Abstract

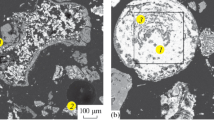

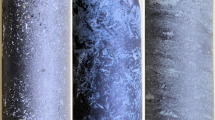

Processing of titanium-containing ores together with the extraction of all the major elements is currently an urgent problem for the usage of mineral products. It is shown that none of the existing processing schemes allows the simultaneous extraction of all the major useful elements such as iron, titanium and vanadium from titanium-containing iron ores. This problem can be solved using a selective extraction of these elements based on ideas regarding the electron reduction mechanism. The following has been experimentally studied: the reaction propagation of solid-phase selective iron reduction that is deep in the grain layer of ilmenite concentrate from the surface of its contact with the powder of carbon-containing material. The results are presented for determining the amount of released metal phase depending on the distance from the concentrate–reducing agent contact boundary. Based on the results regarding the amount of the released metal phase, a conclusion was made for the diffusion processes in a layer of concentrate grains that contact only between themselves, thus determining the rate of iron reduction process. It is shown that near the contact surface between the solid reducing agent and the layer of concentrate grains, the rate of iron reduction is higher than the formation rate of the phases with high iron content from ilmenite. Deep in the ilmenite concentrate layer, the process of iron reduction is preceded by the formation of an iron-containing silicate phase from the concentrate grains, where iron is reduced earlier than it is in the ilmenite grains. The formation of iron-containing silicate phase promotes ilmenite grains to be sintered. Thus, upon the concentrate layer contacting with solid reducing agent in the absence of contact between each ilmenite grain and solid reducing agent, the point contact between grains and void presence within the layer do not prevent the reduction process propagation in the grain layer that contact only with each other.

Similar content being viewed by others

REFERENCES

Li, K.Q., Ni, W., Zhu, M., Zheng, M.J., and Li, Y., Iron extraction from oolitic iron ore by a deep reduction process, J. Iron Steel Res. Int., 2011, vol. 18, no. 8, pp. 9–13.

Kapelyushin, Y., Xing, X., Zhang, J., Jeong, S., Sasaki, Y., and Ostrovski, O., Effect of alumina on the gaseous reduction of magnetite in CO/CO2 gas mixtures, Metall. Mater. Trans. B, 2015, vol. 46, no. 3, pp. 1175–1185.

Anacleto, N.M., Solheim, I., Sorensen, B., Ringdalen, E., and Ostrovski, O., Reduction of chromium oxide and ore by methane-containing gas mixtures, Proc. Int. Ferro-Alloys Congress “INFACON XV,” Cape Town: South. Afr. Inst. Min. Metall., 2018, pp. 71–78.

Leikola, M., Taskinen, P., and Eric, R.H., Reduction of Kemi chromite with methane, J. South. Afr. Inst. Min. Metall., 2018, vol. 118, no. 6, pp. 575–580.

Jung, W.G., Hossain, S.T., Johra, F.T., Kim, J.H., and Chang, Y.C., Reduction of chromium ore by recycled silicon cutting sludge waste with carbon addition, J. Iron Steel Res. Int., 2019, vol. 26, no. 8, pp. 806–817.

Bhalla, A. and Eric, R.H., Mechanism and kinetic modeling of methane-based reduction of Mamatwan manganese ore, Proc. Int. Ferro-Alloys Congress “INFACON XV,” Cape Town: South. Afr. Inst. Min. Metall., 2018, pp. 143–156.

Cheraghi, A., Yoozbashizadeh, H., and Safarian, J., Chemical, microstructural, and phase changes of manganese ores in calcination and pre-reduction by natural gas, Proc. Int. Ferro-Alloys Congress “INFACON XV,” Cape Town: South. Afr. Inst. Min. Metall., 2018, pp. 157–167.

Huang, R., Lv, X.W., Bai, C.G., Deng, Q.Y., and Ma, S.W., Solid state and smelting reduction of Panzhihua ilmenite concentrate with coke, Can. Metall. Q., 2012, vol. 51, no. 4, pp. 434–439.

Gou H.P., Zhang G.H., Hu X.J., and Chou K.C., Kinetic study on carbothermic reduction of ilmenite with activated carbon, Trans. Nonferrous Met. Soc. China, 2017, vol. 27, no. 8, pp. 1856–1861.

Sarkar, B.K., Dastidar, M.G., Dey, R., Das, G.C., Chowdhury, S., and Mahata, D.K., Optimization of reduction parameters of quenched titaniferous magnetite ore by boiler grade coal using box-behnken design, J. Inst. Eng. (India):Ser. D, 2019, vol. 100, pp. 275–282.

Wang, S., Chen, M., Guo, Y., Jiang, T., and Zhao, B., Reduction and smelting of vanadium titanomagnetite metallized pellets, JOM, 2018, vol. 71, no. 3, pp. 1144–1149.

Gudima, N.V. and Shein, Ya.P., Kratkii spravochnik po metallurgii tsvetnykh metallov (Outline of Non-Ferrous Metallurgy), Moscow: Metallurgiya, 1975.

Utkin, N.I., Proizvodstvo tsvetnykh metallov (Non-Ferrous Metals Production), Moscow: Intermet Inzhiniring, 2004.

Fu, W., Wen, Y., and Xie, H., Development of intensified technologies of vanadium-bearing titanomagnetite smelting, J. Iron Steel Res. Int., 2011, vol. 18, no. 4, pp. 7–18.

Panishev, N.V. and Bigeev, V.A., Processing of complex ores of the Southern Urals by deep metallization, Teor. Tekhnol. Metall. Proizvod., 2016, no. 2 (19), pp. 68–70.

Wang, S., Guo, Y., Jiang, T., Chen, F., Zheng, F., Yang, L., and Tang, M., Behavior of titanium during the smelting of vanadium titanomagnetite metallized pellets in an electric furnace, JOM, 2019, vol. 71, no. 1, pp. 323–328.

Leont’ev, L.I., Vatolin, N.A., Shavrin, S.V., and Shumakov, N.S., Pirometallurgicheskaya pererabotka kompleksnykh rud (Pyrometallurgical Processing of Complex Ores), Moscow: Metallurgiya, 1997.

Roshchin, V.E., Asanov, A.V., and Roshchin, A.V., Possibilities of two-stage processing of titaniferous magnetite ore concentrates, Russ. Metall. (Engl. Transl.), 2011, vol. 2011, no. 6, pp. 499–508.

Roshchin, V.E., Gamov, P.A., Roshchin, A.V., and Salikhov, S.P., The electronic theory of reduction and the extraction of metals from ore, Steel Transl., 2019, vol. 49, no. 5, pp. 319–327.

Roshchin, V.E. and Roshchin, A.V., Electron mechanism of reduction processes in blast and ferroalloy furnaces, CIS Iron Steel Rev., 2019, vol. 17, pp. 14–24.

Roshchin, V.E., Roshchin, A.V., Gamov, P.A., and Bil’genov, A.S., Electron and mass transfer during solid carbon reduction of metals in solid complex oxides, Russ. Metall. (Engl. Transl.), 2020, vol. 2020, no. 1, pp. 50–59.

Roshchin, V.E. and Roshchin, A.V., Electronic processes at reduction and extraction of metals from ores, Elektrometallurgiya, 2020, no. 1, pp. 14–24.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by O. Polyakov

About this article

Cite this article

Smirnov, K.I., Gamov, P.A. & Roshchin, V.E. Propagation of Solid-Phase Iron Reduction in a Layer of Ilmenite Concentrate. Steel Transl. 50, 146–150 (2020). https://doi.org/10.3103/S0967091220030092

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091220030092