Abstract—

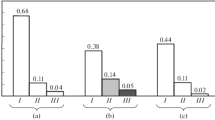

The article addresses factors causing damage—in particular, flow accelerated corrosion wear (FAC) of tube walls—to the evaporator operating in the low-pressure loop of the Ep-258/310/35-15.0/3.14/0.44-540/535/263 (P-132) heat-recovery steam generator used as part of a 795-MW combined-cycle plant. Factors influencing the FAC, namely, improper water chemistry, availability of gas shunts in the steam generator, and high mixture motion velocity in the tubes in combination with the flow path configuration, are described. The damages inflicted to the tubes and their locations in the heat-recovery steam generator low-pressure loop are described. It is shown that gas shunts in the heat-recovery steam generator result in an increased heat absorption and higher velocity of medium in the boundary tubes of low-pressure evaporator tube banks, which intensifies the tube’s wear process. It has been found that the water chemistry used for the Kirishi District Power Plant (DPP) heat-recovery steam generator was not the factor that caused damage to the low-pressure loop tubes. The Kirishi DPP steam generator was compared with other similar large-capacity heat-recovery steam generators. For analyzing the low-pressure evaporator performance indicators, the loop and the processes occurring in it were modeled using the Boiler Designer software. An analysis of the results from comparison of the steam generator design and performance characteristics has shown that it is necessary to change the two-phase mixture motion velocity in the Kirishi DPP steam generator low-pressure loop by modifying the design or operating parameters. The wear of the low-pressure evaporator tube walls was mathematically modeled, the results of which confirm that erosion wear is one of the main factors causing damage to the tubes. The erosion is caused by the intense dynamic effect of two-phase, high-velocity flow jets on the tube walls. General recommendations for decreasing the wear of heat-recovery steam generator tubes are given. It has been determined that the increased wear of tubes in the low-pressure loop of the P-132 steam generator at the Kirishi DPP is caused by a combination of a few factors, such as high velocity of steam–water mixture, availability of bends, and unsatisfactory quality of aligning the tubes at their welding places.

Similar content being viewed by others

Notes

Here and henceforth, the calculation was carried out based on the average heat absorption in the evaporator tube rows.

REFERENCES

D. Moelling, J. Malloy, M. Graham, M. Taylor, and A. Fabricius, “Design factors for avoiding FAC erosion in HRSG low pressure evaporators,” in Power 2013 (Proc. Power Conf., Boston, MA, July 29–Aug. 1, 2013) (American Society of Mechanical Engineers, New York, 2013).

K. A. Pleshanov, K. V. Sterkhov, and M. N. Zaichenko, “Calculating the Dynamic Characteristics of a Boiler-Utilizer at the Novogor’kovskaya Heat and Electric Power Plant,” Power Technology and Engineering 49 (3), 206–211 (2015). https://doi.org/10.1007/s10749-015-0600-8

V. S. Pankov and E. A. Smirnov, “Methods to Combat the Causes of Damage to the Steam-Forming Pipes of the Low-Pressure Circuit in CCPP Heat Recovery Steam Generators,” Power Technology and Engineering 52, 698–702(2019). https://doi.org/10.1007/s10749-019-01017-9

K. A. Pleshanov, K. V. Sterkhov, and P. V. Roslyakov, “Stability of Natural Circulation in a Vertical Boiler-Utilizer Loop with Horizontal Evaporator Pipes during Startup,” Power Technology and Engineering 50 (4), 407–412 (2016). https://doi.org/10.1007/s10749-016-0722-7

W. Kastner, N. Henzel, and B. Stellwag, “Erosion corrosion in power plants—Research work, plant experience and predictive code,” in Proc. 3rd Int. Topical Meeting on Nuclear Power Plant Thermal Hydraulics and Operations, Seoul, Korea, Nov. 14–17, 1988 (Korean Nuclear Society, 1988).

