Abstract

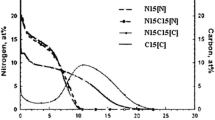

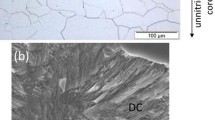

Internal nitridation kinetics were determined for a UNS N08810/800H alloy using a general model of the form \(x^{n}=kt\). Nitridation behavior was studied at service-relevant temperatures 800 °C to 1000 °C in a 95 pct \(\hbox {N}_2/5\,{\text{pct}}\)\(\hbox {H}_2\) atmosphere for times 50 to 750 hours. Optical and scanning electron microscopy were used for microstructural characterization and measurement of nitride penetration. AlN, \(\hbox {Cr}_2\hbox {N}\), and CrN were formed, and the experimentally observed precipitation sequence was consistent with equilibrium calculations for this alloy using Thermo-Calc. A combination of diffusivity data determined using DICTRA and experimentally verified equilibrium calculations showed that Wagner’s analysis for internal oxidation kinetics was valid for AlN penetration. Parabolic kinetics closely approximated measured AlN penetration. This suggests that extension of AlN penetration models to other temperatures and Fe-Ni-Cr-Al alloy systems is reasonable. \(\hbox {Cr}_2\hbox {N}\) penetration did not conform to Wagner’s analysis. Deviation from parabolic behavior was evident, and general model penetration predictions for \(\hbox {Cr}_2\hbox {N}\) were experimentally validated. Using the experimentally determined models, time–temperature–precipitation diagrams for AlN and \(\hbox {Cr}_2\hbox {N}\) penetration were constructed.

Similar content being viewed by others

References

G. Y. Lai: High-Temperature Corrosion and Materials Applications, 1st ed., ASM International, Materials Park, OH, 2007.

C. W. Thomas and M. J. Smillie: Ammonia Technical Manual, American Institute of Chemical Engineers, Montreal, CA, 2011, vol. 52, pp. 101–11.

P. Kodali and J. P. Richert: Corrosion 2003, NACE International, Houston, TX, 2003.

J. J. Hoffman and G. Y. Lai: Corrosion 2005, NACE International, Houston, TX, 2005.

S.N. Monteiro: Corrosion in the Petrochemical Industry, 1st ed., ASM International, Materials Park, OH, 1994, pp. 351–54.

M.F. Ashby and B.F. Dyson: Fracture 84, Pergamon Press, New Dehli, 1984, pp. 3–30.

S. Han and D. J. Young: Oxid. Met., 2001, vol. 55, pp. 223–242.

V. B. Trindade, U. Krupp, B. Gorr, D. Kaczorowski, G. Girardin, and H. J. Christ: Mater. Corros., 2008, vol. 59, pp. 602–608.

D. J. Young: High Temperature Oxidation and Corrosion of Metals, 1st ed., Elsevier, Oxford, UK, 2008, pp. 247–314.

R. Elger, H. Magnusson, and K. Frisk: Mater. Corros., 2017, vol. 68, pp. 143–150.

F.G. Wilson and T. Gladman: Int. Mater. Rev., 1988, vol. 33, pp. 221–288.

J. W. Simmons: Metall. Mater. Trans. A, 1995, vol. 26, pp. 2579–2595.

C. Wagner: Z. Elektrochem., 1959, vol. 63, pp. 772–782.

R. A. Rapp: Corrosion, 1965, vol. 21, pp. 382–401.

M. Udyavar and D.J. Young: Corros. Sci., 2000, vol. 42, pp. 861–883.

M. Welker, A. Rahmel, and M. Schütze: Metall. Trans. A, 1989, vol. 20, pp. 1541–1551.

K. Tjokro and D. J. Young: Oxid. Met., 1995, vol. 44, pp. 453–474.

J.A. Klöwer, U. Brill, and M. Rockel: Mater. Corros., 1997, vol. 48, pp. 511–517.

R. Elger and R. Pettersson: Oxid. Met., 2014, vol. 82, pp. 469–490.

U. Krupp and H.-J. Christ: Metall. Mater. Trans. A, 2000, vol. 31, pp. 47–56.

L. E. Kindlimann and G. S. Ansell: Metall. Trans., 1970, vol. 1, pp. 163–170.

B. A. Pint, M. J. Dwyer, and R. M. Deacon: Oxid. Met., 2008, vol. 69, pp. 211–231.

D. L. Douglass: Oxid. Met., 1995, vol. 44, pp. 81–111.

ASME-B36.10M-2018: Welded and Seamless Wrought Steel Pipe, The American Society of Mechanical Engineers, New York, NY, 2018.

Special Metals Corporation: Incoloy Alloy 800H & 800HT, Special Metals Corporation, 2004, http://www.specialmetals.com/assets/smc/documents/alloys/incoloy/incoloy-alloys-800h-800ht.pdf, accessed (24 Feb 2017).

