of inner surfaces by internal ball burnishing process. J Mater Process Technol 196(1–3):120–128. https://doi.org/10.1016/j.jmatprotec.2007.05.028

Eramo G (2020) Ceramic technology. How to recognize clay processing. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01132-z

Farbstein R, Radić D, Brajković D, Miracle PT (2012) First Epigravettian ceramic figurines from Europe (Vela Spila, Croatia). PLoS One 7(7):e41437. https://doi.org/10.1371/journal.pone.0041437

Fewkes VJ (1944) Catawba pottery-making, with notes on Pamunkey pottery-making, Cherokee pottery-making, and coiling. Proc Am Philos Soc 88(2):69–124 https://www.jstor.org/stable/985665

Fischer C, Lüttge A (2007) Converged surface roughness parameters - a new tool to quantify rock surface morphology and reactivity alteration. Am J Sci 307:955–973. https://doi.org/10.2475/07.2007.01

Fishman SG (2016) The space between: ceramic production and exchange in Roman-Parthian Period Oğlanqala, Azerbaijan. J Archaeol Sci Rep 9:12–24. https://doi.org/10.1016/j.jasrep.2016.06.052

Forte V (2019) Skilled people or specialists? Knowledge and expertise in copper age vessels from Central Italy. J Anthropol Archaeol 55:101072. https://doi.org/10.1016/j.jaa.2019.101072

Forte V, Nunziante Cesaro S, Medeghini L (2018) Cooking traces on Copper Age pottery from Central Italy: an integrated approach comprising use wear analysis, spectroscopic analysis and experimental archaeology. J Archaeol Sci Rep 18:121–138. https://doi.org/10.1016/j.jasrep.2017.12.052

Fowler KD (2011) The Zulu ceramic tradition in Msinga, South Africa. South Afr Humanit 23:173–202

Frankel D (1994) Color variation on prehistoric Cypriot red polished pottery. J Field Archaeol 21(2):205–219. https://doi.org/10.1179/009346994791547634

Frierman J (1971) Lime burning as the precursor of fired ceramics. Isr Explor J 21(4):212–216

Froh J (2004) Archaeological ceramics studied by scanning electron microscopy. Hyperfine Interact 154(1–4):159–176. https://doi.org/10.1023/B:HYPE.0000032074.98045.cc

Furness A (1953) The Neolithic pottery of Knossos. Annu Br Sch Athens 48:94–134

Galli A, Sibilia E, Martini M (2020) Ceramic chronology by luminescence dating. How and when it is possible to date ceramic artefacts. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01140-z

Gillies KJS, Urch DS (1983) Spectroscopic studies of iron and carbon in black surfaced wares. Archaeometry 25(1):29–44. https://doi.org/10.1111/j.1475-4754.1983.tb00659.x

Gimbutas M (1974) Anza, ca. 6500-5000 B.C.: a cultural yardstick for the study of Neolithic Southeast Europe. J Field Archaeol 1(1/2):26–66. https://doi.org/10.2307/529705

Giurgiu A, Ionescu C, Hoeck V, Tămaş T, Roman C, Crandell ON (2017) Insights into the raw materials and technology used for producing Copper Age ceramics in the Southern Carpathians (Romania). Archaeol Anthropol Sci 9:1259–1273. https://doi.org/10.1007/s12520-016-0322-3

Giurgiu-Enea A, Ionescu C, Hoeck V, Tămaş T, Roman C (2019) An archaeometric study of Eneolithic pottery from a cave (Romania). Clay Miner 54(3):255–268. https://doi.org/10.1180/clm.2019.35

Gliozzo E (2020a) Ceramics investigation. Research questions and sampling criteria. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01128-9

Gliozzo E (2020b) Ceramic technology. How to reconstruct the firing process. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01133-y

Gliozzo E, Kirkman IW, Pantos E, Turbanti IM (2004) Black gloss pottery: production sites and technology in Northern Etruria, Part II: Gloss technology. Archaeometry 26(2):227–246. https://doi.org/10.1111/j.1475-4754.2004.00154.x

