Abstract

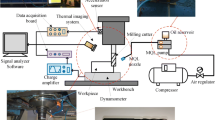

This paper mainly focuses on determination of optimum minimum quantity lubrication (MQL) parameter settings due to enhance the machinability of Ti–6Al–4V alloy, which is an area of huge concern for industrial production and academic research around the globe. MQL is an eco-friendly cooling method, which can be employed during machining Ti–6Al–4V alloys. In this work, a highly efficient MQL system has been developed by appropriate selection of various parameters like nozzle diameter, angle of impingement, oil flow rate, air pressure, etc., for enhancing the turning machinability of Ti–6Al–4V alloys. Cutting temperature, cutting force, and surface roughness have been considered as machinability criteria, where minimization of these responses was desirable. An experimental investigation has been designed by Box–Behnken design of experiments and carried out for turning Ti–6Al–4V alloy by carbide insert under double-jet MQL. Empirical models were developed for the process responses by response surface methodology. By employing ANOVA statistics, all the predictive models were found significant and highly acceptable with more than 90% of R2. MAPE for the temperature, force, and roughness were found to be 3.93%, 1.27%, and 5.78%, respectively, when model responses were compared with experimental responses. As a final point, the desirability function approach has been used to find out the suitable combination of coolant application parameters which were nozzle diameter of 0.5 mm, primary nozzle angle of 20°, primary nozzle angle of 15°, air pressure of 20 bar, and oil flow rate of 50 ml/h with composite desirability value of 0.8301.

Similar content being viewed by others

References

Ezugwu, E.O.; Wang, Z.M.: Titanium alloys and their machinability—a review. J. Mater. Process. Technol. 68, 262–274 (1997). https://doi.org/10.1016/S0924-0136(96)00030-1

Veiga, C.; Davim, J.P.; Loureiro, A.J.R.: Review on machinability of titanium alloys: the process perspective. Rev. Adv. Mater. Sci. 34, 148–164 (2013)

Kosaraju, S.; Anne, V.G.: Optimal machining conditions for turning Ti–6Al–4V using response surface methodology. Adv. Manuf. (2013). https://doi.org/10.1007/s40436-013-0047-9

Settineri, L.; Faga, M.G.: Nanostructured cutting tools coatings for machining titanium. Mach. Sci. Technol. (2008). https://doi.org/10.1080/10910340802067239

Ginting, Y.R.; Boswell, B.; Biswas, W.; Islam, N.: Advancing environmentally conscious machining. Procedia CIRP 26, 391–396 (2015). https://doi.org/10.1016/j.procir.2014.07.087

Kỳvak, T.; Şeker, U.: Effect of cryogenic treatment applied to M42 HSS drills on the machinability of Ti–6Al–4V alloy. Mater. Tehnol. (2015). https://doi.org/10.17222/mit.2014.283

Zhang, N.; Yang, F.; Liu, G.: Cutting performance of micro-textured WC/Co tools in the dry cutting of Ti–6Al–4V alloy. Int. J. Adv. Manuf. Technol. (2020). https://doi.org/10.1007/s00170-020-05161-9

Goindi, G.S.; Sarkar, P.: Dry machining: a step towards sustainable machining—challenges and future directions. J. Clean. Prod. (2017). https://doi.org/10.1016/j.jclepro.2017.07.235

Revuru, R.S.; Zhang, J.Z.; Posinasetti, N.R.; Kidd, T.: Optimization of titanium alloys turning operation in varied cutting fluid conditions with multiple machining performance characteristics. Int. J. Adv. Manuf. Technol. (2018). https://doi.org/10.1007/s00170-017-1299-5

Sreejith, P.S.; Ngoi, B.K.A.: Dry machining: machining of the future. J. Mater. Process. Technol. 101, 287–291 (2000). https://doi.org/10.1016/S0924-0136(00)00445-3

Dhar, N.R.; Khan, M.M.A.: Effects of minimum quantity lubrication (MQL) by vegetable oil-based cutting fluid on machinability of AISI 9310 steel. Int. J. Mach. Mach. Mater. 7, 17–38 (2010). https://doi.org/10.1504/ijmmm.2010.029844

Sinha, M.K.; Madarkar, R.; Ghosh, S.; Rao, P.V.: Effects of minimum quantity lubrication (MQL) on forces and surface roughness in Inconel 718 grinding surface roughness in Inconel 718 grinding, pp. 1–6 (2015)

