Abstract

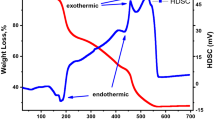

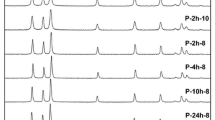

Lead zirconate (PZ) nanopowders were synthesized by the treatment of precursors with high-energy ball milling for a relatively short time. The effects of ball milling time and rotational speed on the produced nanomaterial were investigated. The calcination temperature of the ball-milled powder was determined from the thermogravimetric analysis (TGA) and the differential scanning calorimetry (DSC) results. The structural properties of the calcined nanoparticles were studied by Fourier transmission infrared (FT-IR), x-ray diffraction (XRD), and transmission electron microscope (TEM). Well-crystallized PZ nanopowders were obtained after heating at 800°C for 3 h. The diffraction data were refined by the Rietveld method to accurately determine the crystallographic information. Williamson-Hall, Halder-Wagner, and size-strain plot methods were employed to investigate the average crystallite size and lattice microstrain in the prepared samples. The XRD and TEM images confirmed the formation of nanoparticles with an average size in the range of 20–43 nm. The band gap of the nanopowders varied from 3.11 eV to 3.28 eV as established by diffuse reflectance measurement.

Similar content being viewed by others

References

J. Zhai, X. Li, Y. Yao, and H. Chen, Mater. Sci. Eng. B 99, 230 (2003).

N.H. Fletcher, A.D. Hilton, and B.W. Ricketts, J. Phys. D Appl. Phys. 29, 253 (1996).

I. Burn and D.M. Smyth, J. Mater. Sci. 7, 339 (1972).

U. Sukkha, R. Muanghlua, S. Niemcharoen, B. Boonchom, and N. Vittayakorn, J. Am. Ceram. Soc. 94, 3397 (2011).

M. M. Calzada, in edited by L. Pardo and J. Ricote (Springer Netherlands, Dordrecht, 2011), pp. 93–144.

M.P. Moret, M.A.C. Devillers, K. Wörhoff, and P.K. Larsen, J. Appl. Phys. 92, 468 (2002).

W. Wang, X. Chen, Q. Sun, T. Xin, and M. Ye, J. Alloys Compd. 830, 154581 (2020).

S. Li, R.A. Condrate, S.D. Jang, and R.M. Spriggs, J. Mater. Sci. 24, 3873 (1989).

O. Khamman, W. Chaisan, R. Yimnirun, and S. Ananta, Mater. Lett. 61, 2822 (2007).

S. Begin-Colin, G. Le Caër, M. Zandona, E. Bouzy, and B. Malaman, J. Alloys Compd. 227, 157 (1995).

I.J. Lin and S. Nadiv, Mater. Sci. Eng. 39, 193 (1979).

I.J. Lin, Miner. Sci. Eng. 7, 313 (1975).

B. E. Warren, X-Ray Diffraction (Courier Corporation, 1990).

C. Puchmark, S. Jiansirisomboon, G. Rujijanagul, and T. Tunkasiri, Curr. Appl. Phys. 4, 179 (2004).

K.H. Omran, M.S.A. El-sadek, M. Mostafa, and O.M. Hemeda, Appl. Nanosci. 10, 2315 (2020).

P. Scardi and M. Leoni, Acta Crystallogr. Sect. A Found. Crystallogr. 57, 604 (2001).

A. Le Bail, H. Duroy, and J.L. Fourquet, Mater. Res. Bull. 23, 447 (1988).

J. Rodríguez-Carvajal, CEA/Saclay, Fr. (2001).

G.S. Pawley, J. Appl. Crystallogr. 14, 357 (1981).

S. Teslic and T. Egami, Acta Crystallogr. Sect. B Struct. Sci. 54, 750 (1998).

L.B. Kong, J. Ma, W. Zhu, and O.K. Tan, Mater. Lett. 49, 96 (2001).

