Nanoscale Mapping of Heterogeneous Strain and Defects in Individual Magnetic Nanocrystals

Abstract

:1. Introduction

2. Discussion and Conclusions

3. Materials and Methods

3.1. Sample Growth

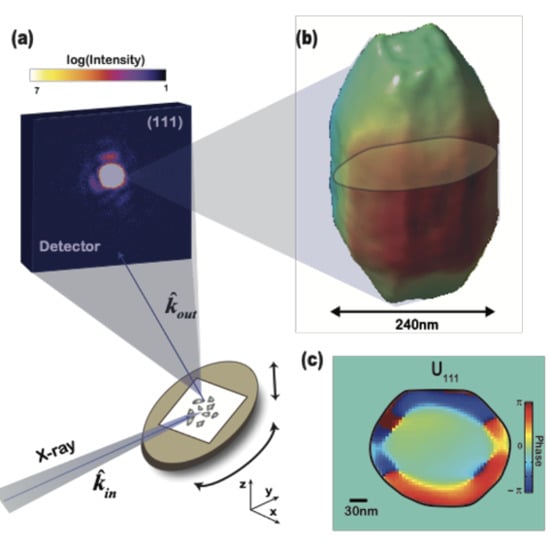

3.2. CXD Experiments and BCDI Data Reconstructions

3.3. Classical Potential Simulations

3.4. Landau–Lifshitz–Gilbert (LLG) Simulation

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| BCDI | Bragg coherent X-ray diffractive imaging |

| CXD | Coherent X-ray diffraction |

| SEM | Scanning electron microscopy |

| XRD | X-ray diffraction |

| NP | Nanoparticle |

| EF-TEM | Energy-filtered transmission electron microscopy |

| HR-TEM | High-resolution transmission electron microscopy |

| PRTF | Phase retrieval transfer function |

References

- Golosovsky, I.; Salazar-Alvarez, G.; López-Ortega, A.; González, M.; Sort, J.; Estrader, M.; Surinach, S.; Baró, M.; Nogués, J. Magnetic proximity effect features in antiferromagnetic/ferrimagnetic core-shell nanoparticles. Phys. Rev. Lett. 2009, 102, 247201. [Google Scholar] [CrossRef] [Green Version]

- Zeng, H.; Li, J.; Wang, Z.; Liu, J.; Sun, S. Bimagnetic core/shell FePt/Fe3O4 nanoparticles. Nano Lett. 2004, 4, 187–190. [Google Scholar] [CrossRef]

- Estrader, M.; López-Ortega, A.; Estradé, S.; Golosovsky, I.; Salazar-Alvarez, G.; Vasilakaki, M.; Trohidou, K.; Varela, M.; Stanley, D.; Sinko, M.; et al. Robust antiferromagnetic coupling in hard-soft bi-magnetic core/shell nanoparticles. Nat. Commun. 2013, 4, 2960. [Google Scholar] [CrossRef] [PubMed]

- Dormann, J.; Fiorani, D. Magnetic Properties of Fine Particles; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Winkler, E.; Zysler, R.; Mansilla, M.V.; Fiorani, D. Surface anisotropy effects in NiO nanoparticles. Phys. Rev. B 2005, 72, 132409. [Google Scholar] [CrossRef]

- Leslie-Pelecky, D.; Rieke, R. Magnetic properties of nanostructured materials. Chem. Mater. 1996, 8, 1770–1783. [Google Scholar] [CrossRef]

- Manna, P.; Yusuf, S.; Basu, M.; Pal, T. The magnetic proximity effect in a ferrimagnetic Fe3O4 core/ferrimagnetic γ-Mn2O3 shell nanoparticle system. J. Phys. Condens. Matter 2011, 23, 506004. [Google Scholar] [CrossRef]

- Hu, Y.; Wu, G.Z.; Liu, Y.; Du, A. Field-induced transitions from negative to positive exchange bias in nanoparticles with inverted ferromagnetic-antiferromagnetic core-shell morphology. J. Appl. Phys. 2012, 111, 053904. [Google Scholar] [CrossRef]

- Nogués, J.; Sort, J.; Langlais, V.; Skumryev, V.; Surinach, S.; Munoz, J.; Baró, M. Exchange bias in nanostructures. Phys. Rep. 2005, 422, 65–117. [Google Scholar] [CrossRef]

