Abstract

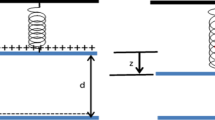

We describe a nondestructive technique for automated analysis of deflection of substrate-mounted membrane structures, which are a key element of devices based on microelectromechanical systems (MEMS devices). The technique includes analysis of substrates with an optical profiler operating in a specialized mode and mathematical processing of measurement results. The technique allows determining the magnitude and sign of deflection of membrane structures for each measurement area. The procedure results in grading the value of deflection and detecting the following types of the state of membrane structures, which are important for assessing the yield and reliability of MEMS devices based on these structures: separation or rupture of the structure, its significant deflection, its slight deflection, and lack of a deflection. All results are displayed in map format on the surface of a substrate with membrane structures with the ability to access more detailed data. The developed technique makes it possible to localize regions with a maximum, predetermined, and low yield of suitable crystals of MEMS devices, as well as flawed regions over the entire substrate surface. The use of the technique significantly increases the accuracy and reduces the measurement time for estimating the yield of suitable membrane structures, and also makes it possible to adjust the process route so as to increase the yield of suitable crystals of MEMS devices.

Similar content being viewed by others

REFERENCES

Bannikov, E.V., The use of PSP in industry, in International Scientific Review of the Problems and Prospects of Modern Science and Education, 2019, pp. 25–28.

Djuzhev, N.A., Gusev, E.E., Dedkova, A.A., and Makhiboroda, M.A., Non-destructive method of surface mapping to improve accuracy of mechanical stresses measurements, IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 289(1), p. 012007. https://doi.org/10.1088/1757-899X/289/1/012007

Djuzhev, N.A., Dedkova, A.A., Gusev, E.E., Makhiboroda, M.A., and Glagolev, P.Y., Non-contact technique for determining the mechanical stress in thin films on wafers by profiler, IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 189(1), p. 012019. https://doi.org/10.1088/1757-899X/189/1/012019

Kireev, V.Yu., Vvedenie v teoriyu mikroelektroniki i nanotekhnologii (Introduction to Microelectronics and Nanotechnology), Moscow: FSUE TsNI-IKhM, 2008.

Djuzhev, N.A., Makhiboroda, M.A., Preobrazhensky, R.Y., Demin, G.D., Gusev, E.E., and Dedkova, A.A., Development and study of a conceptual model of an X-ray source with a field emission cathode, J. Surf. Invest., 2017, vol. 11(2), pp. 443–448. https://doi.org/10.1134/S1027451017020239

Gusev, E.E., Borisova, A.V., Dedkova, A.A., Salnikov, A.A., and Kireev, V.Yu., The effect of ion beam etching on mechanical strength multilayer aluminum membranes, in Proc. 2019 IEEE Conf. Russ. Young Res. Electr. Electron. Eng., ElConRus, 2019, vol. 8657243, pp. 1990–1994. https://doi.org/10.1109/EIConRus.2019.8657243

Zhao, F., Nonlinear solutions for circular membranes and thin plates, in Proc.Model. Signal Process. Control Smart Struct., 2008, vol. 6926, p. 69260W. https://doi.org/10.1117/12.775511

Plaut, R.H., Linearly elastic annular and circular membranes under radial, transverse, and torsional loading. Part I: large unwrinkled axisymmetric deformations, Acta Mech., 2009, vol. 202, pp. 79–99. https://doi.org/10.1007/s00707-008-0037-3

Neggers, J., Hoenagels, J.P.M., Hild, F., Roux, S., and Geers, M.G.D., Direct stress-strain measurements from bulged membranes using topography image correlation, Exp. Mech., 2014, vol. 54, no. 5, pp. 717–727. https://doi.org/10.1007/s11340-013-9832-4

Bespalov, V.A., Vasil’ev, I.A., Djuzhev, N.A., Mazurkin, N.S., Novikov, D.V., and Popkov, A.F., Modeling primary membrane-type gas-flow-rate transducer, Izv. Vyssh. Uchebn. Zaved. Elektron., 2014, no. 3 (107), pp. 50–56.

