Abstract

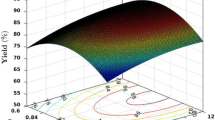

The development of biofuels from oleaginous biomass has attracted a great deal of interest not only because of the environment pollution but also because of the rapid depletion of the fossil fuel reserves. Among the biomass conversion processes, the solvolysis reaction has shown to be an interesting solution which allows the direct conversion of raw materials into biofuel. In the present work, a solvolysis process is applied on Pistacia lentiscus (PL) seeds using ethanol as solvent for bio-oil production. Several temperatures varying from 270 to 330 °C, reaction time in the range 15–45 min and ethanol:PL seed ratio values from 0.5–1.5 ml/g were considered. The response surface methodology (RSM) combined with Box-Behnken design (BBD) is used for modeling and optimizing both the process yield and bio-oil viscosity. The results show that the optimum conditions are obtained for a reaction temperature of 304.91 °C, a reaction time of 35.24 min, and an ethanol:PL seed ratio of 1.16. Under these conditions, the predicted PL bio-oil yield is around 63.5% with a bio-oil viscosity of 5.88 mm2/s. The PL bio-oil physicochemical properties showed a good agreement with those of diesel fuel and in conformity with the international requirements except for the viscosity, whose value was found to be slightly higher than the standard. The engine tests show that the fuel specific consumption increases around 9% with a mixture containing bio-oil up to 30%. On the other hand, slight increases in CO (13%), HC (25%) and particulate (30%) emissions were recorded.

Similar content being viewed by others

References

Srivastava A, Prasad R (2000) Triglycerides-based diesel fuels. Renew Sust Energ Rev 4(2):111–133. https://doi.org/10.1016/S1364-0321(99)00013-1

De Cian E, Wing IS (2019) Global energy consumption in a warming climate. Environ Resour Econ 72(2):365–410. https://doi.org/10.1007/s10640-019-00334-x

Seinfeld JH, Pandis SN (2016) Atmospheric chemistry and physics: from air pollution to climate change. John Wiley & Sons

Leal MRL, Walter AS, Seabra JE (2013) Sugarcane as an energy source. JBC Biorefinery 3(1):17–26. https://doi.org/10.1007/s13399-012-0055-1

da Silva ARG, Errico M, Rong B-G (2018) Evaluation of organosolv pretreatment for bioethanol production from lignocellulosic biomass: solvent recycle and process integration. JBC Biorefinery 8(2):397–411. https://doi.org/10.1007/s13399-017-0292-4

Soni SS, Kotadia DA, Patel VK, Bhatt H (2014) A synergistic effect of microwave/ultrasound and symmetrical acidic ionic liquids on transesterification of vegetable oils with high free fatty acid. JBC Biorefinery 4(4):301–309. https://doi.org/10.1007/s13399-013-0112-4

Durak H, Genel S, Tunç M (2019) Pyrolysis of black cumin seed: significance of catalyst and temperature product yields and chromatographic characterization. JJoLC Technologies R 42(11–12):331–350. https://doi.org/10.1080/10826076.2019.1593194

Durak H (2016) Pyrolysis of Xanthium strumarium in a fixed bed reactor: effects of boron catalysts and pyrolysis parameters on product yields and character. JES Part A: Recovery, Utilization, Effects E 38(10):1400–1409. https://doi.org/10.1080/15567036.2014.947446

Mrad N, Paraschiv M, Aloui F, Varuvel EG, Tazerout M, Nasrallah SB (2013) Liquid hydrocarbon fuels from fish oil industrial residues by catalytic cracking. JIjoer 37(9):1036–1043. https://doi.org/10.1002/er.2906

Alkhatib R, Loubar K, Awad S, Mounif E, Tazerout M (2015) Effect of heating power on the scrap tires pyrolysis derived oil. JJoA Pyrolysis 116:10–17. https://doi.org/10.1016/j.jaap.2015.10.014

Zouad Y, Tarabet L, Khiari K, Mahmoud R (2019) Effect of heating rate and additives (MgO and Al2O3) on a diesel like-fuel issued from waste engine oil pyrolysis. JPS Technology 37(10):1184–1193. https://doi.org/10.1080/10916466.2019.1581810

