Abstract

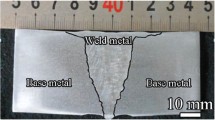

This study investigated the fatigue crack propagation (FCP) behavior of different regions (base metal (BM), heat-affected zone (HAZ) and weld metal (WM)) of dissimilar metal welded joints of L360MS pipeline steel with Inconel 625 welding wire as the filler material. The effect of the microstructure on FCP was discussed. The results indicated that the fatigue crack growth rates (da/dN) for the WM were lower than those for the BM and the HAZ under the same stress ratio. The microstructures of these regions had different characteristics, such as equiaxed austenite, ferrite and pearlite, which could explain the observed differences in properties. For instance, the FCP path revealed that the existence of ductile equiaxed grains and coarse columnar grains caused the WM to have higher fatigue crack growth resistance and a more tortuous crack propagation path than the BM and the HAZ. The microstructure, grain orientation, strain distribution and grain boundaries around the fatigue crack in the HAZ specimens that propagated through the WM and the fusion line were analyzed by electron backscatter diffraction (EBSD). The results showed that the fatigue cracks followed a zigzag path into the HAZ along the high-angle Type II boundary and Type I boundary in the WM.

Graphic Abstract

Similar content being viewed by others

References

Li L Y, Xiao J, Han B, and Wang X L, Int J Pres Ves Pip 179 (2020) 104026.

Zhang L J, Pei Q, and Zhang J X, Mater Des 64 (2014) 462.

Qian X D, Wang Y, Richard Liew J Y, and Zhang M H, Eng Struct 92 (2015) 84.

Wang H T, Wang G Z, Xuan F Z, and Tu S T, Eng Failure Anal 28 (2013) 134.

Thurston K V S, Gludovatz B, Yu Q, Laplanche G, George E P, and Ritchie R O, J Alloys Compd 794 (2019) 525.

Kacar R, and Acarer M, J Mater Process Technol 152 (2004) 91.

Liu H B, Yang S L, Xie C J, Zhang Q, and Cao Y M, J Alloys Compd 741 (2018) 188.

Karolczuk A, Kowalski M, Bański R, and Żok F, Int J Fatigue 48 (2013) 101.

Shang Y B, Shi H J, Wang Z X, and Zhang G D, Mater Des 88 (2015) 598.

Giorgetti V, Santos E A, Marcomini J B, and Sordi V L, Int J Pres Ves Pip 169 (2019) 223.

Kunnathur P Y, Perumal A. V, and Rajasekaran D, Trans Indian Inst Met 71 (2018) 2575.

Ming H, Zhang Z, Wang J, and Han E H, Mater Charact 148 (2019) 100.

Hou J, Peng Q J, Takeda Y, Kuniya J, Shoji T, and Wang J Q, J Mater Sci 45 (2010) 5332.

Öztoprak N, Yeni Ç E, and Kıral B G, Trans Indian Inst Met 72(2) (2019) 511.

Vidyarthy R S, Kulkarni A, and Dwivedi D K, Mater Sci Eng A 695 (2017) 249.

Brayshaw W J, Cooper A J, and Sherry A H, Eng Failure Anal 97 (2019) 820.

Yang J, and Wang L, Eng Fract Mech 192 (2018) 12.

Fan K, Wang G Z, Xuan F Z, and Tu S T, Eng Fract Mech 136 (2015) 279.

Blouin A, Chapuliot S, Marie S, Niclaeys C, and Bergheau J. M, Eng Fract Mech 131 (2014) 58.

Thirugnanam A, Sukumaran K, Raghukandan K, Pillai U T S, and Pai B C, Trans Indian Inst Met 58 (2005) 777.

Yang J, Wang G Z, Xuan F Z, Tu S T, and Liu C J, Mater Des 55 (2014) 542.

Xie Y, Wu Y Q, Burns J, and Zhang J S, Mater Charact 112 (2016) 87.

Rathod D W, Pandey S, Singh P K, and Kumar S, J Nucl Mater 493 (2017) 412.

Ghassen B S, Stéphane C, Arnaud B, Philippe B, and Clémentine J, Procedia Struct Integr 13 (2018) 619.