Dyuzhev, N.A., Gusev, E.E., Gryazneva, T.A., Dedkova, A.A., Dronova, D.A., Kireev, V.Y., Kirilenko, E.P., Migunov, D.M., Novikov, D.V., Patyukov, N.N., Presnukhina, A.A., Bakun, A.D., and Ermakov, D.S., Fabrication and study of parameters and properties of nanostructured membranes for MEMS devices, Nanotechnol. Russ., 2017, vol. 12, nos. 7–8, pp. 426–437. https://doi.org/10.1134/S1995078017040073

Djuzhev, N.A., Gusev, E.E., Dedkova, A.A., and Patiukov, N.N., Determination of mechanical stress in the silicon nitride films with a scanning electron microscope, in Proc. SPIE Int. Soc. Opt. Eng., 2016, p. 1022428. https://doi.org/10.1117/12.2250118

Muruganandam, D., Influence of post weld heat treatment in friction stir welding of AA6061 and AZ61 alloy, Russ. J. Nondestr. Test., 2018, vol. 54, no. 4, pp. 294–301. https://doi.org/10.1134/s1061830918040095

Volchkov, S.O., Dukhan, A.E., Dukhan, E.I., and Kurlyandskaya, G.V., Computer-aided inspection center for magnetoimpedance spectroscopy, Russ. J. Nondestr. Test., 2016, vol. 52, no. 11, pp. 647–652. https://doi.org/10.1134/s1061830916110097

Rudnitsky, V.A., Kren, A.P., and Lantsman, G.A., Determining yield strength of metals by microindentation with a spherical tip, Russ. J. Nondestr. Test., 2019, vol. 55, no. 2, pp. 162–168. https://doi.org/10.1134/S1061830919020098

Donati, S. and Martini, G., 3D profilometry with a self-mixing interferometer: analysis of the speckle error, IEEE Photonics Technol. Lett., 2019, vol. 31, no. 7, pp. 545–548. https://doi.org/10.1109/LPT.2019.2901274

Vairavan, R., Ong, N.R., Sauli, Z., Kirtsaeng, S., Sakuntasathien, S., Shahimin, M.M., Alcain, J.B., Lai, S.L., Paitong, P., and Retnasamy, V., 3D silicon breast surface mapping via structured light profilometry, AIP Conf. Proc., 2017, vol. 1885, no. 1, p. 020252. https://doi.org/10.1063/1.5002446

Bazulin, A.E. and Bazulin, E.G., Application of antenna arrays and organosilicon polymers as an immersion medium for ultrasonic testing of objects with rough surfaces, Russ. J. Nondestr. Test., 2014, vol. 50, no. 7, pp. 377–384. https://doi.org/10.1134/s106183091407002x

Panjan, P., Cekada, M., Panjan, M., Curkovic, L., and Paskvale, S., Surface density of growth defects in different PVD hard coatings prepared by sputtering, Vacuum, 2012, vol. 86, no. 6, pp. 794–798. https://doi.org/10.1016/j.vacuum.2011.07.013

Kovalevskaya, Z.G., Uvarkin, P.V., and Tolmachev, A.I., Some features of the formation of the surface microrelief of steel under ultrasonic finishing treatment, Russ. J. Nondestr. Test., 2012, vol. 48, no. 3, pp. 153–158. https://doi.org/10.1134/s1061830912030047

Osipov, S.P., Usachev, E.Y., Chakhlov, S.V., Shchetinkin, S.A., and Osipov, O.S., Specific features of material recognition by the multi-energy X-Ray method, Russ. J. Nondestr. Test., 2019, vol. 55, no. 4, pp. 308–321. https://doi.org/10.1134/s1061830919040119

Ivina, N.F., Balabaev, S.M., and Tagil’tsev, A.A., Analysis of natural vibrations of round flexing membrane-type piezoelectric transducers with an arbitrary dimension ratio, Russ. J. Nondestr. Test., 2003, vol. 39, no. 8, pp. 589–595.

Vladimirov, A.P. and Kapustin, D.S., Comparative Analysis of Dynamic and Holographic Interferometry Methods with Reference to Deformations of a Membrane, Russ. J. Nondestr. Test., 2004, vol. 40, no. 1, pp. 61–65.

Jiang, C., Kilcullen, P., Liu, X., Ozaki, T., and Liang, J., Three-dimensional structured light profilometry using a bandwidth-limited projector, Proc. SPIE Int. Soc. Opt. Eng., 2019, vol. 109320, p. 109320K. https://doi.org/10.1117/12.2510145

Mao, C-L., Lu, R-S., Dong, J-T., and Zhang, Y-Z., Overview of the 3D profilometry of phase shifting fringe projection, Jiliang Xuebao/Acta Metrol.Sinica, 2018, vol. 39, no. 5, pp. 628–640. https://doi.org/10.3969/j.issn.1000-1158.2018.05.07

Rhee, H.S., Kim, I.R., Jeong, J.H., Son, N.K., Hong, H.B., Cho, S.I., Park, Y.M., Kim, D.W., Choi, Y.K., Ahn, J.H., Kang, S.G., Yeo, K.H., Kim, J.T., Lee, E.C., Youn, J.M., and Yoon, J.S., 8LPP logic platform technology for cost-effective high volume manufacturing, in Symp.VLSI Technol., 2018, pp. 217–218. https://doi.org/10.1109/VLSIT.2018.8510673

