Abstract

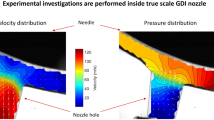

In this study, the effect of fuel temperature on cavitation inception, cavitation development structure, flow regime and near-field spray was explored, especially focus was put on a special kind of vortex-induced string-type cavitation and its effects on spray behavior. It can be seen that the higher the fuel temperature, the smaller the injection pressure corresponding to the cavitation inception is, and the faster it develops under the same injection pressure. The growth of geometry-induced near-wall cavitation at different fuel temperatures is weaker than that of vortex-induced string cavitation. The single initial bubble can be an origin for inducing the string cavitation after entering the nozzle orifice, whose intensity is larger at the higher fuel temperature. Although the effect of initial bubbles at the lower fuel temperature is weaker, continuous initial bubbles can still induce the formation of string cavitation and then stabilize it in the nozzle orifice. String cavitation initiated at the outlet is undemanding to occur at a higher temperature, and it becomes challenging to develop towards the inlet when the injection pressure increases. The frequency of the cloud cavitation shedding increases with the higher fuel temperature incurring a reduction in fuel viscosity.

Graphic abstract

The variation of cavitation patterns at different fuel temperatures in diesel nozzles: The string cavitation intensity increases gradually as the injection pressure increases. Meanwhile, the growth of string cavitation area becomes faster with growing the temperature. When the injection pressure is increased to 0.6 MPa, further augment of the cavitation area is significantly limited due to the space limitation of the orifice, resulting in a slowdown of the growth rate.

The development characteristics of string cavitation with temperature (h = 1 mm)

Similar content being viewed by others

Abbreviations

- K factor :

-

Conicity factor of nozzle orifice

- D :

-

Nozzle orifice diameter

- L :

-

Nozzle orifice length

- I string :

-

Intensity of string cavitation

- I geo :

-

Intensity of geometry-induced cavitation

- A :

-

Cross section area of nozzle orifice

- h :

-

Needle lift

- S string :

-

Area of string cavitation in 2D image

- S orifice :

-

Area of nozzle orifice in 2D image

- P inj :

-

Injection pressure

- P amb :

-

Ambient pressure

- T :

-

Fuel temperature

- o:

-

Outlet of nozzle orifice

- in:

-

Inlet of nozzle orifice

References

Agarwal AK, Som S, Shukla PC, Goyal H, Longman D (2015) In-nozzle flow and spray characteristics for mineral diesel, Karanja, and Jatropha biodiesels. Appl Energy 156:138–148

Aleiferis GP, Serraspereira A, Davies JT, Cracknell FR (2010) Effect of fuel temperature on in-nozzle cavitation and spray formation of liquid hydrocarbons and alcohols from a real-size optical injector for direct-injection spark-ignition engines. Int J Heat Mass Transf 53:4588–4606

Benajes J, Pastor JV, Payri R, Plazas AH (2004) Analysis of the influence of diesel nozzle geometry in the injection rate characteristic. J Fluids Eng 126:63–71

Catania EA, Ferrari S (2008) Temperature variations in the simulation of high-pressure injection-system transient flows under cavitation. Int J Heat Mass Transf 51:2090–2107

Chen Z, He Z, Shang W, Duan L, Zhou H, Guo G, Guan W (2018) Experimental study on the effect of nozzle geometry on string cavitation in real-size optical diesel nozzles and spray characteristics. Fuel 232:562–571

Dernotte J, Hespel C, Houille S, Foucher F, Mounaim-Rousselle C (2012) Influence of fuel properties on the diesel injection process in nonvaporizing conditions. Atomization Sprays 22:461–492

Desantes JM, Salvador FJ, Carreres M, Jaramillo D (2015) Experimental characterization of the thermodynamic properties of diesel fuels over a wide range of pressures and temperatures. SAE Int J Fuels Lubricants 8:190–199

He Z, Zhang Z, Guo G, Qian W, Leng X, Sun S (2016) Visual experiment of transient cavitating flow characteristics in the real-size diesel injector nozzle ☆. Int Commun Heat Mass Transf 78:13–20

Jiménez-Espadafor FJ, Torres M, Velez JA, Carvajal E, Becerra JA (2012) Experimental analysis of low temperature combustion mode with diesel and biodiesel fuels: a method for reducing NOx and soot emissions. Fuel Process Technol 103:57–63

Kawano D, Goto Y, Odaka M, Senda J (2004) Modeling atomization and vaporization processes of flash-boiling spray. SAE Technical Paper. https://doi.org/10.4271/941925.

Knapp RT (1955) Recent investigations of the mechanics of cavitation and cavitation damage. ASME Trans 77:1045–1054

Nurick WH (1976) Orifice cavitation and its effect on spray mixing. Asme Trans J Fluids Eng 98:681–687

Park SH, Yoon SH, Suh HK, Lee CS (2008) Effect of the temperature variation on properties of biodiesel and biodiesel-ethanol blends fuels. Oil Gas Sci Technol 63:737–745

Payri F, Payri R, Salvador FJ, Gimeno J (2007) Influence of Nozzle geometry on spray characteristics in non-evaporative and evaporative conditions. Sae Techn Papers. https://doi.org/10.4271/2007-24-0023

Payri R, Salvador FJ, Gimeno J, Bracho G (2008) Effect of fuel properties on diesel spray development in extreme cold conditions. Proc Inst Mech Eng Part D J Automobile Eng 222:1743–1753

Payri R, Salvador FJ, Gimeno J, Bracho G (2009) Understanding diesel injection characteristics in winter conditions, SAE Technical Paper

