Abstract

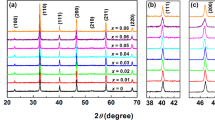

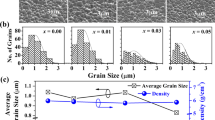

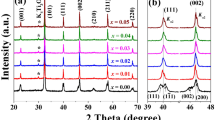

This work investigates the effects of lanthanum doping on the crystal structure, surface morphology, dielectric properties, ferroelectric properties, piezoelectric properties, and electromechanical strain properties of lead-free (Bi0.47Na0.47Ba0.06)1−xLaxTiO3 piezoelectric ceramics. All specimens were fabricated by a traditional solid-state reaction method. The results of crystal structure and dielectric properties categorize all specimens as relaxor materials. The results of dielectric properties and ferroelectric properties confirm the nonergodic-to-ergodic transformation as a function of La content. At the phase transition point, the material shows a high electric field-induced strain of 0.4% under an applied electric field of 5 kV/mm. The large electromechanical strain response at low applied field in the 0.02 mol La specimen may contribute to the two synergistic effects. First, the electric field induced the reversible ergodic-ferroelectric phase transition, which can generate the large strain. Second, the nonergodic and ergodic phases coexist at the phase transformation point, which can reduce the driving field by facilitating the growth of ferroelectric domains.

Similar content being viewed by others

References

M.E. Lines and A.M. Glass, Principles and Applications of Ferroelectric and Related Materials (New York: Oxford University Press Inc., 2001), p. 559.

E. Cross, Nature 432, 24 (2004).

K. Uchino, Ferroelectric Devices (New York: Marcel Decker, 2000), p. 145.

A.J. Bell and O. Deubzer, MRS Bull. 43, 581 (2018).

R. Wang, K. Wang, F. Yao, J.F. Li, F.H. Schader, K.G. Webber, W. Jo, and J. Rödel, J. Am. Ceram. Soc. 98, 2177 (2015).

M. Sutapun, R. Muanghlua, and N. Vittayakorn, Ferroelectrics 490, 1 (2016).

L. Yu, H. Xi, Z. Yu, Y. Liu, and Y. Lyu, Ceram. Int. 45, 14675 (2019).

C. Shi, J. Ma, J. Wu, K. Chen, and B. Wu, Ceram. Int. 46, 2798 (2020).

F. Hussain, A. Khesro, Z. Lu, G. Wang, and D. Wang, Front. Mater. (2020). https://doi.org/10.3389/fmats.2020.00087.

Q. Yao, F. Wang, F. Xu, C.M. Leung, T. Wang, Y. Tang, X. Ye, Y. Xie, D. Sun, and W. Shi, Mater. Interfaces 7, 5066 (2015).

A. Ullah, M. Alam, A. Ullah, C.W. Ahn, J.S. Lee, S. Cho, and I.W. Kim, RSC Adv. 6, 63915 (2016).

J. Chen, Y. Wang, Y. Zhang, Y. Yang, and R. Jin, J. Eur. Ceram. Soc. 37, 2365 (2017).

D. Duraisamy and G.N. Venkatesan, Appl. Phys. Lett. 112, 052903 (2018).

K. Mclaughlin, C.P. Gonzalez, D. Wang, and A. Feteira, J. Alloys Compd. 779, 7 (2019).

M. Habib, M. Munir, S.A. Khan, T.W. Song, M.H. Kim, M.J. Iqbal, I. Qazi, and A. Hussain, J. Phys. Chem. Solids 138, 109230 (2020).

T.H. Dinh, H.S. Han, and J.S. Lee, Mater. Lett. 258, 126793 (2020).

D. Wang, Z. Jiang, B. Yang, S. Zhang, M. Zhang, F. Guo, and W. Cao, J. Mater. Sci. 49, 62 (2014).

A.K. Kalyani, H. Krishnan, A. Sen, A. Senyshyn, and R. Ranjan, Phys. Rev. B Condens. Matter 91, 024101 (2015).

