Abstract

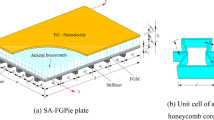

A microstructure-based modelling approach was used to study the deformation behaviour of polycrystalline honeycomb structures under rubbing loading. Rubbing originates from the sliding contact between sealing surfaces in a gas turbine engine. As a stationary component of the sealing system, the honeycomb structure’s role is to prevent catastrophic failure of the rotating component. Therefore, normal forces and surface deformations of the honeycomb structure need to be minimised to limit the heat input into the rotating component. To achieve a detailed representation of the honeycomb material response, the constitutive behaviour of the employed nickel-based superalloys Hastelloy X and Haynes 214 was modelled with a crystal plasticity approach, utilising a finite element framework. Uniaxial tensile tests at relevant temperatures and strain rates resembling the rubbing allowed the identification of crucial model parameters. The simulative studies based on the unit cell of the honeycomb structure revealed that the normal forces and the surface deformations are strongly affected by the microstructural features (size and orientation of the grains) and the applied deformation rate. In addition, a significant amount of residual stresses could be found for the macroscopically unstressed state after cooling and unloading.

Similar content being viewed by others

References

Alabort, E., Barba, D., Sulzer, S., Lißner, M., Petrinic, N., Reed, R.C.: Grain boundary properties of a nickel-based superalloy: characterisation and modelling. Acta Mater. 151, 377–394 (2018)

Alabort, E., Reed, R.C., Barba, D.: Combined modelling and miniaturised characterisation of high-temperature forging in a nickel-based superalloy. Mater. Des. 160, 683–697 (2018)

Böhm, H.: A short introduction to basic aspects of continuum micromechanics. ILSB report, Vienna University of Technology, vol. 206 (1998)

Cordero, Z.C., Knight, B.E., Schuh, C.A.: Six decades of the Hall–Petch effect—a survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 62(8), 495–512 (2016)

Dassault Systèmes: Abaqus 6.13 analysis user’s guide (2013)

Dunne, F., Petrinic, N.: Introduction to Computational Plasticity. Oxford University Press, New York (2005)

Fillafer, A., Krempaszky, C., Werner, E.: On strain partitioning and micro-damage behavior of dual-phase steels. Mater. Sci. Eng. A 614, 180–192 (2014)

Fischer, F., Werner, E., Knothe, K.: The surface temperature of a half-plane subjected to rolling/sliding contact with convection. J. Tribol. 122, 864–866 (2000)

Fischer, T., Werner, E., Ulan kyzy, S., Munz, O.: Modeling the rubbing contact in honeycomb seals. Contin. Mech. Thermodyn. 30(2), 381–395 (2018)

Fischer, T., Werner, E., Ulan kyzy, S., Munz, O.: Crystal plasticity modeling of polycrystalline Ni-base superalloy honeycombs under combined thermo-mechanical loading. Contin. Mech. Thermodyn. 31(3), 703–713 (2019)

Frederick, C., Armstrong, P.: A mathematical representation of the multiaxial Bauschinger effect. G.E.G.B. report RD/B/N, vol. 731 (1966)

Haynes International, I.: Hastelloy X alloy (UNS N06002). High-temperature alloys (1997)

Haynes International, I.: Haynes 214 alloy (UNS N07214). High-temperature alloys (2008)

Hennessey, C., Castelluccio, G.M., McDowell, D.L.: Sensitivity of polycrystal plasticity to slip system kinematic hardening laws for Al 7075-T6. Mater. Sci. Eng. A 687, 241–248 (2017)

Hutchinson, J.W.: Bounds and self-consistent estimates for creep of polycrystalline materials. Proc. R. Soc. A Math. Phys. Eng. Sci. 348(1652), 101–127 (1976)

Kalidindi, S.R.: Incorporation of deformation twinning in crystal plasticity models. J. Mech. Phys. Solids 46(2), 267–271, 273–290 (1998)

Kalpakjian, S., Schmid, S.R., Werner, E.: Werkstofftechnik. Pearson Studium, München (2011)

Kouznetsova, V.: Computational homogenization for the multi-scale analysis of multi-phase materials. Ph.D. thesis, Technical University of Eindhoven (2002)

Meier, F.: Influence of the aluminum-microstructure on the damage behavior of integrated circuits. Ph.D. thesis, Technical University of Munich (2017)

Meier, F., Schwarz, C., Werner, E.: Crystal-plasticity based thermo-mechanical modeling of Al-components in integrated circuits. Comput. Mater. Sci. 94, 122–131 (2014)

Mohr, D.: Multi-scale finite-strain plasticity model for stable metallic honeycombs incorporating microstructural evolution. Int. J. Plast. 22, 1899–1923 (2006)

Munz, O., Pychynski, T., Schwitzke, C., Bauer, H.J.: Continued experimental study on the friction contact between a labyrinth seal fin and a honeycomb stator: slanted position. Aerospace 5(3), 82 (2018)

Petch, N.J.: The cleavage strength of polycrystals. J. Iron Steel Res. Int. 174, 25–28 (1953)

Quey, R., Dawson, P., Barbe, F.: Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 200, 1729–1745 (2011)