- Skumryev, V.; Stoyanov, S.; Zhang, Y.; Hadjipanayis, G.; Givord, D.; Nogues, J. Beating the superparamagnetic limit with exchange bias. Nature 2003, 423, 850–853. [Google Scholar] [CrossRef]

- Schuller, I.K.; Kim, S.; Leighton, C. Magnetic superlattices and multilayers. J. Magn. Magn. Mater. 1999, 200, 571–582. [Google Scholar] [CrossRef]

- Nogués, J.; Lederman, D.; Moran, T.; Schuller, I.K. Positive Exchange Bias in Fe F 2-Fe Bilayers. Phys. Rev. Lett. 1996, 76, 4624. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moser, A.; Berger, A.; Margulies, D.T.; Fullerton, E.E. Magnetic tuning of biquadratic exchange coupling in magnetic thin films. Phys. Rev. Lett. 2003, 91, 097203. [Google Scholar] [CrossRef] [PubMed]

- Granitzer, P.; Rumpf, K.; Krenn, H. Ferromagnetic nanostructures incorporated in quasi-one-dimensional porous silicon channels suitable for magnetic sensor applications. J. Nanomater. 2006, 2006, 18125. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Sanchez, F.; Szambolics, H.; Mihai, A.; Vila, L.; Marty, A.; Attané, J.P.; Toussaint, J.C.; Buda-Prejbeanu, L. Effect of crystalline defects on domain wall motion under field and current in nanowires with perpendicular magnetization. Phys. Rev. B 2010, 81, 134408. [Google Scholar] [CrossRef]

- Singh, M.K.; Agarwal, A.; Swarnkar, R.K.; Gopal, R.; Kotnala, R. Magnetic Properties of Ni/NiO Core–Shell Nanoparticles Synthesized by Nanosecond Laser Irradiance of Water Suspended Ni Particles. Sci. Adv. Mater. 2012, 4, 532–536. [Google Scholar] [CrossRef]

- Jayakumar, O.; Tyagi, A. Synthesis and characterisation of dispersible Ni@ NiO core shell magnetic nanoparticles by polyol method. Int. J. Nanotechnol. 2010, 7, 852–860. [Google Scholar] [CrossRef]

- D’Addato, S.; Grillo, V.; Altieri, S.; Frabboni, S.; Valeri, S. Assembly and structure of Ni/NiO core-shell nanoparticles. Appl. Surf. Sci. 2012, 260, 13–16. [Google Scholar] [CrossRef]

- Yuan, C.; Zhang, Q.; Luo, X.; Zhang, Z. Formation and strain distribution of Ni/NiO core/shell magnetic nanoparticles fabricated by pulsed laser deposition. Sci. China Phys. Mechan. Astron. 2011, 54, 1254–1257. [Google Scholar] [CrossRef]

- Chen, B.; Lutker, K.; Raju, S.V.; Yan, J.; Kanitpanyacharoen, W.; Lei, J.; Yang, S.; Wenk, H.R.; Mao, H.K.; Williams, Q. Texture of nanocrystalline nickel: Probing the lower size limit of dislocation activity. Science 2012, 338, 1448–1451. [Google Scholar] [CrossRef]

- Patel, J.; Authier, A. X- ray topography of defects produced after heat treatment of dislocation- free silicon containing oxygen. J. Appl. Phys. 1975, 46, 118–125. [Google Scholar] [CrossRef]

- Hÿtch, M.J.; Putaux, J.L.; Pénisson, J.M. Measurement of the displacement field of dislocations to 0.03 Å by electron microscopy. Nature 2003, 423, 270–273. [Google Scholar] [CrossRef] [PubMed]

- Bilderback, D.H.; Elleaume, P.; Weckert, E. Review of third and next generation synchrotron light sources. J. Phys. B At. Mol. Opt. Phys. 2005, 38, S773. [Google Scholar] [CrossRef]

- Fohtung, E.; Kim, J.W.; Chan, K.T.; Harder, R.; Fullerton, E.E.; Shpyrko, O.G. Probing the three-dimensional strain inhomogeneity and equilibrium elastic properties of single crystal Ni nanowires. Appl. Phys. Lett. 2012, 101, 033107. [Google Scholar] [CrossRef] [Green Version]