Gliozzo E, Fortina C, Memmi Turbanti I, Turchiano M, Volpe G (2005) Cooking and painted ware from San Giusto (Lucera, Foggia): the production cycle, from the supply of raw materials to the commercialization of products. Archaeometry 47(1):13–29. https://doi.org/10.1111/j.1475-4754.2005.00185.x

Gopher A, Gophna R (1993) Cultures of the eighth and seventh millennia BP in the Southern Levant: a review for the 1990s. J World Prehist 7(3):297–353. https://doi.org/10.1007/BF00974722

Grifa C, De Bonis A, Langella A, Mercurio M, Soricelli G, Morra V (2013) A late Roman ceramic production from Pompeii. J Archaeol Sci 40(2):810–826. https://doi.org/10.1016/j.jas.2012.08.043

Gualtieri S (2020) Ceramic raw materials. How to establish the technological suitability of a raw material. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01135-w

Hamon C (2008) Functional analysis of stone grinding and polishing tools from the earliest Neolithic of North-Western Europe. J Archaeol Sci 35:1502–1520. https://doi.org/10.1016/j.jas.2007.10.017

Hein A, Kilikoglou V (2020) Ceramic raw materials. How to recognize them and locate the supply basins. Chemistry. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01129-8

Henderson J, Ma H, Cui J, Ma R, Xiao H (2020) Isotopic investigations of Chinese ceramics. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01138-7

Herzog Z, Aharoni M, Rainey AF, Moshkovitz S (1984) The Israelite fortress at Arad. Bull Am Sch Orient Res 254:1–34. https://doi.org/10.2307/1356901

Holladay JS Jr (1990) Red slip, burnish, and the Solomonic gateway at Gezer. Bull Am Sch Orient Res 277(278):23–70. https://doi.org/10.2307/1357373

Ionescu C, Fischer C, Hoeck V, Lüttge A (2019) Discrimination of ceramic surface finishing by vertical scanning interferometry. Archaeometry 61(1):31–42. https://doi.org/10.1111/arcm.12410

Ionescu C, Hoeck V (2017) Electron microprobe analysis (EMPA). In: Hunt AMW (ed) The Oxford Handbook of archaeological ceramic analysis. Oxford University Press, Oxford, pp 288–304

Ionescu C, Hoeck V, Crandell ON, Šaric K (2015) Burnishing versus smoothing in ceramic surface finishing: a SEM study. Archaeometry 57(1):18–26. https://doi.org/10.1111/arcm.12089

Iserlis M (2009) Khirbet Kerak ware at Bet Yerah: segregation and integration through technology. Tel Aviv 36(2):181–195. https://doi.org/10.1179/033443509x12506723940767

Kibaroğlu M, Sagona A, Satır M (2011) Petrographic and geochemical investigations of the late prehistoric ceramics from SosHöyük, Erzurum (Eastern Anatolia). J Archaeol Sci 38(11):3072–3084. https://doi.org/10.1016/j.jas.2011.07.006

Kreiter A, CzifraSz BZ, Egri IJ, Pánczél P, Váczi G (2014) Shine like metal: an experimental approach to understand prehistoric graphite coated pottery technology. J Archaeol Sci 52:129–142. https://doi.org/10.1016/j.jas.2014.07.020

Łaciak D, Borowski MP, Łydżba-Kopczyńska B, Baron J, Furmanek M (2019) Archaeometric characterisation and origin of black coatings on prehistoric pottery. Chem Erde – Geochem 79(3):453–466. https://doi.org/10.1016/j.chemer.2019.07.004

LeFree B (1975) Santa Clara pottery today. University of New Mexico Press, Albuquerque

Lepère C (2014) Experimental and traceological approach for a technical interpretation of ceramic polished surfaces. J Archaeol Sci 46:144–155. https://doi.org/10.1016/j.jas.2014.03.010

Lovell JL, Dollfus G, Kafafi Z (2007) The ceramics of the Late Neolithic and Chalcolithic: Abu Hamid and the burnished tradition. Paléorient 33(1):51–76. https://doi.org/10.3406/paleo.2007.5207