ISO-21608:2012: Corrosion of Metals and Alloys: Test Method for Isothermal-Exposure Oxidation Testing under High-Temperature Corrosion Conditions for Metallic Materials, International Organization for Standardization, Geneva, Switzerland, 2012.

MATLAB-R2017b: The Mathworks Inc., Natick, Massachusetts, 2017.

J. Schindelin, I. Arganda-carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, J.-Y. Tinevez, D. J. White, V. Hartenstein, K. Eliceiri, P. Tomancak, and A. Cardona: Nat. Methods, 2012, vol. 9, pp. 676–82.

J.-O. Andersson, T. Helander, L. Höglund, P. Shi, and B. Sundman: Calphad, 2002, vol. 26, pp. 273–312.

J. Erneman, J.-O. Nilsson, H.-O. Andrén, and D. Tobjörk: Metall. Mater. Trans. A, 2009, vol. 40, pp. 539–550.

H. O. Pierson: Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing, and Applications, Noyes Publications, Park Ridge, N.J., 1996, p. 193.

A. L. Beardsley, C. M. Bishop, and M. V. Kral: Mater. Perform. Charact., 2016, vol. 5, pp. 717–39.

J. I. Goldstein, D. E. Newbury, P. Echlin, D. C. Joy, C. E. Lyman, E. Lifshin, L. Sawyer, and J. R. Michael: Scanning Electron Microscopy and X-Ray Microanalysis, 3rd ed., Springer, New York, NY, 2003, p. 72.

L. Tan, L. Rakotojaona, T.R. Allen, R.K. Nanstad, and J.T. Busby: Mater. Sci. Eng. A, 2011, vol. 528, pp. 2755–61.

D. A. Porter, K. E. Easterling, and M. Y. Sherif: Phase Transformations in Metals and Alloys, 3rd ed., CRC Press, Boca Raton, FL, 2009.

M. Kikuchi, M. Kajihara, and S.-K. Choi: Mater. Sci. Eng. A, 1991, vol. 146, pp. 131–50.

A. J. Ramirez, J. C. Lippold, and S. D. Brandi: Metall. Mater. Trans. A, 2003, vol. 34, pp. 1575–97.

T.H. Lee, S.J. Kim, and S. Takaki: Metall. Mater. Trans. A, 2006, vol. 37, pp. 3445–54.

O.-N. Hideki, K. Taguchi, T. Usui, K. Tamura, and Y. Tomatsu: Metall. Mater. Trans. B, 2001, vol. 32, pp. 1113–1118.

ISO-26146:2012: Corrosion of Metals and Alloys: Method for Metallographic Examination of Samples after Exposure to High-Temperature Corrosive Environments, International Organization for Standardization, Geneva, Switzerland, 2012.

M.W. Chase, Jr, C.A. Davies, J.R. Downey, Jr, D.J. Frurip, R.A. McDonald, and A.N. Syverud: JANAF Thermochemical Tables, 3rd ed., American Chemical Society, Washington, DC, 1986, vol. 14, p. 131.

G. C. Savva, G. C. Weatherly, and J. S. Kirkaldy: Metall. Mater. Trans. A, 1996, vol. 27, pp. 1611–1622.

I. C. Chen and D. L. Douglass: Oxid. Met., 1990, vol. 34, pp. 473–496.

D. C. Montgomery and G. C. Runger: Applied Statistics and Probability for Engineers, 5th ed., John Wiley & Sons, Hoboken, NJ, 2011, pp. 445–451.

X. G. Zheng and D. J. Young: Oxid. Met., 1994, vol. 42, pp. 163–190.

P. G. Shewmon: Transformations in Metals, McGraw-Hill, New York, 1969.

J. Litz, A. Rahmel, and M. Schorr: Oxid. Met., 1988, vol. 30, pp. 95–105.

M.A. Harper, J.E. Barnes, and G.Y. Lai: Corrosion 97, NACE International, Houston, TX, 1997.

Acknowledgments

The financial support of the Methanex Corporation in conducting this research is gratefully acknowledged. The authors would like to thank Peter Tait of Methanex New Zealand Ltd. for his support, and Assoc. Prof. Matt Watson and Leigh Richardson from the University of Canterbury Chemical and Process Engineering Department for the use of their facilities and their assistance in conducting nitridation treatments.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted October 9, 2019.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Young, A.M., Kral, M.V. & Bishop, C.M. Time–Temperature–Precipitation Relations for Nitrides and Evaluation of Internal Oxidation Theory for Nitridation of Austenitic Stainless Steel. Metall Mater Trans A 51, 4456–4470 (2020). https://doi.org/10.1007/s11661-020-05868-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05868-0