- Watari, M.; McKendry, R.A.; Vögtli, M.; Aeppli, G.; Soh, Y.A.; Shi, X.; Xiong, G.; Huang, X.; Harder, R.; Robinson, I.K. Differential stress induced by thiol adsorption on facetted nanocrystals. Nat. Mater. 2011, 10, 862–866. [Google Scholar] [CrossRef] [Green Version]

- Harder, R.; Liang, M.; Sun, Y.; Xia, Y.; Robinson, I. Imaging of complex density in silver nanocubes by coherent x-ray diffraction. New J. Phys. 2010, 12, 035019. [Google Scholar] [CrossRef]

- Robinson, I.; Harder, R. Coherent X-ray diffraction imaging of strain at the nanoscale. Nat. Mater. 2009, 8, 291–298. [Google Scholar] [CrossRef]

- Minkevich, A.; Fohtung, E.; Slobodskyy, T.; Riotte, M.; Grigoriev, D.; Schmidbauer, M.; Irvine, A.; Novák, V.; Holỳ, V.; Baumbach, T. Selective coherent x-ray diffractive imaging of displacement fields in (Ga, Mn) As/GaAs periodic wires. Phys. Rev. B 2011, 84, 054113. [Google Scholar] [CrossRef] [Green Version]

- Harder, R.; Robinson, I.K. Coherent X-Ray Diffraction Imaging of Morphology and Strain in Nanomaterials. JOM 2013, 65, 1202–1207. [Google Scholar] [CrossRef] [Green Version]

- Clark, J.; Beitra, L.; Xiong, G.; Higginbotham, A.; Fritz, D.; Lemke, H.; Zhu, D.; Chollet, M.; Williams, G.; Messerschmidt, M.; et al. Ultrafast Three-Dimensional Imaging of Lattice Dynamics in Individual Gold Nanocrystals. Science 2013, 341, 56–59. [Google Scholar] [CrossRef] [Green Version]

- Chapman, H.N.; Barty, A.; Bogan, M.J.; Boutet, S.; Frank, M.; Hau-Riege, S.P.; Marchesini, S.; Woods, B.W.; Bajt, S.; Benner, W.H.; et al. Femtosecond diffractive imaging with a soft-X-ray free-electron laser. Nat. Phys. 2006, 2, 839–843. [Google Scholar] [CrossRef] [Green Version]

- Pateras, A.; Harder, R.; Cha, W.; Gigax, J.G.; Baldwin, J.K.; Tischler, J.; Xu, R.; Liu, W.; Erdmann, M.J.; Kalt, R.; et al. Combining Laue diffraction with Bragg coherent diffraction imaging at 34-ID-C. arXiv 2020, arXiv:2002.11859. [Google Scholar]

- Li, L.; Xie, Y.; Maxey, E.; Harder, R. Methods for operando coherent X-ray diffraction of battery materials at the Advanced Photon Source. J. Synchrotron Radiat. 2019, 26, 220–229. [Google Scholar] [CrossRef] [PubMed]

- Fienup, J.R. Phase retrieval algorithms: A comparison. Appl. Opt. 1982, 21, 2758–2769. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fienup, J.R. Phase retrieval algorithms: A personal tour. Appl. Opt. 2013, 52, 45–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, C.; Liu, S.; Sheridan, J.T. Iterative phase retrieval algorithms. I: Optimization. Appl. Opt. 2015, 54, 4698–4708. [Google Scholar] [CrossRef] [Green Version]

- Minkevich, A.; Baumbach, T.; Gailhanou, M.; Thomas, O. Applicability of an iterative inversion algorithm to the diffraction patterns from inhomogeneously strained crystals. Phys. Rev. B 2008, 78, 174110. [Google Scholar] [CrossRef]

- Karpov, D.; Liu, Z.; dos Santos Rolo, T.; Harder, R.; Balachandran, P.; Xue, D.; Lookman, T.; Fohtung, E. Three-dimensional imaging of vortex structure in a ferroelectric nanoparticle driven by an electric field. Nat. Commun. 2017, 8, 1–8. [Google Scholar] [CrossRef]

- Liu, Z.; Schold, E.; Karpov, D.; Harder, R.; Lookman, T.; Fohtung, E. Needle-Like Ferroelastic Domains in Individual Ferroelectric Nanoparticles. Adv. Electron. Mater. 2020, 6, 1901300. [Google Scholar] [CrossRef]