Maggetti M (1982) Phase analysis and its significance for technology and origin. In: Olin JS, Franklin AD (eds) Archaeological ceramics. Smithsonian Institute Press, Washington DC, pp 121–133 https://www.jstor.org/stable/20177403

Maggetti M, Galetti G, Schwander H, Picon M, Wessicken R (1981) Campanian pottery; the nature of the black coating. Archaeometry 23(2):199–207. https://doi.org/10.1111/j.1475-4754.1981.tb00306.x

Malone C (2003) The Italian Neolithic: a synthesis of research. J World Prehist 17(3):235–312. https://doi.org/10.1023/B:JOWO.0000012729.36053.42

Maritan L (2020) Ceramic abandonment. How to recognise post-depositional transformations. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01141-y

Martineau R (2010) Brunissage, polissage et degres de sechage: un referentielexperimental. In: Giligny F, Méry S (eds), Approche de la chaîne opératoire de la céramique. Le façonnage. Nouv Archéol 119:13–19

Mazar A, Bruins HJ, Panitz-Cohen N, Van der Plicht J (2005) Ladder of time at Tel Rehov: stratigraphy, archaeological context, pottery and radiocarbon dates. In: Levy TE, Higham T (eds) The Bible and radiocarbon dating. Archaeology, Text and Science, London, pp 193–255. https://www.researchgate.net/publication/270959088. Accessed 10 Jan 2020

Mentesana R, Kilikoglou V, Todaro S, Day PM (2019) Reconstructing change in firing technology during the Final Neolithic–Early Bronze Age transition in Phaistos, Crete. Just the tip of the iceberg? Archaeol Anthropol Sci 11(3):871–894. https://doi.org/10.1007/s12520-017-0572-8

Méry S, Anderson P, Inizan M-L, Lechevallier M, Pelegrin J (2007) A pottery workshop with flint tools on blades knapped with copper at Nausharo (Indus civilisation, ca. 2500 BC). J Archaeol Sci 34:1098–1116. https://doi.org/10.1016/j.jas.2006.10.002

Mirti P, Perardi A, Gulmini M, Preacco MC (2006) A scientific investigation on the provenance and technology of a black-figure amphora attributed to the Priam group. Archaeometry 48(1):31–43. https://doi.org/10.1111/j.1475-4754.2006.00241.x

Montana G (2020) Ceramic raw materials. How to recognize them and locate the supply basins. Mineralogy, petrography. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01130-1

Mowat L (1988) The Chimu potter: mass-producer or mastercraftsman? Some thoughts based on the Spottiswoode collection. Newsl (Mus Ethnogr Gr) 22:1–33. https://www.jstor.org/stable/40839093. Accessed 10 Jan 2020

Murphy EA, Poblome J (2012) Technical and social considerations of tools from Roman-period ceramic. J Mediterr Archaeol 25(2):197–217. https://doi.org/10.1558/jmea.v25i2.69

Neinhuis C, Barthlott W (1997) Characterization and distribution of water-repellent, self-cleaning plant surfaces. Ann Bot 79:667–677. https://doi.org/10.1006/anbo.1997.0400

Nelson K, Khalifa E (2010) Nabta Playa Black-topped pottery: technological innovation and social change. Br Mus Stud Anc Egypt Sudan 16:133–148. https://pdfs.semanticscholar.org/1d85/79cc60b640a728323073dfd48355048611d9.pdf?_ga=2.43480357.1232718713.1594309370-364891462.1591290255. Accessed 9 July 2020

Neuendorf KKE, Mehl JP Jr, Jacson JA (2011) Glossary of geology, 5th edn, American Geosciences Institute Alexandria, Virginia

Nieuwenhuyse OP, Akkermans PMMG, Van der Plicht J (2010) Not so coarse, nor always plain–the earliest pottery of Syria. Antiquity 84(323):71–85. https://doi.org/10.1017/S0003598X00099774

Orton C, Tyers P, Vince A (1993) Pottery in archaeology. Cambridge University Press, Cambridge

Papageorgiou I (2020) Ceramic investigation. How to perform statistical analyses. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01142-x

