Abstract

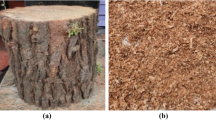

With the high usage of the synthetic fiber, the amount of the waste materials has increased as the degradation process is quite slow and with the burning of the synthetic fibers creates toxic gas and other environmental hazards. Presently natural fibershas many implications like low density, cheap, high specific properties, non-abrasive and less harmful during manufacturing and most importantly the abundance in nature and can be made by planting. Because of which it is giving a good run compare to conventional glass and carbon fibers composites. The glass fiber composite is replaced by natural fiber composites for environmental sustainability. Fiber extracted from plants is renewable and low levels of embodied energy compared to synthetic fibers. This paper deals with comparison of mechanical properties of a hybrid composite (abaca + sisal) and comparing the results with the ABAQUS simulation results. This hybrid composite consists of three layers with top and bottom layers of sisal fibers and the middle layer is made up of abaca fiber. These hybrid composites (sisal + abaca) were fabricated with different orientations (0 °, 45 °, 90 °) of fiber. The above said composite is fabricated by using hand layup method. Epoxy resin along with Huntsman Resin 951 hardener was used as the binding agent throughout the layer. The ultimate tensile strength and percentage elongation of the composite were 90 ° oriented fiber composite is found to be higher value compared to 0 °, 45 ° oriented fiber. Flexural strength of the composite was 45 °, 90 ° orientedfiber composite having same value, whereas 0 ° fiber-oriented composite having least value. The ultimate shear strength of composite was 45 ° oriented fiber composite is found to be higher value compare to the other two oriented fiber composites (90 °, 0 °). The breaking load of composite 0 ° oriented fiber composite is high value compareto the other two oriented fiber composites (45 °, 90 °). Scanning electron microscope is used to analyse the internal structural of the broken specimen.

Similar content being viewed by others

References

E. Agung, S. M. Sapuan, M. M. Hamdan, H. M. D. K. Zaman, and U. Mustofa, Polym. Polym. Compos., 19, 697 (2011).

L. A. Pothan, Z. Oommen, and S. Thomas, Compos. Sci. Technol., 63, 283 (2003).

L. A. Pothan and S. Thomas, Compos. Sci. Technol., 63, 1231 (2003).

L. A. Pothan, N. R. Neelakantan, B. Rao, and S. Thomas, J. Reinf. Plast. Compos, 23, 153 (2004).

L. A. Pothan and S. Thomas, J. Appl. Polym. Sci., 91, 3856 (2004).

S. V. Joshi, L. T. Drzal, A. K. Mohanty, and S. Arora, Compos. Part A-Appl. Sci. Manuf., 35, 371 (2004).

B. Nayak, R. Sahu, and P. Karthikeyan, “Study of Tensile and Compressive Behaviour of the In-house Synthesized Al-alloy Nano Composite”, in IOP Conference Series: Materials Science and Engineering, Vol. 402, p.012070 2018.

R. K. Adhikari and B. S. K. Gowda, Materials Today: Proceedings, 4, 7171 (2017).

Z. Song, L. Shiqiang, J. Lei, R. L. Noble, and Z. Wang, Compos. Struct., 185, 600 (2018).

W. Ouarhim, N. Zari, R. Bouhfid, and A. K. Qaiss in “Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites” (M. Jawaid, M. Thariq, and N. Saba Eds.), pp.43–60, Woodhead Publishing, 2019.

C. Elanchezhian, B. Vijaya Ramnath, G. Ramakrishnan, M. Rajendrakumar, V. Naveenkumar, and M. K. Saravanakumar, Materials Today: Proceedings, 5, 1785 (2018).

Y. Li, C. Hu, and Y. Yu, Compos. Part A-Appl. Sci. Manuf., 39, 570 (2008).

A. Gowthami, K. Ramanaiah, A. V. R. Prasad, K. H. C. Reddy, K. M. Rao, and G. Sridhar Babu, Environ. Sci., 4, 199 (2013).

L. Onal and S. Adanur, J. Ind. Text., 31, 255 (2002).

D. Liu and X. Dang, “Testing and Simulation of Laminated Composites Subjected to Impact Loading”, in Composite Materials: Fatigue and Fracture, 7th Volume, ed. R. Bucinell (West Conshohocken, PA: ASTM International), pp.273–284, 1998.

B. Yang, V. Kozey, S. Adanur, and S. Kumar, Compos. Part B: Eng, 31, 715 (2000).

K. F. Wang and B. L. Wang, Compos. Struct., 206, 594 (2018).

S. Pujari, A. Ramakrishna, and M. Suresh Kumar, Int. J. Curr. Eng. Technol., 2, 121 (2014).

B. V. Ramnath, S. J. Kokan, R. N. Raja, R. Sathyanarayanan, C. Elanchezhian, A. R. Prasad, and V. M. Manickavasagam, Mater. Des., 51, 357 (2013).

O. Faruk, K. A. Bledzki, F. Hans-Peter, and M. Sain, Macromol. Mater. Eng., 299, 9 (2014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Venkatesan, K., Bhaskar, G.B. Evaluation and Comparison of Mechanical Properties of Natural Fiber Abaca-sisal Composite. Fibers Polym 21, 1523–1534 (2020). https://doi.org/10.1007/s12221-020-9532-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9532-5