Kassargy C, Awad S, Burnens G, Kahine K, Tazerout M (2017) Experimental study of catalytic pyrolysis of polyethylene and polypropylene over USY zeolite and separation to gasoline and diesellike fuels. JJoA Pyrolysis A 127:31–37. https://doi.org/10.1016/j.jaap.2017.09.005

Liu Z, Zhang F-S (2008) Effects of various solvents on the liquefaction of biomass to produce fuels and chemical feedstocks. Energy Convers Manag 49(12):3498–3504. https://doi.org/10.1016/j.enconman.2008.08.009

Briones R, Serrano L, Llano-Ponte R, Labidi J (2011) Polyols obtained from solvolysis liquefaction of biodiesel production solid residues. Chem Eng J 175:169–175. https://doi.org/10.1016/j.cej.2011.09.090

Alhassan Y, Kumar N, Bugaje IM (2016) Hydrothermal liquefaction of de-oiled Jatropha curcas cake using deep eutectic solvents (DESs) as catalysts and co-solvents. Bioresour Technol 199:375–381. https://doi.org/10.1016/j.biortech.2015.07.116

Chen H, Zhai Y, Xu B, Xiang B, Zhu L, Li P, Liu X, Li C, Zeng G (2015) Feasibility and comparative studies of thermochemical liquefaction of Camellia oleifera cake in different supercritical organic solvents for producing bio-oil. Energy Convers Manag 89:955–962. https://doi.org/10.1016/j.enconman.2014.11.003

Brilman D, Drabik N, Wądrzyk M (2017) Hydrothermal co-liquefaction of microalgae, wood, and sugar beet pulp. JBC Biorefinery 7(4):445–454. https://doi.org/10.1007/s13399-017-0241-2

Durak H (2019) Characterization of products obtained from hydrothermal liquefaction of biomass (Anchusa azurea) compared to other thermochemical conversion methods. JBC Biorefinery 9(2):459–470. https://doi.org/10.1007/s13399-019-00379-4

Xu Y, Hu Y, Peng Y, Yao L, Dong Y, Yang B, Song R (2020) Catalytic pyrolysis and liquefaction behavior of microalgae for bio-oil production. JBT 300:122665. https://doi.org/10.1016/j.biortech.2019.122665

Kassargy C, Awad S, Kahine K, Khiari K, Loubar K, Tazerout M (2016) Study on the simultaneous lipids transesterification and cellulosic matter liquefaction of oleaginous seeds of Pistacia atlantica. Energy Convers Manag 124:369–376. https://doi.org/10.1016/j.enconman.2016.07.034

Karagöz S, Bhaskar T, Muto A, Sakata Y (2006) Hydrothermal upgrading of biomass: effect of K2CO3 concentration and biomass/water ratio on products distribution. Bioresour Technol 97(1):90–98. https://doi.org/10.1016/j.biortech.2005.02.051

Xu C, Etcheverry T (2008) Hydro-liquefaction of woody biomass in sub-and super-critical ethanol with iron-based catalysts. Fuel 87(3):335–345. https://doi.org/10.1016/j.fuel.2007.05.013

Braz A, Mateus MM, dos Santos RG, Machado R, Bordado JM, Correia M (2019) Modelling of pine wood sawdust thermochemical liquefaction. JNJB Bioenergy 120:200–210. https://doi.org/10.1016/j.biombioe.2018.11.001

Bhaskar T, Sera A, Muto A, Sakata Y (2008) Hydrothermal upgrading of wood biomass: influence of the addition of K2CO3 and cellulose/lignin ratio. Fuel 87(10–11):2236–2242. https://doi.org/10.1016/j.fuel.2007.10.018

Demirbaş A (2000) Effect of lignin content on aqueous liquefaction products of biomass. Energy Convers Manag 41(15):1601–1607. https://doi.org/10.1016/S0196-8904(00)00013-3

Kabyemela BM, Adschiri T, Malaluan RM, Arai K (1997) Kinetics of glucose epimerization and decomposition in subcritical and supercritical water. Ind Eng Chem Res 36(5):1552–1558. https://doi.org/10.1021/ie960250h

