Abstract

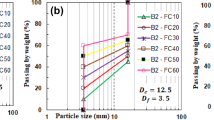

The geo-mechanical behavior of granular materials rigorously depends on their initial packing density, stress level and particle size distribution. Moreover, the behavior of binary granular soil is affected by the quality and quantity of their small particles named the fines content (FC). The contribution mechanism of the FC to the load-bearing structure of the soil at various particle sizes, stress levels and densities is still pending. The present study aimed to use a micromechanical approach to simulate the behavior of binary mixtures with particle size ratios (α) of 2.5 to 7.1 and study the effect of stress level and initial packing density on the stress–strain behavior using discrete element method (DEM). Accordingly, the effect of FC on the internal friction angle, anisotropy parameters, coordination number and coarse–fine (C–F) contacts have been studied. The results indicate that the variation in peak shear strength versus FC is bell-shaped with a minimum for FC of 30% to 40% and this is independent of initial packing density and stress level, but depending on the value of α. The greater particle size ratios (α = 7.1) increase the tendency of fines particles to rotate during biaxial testing, reduced the shear strength in comparison with samples with small particle size ratios (α = 2.5). Exceeding the threshold FC (30–40%) led to formation of stronger force chains among the fines and increased the role of FC on the peak shear strength.

Similar content being viewed by others

Abbreviations

- a c :

-

Anisotropy coefficient of contact normal

- a n :

-

Anisotropy coefficient of normal contact force

- a t :

-

Anisotropy coefficient of tangent contact force

- ε 1 :

-

Axial strain

- C–C :

-

Coarse–coarse

- C–F :

-

Coarse–fine

- P :

-

Confining pressure

- C N :

-

Coordination number

- D :

-

Packing density

- FC :

-

Fines content

- F–F :

-

Fine–Fine

- μ:

-

Friction coefficient between particles

- φ :

-

Internal friction angle

- D c :

-

Maximum diameter of coarse grains

- D f :

-

Minimum diameter of fine grains

- K n :

-

Normal stiffness

- F n :

-

Normal force

- N t :

-

Number of particles

- PSD :

-

Particle size distribution

- α:

-

Particle size ratio

- PFA :

-

Peak friction angle

- δ:

-

Relative tangential surface displacement at the contact

- q :

-

Shear stress

- q/p :

-

Stress ratio

- K S :

-

Tangent stiffness

- ε v :

-

Volumetric strain

- ζ :

-

Relative displacement of particle in the normal direction

References

Abdel-Ghani, M., Petrie, J.G., Seville, J.P.K., Clift, R., Adams, M.J.: Mechanical properties of cohesive particulate solids. Powder Technol. 65, 113–123 (1991)

Abedi, S., Mirghasemi, A.A.: Particle shape consideration in numerical simulation of assemblies of irregularly shaped particles. Particuology 9(4), 387–397 (2011)

Atkinson, J.: The Mechanics of Soils and Foundations, Second Edition. (2011)

Bayesteh, H., Ghasempour, T.: Role of the location and size of soluble particles in themechanical behavior of collapsible granular soil: a DEM simulation. Comput. Part. Mech. 6(3), 327–341 (2018)

Bayesteh, H., Mirghasemi, A.: Procedure to detect the contact of platy cohesive particles in discrete element analysis. Powder Technol. Vol. 244, 75–84 (2013)

Been, K., Jefferies, M.G.: A state parameter for sands. Géotechnique 35(2), 99–112 (1985)

Brandon, T.L., Clough, G.W., Rahardjo, P.P.: Fabrication of silty sand samples for large and small scale tests. Geotech. Test. J. 14(1), 46–55 (1991)

Chang, C.S., Deng, Y.: A particle packing model sand-silt mixtures with the effect of dual-skeleton. Granul. Matter 19, 80 (2017)

Chang, W., Phantachang, T.: Effects of gravel content on shear resistance of gravelly soils. Eng. Geol. 207, 78–90 (2016)

Cho, G.-C., Dodds, J., Santamarina, J.C.: Particle shape effects on packing density, stiffness, and strength: natural and crushed sands. ASCE J. Geotech. Geoenviron. Eng. 132(5), 591–602 (2006)

Choo, H., Burns, S.E.: Shear wave velocity of granular mxtures of silica particles as a function of finer fraction, size ratios and void ratios. Granul. Matter 17, 567–578 (2015)

