Abstract

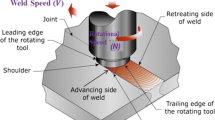

Friction stir welding (FSW) is a solid-state process, where a tool that consists of a shoulder and a pin rotates between the plates to be welded by plastic deformation. This process involves several physical phenomena. To better understand this complex phenomenon, simulations have been performed for a range of maximum viscosity values. The viscosity model used in friction stir welding simulations depends on two variables, the temperature and strain rate; however, the viscosity goes toward infinity for low values of temperature and strain rates. This study analyzed two different friction stir welding simulation, by observing how the viscosity functions behave for low values of temperature and strain rates. The maximum viscosity value was shown to be restricted to values, where the velocity field tends to zero. Furthermore, when the viscosity value exceeds the maximum value, the temperature and viscosity field is significantly impaired. In the correct results, the change in viscosity is restricted to stir zone.

Similar content being viewed by others

References

Thomas WMW, Norris I, Nicholas ED, Needham JC, Murch MG, Temple-Smith P, Dawes CJ (1991) Friction stir welding process developments and variant techniques, Intl. Patent Application no PCT/GB92/02203 and GB Patent Application no. 9125978.9

Cho HH, Hong ST, Roh JH, Choi HS, Kang SH, Steel RJ, Han HN (2013) Three-dimensional numerical and experimental investigation on friction stir welding processes of ferritic stainless steel. Acta Mater 61(7):2649. https://doi.org/10.1016/j.actamat.2013.01.045

Andrade TC, Silva CC, de Miranda HC, Motta MF, Farias JP, Bergman LA, dos Santos JF (2015) Microestrutura de uma solda dissimilar entre o aço inoxidável ferrítico AISI 410S e o aço inoxidável austenítico AISI 304L soldado pelo processo FSW. Soldagem e Inspecao 20(4):467. https://doi.org/10.1590/0104-9224/SI2004.13

Al-araji NM, Kadum KM, Al-dayni AA (2011) Effect of friction stir welding pressure on the microstructure and mechanical properties of weld joints. Int J Sci Eng Res 2(12):1

Patel N, Bhatt K, Mehta V (2016) Influence of tool pin profile and welding parameter on tensile strength of magnesium alloy AZ91 during FSW. Procedia Technol 23:558. https://doi.org/10.1016/j.protcy.2016.03.063

Gadakh VS, Kumar A (2017) FSW tool design using TRIZ and parameter optimization using Grey Relational Analysis. Mater Today Proc 5(2):6655. https://doi.org/10.1016/j.matpr.2017.11.322

He X, Gu F, Ball A (2014) A review of numerical analysis of friction stir welding. Prog Mater Sci 65:1. https://doi.org/10.1016/j.pmatsci.2014.03.003

Frigaard Ø, Grong Ø, Midling OT (2001) A process model for friction stir welding of age hardening aluminum alloys. Metall Mater Trans A 32(5):1189. https://doi.org/10.1007/s11661-001-0128-4

Seidel TU, Reynolds AP (2003) Two-dimensional friction stir welding process model based on fluid mechanics. Sci Technol Weld Join 8(3):175. https://doi.org/10.1179/136217103225010952

Sellars CM, Tegart WJM (1972) Hot workability. Int Metall Rev 17(1):1. https://doi.org/10.1179/imtlr.1972.17.1.1

Sheppard T, Wright DS (1979) Determination of flow stress: part 1 constitutive equation for aluminum alloys at elevated temperatures. Met Technol. https://doi.org/10.1179/030716979803276264

Ulysse P (2002) Three-dimensional modeling of the friction stir-welding process. Int J Mach Tools Manuf. https://doi.org/10.1016/S0890-6955(02)00114-1

Nandan R, Roy GG, Debroy T (2006) Numerical simulation of three-dimensional heat transfer and plastic flow during friction stir welding. Metall Mater Trans 37A(4):1247. https://doi.org/10.1007/s11661-006-1076-9

Nandan R, Roy GG, Lienert TJ, Debroy T (2007) Three-dimensional heat and material flow during friction stir welding of mild steel. Acta Mater 55(3):883. https://doi.org/10.1016/j.actamat.2006.09.009

Nandan R, Lienert TJ, DebRoy T (2008) Toward reliable calculations of heat and plastic flow during friction stir welding of Ti–6Al–4V alloy. Int J Mater Res 99(4):434. https://doi.org/10.3139/146.101655

Hart EW (1976) Constitutive relations for the nonelastic deformation of metals. J Eng Mater Technol 98(3):193. https://doi.org/10.1115/1.3443368

Cho JH, Boyce DE, Dawson PR (2005) Modeling strain hardening and texture evolution in friction stir welding of stainless steel. Mater Sci Eng A 398(1–2):146. https://doi.org/10.1016/j.msea.2005.03.002

Fisher ES (1966) Temperature dependence of the elastic moduli in alpha uranium single crystals, part IV (298 to 923 K). J Nucl Mater 18(1):39. https://doi.org/10.1016/0022-3115(66)90094-8

Nandan R, Roy GG, Lienert TJ, DebRoy T (2006) Numerical modelling of 3D plastic flow and heat transfer during friction stir welding of stainless steel. Sci Technol Weld Join 11(5):526. https://doi.org/10.1179/174329306X107692

Deng Z, Lovell MR, Tagavi KA (2001) Influence of material properties and forming velocity on the interfacial slip characteristics of cross wedge rolling. J Manuf Sci Eng 123(4):647. https://doi.org/10.1115/1.1383028

Kong HS, Ashby MF (1991) Friction-heating maps and their applications. MRS Bull 16(10):41. https://doi.org/10.1557/S0883769400055822

Zhang S, Chen G, Liu Q, Li H, Zhang G, Wang G, Shi Q (2018) Numerical analysis and analytical modeling of the spatial distribution of heat flux during friction stir welding. J Manuf Proces 33:245. https://doi.org/10.1016/j.jmapro.2018.05.021

Yaduwanshi DK, Bag S, Pal S (2016) Numerical modeling and experimental investigation on plasma-assisted hybrid friction stir welding of dissimilar materials. Mater Des 92:166. https://doi.org/10.1016/j.matdes.2015.12.039

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Francis HR Franca, Ph.D.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 1 AISI 304 stainless steel constants

1.2 2 Ti–6Al–4V alloy constants

Rights and permissions

About this article

Cite this article

Silva, Y.C., Oliveira Júnior, F.J.V., Marcondes, F. et al. Analysis of viscosity function models used in friction stir welding. J Braz. Soc. Mech. Sci. Eng. 42, 430 (2020). https://doi.org/10.1007/s40430-020-02504-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02504-1