Pervaiz, S.; Deiab, I.; Rashid, A.; Nicolescu, M.: Minimal quantity cooling lubrication in turning of Ti6Al4V: influence on surface roughness, cutting force and tool wear. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. (2017). https://doi.org/10.1177/0954405415599946

Krishnaraj, V.; Krishna, B.H.; Sheikh-Ahmad, J.Y.: An experimental study on end milling of titanium alloy (Ti–6Al–4V) under dry and minimum quantity lubrication conditions. Int. J. Mach. Mach. Mater. (2017). https://doi.org/10.1504/IJMMM.2017.086163

Yıldırım, Ç.V.; Kıvak, T.; Erzincanlı, F.: Tool wear and surface roughness analysis in milling with ceramic tools of Waspaloy: a comparison of machining performance with different cooling methods. J. Braz. Soc. Mech. Sci. Eng. (2019). https://doi.org/10.1007/s40430-019-1582-5

Su, Y.; He, N.; Li, L.; Iqbal, A.; Xiao, M.H.; Xu, S.; et al.: Refrigerated cooling air cutting of difficult-to-cut materials. Int. J. Mach. Tools Manuf. (2007). https://doi.org/10.1016/j.ijmachtools.2006.07.005

Yildirim, Ç.V.; Kivak, T.; Sarikaya, M.; Şirin, Ş.: Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 9(2), 2079–2092. (2020). https://doi.org/10.1016/j.jmrt.2019.12.069

Dhar, N.R.; Siddiqui, A.T.; Rashid, M.H.: Effect of high-pressure coolant jet on grinding temperature, chip and surface roughness in grinding AISI-1040 steel. J. Eng. Appl. Sci. 1, 22–28 (2006)

Şirin, Ş.; Kıvak, T.: Performances of different eco-friendly nanofluid lubricants in the milling of Inconel X-750 superalloy. Tribol. Int. (2019). https://doi.org/10.1016/j.triboint.2019.04.042

Yan, L.; Yuan, S.; Liu, Q.: Influence of minimum quantity lubrication parameters on tool wear and surface roughness in milling of forged steel. Chin. J. Mech. Eng. (Engl. Ed.) (2012). https://doi.org/10.3901/cjme.2012.03.419

Upadhyay, V.; Jain, P.K.; Mehta, N.K.: Minimum quantity lubrication assisted turning—an overview. DAAAM Int. Sci. B (2012). https://doi.org/10.2507/daaam.scibook.2012.39

Obikawa, T.; Kamata, Y.; Shinozuka, J.: High-speed grooving with applying MQL. Int. J. Mach. Tools Manuf. 46, 1854–1861 (2006). https://doi.org/10.1016/j.ijmachtools.2005.11.007

Hadad, M.; Sadeghi, B.: Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy. J. Clean. Prod. 54, 332–343 (2013). https://doi.org/10.1016/j.jclepro.2013.05.011

Masoudi, S.; Vafadar, A.; Hadad, M.; Jafarian, F.: Experimental investigation into the effects of nozzle position, workpiece hardness, and tool type in MQL turning of AISI 1045 steel. Mater. Manuf. Process. 33, 1011–1019 (2018). https://doi.org/10.1080/10426914.2017.1401716

Attanasio, A.; Gelfi, M.; Giardini, C.; Remino, C.: Minimal quantity lubrication in turning: effect on tool wear. Wear 260, 333–338 (2006). https://doi.org/10.1016/j.wear.2005.04.024

Sharma, V.S.; Dogra, M.; Suri, N.M.: Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 49, 435–453 (2009). https://doi.org/10.1016/j.ijmachtools.2008.12.010

Diniz, A.E.; Micaroni, R.: Influence of the direction and flow rate of the cutting fluid on tool life in turning process of AISI 1045 steel. Int. J. Mach. Tools Manuf. 47, 247–254 (2007). https://doi.org/10.1016/j.ijmachtools.2006.04.003

Huang, S.; Lv, T.; Wang, M.; Xu, X.: Effects of machining and oil mist parameters on electrostatic minimum quantity lubrication—EMQL turning process. Int. J. Precis Eng. Manuf. Green Technol. (2018). https://doi.org/10.1007/s40684-018-0034-5

Liu, Z.Q.; Cai, X.J.; Chen, M.; An, Q.L.: Investigation of cutting force and temperature of end-milling Ti–6Al–4V with different minimum quantity lubrication (MQL) parameters. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. (2011). https://doi.org/10.1177/2041297510393793