C. Zhao, H. Wang, J. Xiong, and J. Wu, Dalton Trans. 45, 6466 (2016).

S. Murakami, N.T.A.F. Ahmed, D. Wang, A. Feteira, D.C. Sinclair, and I.M. Reaney, J. Eur. Ceram. Soc. 38, 4220 (2018).

S. Murakami, D. Wang, A. Mostaed, A. Khesro, A. Feteira, D.C. Sinclair, Z. Fan, X. Tan, and I.M. Reaney, J. Am. Ceram. Soc. 101, 5428 (2018).

T. Takenaka, K. Maruyama, and K. Sakata, Jpn. J. Appl. Phys. 30, 2236 (1991).

H.D. Li, C.D. Feng, and W.L. Yao, Mater. Lett. 58, 1194 (2004).

H. Sun, X. Wang, and X. Yao, Ceram. Int. 38S, S373 (2012).

J. Hao, W. Li, J. Zhai, and H. Chen, Mater. Sci. Eng. R 135, 1 (2019).

W. Jo, T. Granzow, E. Aulbach, J. Rödel, and D. Damjanovic, J. Appl. Phys. 105, 094102 (2009).

D.S. Lee, D.H. Lim, M.S. Kim, K.H. Kim, and S.J. Jeong, Appl. Phys. Lett. 99, 062906 (2011).

T.H. Dinh, J.K. Kang, J.S. Lee, N.H. Khansur, J. Daniels, H.Y. Lee, F.Z. Yao, K. Wang, J.F. Li, H.S. Han, and W. Jo, J. Eur. Ceram. Soc. 36, 3401 (2016).

D. Gobeljic, V.V. Shvartsman, A. Belianinov, B. Okatan, J. Baris, S. Jesse, S. Kalinin, C. Groh, J. Rödel, and D.C. Lupascu, Nanoscale 8, 2168 (2016).

M. Acosta, L.A. Schmitt, L.M. Luna, M.C. Scherrer, M. Brilz, K.G. Webber, M. Deluca, H.J. Kleebe, J. Rödel, and W. Donner, J. Am. Ceram. Soc. 98, 3405 (2015).

J. Koruza, V. Rojas, L. Molina-Luna, U. Kunz, M. Duerrschnabel, H.J. Kleebe, and M. Acosta, J. Eur. Ceram. Soc. 36, 1009 (2016).

M.I. Morozov and D. Damjanovic, J. Appl. Phys. 107, 034106 (2010).

F. Li, Y. Liu, Y. Lyu, Y. Qi, Z. Yu, and C. Lu, Ceram. Int. 43, 106 (2017).

X. Liu, C.L. Yuan, X.Y. Liu, F.H. Luo, Q. Feng, J. Xu, G.H. Chen, and C.R. Zhou, Mater. Chem. Phys. 181, 444 (2016).

X. Lu, J. Xu, L. Yang, C. Zhou, Y.Y. Zhao, C. Yuan, Q. Li, G. Chen, and H. Wang, J. Mater. 2, 87 (2016).

L. Li, M. Xu, Q. Zhang, P. Chen, N. Wang, D. Xiong, B. Peng, and L. Liu, Ceram. Int. 44, 343 (2018).

J. Cao, Y. Wang, and Z. Li, Ferroelectrics 520, 224 (2017).

Y. Mendez-Gonzalez, A. Peláiz-Barranco, J.D.S. Guerra, A. Pentón-Madrigal, and P. Saint-Grégoire, Mater. Chem. Phys. 208, 103 (2018).

B. Hu, Z. Pan, M. Dai, F.F. Guo, H. Ning, Z.B. Gu, J. Chen, M.H. Lu, S.T. Zhang, B. Yang, and W. Cao, J. Am. Ceram. Soc. 97, 3877 (2014).

R.D. Shannon, Acta Cryst. A32, 751 (1976).