Bai B, Jin H, Fan C, Cao C, Wei W, Cao W (2019) Experimental investigation on liquefaction of plastic waste to oil in supercritical water. JWm 89:247–253. https://doi.org/10.1016/j.wasman.2019.04.017

Wang C, Pan J, Li J, Yang Z (2008) Comparative studies of products produced from four different biomass samples via deoxy-liquefaction. Bioresour Technol 99(8):2778–2786. https://doi.org/10.1016/j.biortech.2007.06.023

Boocock D, Sherman K (1985) Further aspects of powdered poplar wood liquefaction by aqueous pyrolysis. Can J Chem Eng 63(4):627–633. https://doi.org/10.1002/cjce.5450630415

Yan Y, Xu J, Li T, Ren Z (1999) Liquefaction of sawdust for liquid fuel. Fuel Process Technol 60(2):135–143. https://doi.org/10.1016/S0378-3820(99)00026-0

Karagöz S, Bhaskar T, Muto A, Sakata Y, Uddin MA (2004) Low-temperature hydrothermal treatment of biomass: effect of reaction parameters on products and boiling point distributions. Energy Fuel 18(1):234–241. https://doi.org/10.1021/ef030133g

Hadhoum L, Balistrou M, Burnens G, Loubar K, Tazerout M (2016) Hydrothermal liquefaction of oil mill wastewater for bio-oil production in subcritical conditions. JBt 218:9–17. https://doi.org/10.1016/j.biortech.2016.06.054

Khiari K, Tarabet L, Awad S, Loubar K, Mahmoud R, Tazerout M (2019) Optimization of Pistacia lentiscus oil transesterification process using central composite design. JW Valorization B 10(9):2575–2581. https://doi.org/10.1007/s12649-018-0257-2

Khiari K, Awad S, Loubar K, Tarabet L, Mahmoud R, Tazerout M (2016) Experimental investigation of pistacia lentiscus biodiesel as a fuel for direct injection diesel engine. JEC Management 108:392–399. https://doi.org/10.1016/j.enconman.2015.11.021

Tarabet L, Loubar K, Lounici MS, Hanchi S, Tazerout M (2012) Eucalyptus biodiesel as an alternative to diesel fuel: preparation and tests on DI diesel engine. JBRI 2012:1–8. https://doi.org/10.1155/2012/235485

Hadhoum L, Burnens G, Loubar K, Balistrou M, Tazerout M (2019) Bio-oil recovery from olive mill wastewater in sub−/supercritical alcohol-water system. JF 252:360–370. https://doi.org/10.1016/j.fuel.2019.04.133

Yu Y, Lou X, Wu H (2008) Some recent advances in hydrolysis of biomass in hot-compressed water and its comparisons with other hydrolysis methods. JE Fuels 22(1):46–60. https://doi.org/10.1021/ef700292p

H-j H, X-z Y, G-m Z, Liu Y, Li H, Yin J, Wang X-lJ (2013) Thermochemical liquefaction of rice husk for bio-oil production with sub-and supercritical ethanol as solvent. Joa Pyrolysis a 102:60–67. https://doi.org/10.1016/j.jaap.2013.04.002

Cheng C, Cheung C, Chan T, Lee S, Yao C, Tsang K (2008) Comparison of emissions of a direct injection diesel engine operating on biodiesel with emulsified and fumigated methanol. JF 87(10–11):1870–1879. https://doi.org/10.1016/j.fuel.2008.01.002

Sahoo B, Sahoo N, Saha U (2009) Effect of engine parameters and type of gaseous fuel on the performance of dual-fuel gas diesel engines—a critical review. JR, Reviews SE 13(6–7):1151–1184. https://doi.org/10.1016/j.rser.2008.08.003

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khiari, K., Tarabet, L., Awad, S. et al. Optimization of bio-oil production from Pistacia lentiscus seed liquefaction and its effect on diesel engine performance and pollutant emissions. Biomass Conv. Bioref. 12, 3359–3372 (2022). https://doi.org/10.1007/s13399-020-00913-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00913-9