Damir, A.; Sadek, A.; Attia, H.; Tendolkar, A.: Characterization and optimization of machinability and environmental impact of machining of Ti–6Al–4V with minimum quantity lubrication. Int. J. Robot. Mechatron. (2017). https://doi.org/10.21535/ijrm.v4i1.971

Shanmughasundaram, P.; Subramanian, R.: Influence of graphite and machining parameters on the surface roughness of Al-fly ash/graphite hybrid composite: a Taguchi approach. J. Mech. Sci. Technol. 27, 2445–2455 (2013). https://doi.org/10.1007/s12206-013-0630-9

Do, T.-V.; Hsu, Q.-C.: Optimization of minimum quantity lubricant conditions and cutting parameters in hard milling of AISI H13 steel. Appl. Sci. 6, 83 (2016). https://doi.org/10.3390/app6030083

Mia, M.; Al Bashir, M.; Khan, M.A.; Dhar, N.R.: Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). Int. J. Adv. Manuf. Technol. 89, 675–690 (2017). https://doi.org/10.1007/s00170-016-9080-8

Liu, G.; Li, C.; Zhang, Y.; Yang, M.; Jia, D.; Zhang, X.; et al.: Process parameter optimization and experimental evaluation for nanofluid MQL in grinding Ti–6Al–4V based on grey relational analysis. Mater. Manuf. Process. (2018). https://doi.org/10.1080/10426914.2017.1388522

Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M.: Response Surface Methodology: Process and Product Optimization Using Designed Experiments, vol. 38. Wiley, New York (1996). https://doi.org/10.2307/1270613

Nam, J.; Kim, J.W.; Kim, J.S.; Lee, J.; Lee, S.W.: Parametric analysis and optimization of nanofluid minimum quantity lubrication micro-drilling process for titanium alloy (Ti–6Al–4V) using response surface methodology and desirability function. Procedia Manuf. 26, 403–414 (2018). https://doi.org/10.1016/j.promfg.2018.07.048

Lorza, R.; Calvo, M.; Labari, C.; Fuente, P.: Using the multi-response method with desirability functions to optimize the zinc electroplating of steel screws. Metals (Basel) (2018). https://doi.org/10.3390/met8090711

Gok, A.: A new approach to minimization of the surface roughness and cutting force via fuzzy TOPSIS, multi-objective grey design and RSA. Meas. J. Int. Meas. Confed. (2015). https://doi.org/10.1016/j.measurement.2015.03.037

Chatterjee, S.; Mondal, A.K.; Mahapatra, S.: Combined approach for studying the parametric effects on quality of holes using RSM and PCA in drilling of Aisi-304 stainless steel. In: 5th International & 26 th All India Manufacturing Technology, Design and Research Conference (AIMTDR 2014), pp. 5–10 (2014)

Li, N.; Hu, Y.; Lu, Y.Z.; Zeng, R.J.; Sheng, G.P.: Multiple response optimization of the coagulation process for upgrading the quality of effluent from municipal wastewater treatment plant. Sci. Rep. (2016). https://doi.org/10.1038/srep26115

Gupta, M.K.; Sood, P.K.; Sharma, V.S.: Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J. Clean. Prod. 135, 1276–1288 (2016). https://doi.org/10.1016/j.jclepro.2016.06.184

Gupta, M.K.; Sood, P.K.; Sharma, V.S.: Machining parameters optimization of titanium alloy using response surface methodology and particle swarm optimization under minimum-quantity lubrication environment. Mater. Manuf. Process. 31, 1671–1682 (2016). https://doi.org/10.1080/10426914.2015.1117632

Mia, M.; Dhar, N.R.: Modeling of surface roughness using RSM, FL and SA in dry hard turning. Arab. J. Sci. Eng. (2018). https://doi.org/10.1007/s13369-017-2754-1

Najiha, M.S.; Rahman, M.M.; Kadirgama, K.; Noor, M.M.; Ramasamy, D.: Multi-objective optimization of minimum quantity lubrication in end milling of aluminum alloy AA6061T6. Int. J. Automot. Mech. Eng. 12, 3003–3017 (2015). https://doi.org/10.15282/ijame.12.2015.15.0250

Das, M.K.; Kumar, K.; Barman, T.K.; Sahoo, P.: Investigation on electrochemical machining of EN31 steel for optimization of MRR and surface roughness using artificial bee colony algorithm. Procedia Eng. (2014). https://doi.org/10.1016/j.proeng.2014.12.309