Paterson SR, Vernon RH, Fowler TK Jr (1991) Aureole tectonics. In Kerrick DM (ed), contact metamorphism. Rev Mineral 26:673–722

Perkins P (2007) The collection of Bucchero in the British museum. Etrusc Stud 10:27–34. https://doi.org/10.1515/etst.2004.10.1.27

Peterson S, Peterson J (2003) The craft and art of clay. Laurence King Publisher, London

Pradell T, Molera J (2020) Ceramic technology. How to characterise ceramic glazes. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01136-9

Pritchard AV (1974) The origin of Neolithic pottery forms. Theses and dissertations (Comprehensive), Wilfrid Laurier University, Scholars Commons & Laurier, Paper 1580, Waterloo, Ontario

Rice PM (1987) Pottery analysis. A source book. University of Chicago Press, Chicago

Rutter JB (1975) Ceramic evidence for northern intruders in southern Greece at the beginning of the late Helladic IIIC period. Am J Archaeol 79(1):17–32. https://doi.org/10.2307/503336

Rutter JB (1983) Fine gray-burnished pottery of the Early Helladic III Period the ancestry of gray Minyan. Hesperia 52(4):327–355. https://doi.org/10.2307/147968

Rutter JB (1990) Some comments on interpreting the dark surfaced handmade burnished pottery of the 13th and 12th century BC Aegean. J Mediterr Archaeol 3(1):29–49. https://doi.org/10.1558/jmea.v3i1.29836

Rye OS (1981) Pottery technology: principles and reconstruction. Taraxacum Inc, Washington DC

Schiffer MB (1990) The influence of surface treatment on heating effectiveness of ceramic vessels. J Archaeol Sci 17:373–381. https://doi.org/10.1016/0305-4403(90)90002-M

Schiffer MB, Skibo JM (1989) A provisional theory of ceramic abrasion. Am Anthropol 91(1):101–115. https://doi.org/10.1525/aa.1989.91.1.02a00060

Schiffer MB, Skibo JM, Boelke TC, Neupert MA, Aronson M (1994) New perspectives on experimental archaeology: surface treatments and thermal response of the clay cooking pot. Am Antiq 59(2):197–217. https://doi.org/10.2307/281927

Sciau Ph, Sanchez C, Gliozzo E (2020) Ceramic technology. How to characterise terra sigillata ware. Archaeol Anthrop Sci. https://doi.org/10.1007/s12520-020-01137-8

Shepard AO (1976) Ceramics for the archaeologist. Carnegie Institute, Washington DC

Silvennoinen R, Peiponen K-E, Myller K (eds) (2008) Specular gloss. Elsevier, Amsterdam. https://doi.org/10.1016/B978-008045314-9.50013

Skibo JM, Butts TC, Schiffer MB (1997) Ceramic surface treatment and abrasion resistance: an experimental study. J Archaeol Sci 24:311–317. https://doi.org/10.1006/jasc.1996.0115

Stahl AB, das Dores Cruz M, Neff H, Glascock MD, Speakman RJ, Giles B, Smith L (2008) Ceramic production, consumption and exchange in the Banda area, Ghana: insights from compositional analyses. J Anthropol Archaeol 27:363–381. https://doi.org/10.1016/j.jaa.2008.04.001

Stout AM, Hurst A (1985) X-ray diffraction of Early Iron Age pottery from Western Norway. Archaeometry 27(2):225–230. https://doi.org/10.1111/j.1475-4754.1985.tb00365.x

Szakmány G, Starnini E (2007) Archaeometric research on the first pottery production in the Carpathian Basin: manufacturing traditions of the Early Neolithic, Körös culture ceramics. Archeom Műh 2:5–21

Thér R (2020) Ceramic technology. How to reconstruct and describe pottery-forming practices. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-020-01131-0

Thér R, Mangel T, Gregor M (2017) Potter’s wheel in the Iron Age in Central Europe: process or product innovation? J Archaeol Method Theory 24:1256–1290. https://doi.org/10.1007/s10816-016-9312-0

Tite MS (1999) Pottery production, distribution, and consumption: the contribution of the physical sciences. J Archaeol Method Theory 6:181–233. https://doi.org/10.1023/A:1021947302609

