Abstract

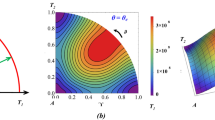

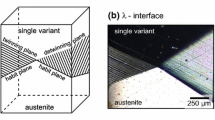

A phase-field model for the phase transition between austenite and martensite and twinning between two martensitic variants is presented from our previous theory [1] with the main focus on the influence of interfacial stress that is consistent with the sharp interface limit. Each variant-variant transformation can be represented by only one order parameter. Thus, it allows us to get the analytical solution of interface energy and width. Coupled phase-field and elasticity equations are solved for cubic-to-tetragonal phase transformation in NiAl shape memory alloy. The effects of interfacial stress are studied for martensite-martensite interfaces in detail, which was absent in [1]. Additionally, stress and temperature-induced growth of the martensitic phase inside austenite and twining are simulated. Some of the nontrivial experimentally observed microstructures reproduced in the simulations [1] are analyzed in detail. It includes tip splitting and bending, and twins crossing. This theory can be extended for electric, reconstructive, and magnetic phase transformations.

Similar content being viewed by others

References

V. I. Levitas, A. M. Roy, and D. L. Preston, Phys. Rev. B 88, 054113 (2013).

E. K. Salje, Phase Transitions in Ferroelastic and Co-Elastic Crystals: An Introduction for Mineralogists (Cambridge Univ. Press, Cambridge, 1991).

R. Ahluwalia, T. Lookman, A. Saxena, and A. R. Bishop, Phys. Rev. Lett. 91, 055501 (2003).

A. Artemev, Y. Jin, and A. G. Khachaturyan, Acta Mater. 49, 1165 (2001).

S. H. Curnoe and A. E. Jacobs, Phys. Rev. B 64, 064101 (2001).

V. I. Levitas and D. L. Preston, Phys. Rev. B 66, 134206 (2002).

V. I. Levitas and D. L. Preston, Phys. Rev. B 66, 134207 (2002).

V. I. Levitas, D. L. Preston, and D. W. Lee, Phys. Rev. B 68, 134201 (2003).

Y. U. Wang, Y. M. Jin, A. M. Cuitino, and A. G. Khachaturyan, Acta Mater. 49, 1847 (2001).

A. M. Roy, Appl. Phys. A 126, 576 (2020).

A. M. Roy, Mat. Sci. Res. India, Special Issue (2020). https://doi.org/10.13005/msri.17.special-issue1.02

V. I. Levitas and D.-W. Lee, Phys. Rev. Lett. 99, 245701 (2007).

T. Lookman, A. Saxena, and R. C. Albers, Phys. Rev. Lett. 100, 145504 (2008).

D. A. Porter, K. E. Easterling, and M. Sherif, Phase Transformations in Metals and Alloys (CRC, Boca Raton, 2009).

V. I. Levitas, Phys. Rev. B 87, 054112 (2013).

V. I. Levitas, Acta Mater. 61, 4305 (2013).

V. I. Levitas, Int. J. Plast. 49, 85 (2013).

V. I. Levitas, J. Mech. Phys. Solids 70, 154 (2014).

V. I. Levitas and A. M. Roy, Phys. Rev. B 91, 174109 (2015).

V. I. Levitas and A. M. Roy, Acta Mater. 105, 244 (2016).

A. M. Roy, Graduate Thesis and Dissertations, No. 14635 (Iowa State Univ., Ames, 2015).

G. I. Toth, T. Pusztai, and L. Granasy, Phys. Rev. B 92, 184105 (2015).

F. D. Fischer, T. Waitz, D. Vollath, and N. K. Simha, Prog. Mater. Sci. 53, 481 (2008).

H. Duan, E. Xie, L. Han, and Z. Xu, Adv. Mater. 20, 3284 (2008).

COMSOL, Inc. http://www.comsol.com.

Ph. Boullay, D. Schryvers, and R. V. Kohn, Phys. Rev. B 64, 144105 (2001).

Ph. Boullay, D. Schryvers, and J. M. Ball, Acta. Mater. 51, 1421 (2003).

Acknowledgments

I am grateful to Dr. V.I. Levitas from Iowa State University for his kind guidance and assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Funding

This work was supported by the Los Alamos National Laboratory (contract no. 104321) and the U.S. National Science Foundation (grant no. CMMI-0969143).

Supplementary Materials to the article

Rights and permissions

About this article

Cite this article

Roy, A.M. Influence of Interfacial Stress on Microstructural Evolution in NiAl Alloys. Jetp Lett. 112, 173–179 (2020). https://doi.org/10.1134/S0021364020150023

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0021364020150023