Abstract

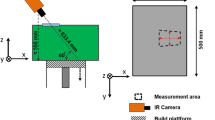

This study aims to optimize the uniformity of the temperature field during sintering to improve part performance. A temperature-field monitoring system is established based on an infrared thermal imager and the temperature field data obtained during the sintering of a part can be measured in real time. The relationship among the sintering temperature field, sintering process parameters, and part performance is established experimentally. Subsequently, a temperature field monitoring and analysis system is constructed, and various sintering temperature-field control strategies are established for various part sizes. Finally, a dynamic control strategy for controlling the temperature field during sintering is proposed, experimentally validated, and fully integrated into a developed powder bed fusion (PBF) equipment. For eight-shaped standard parts, the range of sintering temperature field is optimized from 44.1 °C to 19.7 °C, whereas the tensile strength of the parts increased by 15.4%. For large-size H parts, localized over burning is eliminated and the final quality of the part is optimized. This strategy is critical for the optimization of the PBF process for large-sized parts, in particular in the large-sized die manufacturing industry, which offers promise in the optimization of part performance.

Similar content being viewed by others

References

Bidare P, Bitharas I, Ward RM et al (2018) Laser powder bed fusion at sub-atmospheric pressures. Int J Mach Tools Manuf 130/131:65–72

Criales LE, Arısoy YM, Lane B et al (2017) Laser powder bed fusion of nickel alloy 625: experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int J Mach Tools Manuf 121:22–36

Josupeit S, Ordia L, Schmid H (2016) Modelling of temperatures and heat flow within laser sintered part cakes. Addit Manuf 12:189–196

Ganci M, Zhu W, Buffa G et al (2017) A macroscale FEM-based approach for selective laser sintering of thermoplastics. Int J Adv Manuf Technol 91:3169–3180

Setti GDO, Lopes Da Silva JV, De Oliveira MF et al (2014) Surface methods for monitoring the densification of parts in the selective laser sintering process. Rapid Prototyp J 20:157–163

Bai J, Zhang B, Song J et al (2016) The effect of processing conditions on the mechanical properties of polyethylene produced by selective laser sintering. Polym Test 52:89–93

Song JL, Li YT, Deng QL et al (2007) Rapid prototyping manufacturing of silica sand patterns based on selective laser sintering. J Mater Process Technol 187/188:614–618

Brajlih T, Paulic M, Irgolic T et al (2016) Study of the complementary usages of selective laser sintering during the high volume production of plastic parts. Rapid Prototyp J 22:735–742

Van Hooreweder B, Kruth J (2014) High cycle fatigue properties of selective laser sintered parts in polyamide 12. CIRP Ann Manuf Technol 63:241–244

Xing J, Sun W, Rana RS (2013) 3D modeling and testing of transient temperature in selective laser sintering (SLS) process. Optik 124:301–304

Wegner A, Witt G (2011) Process monitoring in laser sintering using thermal imaging. In: The 22nd annual international solid freedom fabrication symposium-an additive manufacturing conference, Austin, TX

Wegner A, Witt G (2015) Understanding the decisive thermal processes in laser sintering of polyamide 12. In: Proceedings of the polymer processing society 30th annual meeting, Cleveland, Ohio. https://doi.org/10.1063/1.4918511

Wroe WW, Gladstone J, Phillips T et al (2016) In-situ thermal image correlation with mechanical properties of nylon-12 in SLS. Rapid Prototyp J 22(5):794–800

Abdelrahman M, Starr TL (2016) Quality certification and control of polymer laser sintering: layerwise temperature monitoring using thermal imaging. Int J Adv Manuf Technol 84:831–842

Zeng K, Pal D, Stucker B (2012) A review of thermal analysis methods in laser sintering and selective laser melting. In: The 23rd annual international solid freeform fabrication symposium—an additive manufacturing conference, Austin, TX, pp 796–814

Kim H, Lin Y, Tseng TB (2018) A review on quality control in additive manufacturing. Rapid Prototyp J 24:645–669

Acknowledgements

This work is supported by the National High Technology Research and Development Program of China (863 Program) (Grant No. 2015AA042503).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, XK., Tian, XY., Zhong, Q. et al. Real-time process control of powder bed fusion by monitoring dynamic temperature field. Adv. Manuf. 8, 380–391 (2020). https://doi.org/10.1007/s40436-020-00317-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-020-00317-y