Abstract

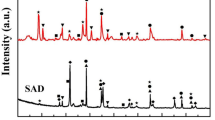

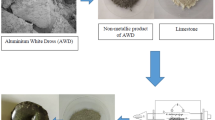

The aim of this work is to produce α-alumina particles from aluminum (Al) dross via leaching–precipitation–calcination processes. In the leaching test, the effects of parameters such as the temperature, NaOH concentration, and time were investigated based on the Taguchi approach. In addition, the effect of the particle size on the Al extraction rate was determined. The Al extraction rate ranged from 78.64% to 93.11% and from 78.35% to 91.99% for ground dross and as-received dross, respectively. In the precipitation test, the pH of the leachate solution was decreased using HCl to remove Al ions as Al hydroxide precipitate. The precipitate was calcined at 1000°C to 1200°C for 270 min. The morphological and polymorphic properties of the products were characterized by scanning electron microscopy, atomic force microscopy, and x-ray diffraction analysis. The experimental findings indicated that the calcination temperature and stabilization time were critical for producing α-alumina particles rather than other polymorphs.

Similar content being viewed by others

References

M. Yoldi, E.G. Fuentes-Ordoñez, S.A. Korili, and A. Gil, Miner. Eng. 140, 105884 (2019).

E.M. Ewais and N.H. Besisa, Mater. Des. 141, 110 (2018).

M.I. Castro, J.A. Robles, D.C. Hernández, J.E. Bocardo, and J.T. Torres, Ceram. Int. 35, 921 (2009).

M.H.A. Aziz, M.H.D. Othman, N.A. Hashim, M.A. Rahman, J. Jaafar, S.K. Hubadillah, and Z.S. Tai, Ceram. Int. 45, 2069 (2019).

H.N. Yoshimura, A.P. Abreu, A.L. Molisani, A.C. De Camargo, J.C.S. Portela, and N.E. Narita, Ceram. Int. 34, 581 (2008).

P. Ramaswamy, S. Ranjit, S. Bhattacharjee, and S.A. Gomes, Mater. Today Proc. 19, 670 (2019).

U. Singh, M.S. Ansari, S.P. Puttewar, and A. Agnihotri, Russ. J. Non-Ferrous Met. 57, 296 (2016).

R. Saravanakumar, K. Ramachandran, L.G. Laly, P.V. Ananthapadmanabhan, and S. Yugeswaran, Waste Manag. 77, 565 (2018).

A.K. Tripathy, S. Mahalik, C.K. Sarangi, B.C. Tripathy, K. Sanjay, and I.N. Bhattacharya, Miner. Eng. 137, 181 (2019).

M. Mahinroosta and A. Allahverdi, J. Environ. Manag. 212, 278 (2018).

L.F. How, A. Islam, M.S. Jaafar, and Y.H. Taufiq-Yap, Waste Biomass Valor. 8, 321 (2017).

Q. Yang, Q. Li, G. Zhang, Q. Shi, and H. Feng, Hydrometallurgy 187, 158 (2019).

T.H. Nguyen, T.T.H. Nguyen, and M.S. Lee, J. Korean Inst. Resour. Recycl. 27, 78 (2018).

B. Dash, B.R. Das, B.C. Tripathy, I.N. Bhattacharya, and S.C. Das, Hydrometallurgy 92, 48 (2008).

P.E. Tsakiridis, P. Oustadakis, and S. Agatzini-Leonardou, J. Environ. Chem. Eng. 1, 23 (2013).

E. David and J. Kopac, J. Hazard. Mater. 209–210, 501 (2012).

A. Meshram, A. Jain, M.D. Rao, and K.K. Singh, J. Mater. Cycles Waste Manag. 21, 984 (2019).

E. Elsarrag, A. Elhoweris, and Y. Alhorr, Energy Sustain. Soc. 7, 9 (2017).

T.T.N. Nguyen, M.S. Lee, and T.H. Nguyen, Processes 6, 29 (2018).

T.T.N. Nguyen and M.S. Lee, Korean J. Met. Mater. 57, 154 (2019).

H. Guo, J. Wang, X. Zhang, F. Zheng, and P. Li, Metall. Mater. Trans. B 49, 2906 (2018).

E.A. EI-Katatny, S.A. Halawy, M.A. Mohamed, and M.I. Zaki, J. Chem. Technol. Biotechnol. 75, 394 (2000).

M. Mahinroosta and A. Allahverdi, Int. Nano Lett. 8, 255 (2018).

B.R. Das, B. Dash, B.C. Tripathy, I.N. Bhattacharya, and S.C. Das, Miner. Eng. 20, 252 (2007).

M.S.R. Sarker, M.Z. Alam, M.R. Qadir, M.A. Gafur, and M. Moniruzzaman, Int. J. Miner. Metall. Mater. 22, 429 (2015).

J.M. Andersson, Linköping University, Ph.D. Thesis (2005), p. 43.

T.T.N. Nguyen, S.J. Song, and M.S. Lee, J. Mater. Res. Technol. 9, 2568 (2020).

M. Erdemoğlu, M. Birinci, T. Uysal, E.P. Tüzer, and T.S. Barry, J. Mater. Sci. 53, 13801 (2018).

E. Taşkin, K. Yildiz, and A. Alp, Min. Metall. Explor. 26, 222 (2009).

T.C. Alex, R. Kumar, S.K. Roy, and S.P. Mehrotra, Hydrometallurgy 144, 99 (2014).

M.G. Ghoniem, T.M. Sami, S.A. El-Reefy, and S.A. Mohamed, Waste Manag. Environ. 180, 29 (2014).

F. Rey-Garcia, Universidade De Santiago De Compostela, Ph.D. Thesis (2012). p. 211.

M. Mahinroosta and A. Allahverdi, J. Clean. Prod. 179, 9 (2018).

A. Niyompan and R. Tipakontitikul, Preparation of β″-Alumina Solid Electrolyte for Electric Car Battery (Ubon Ratchathani: Department of Physics, Faculty of Science, Ubon Ratchathani University, 2009).

W.L. Suchanek and J.M. Garcés, CrystEngComm 12, 2996 (2010).

P.K. Kiyohara, H.S. Santos, A.C.V. Coelho, and P.D.S. Santos, An Acad Bras Cienc 72, 471 (2000).

Acknowledgements

This study was supported by Cukurova University (Project ID: FBA-2019-10123). In addition, the authors would like to thank specialists Ahmet Faruk Yazıcı and Resul Ozdemır in Abdullah Gul University Central Research Facility for SEM and AFM analyses, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Türk, M., Altıner, M., Top, S. et al. Production of Alpha-Alumina from Black Aluminum Dross Using NaOH Leaching Followed by Calcination. JOM 72, 3358–3366 (2020). https://doi.org/10.1007/s11837-020-04281-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04281-7