X. Jia, J. Zhang, Y. Gao, J. Wang, and P. Zheng, Mater. Res. Bull. 89, 11 (2017).

X. Jia, J. Zhang, L. Wang, J. Wang, H. Du, Y. Yao, L. Ren, F. Wen, and P. Zheng, J. Am. Ceram. Soc. 102, 5203 (2019).

R. Zuo, C. Ye, Z. Fang, and J. Li, J. Eur. Ceram. Soc. 28, 871 (2008).

W.S. Kang and J.H. Koh, J. Eur. Ceram. Soc. 35, 2057 (2015).

Y.S. Sung, J.M. Kim, J.H. Cho, T.K. Song, M.H. Kim, H.H. Hong, T.G. Park, D. Do, and S.S. Kim, Appl. Phys. Lett. 96, 022901 (2010).

L.E. Cross, Ferroelectrics 151, 305 (1994).

C. Ma, X. Tan, D. Dul’kin, and M. Roth, J. Appl. Phys. 108, 104105 (2010).

G.A. Samara, J. Phys. Condens. Matter 15, R367 (2003).

K. Wang, A. Hussain, W. Jo, and J. Rödel, J. Am. Ceram. Soc. 95, 2241 (2012).

H.S. Han, W. Jo, J. Rödel, I.K. Hong, W.P. Tai, and J.S. Lee, J. Phys. Condens. Matter 24, 365901 (2012).

R. Ahluwalia, T. Lookman, A. Saxena, and W. Cao, Phys. Rev. B Condens. Matter 72, 014112 (2005).

R. Theissmann, L.A. Schmitt, J. Kling, R. Schierholz, and K.A. Schonau, J. Appl. Phys. 102, 024111 (2007).

L.F. Wang and J.M. Liu, Appl. Phys. Lett. 91, 092908 (2007).

T. Sluka, A.K. Tagantsev, D. Damjanovic, M. Gureev, and N. Setter, Nat. Commun. 3, 748 (2012).

C.C. Jin, F.F. Wang, L.L. Wei, J. Tang, Y. Li, Q.R. Yao, C.Y. Tian, and W.Z. Shi, J. Alloys Compd. 585, 185 (2014).

J. Hao, Z. Xu, R. Chu, W. Li, J. Du, and G. Li, J. Phys. D Appl. Phys. 48, 472001 (2015).

W. Bai, P. Li, L. Li, J. Zhang, B. Shen, and J. Zhai, J. Alloys Compd. 649, 772 (2015).

L. Li, J. Hao, Z. Xu, W. Li, R. Chu, and G. Li, Ceram. Int. 42, 14886 (2016).

W. Bai, D. Chen, Y. Huang, B. Chen, J. Zhai, and Z. Ji, J. Alloys Compd. 667, 6 (2016).

W. Bai, D. Chen, P. Zheng, B. Chen, J. Zhai, and Z. Ji, Dalton Trans. 45, 8573 (2016).

J. Hao, Z. Xu, R. Chu, W. Li, P. Fu, J. Du, and G. Li, J. Eur. Ceram. Soc. 36, 4003 (2016).

U. Obilor, C. Pascual-Gonzalez, S. Murakami, I.M. Reaney, and A. Feteira, Mater. Res. Bull. 97, 385 (2018).

N.U. Khan, A. Ullah, A. Ullah, M.Y. Khan, T.H. Kim, I.W. Kim, and C.W. Ahn, Sens. Actuators A 291, 156 (2019).

R. Dittmer, W. Jo, J. Rödel, S. Kalinin, and N. Balke, Adv. Funct. Mater. 22, 4208 (2012).

Acknowledgments

This study was supported by a National Research Foundation (NRF) Grant (2016R1D1A3B01008169).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dinh, T.H., Han, HS., Tran, V.D.N. et al. 0.4% Electrostrain at Low Field in Lead-Free Bi-Based Relaxor Piezoceramics by La Doping. J. Electron. Mater. 49, 6080–6086 (2020). https://doi.org/10.1007/s11664-020-08348-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08348-8