Abstract

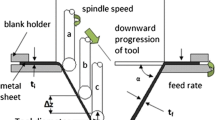

Incremental forming is a flexible and adaptable process with a high scope in future for prototyping sector and batch shop production. It finds application in almost every engineering field. One such prominent field is the research and development. The research and development are often associated with prototyping of a variety of products for evaluating and testing the design and clarifying production costs and issues. In this paper, experimentation of Ti-6Al-4V sheets using SPIF was studied, and the influence of tool feed (f), incremental step depth (d) and spindle speed (s) to the surface roughness (Ra), wall angle (θ), and average thickness (t) were evaluated. The method was carried out using CNC Milling Machine with the help of a fixture and hemispherical end tool. Response surface methodology was used to design the experiments, and ANOVA was performed to find the factor which affected the selected method significantly. Finally, the input parameters were optimized to achieve maximum wall thickness, minimum surface roughness, and maximum wall angle.

Similar content being viewed by others

References

Jong-Jin P, and Yung-Ho Kim. J Mater Process Technol 140 (2003) 447

Kopac J, Kampus Z, J Mater Process Technol 162–163 (2005) 622.

Kim Y H, Park J J, (2002) J Mater Process Technol 130–131 (2002) 42.

Cerro E M, Arana J, Rivero A, Rodrıguez P P, J Mater Process Technol 177 (2006) 404.

TalebAraghi B, Manco G L, Bambach M, Hirt G, CIRP Ann Manuf Technol 58 (2009) 225.

Capece Minutolo F, Durante M, Formisano A, and Langella A, J Mater Process Technol 194 (2007) 145.

Yao Z, Li Y, Yang M, Yuan Q, and Shi P, Adv Mech Eng 9 (2017) 1.

Jadhav S, Basic investigations of the Incremental Sheet Metal Forming Process, Doctorate thesis, University of Dortmund, Germany (2015).

Bhattacharya A, Maneesh K, Venkata Reddy N, Cao J, J Manuf Sci Eng 133 (2011) 0610201.

Hussaina G, Gaoa L, Hayat N, Zirana X, J Mater Process Technol 209 (2009) 4237.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

ajay, C.V. Parameter Optimization in Incremental Forming of Titanium Alloy Material. Trans Indian Inst Met 73, 2403–2413 (2020). https://doi.org/10.1007/s12666-020-02044-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02044-1