Hashmi, K.H.; Zakria, G.; Raza, M.B.; Khalil, S.: Optimization of process parameters for high speed machining of Ti–6Al–4V using response surface methodology. Int. J. Adv. Manuf. Technol. 85, 1847–1856 (2016). https://doi.org/10.1007/s00170-015-8057-3

Khatri, A.; Jahan, M.P.: Investigating tool wear mechanisms in machining of Ti–6Al–4V in flood coolant, dry and MQL conditions. Procedia Manuf. (2018). https://doi.org/10.1016/j.promfg.2018.07.051

Bermingham, M.J.; Sim, W.M.; Kent, D.; Gardiner, S.; Dargusch, M.S.: Tool life and wear mechanisms in laser assisted milling Ti–6Al–4V. Wear (2015). https://doi.org/10.1016/j.wear.2014.11.001

Perçin, M.; Aslantas, K.; Ucun, I.; Kaynak, Y.; Çicek, A.: Micro-drilling of Ti–6Al–4V alloy: the effects of cooling/lubricating. Precis. Eng. (2016). https://doi.org/10.1016/j.precisioneng.2016.02.015

Singh, R.; Dureja, J.S.; Dogra, M.; Randhawa, J.S.: Optimization of machining parameters under MQL turning of Ti–6Al–4V alloy with textured tool using multi-attribute decision-making methods. World J. Eng. (2019). https://doi.org/10.1108/WJE-06-2019-0170

VenkataRamana, M.; KrishnaMohanRao, G.; HanumanthaRao, D.: Multi objective optimization of process parameters in turning of Ti–6Al–4V alloy. Mater. Today Proc. (2018). https://doi.org/10.1016/j.matpr.2018.06.247

Tendolkar, A.; Damir, A.; Attia, H.; Hendrick, P.; Diakodimitris, C.: Characterisation and optimisation of minimum quantity lubrication in milling of Ti–6Al–4V alloy using phase Doppler anemometry (PDA). Int. J. Mechatron. Manuf. Syst. (2014). https://doi.org/10.1504/IJMMS.2014.067164

Zaman, P.B.; Dhar, N.R.: Design and evaluation of an embedded double jet nozzle for MQL delivery intending machinability improvement in turning operation. J. Manuf. Process. 44, 179–196 (2019). https://doi.org/10.1016/j.jmapro.2019.05.047

Xiong, Y.; Wu, J.; Deng, C.; Wang, Y.: Machining process parameters optimization for heavy-duty CNC machine tools in sustainable manufacturing. Int. J. Adv. Manuf. Technol. (2016). https://doi.org/10.1007/s00170-013-4881-5

Montgomery, D.: Introduction to statical quality. Control (2009). https://doi.org/10.1002/1521-3773(20010316)40:6%3c9823:AID-ANIE9823%3e3.3.CO;2-C

Antony, J.: Design of Experiments for Engineers and Scientists. Elsevier, New York (2003). https://doi.org/10.1016/B978-0-7506-4709-0.X5000-5

Montgomery, D.C.: Design and Analysis of Experiments, 8th edn. Wiley, New York (2013)

Carley, K.M.; Kamneva, N.Y.; Reminga, J.: Response surface methodology: CASOS technical report. Network (2004). https://doi.org/10.1002/wics.73

Koc, B.; Kaymak-Ertekin, F.: Response surface methodology and food processing applications. GIDA J. Food 35(1), 63–70 (2009)

Boyaci, I.H.: A new approach for determination of enzyme kinetic constants using response surface methodology. Biochem. Eng. J. (2005). https://doi.org/10.1016/j.bej.2005.04.001

Manohar, M.; Jomy Joseph, T.S.: Application of Box Behnken design to optimize the parameters for turning Inconel 718 using coated carbide tools. Int. J. Sci. Eng. Res. (2013). https://doi.org/10.4314/tjpr.v11i5.2

Sarikaya, M.; Güllü, A.: Multi-response optimization of minimum quantity lubrication parameters using Taguchi-based grey relational analysis in turning of difficult-to-cut alloy Haynes 25. J. Clean. Prod. (2015). https://doi.org/10.1016/j.jclepro.2014.12.020