N. Sahu and S. Panigrahi, Ceram. Int. 38, 1085 (2011).

A. Taylor (1961).

M.S. Abd El-Sadek, H.S. Wasly, and K.M. Batoo, Appl. Phys. A 125, 283 (2019).

G.K. Williamson and W.H. Hall, Acta Metall. 1, 22 (1953).

H.P. Klug and L.E. Alexander, X-Ray Diffraction Procedures: For Polycrystalline and Amorphous Materials (1974).

S. Murugesan, R. Thirumurugesan, E. Mohandas, and P. Parameswaran, Mater. Chem. Phys. 225, 320 (2019).

F. Izumi and T. Ikeda, Implementation of the Williamson-Hall and Halder-Wagner Methods into RIETAN-FP (2014).

N.C. Halder and C.N.J. Wagner, Acta Crystallogr. 20, 312 (1966).

K. Venkateswarlu, A. Chandra Bose, and N. Rameshbabu, Phys. B Condens. Matter 405, 4256 (2010).

P. Muhammed Shafi and A. Chandra Bose, AIP Adv. 5, 057137 (2015).

M.A. Tagliente and M. Massaro, Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 266, 1055 (2008).

D. Nath, F. Singh, and R. Das, Mater. Chem. Phys. 239, 122021 (2020).

H. Irfan, K. Mohamed Racik, and S. Anand, J. Asian Ceram. Soc. 6, 54 (2018).

V. Soleimanian and M. Mojtahedi, Appl. Phys. A Mater. Sci. Process. 119, 977 (2015).

V. Uvarov and I. Popov, Mater. Charact. 58, 883 (2007).

A. Weibel, R. Bouchet, F. Boulc, and P. Knauth, Chem. Mater. 17, 2378 (2005).

A. Pragatheeswaran, R. Ravi, and S.R. Bakshi, Adv. Powder Technol. 30, 2759 (2019).

H. Dutta, P. Sahu, S.K. Pradhan, and M. De, Mater. Chem. Phys. 77, 153 (2003).

H. Fujishita, Y. Ishikawa, S. Tanaka, A. Ogawaguchi, and S. Katano, J. Phys. Soc. Jpn. 72, 1426 (2003).

F. Jona, G. Shirane, F. Mazzi, and R. Pepinsky, Phys. Rev. 105, 849 (1957).

S. Piskunov, A. Gopeyenko, E.A. Kotomin, Y.F. Zhukovskii, and D.E. Ellis, Comput. Mater. Sci. 41, 195 (2007).

S. Verma, S. Rani, S. Kumar, and M.A.M. Khan, Ceram. Int. 44, 1653 (2018).

R.M. Silverstein and G.C. Bassler, J. Chem. Educ. 39, 546 (1962).

J.M. Hollas, Modern Spectroscopy (Wiley, 2004).

D. Sun, X. Jin, H. Liu, J. Zhu, Y. Zhu, and Y. Zhu, Ferroelectrics 355, 145 (2007).

A. Tawfik, O.M. Hemeda, A.M.A. Henaish, and A.M. Dorgham, Mater. Chem. Phys. 211, 1 (2018).

P. Kubelka, JOSA 38, 448 (1948).

G.F. Teixeira, M.A. Zaghete, G. Gasparotto, M.G.S. Costa, J.W.M. Espinosa, E. Longo, and J.A. Varela, J. Alloys Compd. 512, 124 (2012).

K. Suzuki, M. Terauchi, Y. Uemichi, and K. Kijima, Jpn. J. Appl. Phys. 44, 7593 (2005).

P. Bharathi, P. Thomas, and K.B.R. Varma, J. Mater. Chem. C 3, 4762 (2015).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Omran, K.H., Abd El-sadek, M.S., Mostafa, M. et al. Microstructural Analysis and Optical Properties of Lead Zirconate Nanoparticles. JOM 73, 630–639 (2021). https://doi.org/10.1007/s11837-020-04296-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04296-0