Wang X F, Shao C D, Liu X, and Lu F G, J Mater Sci Technol 34 (2018) 720.

Du L Y, Wang G Z, Xuan F Z, and Tu S T, Nucl Eng Des 265 (2013) 145.

Velu M., Mater Today Proc 5(5) (2018) 11364.

Kangazian J, and Shamanian M, Mater Charact 155 (2019) 109802.

Dong L J, Peng Q J, Han E H, Ke W, and Wang L, J Mater Sci Technol 34(8) (2018) 1281.

Zhu R L, Wang J Q, Zhang Z M, and Han E H, Corros Sci 120 (2017) 219.

Zhu R L, Wang J Q, Zhang L T, Zhang Z M, and Han E H, Corros Sci 112 (2016) 373.

Dong L J, Peng Q J, Xue H, Han E H, Ke W, and Wang L, Corros Sci 132 (2018) 9.

Huang J Y, Chiang M F, Jeng S L, Huang J S, and Kuo R C, J Nucl Mater 432 (2013) 189.

Yeh T K, Huang G R, Wang M Y, and Tsai C H, Prog nucl Energ 63 (2013) 7.

Cortés R, Rodríguez N K, Ambriz R R, López V H, Ruiz A, and Jaramillo D, Mater Sci Eng A 745 (2019) 20.

Wang B, Lei B B, Wang W, Xu M, and Wang L, Eng Failure Anal 58 (2015) 56.

Jang C, Cho P Y, Kim M, Oh S J, and Yang J S, Mater Des 31 (2010) 1862.

Wang W, Liu T G, Cao X Y, Lu Y H, and Shoji T, Mater Sci Eng A 729 (2018) 331.

Ki H, Kim C.S, Jeon Y.C, and Kwun S I, Mater. Sci. Forum 580-582 (2008) 593.

Huang J Y, Young M C, Jeng S L, Yeh J J, Huang J S, and Kuo R C,Mater Trans 49 (2008) 1667.

Nelson T W, Lippold J C, and Mills M J. Sci Technol Weld Joi 3(5) (2013) 249.

Wang C X, Wang T, Cao L L, and Zhang G J, J Alloys Compd 790 (2019) 563.

Hou J, Peng Q J, Lu Z P, Shoji T, Wang J Q, Han E H, and Ke W, Corros Sci 53 (2011) 1137.

Hou J, Peng Q J, Takeda Y, Kuniya J, and Shoji T, Corros Sci 52 (2010) 3949.

Sarikka T, Ahonen M, Mouginot R, Nevasmaa P, Karjalainen-Roikonen P, Ehrnstén U, and Hänninen H, Int J Pres Ves Pip 145 (2016) 13.

Hong H L, Zhu R L, Zhang Z M, Wang J Q, Han E H, Ke W, and Su M X, Mater Sci Eng A 669 (2016) 279.

Shenoy M M, Kumar R S, and McDowell D L, Int J Fatigue 27 (2005) 113.

Smith R A, Int J Fracture 9(3) (1973) 352.

Yanagimotoa F, Hemmi T, Suzuki Y, Takashim Y, Kawabata T, and Shibanuma K, Acta Mater 177 (2019) 96.

Guan M F, and Yu H. Sci China Technol Sci 56 (2013) 71.

Wert J A, and Huang X, Philos Mag 83 (2003) 969.

Winther G, Acta Mater 51 (2003) 417.

Hu D Y, and Wang R Q, Mater Sci Eng A 515 (2009) 183.

Xiao X P, Yi Z Y, Chen T T, Liu R Q, and Wang H, J Alloys Compd 660 (2016) 178.

Goldsmith N T, Wanhill R J H, and Molent L, Eng Failure Anal 96 (2019) 426.

Ivanova V S, Kunavin S A, and Shanjavskij A A, Proceedings of The 7th International Conference On Fracture (ICF7), Pergamon, Oxford (1989), p 3677.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Y., Wang, B., Xu, Y. et al. Investigation on the Fatigue Crack Propagation Behavior of L360MS Pipeline Steel Welded Joints with Inconel 625 Weld Metal. Trans Indian Inst Met 73, 2387–2402 (2020). https://doi.org/10.1007/s12666-020-02041-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-02041-4