Powell CF, Kastengren AL, Liu Z, Fezzaa K (2010) The effects of diesel injector needle motion on spray structure. J Eng Gas Turbines Power 133:207–217

Salvador FJ, Martínez-López J, Romero JV, Roselló MD (2014) Study of the influence of the needle eccentricity on the internal flow in diesel injector nozzles by computational fluid dynamics calculations. Int J Comput Math 91:24–31

Seykens XLJ, Somers LMT, Baert RSG (2004) Modeling of common rail fuel injection system and influence of fluid properties on injection process. Proc Vafsep

Som S, Ramirez AI, Aggarwal SK, Kastengren AL, El-Hannouny E, Longman DE, Powell CF, Senecal PK (2009) Development and validation of a primary breakup model for diesel engine applications. In: Sae World congress & exhibition

Som S, Ramirez AI, Longman DE, Aggarwal SK (2011) Effect of nozzle orifice geometry on spray, combustion, and emission characteristics under diesel engine conditions ☆. Fuel 90:1267–1276

Sou A, Biçer B, Tomiyama A (2014) Numerical simulation of incipient cavitation flow in a nozzle of fuel injector. Comput Fluids 103:42–48

Su HP, Suh HK, Chang SL (2008) Effect of cavitating flow on the flow and fuel atomization characteristics of biodiesel and diesel fuels. Energy Fuels 22:605–613

Su HP, Kim HJ, Suh HK, Chang SL (2009) Experimental and numerical analysis of spray-atomization characteristics of biodiesel fuel in various fuel and ambient temperatures conditions. Int J Heat Fluid Flow 30:960–970

Su HP, Yoon SH, Chang SL (2011) Effects of multiple-injection strategies on overall spray behavior, combustion, and emissions reduction characteristics of biodiesel fuel. Appl Energy 88:88–98

Suh HK, Chang SL (2008) Effect of cavitation in nozzle orifice on the diesel fuel atomization characteristics. Int J Heat Fluid Flow 29:1001–1009

Suh HK, Park SH, Lee CS (2008) Experimental investigation of nozzle cavitating flow characteristics for diesel and biodiesel fuels. Int J Autom Technol 9:217–224

Sun ZY, Li GX, Chen C, Yu YS, Gao GX (2015) Numerical investigation on effects of nozzle’s geometric parameters on the flow and the cavitation characteristics within injector’s nozzle for a high-pressure common-rail DI diesel engine. Energy Convers Manage 89:843–861

Taghavifar H, Khalilarya S, Jafarmadar S, Baghery F (2016) 3-D numerical consideration of nozzle structure on combustion and emission characteristics of DI diesel injector. Appl Math Model 40:8630–8646

Tinprabath P, Hespel C, Chanchaona S, Foucher F (2015) Influence of biodiesel and diesel fuel blends on the injection rate under cold conditions. Fuel 144:80–89

Vergnes C, Foucher F, Mounaim-Rousselle C (2009) Discharge coefficients for a diesel injector during cold starting conditions. Atomization Sprays 19:621–631

Viera JP, Payri R, Swantek AB, Duke DJ, Sovis N, Kastengren AL, Powell CF (2016) Linking instantaneous rate of injection to X-ray needle lift measurements for a direct-acting piezoelectric injector. Energy Convers Manage 112:350–358

Wang Z, Ding H, Wyszynski ML, Tian J, Xu H (2015) Experimental study on diesel fuel injection characteristics under cold start conditions with single and split injection strategies. Fuel Process Technol 131:213–222

Wang C, Moro A, Xue F, Wu X, Luo F (2018) The influence of eccentric needle movement on internal flow and injection characteristics of a multi-hole diesel nozzle. Int J Heat Mass Transf 117:818–834

Wei H, Xi C, Wang G, Lei Z, An S, Shu G (2017) Effect of swirl flow on spray and combustion characteristics with heavy fuel oil under two-stroke marine engine relevant conditions. Appl Therm Eng 124:302–314

Yamane T, Sumi T, Ohsawa K, Oda T (2014) Numerical analysis of needle eccentricity effects on internal flow of enlarged VCO diesel injector. Trans Japan Soc Mech Eng 80:TEP0094

Yu W, Yang W, Mohan B, Tay KL, Zhao F (2015) Macroscopic spray characteristics of wide distillation fuel (WDF). Appl Energy S0306261915016244

Yu W, Yang W, Mohan B, Tay K, Zhao F, Zhang Y, Chou S, Kraft M, Alexander MA, Yong A (2016) Numerical and experimental study on internal nozzle flow and macroscopic spray characteristics of a kind of wide distillation fuel (WDF)—kerosene, In: Sae world congress & exhibition

Zhang L, He Z, Guan W, Wang Q, Som S (2018) Simulations on the cavitating flow and corresponding risk of erosion in diesel injector nozzles with double array holes. Int J Heat Mass Transf 124:900–911

Zhang W, Liu H, Liu C, Jia M, Xi X (2019) Numerical investigation into primary breakup of diesel spray with residual bubbles in the nozzle. Fuel 250:265–276

Acknowledgments

This research was supported by the National Natural Science Foundation of China (no. 51776088), a Project Funded by the Priority Academic Program Development of Jiangsu High Education Institutions, High-tech Research Key laboratory of Zhenjiang (SS2018002), and Research Innovation Plan for Postgraduates in Jiangsu Universities (no. KYCX19_1595).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cao, T., He, Z., Si, Z. et al. Optical experimental study on cavitation development with different patterns in diesel injector nozzles at different fuel temperatures. Exp Fluids 61, 185 (2020). https://doi.org/10.1007/s00348-020-03006-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-020-03006-5