Bhushan, R.K.: Optimization of cutting parameters for minimizing power consumption and maximizing tool life during machining of Al alloy SiC particle composites. J. Clean. Prod. (2013). https://doi.org/10.1016/j.jclepro.2012.08.008

Derringer, G.; Suich, R.: Simultaneous optimization of several response variables. J. Qual. Technol. (1980). https://doi.org/10.1080/00224065.1980.11980968

Derringer, G.C.: A balancing act : optimizing a product’s properties. Qual. Prog. 27, 51–58 (1994)

Ehrgott, M.: Multicriteria Optimization. Springer, Berlin (2005). https://doi.org/10.1007/3-540-27659-9

Lin, Z.C.; Ho, C.Y.: Analysis and application of grey relation and ANOVA in chemical–mechanical polishing process parameters. Int. J. Adv. Manuf. Technol. 21, 10–14 (2003). https://doi.org/10.1007/s001700300001

Singh, K.P.; Singh, A.K.; Gupta, S.; Sinha, S.: Optimization of Cr(VI) reduction by zero-valent bimetallic nanoparticles using the response surface modeling approach. Desalination (2011). https://doi.org/10.1016/j.desal.2010.11.056

Sachin, B.; Narendranath, S.; Chakradhar, D.: Enhancement of surface integrity by cryogenic diamond burnishing toward the improved functional performance of the components. J. Braz. Soc. Mech. Sci. Eng. (2019). https://doi.org/10.1007/s40430-019-1918-1

Sahu, N.K.; Andhare, A.: Design of experiments applied to industrial process. Stat. Approaches Emphas. Des. Exp. Appl. Chem. Process. (2018). https://doi.org/10.5772/intechopen.73558

Majumder, H.; Paul, T.R.; Dey, V.; Dutta, P.; Saha, A.: Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Meas. J. Int. Meas. Confed. (2017). https://doi.org/10.1016/j.measurement.2017.05.007

Saha, A.; Mondal, S.C.: Multi-objective optimization in WEDM process of nanostructured hardfacing materials through hybrid techniques. Meas. J. Int. Meas. Confed. (2016). https://doi.org/10.1016/j.measurement.2016.07.087

Mia, M.; Khan, M.A.; Dhar, N.R.: Study of surface roughness and cutting forces using ANN, RSM, and ANOVA in turning of Ti–6Al–4V under cryogenic jets applied at flank and rake faces of coated WC tool. Int. J. Adv. Manuf. Technol. (2017). https://doi.org/10.1007/s00170-017-0566-9

Duchosal, A.; Leroy, R.; Vecellio, L.; Louste, C.; Ranganathan, N.: An experimental investigation on oil mist characterization used in MQL milling process. Int. J. Adv. Manuf. Technol. 66, 1003–1014 (2013). https://doi.org/10.1007/s00170-012-4384-9

Sharma, V.S.; Dogra, M.; Suri, N.M.: Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. (2009). https://doi.org/10.1016/j.ijmachtools.2008.12.010

Park, K.H.; Olortegui-Yume, J.; Yoon, M.C.; Kwon, P.: A study on droplets and their distribution for minimum quantity lubrication (MQL). Int. J. Mach. Tools Manuf. (2010). https://doi.org/10.1016/j.ijmachtools.2010.05.001

Rohit, J.N.; Surendra Kumar, K.; Sura Reddy, N.; Kuppan, P.; Balan, A.S.S.: Computational fluid dynamics analysis of MQL spray parameters and its influence on MQL milling of SS304 (2018). https://doi.org/10.1007/978-981-10-8518-5_2

Manjaiah, M.; Deenashree, K.N.; Basavarajappa, S.: WED-machining characteristics of Ti6Al4V alloy based on central composite design. Int. J. Mater. Prod. Technol. (2019). https://doi.org/10.1504/IJMPT.2019.102634

Acknowledgements

The authors are grateful to the Directorate of Advisory Extension and Research Services (DAERS), BUET, Bangladesh for providing research funds, Sanction No. DAERS/CASR/R-01/2019/DR-2485 (48) dated 26/08/2019 and for providing the laboratory facility to carry out the research work. Authors also thankful to their other team members S. Saha and I.H. Tusar for their availability during experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zaman, P.B., Dhar, N.R. Multi-objective Optimization of Double-Jet MQL System Parameters Meant for Enhancing the Turning Performance of Ti–6Al–4V Alloy. Arab J Sci Eng 45, 9505–9526 (2020). https://doi.org/10.1007/s13369-020-04806-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04806-x