Lanzillo, N.A., Motoyama, K., Hook, T., and Clevenger, L., Impact of line and via resistance on device performance at the 5nm gate all around node and beyond, in IEEE Int. Interconnect Technol. Conf., 2018, vol. 8430294, pp. 70–72. https://doi.org/10.1109/IITC.2018.8430294

Bae, G., Bhuwalka, K.K., Lee, S-H., Song, M.-G., Jeon, T-S., Kim, C., Kim, W., Park, J., Kim, S., Kwon, U., Jeon, J., Nam, K-J., Lee, S., Lian, S., Seo, K-I., Lee, S-G., Park, J.H., Heo, Y-C., Rodder, M.S., Kittl, J.A., Kim, Y., Hwang, K., Kim, D-W., Liang, M-S., and Jung, E.S., A novel tensile Si (n) and compressive SiGe (p) dual-channel CMOS FinFET co-integration scheme for 5nm logic applications and beyond, Tech. Dig.—Int. Electron Devices Meet., 2017, vol. 7838496, pp. 28.1.1–28.1.4. https://doi.org/10.1109/IEDM.2016.7838496

Ming, L., Kyoung, H.Y., Sung, D.S., Yun, Y.Y., Kim, D-W., Tae, Y.C., Kyung, S.O., and Lee,W-S., Sub-10 nm gate all-around CMOS nanowire transistors on bulk Si substrate, Dig. Tech. Pap.—Symp. VLSI Technol., 2009, vol. 5200646, pp. 94–95.

Braun, T., Becker, K.-F., Voges, S., Bauer, J., Kahle, R., Bader, V., Thomas, T., Aschenbrenner, R., and Lang, K.-D., 2418 Fan-out panel level packing, in Proc. Electron. Compon. Technol. Conf., 2014, vol. 6897401, pp. 940–946. https://doi.org/10.1109/ECTC.2014.6897401

Koitzsch, M., Lewke, D., Schellenberger, M., Pfitzner, L., Ryssel, H., and Zühlke, H-U., Enhancements in resizing single crystalline silicon wafers up to 450 mm by using thermal laser separation, in ASMC (Adv. Semicond. Manuf. Conf.) Proc., 2012., vol. 6212923, pp. 336–341. https://doi.org/10.1109/ASMC.2012.6212923

Yang, Y. and Kushner, M.J., 450 mm dual frequency capacitively coupled plasma sources: Conventional, graded, and segmented electrodes, J. Appl. Phys., 2010, vol. 108, no. 11, pp. 113306. https://doi.org/10.1063/1.3517104

Fischer, A., Kissinger, G., Load induced stresses and plastic deformation in 450 mm silicon wafers, Appl. Phys. Lett., 2007, vol. 91, no. 11, p. 111911. https://doi.org/10.1063/1.2784964

Pettinato, J.S. and Pillai, D., Technology decisions to minimize 450-mm wafer size transition risk, IEEE Trans. Semicond. Manuf., 2005, vol. 18, no. 4, pp. 501–509. https://doi.org/10.1109/TSM.2005.858471

Ge, M., Zhu, H., Huang, C., Liu, A., and Bi, W., Investigation on critical crack-free cutting depth for single crystal silicon slicing with fixed abrasive wire saw based on the scratching machining experiments, Mater. Sci. Semicond. Process., 2018, vol. 74, pp. 261–266. https://doi.org/10.1016/j.mssp.2017.10.027

Dedkova, A.A. and Dyuzhev, N.A., Data processing program for a series of measurements of membrane structures to determine their deflection and qualitative features. Computer program certificate no. 2019663188.

ACKNOWLEDGMENTS

The authors are grateful to the leading engineer of the Shared Use Center for Microsystems and Electronic Component Base of MIET V.Yu. Kireev for discussing the materials presented in this article and useful comments made.

Funding

This work was performed using the equipment of MIET’s SUC “Microsystems and Electronic Component Base” with the support of the Ministry of Science and Higher Education of the Russian Federation, agreement 075-15-2019-1650, unique project no. RFMEFI59419X0018.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Potapchouck

Rights and permissions

About this article

Cite this article

Dedkova, A.A., Dyuzhev, N.A., Gusev, E.E. et al. Fast Nondestructive Technique for Analyzing Deflection of Membranes Located on the Substrate. Russ J Nondestruct Test 56, 452–459 (2020). https://doi.org/10.1134/S1061830920050046

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830920050046