Abstract

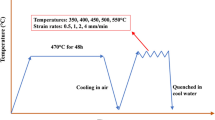

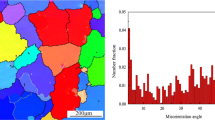

The hot compression tests for Mo–3 vol.%Al2O3 alloys were conducted on a Gleeble-1500D thermo-mechanical simulator in the temperatures range of 1000–1300 °C and strain rates range of 0.005–1 s−1. The hot deformation behavior, mechanism associated with microstructure evolution of Mo–3 vol.%Al2O3 alloys was investigated by electron backscattering diffraction analysis. Three types of stress–strain curves were analyzed by quantifying the work hardening rate. The deformation mechanism at 1000–1300 °C mainly included the plastic deformation of Mo–3 vol.%Al2O3 alloy, as well as the dynamic recovery and recrystallization of Mo matrix. The modified Arrhenius, Modified Johnson–Cook and modified Zerilli–Armstrong constitutive equations were established and evaluated by the correlation coefficient (Rc) and average absolute relative error (\({\bar{\text{e}}}\)). The flow stress of Mo–3 vol.%Al2O3 alloys could be well predicted by those three constitutive models, but modified Arrhenius constitutive model had a higher predicated accuracy.

Graphic Abstract

The hot deformation behavior, mechanism associated with microstructure evolution of Mo–3 vol.% Al2O3 alloys has been investigated by EBSD analysis. Three types of stress–strain curves were analyzed by quantifying the work hardening rate. The deformation mechanism at 1000–1300 °C mainly included the plastic deformation of Mo–3 vol.% Al2O3 alloy, as well as the dynamic recovery and recrystallization of Mo matrix. Moreover, modified Arrhenius constitutive model had a higher predicated accuracy for Mo–3 vol.% Al2O3 alloys than modified JC and modified ZA constitutive models.

Similar content being viewed by others

References

G.-J. Zhang, G. Liu, Y.-J. Sun, F. Jiang, L. Wang, R. Wang, J. Sun, Int. J. Refract. Met. Hard Mater. 27, 173–176 (2009)

J.H. Perepezko, Science 326, 1068–1069 (2009)

X. Zhao, Z. Ye, Surf. Coat. Technol. 228, S266–S270 (2013)

S. Majumdar, S. Raveendra, I. Samajdar, P. Bhargava, I. Sharma, Acta Mater. 57, 4158–4168 (2009)

L. Xu, S. Wei, J. Li, G. Zhang, B. Dai, Int. J. Refract. Met. Hard Mater. 30, 208–212 (2012)

L. Xu, S. Wei, D. Zhang, Y. Li, G. Zhang, J. Li, Int. J. Refract. Met. Hard Mater. 41, 483–488 (2013)

Y. Zhou, Y. Gao, S. Wei, K. Pan, Y. Hu, Int. J. Refract Metal Hard Mater. 54, 186–195 (2016)

A. Chaudhuri, A. Sarkar, S. Suwas, Int. J. Refract. Met. Hard Mater. 73, 168–182 (2018)

G. Liu, G. Zhang, F. Jiang, X. Ding, Y. Sun, J. Sun, E. Ma, Nat. Mater. 12, 344–350 (2013)

M. Xiao, F. Li, H. Xie, Y. Wang, Mater. Des. 34, 112–119 (2012)

Y. Wang, J. Peng, L. Zhong, F. Pan, J. Alloy Compd. 681, 455–470 (2016)

B. Meng, M. Wan, X. Wu, Y. Zhou, C. Chang, Int. J. Refract. Met. Hard Mater. 45, 41–47 (2014)

A. Chaudhuri, A.N. Behera, A. Sarkar, R. Kapoor, R.K. Ray, S. Suwas, Acta Mater. 164, 153–164 (2019)

P. Follansbee, U. Kocks, Acta Metall. 36, 81–93 (1988)

C.M. Sellars, W. McTegart, Acta Metall. 14, 1136–1138 (1966)

Y. Lin, L.-T. Li, Y.-X. Fu, Y.-Q. Jiang, J. Mater. Sci. 47, 1306–1318 (2012)

R.-X. Chai, C. Guo, L. Yu, Mater. Sci. Eng. A 534, 101–110 (2012)

D. Samantaray, S. Mandal, U. Borah, A. Bhaduri, P. Sivaprasad, Mater. Sci. Eng. A 526, 1–6 (2009)

F.J. Zerilli, R.W. Armstrong, J. Appl. Phys. 61, 1816–1825 (1987)

J. Wang, G. Zhao, L. Chen, J. Li, Mater. Des. 90, 91–100 (2016)

S. Zhou, K. Deng, J. Li, K. Nie, F. Xu, H. Zhou, J. Fan, Mater. Des. 64, 177–184 (2014)

C. Cui, Y. Gao, S. Wei, G. Zhang, Y. Zhou, X. Zhu, J. Alloy Compd. 716, 321–329 (2017)

Y. Yan, L. Geng, A. Li, Mater. Sci. Eng. A 448, 315–325 (2007)

H. Johansen-Berg, T.E. Behrens, Diffusion MRI: from Quantitative Measurement to in vivo Neuroanatomy (Academic Press, Cambridge, 2013)

R. Liang, A.S. Khan, Int. J. Plast. 15, 963–980 (1999)

Acknowledgements

This work was funded by the Key-Area Research and Development Program of GuangDong Province (2019B010942001), the Guangxi Innovation Driven Development Project (GUIKEAA18242001), the Fundamental Research Funds for the Central Universities of China (xzy012019001, xtr0118008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yao, L., Gao, Y. & Xu, L. Hot Compression Mechanism and Comparative Study on Constitutive Models of Mo–3 vol%Al2O3 Alloys. Met. Mater. Int. 27, 5335–5345 (2021). https://doi.org/10.1007/s12540-020-00831-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00831-5