- Pateras, A.; Harder, R.; Manna, S.; Kiefer, B.; Sandberg, R.L.; Trugman, S.; Kim, J.W.; de la Venta, J.; Fullerton, E.E.; Shpyrko, O.G.; et al. Room temperature giant magnetostriction in single-crystal nickel nanowires. NPG Asia Mater. 2019, 11, 1–7. [Google Scholar] [CrossRef]

- Ulvestad, A.; Nashed, Y.; Beutier, G.; Verdier, M.; Hruszkewycz, S.; Dupraz, M. Identifying defects with guided algorithms in bragg coherent diffractive imaging. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Karpov, D.; Liu, Z.; Kumar, A.; Kiefer, B.; Harder, R.; Lookman, T.; Fohtung, E. Nanoscale topological defects and improper ferroelectric domains in multiferroic barium hexaferrite nanocrystals. Phys. Rev. B 2019, 100, 054432. [Google Scholar] [CrossRef] [Green Version]

- Kawaguchi, T.; Keller, T.F.; Runge, H.; Gelisio, L.; Seitz, C.; Kim, Y.Y.; Maxey, E.R.; Cha, W.; Ulvestad, A.; Hruszkewycz, S.O.; et al. Gas-Induced Segregation in Pt-Rh Alloy Nanoparticles Observed by In Situ Bragg Coherent Diffraction Imaging. Phys. Rev. Lett. 2019, 123, 246001. [Google Scholar] [CrossRef]

- Robinson, I.; Assefa, T.A.; Cao, Y.; Gu, G.; Harder, R.; Maxey, E.; Dean, M.P. Domain texture of the orthorhombic phase of La2−xBaxCuO4. J. Supercond. Nov. Magn. 2020, 33, 99–106. [Google Scholar] [CrossRef] [Green Version]

- Ulvestad, A.; Cherukara, M.; Harder, R.; Cha, W.; Robinson, I.; Soog, S.; Nelson, S.; Zhu, D.; Stephenson, G.; Heinonen, O.; et al. Bragg coherent diffractive imaging of zinc oxide acoustic phonons at picosecond timescales. Sci. Rep. 2017, 7, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hofmann, F.; Tarleton, E.; Harder, R.J.; Phillips, N.W.; Ma, P.W.; Clark, J.N.; Robinson, I.K.; Abbey, B.; Liu, W.; Beck, C.E. 3D lattice distortions and defect structures in ion-implanted nano-crystals. Sci. Rep. 2017, 7, 45993. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Phillips, N.; Yu, H.; Das, S.; Yang, D.; Mizohata, K.; Liu, W.; Xu, R.; Harder, R.; Hofmann, F. Nanoscale Lattice Strains in Self-ion-implanted Tungsten. Acta Mater. 2020, 195, 219–228. [Google Scholar] [CrossRef]

- Singer, A.; Zhang, M.; Hy, S.; Cela, D.; Fang, C.; Wynn, T.; Qiu, B.; Xia, Y.; Liu, Z.; Ulvestad, A.; et al. Nucleation of dislocations and their dynamics in layered oxide cathode materials during battery charging. Nat. Energy 2018, 3, 641–647. [Google Scholar] [CrossRef]

- Karpov, D.; Fohtung, E. Bragg coherent diffractive imaging of strain at the nanoscale. J. Appl. Phys. 2019, 125, 121101. [Google Scholar] [CrossRef] [Green Version]

- Quiney, H.; Williams, G.; Fohtung, E. Editorial for special issue on coherent diffractive imaging. J. Opt. 2017, 20, 010201. [Google Scholar] [CrossRef] [Green Version]

- Yau, A.; Cha, W.; Kanan, M.W.; Stephenson, G.B.; Ulvestad, A. Bragg coherent diffractive imaging of single-grain defect dynamics in polycrystalline films. Science 2017, 356, 739–742. [Google Scholar] [CrossRef] [Green Version]

- Newton, M.C.; Shi, X.; Wagner, U.; Rau, C. Coherent diffraction imaging of a progressively deformed nanocrystal. Phys. Rev. Mater. 2019, 3, 043803. [Google Scholar] [CrossRef] [Green Version]

