Abstract

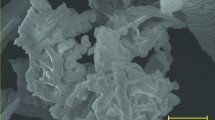

The reinforcement degree offered by silica as a spherical filler with low aspect ratio and high filler–filler interaction was compared with mica as a platelet filler with higher aspect ratio and lower filler–filler interaction. By replacing half of the carbon black with silica or mica in a typical formulation, rubber composites were prepared and their properties were evaluated under two conditions: In the first one, the impact of increasing the amount of a chemical surface modifier, namely silane TESPT (bis triethoxysilylpropyl tetrasulfide), was investigated and in the second one, the increasing amount of a physical modifier namely DPG (diphenyl guanidine) on the performance of the two fillers was explored. The resulting composites were subjected to physico-mechanical experiments including the bound rubber, tensile test, and the dynamic mechanical thermal analysis (DMTA). Results indicated that the greater amount of filler–filler interaction resulting from the higher SiO2 and hydroxyl content in silica has a dominating role over the aspect ratio of mica which is then led to a remarkable difference in their bound rubber. However, the mica-containing composites were capable of competing with silica when the DPG was used. Nevertheless, the compound only containing carbon black with 19.7 MPa of tensile strength and 24.4 kgf/cm of tear strength showed the best mechanical properties among other fillers, and by replacing 30 phr carbon black, these properties decreased approximately 15 ± 3%. Based on DMTA findings, promising data were obtained for the mica-reinforced rubbers with regard to the tire application.

Similar content being viewed by others

References

Liu J, Wang S, Tang Z, Huang J, Guo B, Huang G (2016) Bioinspired engineering of two different types of sacrificial bonds into chemically cross-linked cis-1,4-polyisoprene toward a high-performance elastomer. Macromolecules 49:8593–8604

Kalfus J, Jancar J (2008) Reinforcing mechanisms in amorphous polymer nano-composites. Compos Sci Technol 68:3444–3447

Mittal V (2009) Optimization of polymer nanocomposite properties. Wiley, New York

Kohls DJ, Beaucage G (2002) Rational design of reinforced rubber. Curr Opin Solid State Mater Sci 6:183–194

Gheller J Jr, Ellwanger MV, Oliveira V (2016) Polymer–filler interactions in a tire compound reinforced with silica. J Elastomers Plast 48:217–226

Ahmed NM, El-Sabbagh SH (2014) The influence of kaolin and calcined kaolin on SBR composite properties. Polym Compos 35:570–580

Ahmadi SJ, G’Sell C, Huang Y, Ren N, Mohaddespour A, Hiver JM (2009) Mechanical properties of NBR/clay nanocomposites by using a novel testing system. Compos Sci Technol 69:2566–2572

Lagazzo A, Lenzi S, Botter R, Cirillo P, Demicheli F, Beruto DT (2010) A rheological method for selecting nano-kaolin powder as filler in SBR rubber. Particuology 8:245–250

Liu Q, Zhang Y, Xu H (2008) Properties of vulcanized rubber nanocomposites filled with nanokaolin and precipitated silica. Appl Clay Sci 42:232–237

Guy L, Daudey S, Cochet P, Bomal Y (2009) New insights in the dynamic properties of precipitated silica filled rubber using a new high surface silica. Kautsch Gummi Kunstst 62:383–391

Mouri H, Akutagawa K (1999) Improved tire wet traction through the use of mineral fillers. Rubber Chem Technol 72:960–968

Mark J, Ngai K, Graessley W, Mandelkern L, Samulski E, Wignall G, Koenig J (2004) Physical properties of polymers. Cambridge University, Cambridge

Kamal MM, Clarke J, Ahmad MA (2009) Comparison of properties of natural rubber compounds with various fillers. J Rubber Res 12:27–44

Leblanc JL (2002) Rubber–filler interactions and rheological properties in filled compounds. Prog Polym Sci 27:627–687

Wu W, Tian L (2013) Formulation and morphology of kaolin-filled rubber composites. Appl Clay Sci 80:93–97