Tite MS (2008) Ceramic production, provenance and use - a review. Archaeometry 50:216–231. https://doi.org/10.1111/j.1475-4754.2008.00391.x

Tomkins P (2007) Communality and competition: the social life of food and containers at aceramic and Early Neolithic Knossos, Crete. In: Mee C, Renard J (eds) Cooking up the past. Food and culinary practices in the Neolithic and Bronze Age Aegean. Oxbow Books, Oxford, pp 174–199

Vandiver PB, Soffer O, Klima B, Svoboda J (1989) The origins of ceramic technology at DolniVĕstonice, Czechoslovakia. Science 246:1002–1008. https://doi.org/10.1126/science.246.4933.1002

Vinson SP (1978) Neolithic pottery of inland Apulia: field work and speculation. Am J Archaeol 82(4):449–459 https://www.jstor.org/stable/i222002

Vitelli KD (1989) Were pots first made for foods? Doubts from Franchthi. World Archaeol 21(1):17–29. https://doi.org/10.1080/00438243.1989.9980088

von Dassow S (2004) All polished up. In: Turner A (ed) Pottery making techniques. The American Ceramic Society, Ohio, pp 116–120

von Dassow S (2009) Low-firing and burnishing. Herbert Press, The American Ceramic Society, Ohio

Wang Q, Andrews KC (2002) Technological investigation of the decorative coatings on Yangshao pottery from Henan, China. Archaeometry 44(2):241–250. https://doi.org/10.1111/1475-4754.t01-1-00056

Wayessa BL (2011) The technical style of Wallaga pottery making: an ethnoarchaeological study of Oromo potters in Southwest Highland Ethiopia. Afr Archaeol Rev 28:301–326. https://doi.org/10.1007/s10437-011-9103-7

Williams E (1995) The spatial organization of pottery production in Huancito, Michoacan, Mexico. Pap Inst Archaeol 6:47–56. https://doi.org/10.5334/pia.78

Zielinski M, Sánchez M, Romero E, Atique A (2014) Precise observation of soil surface curling. Geoderma 226-227:85–93. https://doi.org/10.1016/j.geoderma.2014.02.005

https://www.physicsclassroom.com/class/refln/Lesson-1/Specular-vs-Diffuse-Reflection. Accessed 3 Jan 2020

Acknowledgements

CI acknowledges financial support by the Excellence Research Program (Romanian Ministry of Education and Ministry of Research) through the UEFISCDI/CNCS project PN-III-P4-ID-PCE-2016-0229, as well as support through AGC 31230/2020 project granted by the Babeș-Bolyai University Cluj-Napoca. The authors are thankful for the observations of the reviewers, which helped to improve the paper. Many thanks are due to Dr. Cristian Roman (Corvin Castle Museum, Hunedoara) and Alexandra Enea-Giurgiu (Babeș-Bolyai University, Cluj-Napoca) for providing Copper Age pottery samples. Dr. Lucian Barbu-Tudoran (National Institute for Research and Development of Isotopic and Molecular Technologies, Cluj-Napoca) is thanked for helping with CFE-SEM analysis. Dr. Cornelius Fischer (Institut für Ressourcenökologie, Leipzig) is acknowledged for providing the VIS images. Special thanks are due to Sumi von Dassow, who kindly provided the image of her burnished artwork.

Availability of data and material

Data sharing is not applicable to this review article as no new data were created or analyzed in this study.

Funding

Romanian Ministry of Education and Ministry of Research—award no. PN-III-P4-ID-PCE-2016-0229—Recipient: Corina Ionescu. Babeș-Bolyai University Cluj-Napoca—award AGC no. 31230/2020 —Recipient: Corina Ionescu.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is a Topical Collection on Ceramics: Research questions and answers

Rights and permissions

About this article

Cite this article

Ionescu, C., Hoeck, V. Ceramic technology. How to investigate surface finishing. Archaeol Anthropol Sci 12, 204 (2020). https://doi.org/10.1007/s12520-020-01144-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-020-01144-9