- Ulvestad, A.; Singer, A.; Clark, J.N.; Cho, H.M.; Kim, J.W.; Harder, R.; Maser, J.; Meng, Y.S.; Shpyrko, O.G. Topological defect dynamics in operando battery nanoparticles. Science 2015, 356, 1344–1347. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xiong, G.; Moutanabbir, O.; Reiche, M.; Harder, R.; Robinson, I. Coherent X-ray Diffraction Imaging and Characterization of Strain in Silicon-on-Insulator Nanostructures. Adv. Mater. 2014, 26, 7747–7763. [Google Scholar] [CrossRef] [Green Version]

- Cherukara, M.J.; Pokharel, R.; O’Leary, T.S.; Baldwin, J.K.; Maxey, E.; Cha, W.; Maser, J.; Harder, R.J.; Fensin, S.J.; Sandberg, R.L. Three-dimensional X-ray diffraction imaging of dislocations in polycrystalline metals under tensile loading. Nat. Commun. 2018, 9, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Hofmann, F.; Phillips, N.W.; Das, S.; Karamched, P.; Hughes, G.M.; Douglas, J.O.; Cha, W.; Liu, W. Nanoscale imaging of the full strain tensor of specific dislocations extracted from a bulk sample. Phys. Rev. Mater. 2020, 4, 013801. [Google Scholar] [CrossRef] [Green Version]

- Chan, K.T.; Kan, J.J.; Doran, C.; Ouyang, L.; Smith, D.J.; Fullerton, E.E. Oriented growth of single-crystal Ni nanowires onto amorphous SiO2. Nano Lett. 2010, 10, 5070–5075. [Google Scholar] [CrossRef]

- Chan, K.T.; Kan, J.J.; Doran, C.; Ouyang, L.; Smith, D.J.; Fullerton, E.E. Controlled growth behavior of chemical vapor deposited Ni nanostructures. Philos. Mag. 2012, 92, 2173–2186. [Google Scholar] [CrossRef]

- Pfeifer, M.; Williams, G.; Vartanyants, I.; Harder, R.; Robinson, I. Three-dimensional mapping of a deformation field inside a nanocrystal. Nature 2006, 442, 63–66. [Google Scholar] [CrossRef]

- Manna, S.; Kim, J.W.; Lubarda, M.V.; Wingert, J.; Harder, R.; Spada, F.; Lomakin, V.; Shpyrko, O.; Fullerton, E.E. Characterization of strain and its effects on ferromagnetic nickel nanocubes. AIP Adv. 2017, 7, 125025. [Google Scholar] [CrossRef] [Green Version]

- Miao, J.; Sayre, D.; Chapman, H. Phase retrieval from the magnitude of the Fourier transforms of nonperiodic objects. JOSA A 1998, 15, 1662–1669. [Google Scholar] [CrossRef]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering; John Wiley & Sons: New York, NY, USA, 2011; Volume 5. [Google Scholar]

- Landau, L.; Lifshitz, E.; Sykes, J.; Reid, W.; Dill, E. Theory of Elasticity: Volume 7 of Course of Theoretical Physics. Phys. Today 1960, 13, 44. [Google Scholar] [CrossRef]

- Frank, F.; Read, W., Jr. Multiplication processes for slow moving dislocations. Phys. Rev. 1950, 79, 722. [Google Scholar] [CrossRef]

- Kresse, G.; Hafner, J. Ab initio molecular dynamics for open-shell transition metals. Phys. Rev. B 1993, 48, 13115. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169. [Google Scholar] [CrossRef]

- Prieve, D.C.; Russel, W.B. Simplified predictions of Hamaker constants from Lifshitz theory. J. Colloid Interface Sci. 1988, 125, 1–13. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758. [Google Scholar] [CrossRef]

- Wyckoff, R.W.G. Crystal Structures; Interscience Publishers: New York, NY, USA, 1963; Volume 1. [Google Scholar]

- Skrotskii, G.V. The landau-lifshitz equation revisited. Uspekhi Fiz. Nauk 1984, 144, 681. [Google Scholar] [CrossRef]

- Lakshmanan, M. The fascinating world of the Landau–Lifshitz–Gilbert equation: An overview. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2011, 369, 1280–1300. [Google Scholar] [CrossRef] [PubMed]

- Aharoni, A. Introduction to the Theory of Ferromagnetism; Clarendon Press: Oxford, UK, 2000; Volume 109. [Google Scholar]