Zhang Q, Liu Q, Zhang Y, Cheng H, Lu Y (2012) Silane-grafted silica-covered kaolinite as filler of styrene butadiene rubber. Appl Clay Sci 65:134–138

Kaewsakul W (2013) Silica-reinforced natural rubber for low rolling resistance, energy-saving tires: aspects of mixing, formulation and compatibilization. University of Twente, Enschede

Sattayanurak S, Noordermeer JWM, Sahakaro K, Kaewsakul W, Dierkes WK, Blume A (2019) Silica-reinforced natural rubber: synergistic effects by addition of small amounts of secondary fillers to silica-reinforced natural rubber tire tread compounds. Adv Mater Sci Eng. https://doi.org/10.1155/2019/5891051

Dierkes WK (2005) Economic mixing of silica-rubber compounds: interaction between the chemistry of the silica-silane reaction and the physics of mixing. University of Twente, Enschede

Hewitt N, Ciullo P (2007) Compounding precipitated silica in elastomers: theory and practice. William Andrew, New Jersey

Issel H, Steger L, Bischoff A (2005) Application of dithiophosphates in silica reinforced elastomer compounds. Kautsch Gummi Kunstst 58:529

Vilmin F, Bottero I, Travert A, Malicki N, Gaboriaud F, Trivella A, Thibault-Starzyk F (2014) Reactivity of bis[3-(triethoxysilyl)propyl] tetrasulfide (TESPT) silane coupling agent over hydrated silica: operando IR spectroscopy and chemometrics study. J Phys Chem C 118:4056–4071

Mihara S (2009) Reactive processing of silica-reinforced tire rubber: new insight into the time-and temperature-dependence of silica rubber interaction. University of Twente, Enschede

Ash M (2007) Handbook of fillers, extenders, and diluents, 2nd edn. Synapse Information Resources Inc.

Choi SS, Im SH, Nah C (2012) Influence of solvent swell and bound rubber on wax solubility of carbon black-reinforced NR composite. J Appl Polym Sci 125(S1):E342–E347

Choi SS, Ko E (2014) Novel test method to estimate bound rubber formation of silica-filled solution styrene-butadiene rubber compounds. Polym Test 40:170–177

Berspacher M, Nikiel L, Yang HH, O Farrel PO, Schwartz GA (2002) Flocculation in carbon black filled rubber compounds. Kautsch Gummi Kunstst 55:596–604

Sengloyluan K (2015) Silica-reinforced natural rubber: use of natural rubber grafted with chemical functionalities as compatibilizer. University of Twente, Enschede

Muniandy K, Ismail H, Othman N (2012) Effects of partial replacement of rattan powder by commercial fillers on the properties of natural rubber composites. BioResources 7:4640–4657

Ismail H, Ishak S, Hamid ZAA (2014) Effect of silane coupling agent on the curing, tensile, thermal, and swelling properties of ethylene-propylene-diene monomer rubber (EPDM)/mica composites. J Vinyl Addit Technol 20:116–121

Ezzoddin S, Abbasian A, Aman-Alikhani M, Ganjali ST (2013) The influence of non-carcinogenic petroleum-based process oils on tire compounds’ performance. Iran Polym J 22:697–707

Maghami S (2016) Silica-filled tire tread compounds: an investigation into the viscoelastic properties of the rubber compounds and their relation to tire performance. University of Twente, Enschede

Kashani MR (2009) Aramid-short-fiber reinforced rubber as a tire tread composite. J Appl Polym Sci 113:1355–1363

Hamdan S, Hasihim DMA, Yusop M (2004) Dynamic mechanical thermal analysis (DMTA) of thermoplastic natural rubber (TPNR) barium ferrite (BaFe12O19) composites. ASEAN J Sci Technol Dev 21:69–79

Malas A, Das CK (2012) Carbon black–clay hybrid nanocomposites based upon EPDM elastomer. J Mater Sci 47:2016–2024

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Roshanaei, H., Khodkar, F. & Alimardani, M. Contribution of filler–filler interaction and filler aspect ratio in rubber reinforcement by silica and mica. Iran Polym J 29, 901–909 (2020). https://doi.org/10.1007/s13726-020-00850-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00850-4