Quey, R., Renversade, L.: Optimal polyhedral description of 3D polycrystals: method and application to statistical and synchrotron X-ray diffraction data. Comput. Methods Appl. Mech. Eng. 330, 308–333 (2018)

Reed, R.C.: The Superalloys: Fundamentals and Applications. Cambridge University Press, Cambridge (2006)

Rossmann, A.: Die Sicherheit von Turbo-Flugtriebwerken: Reibverschleiß, Anstreifen und Spalthaltung, Labyrinthdichtungen, Bürstendichtungen, Containment, Feuer und Explosionen. Turbo Consult, Karlsfeld (2000)

Rossmann, A.: Probleme der Maschinenelemente erkennen, verhüten und lösen—Band 2B: Versagensformen, typische Schadensbilder, Mechanismen, Ursachen von Elementen durchströmter Systeme: Berührende und berührungsfreie Dichtungen, Rohrleitungen, Schlauchleitungen. Turbo Consult, Karlsfeld (2010)

Roters, F., Diehl, M., Shanthraj, P., Eisenlohr, P., Reuber, C., Wong, S., Ma, D., Jia, N., Kok, P., Fujita, N., Ebrahimi, A., Hochrainer, T., Grilli, N., Janssens, K., Stricker, M., Weygand, D., Meier, F., Werner, E., Fabritius, H.O., Nikolov, S., Friak, M., Raabe, D.: Damask—the Düsseldorf advanced material simulation kit for modelling multi-physics crystal plasticity, damage and thermal phenomena from the single crystal up to the component scale. Comput. Mater. Sci. 158, 420–478 (2019)

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D., Bieler, T., Raabe, D.: Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: therory, experiments, applications. Acta Mater. 58(4), 1152–1211 (2010)

Roters, F., Eisenlohr, P., Kords, C., Tjahjanto, D., Diehl, M., Raabe, D.: Damask: the Düsseldorf advanced material simulation kit for studying crystal plasticity using an FE based or a spectral numerical solver. Procedia IUTAM 3, 3–10 (2012)

Rycroft, C.H.: Voro++: a three-dimensional Voronoi cell library in C++. Chaos 19, 041111 (2009)

Sedláček, R.: Finite Elemente in der Werkstoffmechanik. Verlag Dr. Hut, München (2009)

Smarsly, W., Zheng, N., Buchheim, C., Nindel, C., Silvestro, C., Sporer, D., Tuffs, M., Schreiber, K., Bomba, C.L., Anderson, O., Goehler, H., Simms, N., McColvin, G.: Advanced high temperature turbine seals materials and designs. Mater. Sci. Forum 492–493, 21–26 (2005)

Sporer, D., Shiembob, L.: Alloy selection for honeycomb gas path seal systems. Proc. AMSE Turbo Expos. 4, 763–774 (2004)

Taxer, T., Schwarz, C., Smarsly, W., Werner, E.: A finite element approach to study the influence of cast pores on the mechanical properties of the Ni-base alloy MAR-M247. Mater. Sci. Eng. A 575, 144–151 (2013)

Ulan kyzy, S., Völkl, R., Munz, O., Fischer, T., Glatzel, U.: The effect of brazing on microstructure of honeycomb liner material Hastelloy X. J. Mater. Eng. Perform. 28(4), 1909–1913 (2019)

Varshni, Y.P.: Temperature dependence of the elastic constants. Phys. Rev. B 2(10), 3952–3958 (1970)

von Kobylinski, J., Lawitzki, R., Hofmann, M., Krempaszky, C., Werner, E.: Micromechanical behaviour of Ni-based superalloys close to the yield point: a comparative study between neutron diffraction on different polycrystalline microstructures and crystal plasticity finite element modelling. Contin. Mech. Thermodyn. 31(3), 691–702 (2019)

Werner, E., Siegmund, T., Weinhandl, H., Fischer, F.D.: Properties of random polycrystalline two-phase materials. Appl. Mech. Rev. 47(1S), 231–240 (1994)

Werner, E., Wesenjak, R., Fillafer, A., Meier, F., Krempaszky, C.: Microstructure-based modelling of multiphase materials and complex structures. Contin. Mech. Thermodyn. 28(5), 1325–1346 (2015)

Zhang, M., McDowell, D.L., Neu, R.W.: Microstructure sensitivity of fretting fatigue based on computational crystal plasticity. Tribol. Int. 42, 1286–1296 (2009)

Zhang, M., Neu, R.W., McDowell, D.L.: Microstructure-sensitive modeling: application to fretting contacts. Int. J. Fatigue 31, 1397–1406 (2009)

Acknowledgements

This work is part of the research project WE 2351/14-1 funded by the Deutsche Forschungsgemeinschaft (DFG). The authors are grateful to the Max Planck Institut für Eisenforschung (MPIE) in Düsseldorf for providing the flexible and easy-to-use multi-physics simulation kit DAMASK.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fischer, T., Ulan kyzy, S., Munz, O. et al. Microstructure-based modelling of rubbing in polycrystalline honeycomb structures. Continuum Mech. Thermodyn. 32, 1371–1383 (2020). https://doi.org/10.1007/s00161-019-00852-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-019-00852-5