- D’Addato, S.; Spadaro, M.C.; Luches, P.; Grillo, V.; Frabboni, S.; Valeri, S.; Ferretti, A.; Capetti, E.; Ponti, A. Controlled growth of Ni/NiO core–shell nanoparticles: Structure, morphology and tuning of magnetic properties. Appl. Surf. Sci. 2014, 306, 2–6. [Google Scholar] [CrossRef]

- Lindquist, A.; Feinberg, J.M.; Harrison, R.; Loudon, J.; Newell, A. Domain wall pinning and dislocations: Investigating magnetite deformed under conditions analogous to nature using transmission electron microscopy. J. Geophys. Res. Solid Earth 2015, 120, 1415–1430. [Google Scholar] [CrossRef] [Green Version]

- Fidler, J.; Kirchmayer, H.; Skalicky, P. Pinning of magnetic domain walls at dislocations and precipitates in Co5Sm crystals. Philos. Mag. B 1981, 43, 765–780. [Google Scholar] [CrossRef]

- Chapman, H.N.; Barty, A.; Marchesini, S.; Noy, A.; Hau-Riege, S.P.; Cui, C.; Howells, M.R.; Rosen, R.; He, H.; Spence, J.C.; et al. High-resolution ab initio three-dimensional x-ray diffraction microscopy. JOSA A 2006, 23, 1179–1200. [Google Scholar] [CrossRef] [PubMed]

- Marchesini, S.; Chapman, H.; Barty, A.; Cui, C.; Howells, M.; Spence, J.; Weierstall, U.; Minor, A. Phase aberrations in diffraction microscopy. arXiv 2005, arXiv:0510033. [Google Scholar]

- Baskes, M. Probing the structure of iron at extreme conditions by X-ray absorption near-edge structure calculations. Phys. Rev. B 1992, 46, 2727–2742. [Google Scholar] [CrossRef]

- Zhou, X.; Johnson, R.; Wadley, H. Misfit-energy-increasing dislocations in vapor-deposited CoFe/NiFe multilayers. Phys. Rev. B 2004, 69, 144113. [Google Scholar] [CrossRef] [Green Version]

- Mackay, A.L. A dense non-crystallographic packing of equal spheres. Acta Crystallogr. 1962, 15, 916–918. [Google Scholar] [CrossRef]

- Baletto, F.; Ferrando, R.; Fortunelli, A.; Montalenti, F.; Mottet, C. Crossover among structural motifs in transition and noble-metal clusters. J. Chem. Phys. 2002, 116, 3856. [Google Scholar] [CrossRef]

- Cleveland, C.; Landman, U.; Schaaff, T.; Sha, M. gullin, PW Stephens and RL Whetten. Phys. Rev. Lett. 1997, 79, 1873–1876. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953. [Google Scholar] [CrossRef] [Green Version]

| Dislocation | Dislocation | Source Size | Critical Shear | Stacking Fault | |

|---|---|---|---|---|---|

| ( 0.22 nm) | Type | Stress | Energy | ||

| (i) | 28b | full | 43 nm | = 12.32 GPa | - |

| (ii) | 28b | full | 43 nm | = 12.32 GPa | - |

| (iii) | 27b | full | 42 nm | = 12.16 GPa | - |

| (iv) | 19b | partial | 30 nm | = 11.98 GPa | 1421 mJ/m |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Harder, R.; Liu, Z.; Shpyrko, O.; Fullerton, E.; Kiefer, B.; Fohtung, E. Nanoscale Mapping of Heterogeneous Strain and Defects in Individual Magnetic Nanocrystals. Crystals 2020, 10, 658. https://doi.org/10.3390/cryst10080658

Shi X, Harder R, Liu Z, Shpyrko O, Fullerton E, Kiefer B, Fohtung E. Nanoscale Mapping of Heterogeneous Strain and Defects in Individual Magnetic Nanocrystals. Crystals. 2020; 10(8):658. https://doi.org/10.3390/cryst10080658

Chicago/Turabian StyleShi, Xiaowen, Ross Harder, Zhen Liu, Oleg Shpyrko, Eric Fullerton, Boris Kiefer, and Edwin Fohtung. 2020. "Nanoscale Mapping of Heterogeneous Strain and Defects in Individual Magnetic Nanocrystals" Crystals 10, no. 8: 658. https://doi.org/10.3390/cryst10080658