Cundall, P.A., Strack, O.D.: A discrete numerical model for granular assemblies. Geotechnique 29, 47–65 (1979)

Dai, B., Yang, J., Luo, X.: A numerical analysis of the shear behavior of granular soil with fines. Particuology 21, 160–172 (2015)

De Frias Lopez, R., Ekbland, J., Silfwerbrand, J.: Resilient properties of binary granular mixtures: a numerical investigation. Geocomput. Geotech. 76, 222–233 (2016)

De Frias Lopez, R., Silfwerbrand, J., Jelagin, D., Birgisson, B.: Force transmission and soil fabric of binary granular mixtures. Geotechnique 7(66), 578–583 (2016)

Dias, R.P., Teixeira, J.A., Mota, M.G., Yelshin, A.I.: Particulate binary mixtures: dependence of packing porosity on particle size ratio. Ind. Eng. Res. 43, 7912–7919 (2004)

Dodds, J.A.: The porosity and contact points in multicomponent random sphere packings calculated by a simple statistical geometric model. J. Colloid Interface Sci. 77(2), 317–327 (1980)

Evans, M.D., Zhou, S.: Liquefaction behavior of sand-gravel composites. J. Geotech. Eng. ASCE 121(3), 287–298 (1995)

Georgiannou, V.N.: The responre of sands with additions of particles of various shapes and sizes. Géotechnique 56(9), 639–649 (2006)

Gong, J., Liu, J.: Mechanical transitional behavior of binary mixtures via DEM: effect of differences in contact-type friction coefficients. Comput. Geotech. 85, 1–14 (2016)

Gong, J., Liu, J.: Effect of aspect ratio on triaxial compression of multi-sphere ellipsoid assemblies simulated using a discrete element method. Particuology 32, 49–62 (2017)

Gong, J., Liu, J., Cui, L.: Shear behaviors of granular mixtures of gravel-shaped coarse and spherical fine particles investigated via discrete element method. Powder Technol. 353, 178–194 (2019)

Gong, J., Nie, Z., Zhu, Y., Liang, Z., Wang, X.: Exploring the effects of particle shape and content of fines on the shear behavior of sand-fines mixtures via the DEM. Comput. Geotech. 106, 161–176 (2019)

Gong, J., Wang, X., Li, L., Nie, Z.: DEM study of the effect of fines content on the small-strain stiffness of gap-graded soils. Comput. Geotech. 112, 35–40 (2019)

Hamidi, A., Azini, E., Masoudi, B.: Effect of gradation on the shear strength–dilation behavior of well graded sand–gravel mixtures. Sci. Iran. 19(3), 393–402 (2012)

Huang, T.-T., Huang, A.-B., Kuo, Y.-C., Tsai, M.-D.: A laboratory study on the undrained strength of a silty sands from Central Western Tiwan. Soil Dyn. Earthq. Eng. 24(9), 733–743 (2004)

Khalili, Y., Mahboubi, A.: Discrete simulation and micromechanical analysis of two-dimensional saturated granular media. Particuology 15, 138–150 (2014)

Kokusho, T., Hara, T., Hiraoka, R.: Undrained shear strength of granular soils with different particle gradations. J. Geotech Geoenviron. Eng. 130(6), 621–629 (2004)

Lade, P.V., Liggic, C.D., Yamamuro, J.A.: Effects of non-plastic fines on minimum nad maximum void ratios of sand. Geotech. Test J. 21, 336–347 (1998)

Lade, P.V., Yamamuro, J.A.: Effects of nonplastic on static liquefaction of sands. Can. Geotech. J. 34, 918–928 (1997)

Lamei, M., Mirghasemi, A.A.: A discrete element model for simulating saturated granular soil. Particuology 9(6), 650–658 (2011)

Minh, N.H., Ceng, Y.P., Thornton, C.: Strong force networks in granular mixtures. Granul. Matter 16(1), 69–78 (2014)

Mirghasemi, A., Rothenburg, L., Matyas, E.: Influence of particle shape on engineering properties of assemblies of two-dimensional polygon-shaped particles. Géotechnique 52(3), 209–217 (2002)

Monkul, M.M., Yamamuro, J.A.: Influence of silt size and content on liquefaction behavior of sands. Can. Geotech. J. 48, 931–942 (2011)

Ng, T.T., Zhou, W., Chang, X.L.: Effect of particle shape and fine content on the behavior of binary mixture. J. Eng. Mech. 143, C4016008 (2016)