G. V. Tomarov and A. A. Shipkov, “Flow-accelerated corrosion 2016 international conference,” Therm. Eng. 64, 345–349 (2017). https://doi.org/10.1134/S004060151705007X

R. B. Dooley, Guidelines for Controlling Flow-Accelerated Corrosion in Fossil and Combined Cycle Plants: EPRI Final Report (Electric Power Research Inst., 2005).

V. I. Nikitin, I. I. Belyakov, and V. I. Breus, “Damage to steam-generating tubes of low-pressure circuit of drum-type heat recovery boiler used in the PGU-450 combined-cycle unit at Severozapadnaya cogeneration plant,” Therm. Eng. 56, 124–128 (2009).

G. V. Tomarov, Yu. V. Petrov, A. A. Shipkov, O. A. Dovgii, V. N. Semenov, and A. V. Mikhailov, “Making the tube system’s fitting parts of the low-pressure evaporators used in the heat-recovery boilers of combined-cycle units more resistant to erosion-corrosion wear during operation,” Therm. Eng. 55, 154–160 (2008).

J. H. Brunton and M. C. Rochester, “Erosion of solid surfaces by the impact of liquid drops,” Treatise Mater. Sci. Technol. 16, 185–248 (1979).

F. J. Heymann, “High speed impact between a liquid drop and a solid surface,” J. Appl. Phys. 40, 5113–5122 (1969). https://doi.org/10.1063/1.1657361

V. L. Eriksen, Heat Recovery Steam Generator Technology (Woodhead, Duxford, 2017).

N. A. Barton, Erosion in Elbows in Hydrocarbon Production Systems: Review Document (Health & Safety Executive, TUV NEL, Glasgow, 2003).

N. S. Galetskii and A. L. Shvarts, “Features of erosion-corrosion wear in low-pressure evaporators of combined-cycle plant heat-recovery boilers at high void factor values,” Therm. Eng. 60, 917–920 (2013).

C. Daublebsky von Eichhain, “Verbesserung des Betriebes von Kraftwerken Durch Einsatz Eines Simulation Swerkzeugs,” in Application Package for Calculating Heat Power Engineering Equipment “Boiler Designer-2014” (Proc. Int. Sci-Pract. Conf., Moscow, May 26–29,2014) (Torus, Moscow, 2014), pp. 83–96.

N. Yu. Danilin, “Design aspects of eliminating gas shunts in the heating surfaces of vertical heat recovery steam generators,” Energetik, No. 4, 55–56 (2014).

K. A. Pleshanov, E. G. Khlyst, M. N. Zaichenko, and K. V. Sterkhov, “Design of a natural circulation circuit for 85 MW steam boiler,” Therm. Sci. 21, 1503–1513 (2017). https://doi.org/10.2298/TSCI161005320P

K. A. Pleshanov, I. L. Ionkin, P. V. Roslyakov, R. S. Maslov, A. V. Ragutkin, and O. E. Kondrat’eva, “Combustion of bark and wood waste in the fluidized bed boiler,” Therm. Eng. 63, 813–818 (2016). https://doi.org/10.1134/S0040601516110057

K. A. Pleshanov, K. V. Sterkhov, D. A. Khokhlov, and M. N. Zaichenko, “Design recommendations development for vertical heat recovery steam generations with natural circulation,” Euroheat Power (Engl. Ed.) 16, 12–17 (2019).

V. A. Dvoinishnikov and D. A. Khokhlov, “The effect the design solutions adopted for a pilot vortex burner with central admission of medium have on setting up the conditions for stable combustion of air-fuel mixture,” Therm. Eng. 62, 278–285 (2015). https://doi.org/10.1134/S0040601515040011

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Pleshanov, K.A., Maslov, R.S., Pankov, V.S. et al. Investigation into Factors Causing Damage to Low-Pressure Loop Evaporating Tubes of Large-Capacity Heat-Recovery Steam Generators. Therm. Eng. 67, 543–553 (2020). https://doi.org/10.1134/S0040601520080030

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520080030