O’Sullivan, C.: Praticulate Discrete Element Modeling A Geomechanics Perspective. Taylor & Francis, USA (2011)

Ogarko, V., Luding, S.: Equation of state and jamming density for equivalent bi- and polydisperse, smooth, hard sphere systems. J. Chem. Phys. 136, 124508 (2012)

Rahman, M.M., Lo, S.R., Baki, M.A.L.: Equivalent granular state parameter and undrained behavior of sand–fines mixtures. Acta Geotech. 6(4), 183–194 (2011)

Robertson, P.K., Campanella, R.G.: Liquefaction potential of sands using the CPT. ASCE J. Geotech. Eng. 111(3), 384–403 (1985)

Rothenburg, L., Bathurst, R.J.: Analytical study of induced anisotropy in idealized granular materials. Géotechnique 39(4), 601–614 (1989)

Rothenburg, L., Bathurst, R.: Numerical simulation of idealized granular assemblies with plane elliptical particles. Comput. Geotech. 11, 315–329 (1991)

Rothenburg, L., Kruyt, N.: Critical state and evolution of coordination number in simulated granular materials. Int. J. Solids Struct. 41, 5763–5774 (2004)

Rui, R., Van, T.F., Xia, X., Van Eekelen, S., Hu, G., Xia, Y.: Evolution of soil arching: 2D DEM simulations. Comput. Geotech. 73, 109–209 (2016)

Santos, A., Yuste, S.B., López de Haro, M., Ogarko, V.: Equation of state of polydisperse hard-disk mixtures in the high-density regime. Phys. Rev. E 96, 062603 (2017)

Seyedi Hosseininia, E.: A micromechanical study on the stress rotation in granular materials due to fabric evolution. Powder Technol. 283, 462–474 (2015)

Seyedi Hosseininia, E.: Discrete element modeling of inherently anisotropic granular assemblies with polygonal particles. Particuology 10, 542–552 (2012)

Seyedi Hosseininia, E.: Investigating the micromechanical evolutions within inherently anisotropic granular materials using discrete element method. Granul. Matter 14, 483–503 (2012)

Seyedi Hosseininia, E., Mirghasemi, A.A.: Numerical simulation of breakage of two-dimensional polygon-shaped particles using discrete element method. Powder Technol. 166, 100–112 (2006)

Shire, T., OSullivan, C., Hanley, K.J.: The influence of fines content and size-ratio on the micro-scale properties of dense bimodal materials. Granular Matter 18, 52 (2016)

Simoni, A., Houlsby, G.: The direct shear strength and dilatancy of sand–gravel mixtures. Geotech. Geol. Eng. 24, 523–549 (2006)

Thevanayagam, S., Shenthan, T., Mohan, S., Liang, J.: Undrained fragility of clean sands, silty sands and sandy silts. J. Geotech. Geoenviron. 128(10), 849–859 (2002)

Tong, Z., Fu, P., Dafalias, Y.F.: Experimental investigation of shear strength of sands with inherent fabric anisotropy. Acto Geot 9, 257–275 (2014)

Ueda, T., Matsushima, T., Yamada, Y.: Effect of particle size ratio and volume fraction on shear strength of binary granular mixture. Granul. Matter 13(6), 731–742 (2011)

Vahidi-Nia, F., Lashkari, A., Binesh, S.M.: An insight into the mechanical behavior of binary granular soils. Particuology 21, 82–89 (2015)

Vallejo, L.E.: Interpretation of the limits in shear strength in binary granular material-clay mixture. Can. Geotech. J. 38(5), 97–104 (2001)

Wlacek, J., Staslak, M.: Effect of the particle size ratio on the structural properties of granular mixtures with discrete particle size distribution. Granul. Matter 20, 31 (2018)

Wood, F.M., Yamamuro, J.A., Lade, P.V.: Effect of depositional method on the undrained response of silty sand. Can. Geotech. J. 45, 1525–1537 (2008)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vahidi-Nia, F., Bayesteh, H. & Khodaparast, M. Effect of initial packing density, stress level and particle size ratio on the behavior of binary granular material: a micromechanical approach. Granular Matter 22, 68 (2020). https://doi.org/10.1007/s10035-020-01036-8

Received:

Published:

DOI: https://doi.org/10.1007/s10035-020-01036-8