Abstract

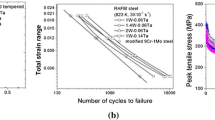

The goals of this study were to quantify and explain the effects of microstructure on the resistance of low-carbon steels to low-cycle fatigue and to extremely low-cycle fatigue (ELCF). Three different microstructures (ferrite–pearlite, ferrite–martensite, and ferrite–bainite–martensite) were tested, and their fatigue properties were analyzed using the strain-based Coffin–Manson model and an energy-based model. According to the Coffin–Manson model, ferrite–pearlite showed the best ELCF resistance, whereas in the energy-based model that considers the effect of tensile strength ferrite–bainite–martensite revealed the highest ELCF resistance. At similar tensile strength, ferrite–bainite–martensite had longer ELCF life than ferrite–martensite; the difference may be a result of the smaller strain incompatibility between bainite and ferrite than between ferrite and martensite. In all three microstructures, cracks initiated at the surface and propagated into the interior; this result indicates that fracture mode was not altered during cyclic loading at high strain amplitudes. Ferrite–martensite microstructure developed many sub-cracks surrounding a main crack; they could facilitate propagation of a main crack, and thereby degrade fatigue life at high strain amplitudes.

Graphic Abstract

Similar content being viewed by others

References

L. Kang, H. Ge, Predicting ductile crack initiation of steel bridge structures due to extremely low-cycle fatigue using local and non-local models. J. Earthq. Eng. 17, 323–349 (2013). https://doi.org/10.1080/13632469.2012.746211

X. Tian, H. Zhang, Q. Duan, Y. Ji, Establishment and application of fatigue life prediction models for coiled tubing. in ASME 2015 Pressure Vessels Piping Conference PVP2015, vol. 3 (Design, American Society of Mechanical Engineers, 2015), pp. 1–7. https://doi.org/10.1115/PVP2015-45130.

J. Wainstein, J. Perez Ipiña, Fracture toughness of HSLA coiled tubing used in oil wells operations. J. Press. Vessel Technol. Trans ASME. 1, 34 (2012). https://doi.org/10.1115/1.4004569

S. M. Tipton. Low-cycle fatigue testing of tubular material using non-standard specimens. in: Rice R, Tritsch D, editors. Eff. Prod. Qual. Des. Criteria Struct. Integr., ASTM International; 1998, pp. 102–19. https://doi.org/10.1520/STP1337-EB.

S.S. Manson, Behavior of materials under conditions of thermal stress, Technical note 2933, National Advisory Committee for Aeronautics, USA (1953)

L.F. Coffin Jr., A study of the effects of cyclic thermal stresses on a ductile metal. Trans. Am. Soc. Mech. Eng. 76, 931–950 (1954)

K. Shimada, J. Komotori, M. Shimizu, The applicability of the Manson–Coffin law and Miner’s law to extremely low cycle fatigue. Trans. Jpn. Soc. Mech. Eng. Ser. A 53, 1178–1185 (1987). https://doi.org/10.1299/kikaia.53.1178

M. Kuroda, Extremely low cycle fatigue life prediction based on a new cumulative fatigue damage model. Int. J. Fatigue 24, 699–703 (2002). https://doi.org/10.1016/S0142-1123(01)00170-0

L. Xue, A unified expression for low cycle fatigue and extremely low cycle fatigue and its implication for monotonic loading. Int. J. Fatigue 30, 1691–1698 (2008). https://doi.org/10.1016/j.ijfatigue.2008.03.004

J.C.R. Pereira, A.M.P. de Jesus, J. Xavier, A.A. Fernandes, Ultra low-cycle fatigue behaviour of a structural steel. Eng. Struct. 60, 214–222 (2014). https://doi.org/10.1016/j.engstruct.2013.12.039

R. Liu, Z.J. Zhang, P. Zhang, Z.F. Zhang, Extremely-low-cycle fatigue behaviors of Cu and Cu–Al alloys: damage mechanisms and life prediction. Acta Mater. 83, 341–356 (2015). https://doi.org/10.1016/j.actamat.2014.10.002

A.M. Kanvinde, G.G. Deierlein, Cyclic void growth model to assess ductile fracture initiation in structural steels due to ultra low cycle fatigue. J. Eng. Mech. 133, 701–712 (2007). https://doi.org/10.1061/(ASCE)0733-9399(2007)133:6(701)

A. Sherman, R. Davies, The effect of martensite content on the fatigue of a dual-phase steel. Int. J. Fatigue 3, 36–40 (1981). https://doi.org/10.1016/0142-1123(81)90047-5

H.J. Roven, E. Nes, Cyclic deformation of ferritic steel—I. Stress–strain response and structure evolution. Acta Metall. Mater. 39, 1719–1733 (1991). https://doi.org/10.1016/0956-7151(91)90141-M

S. Mediratta, V. Ramaswamy, P. Rao, Influence of ferrite–martensite microstructural morphology on the low cycle fatigue of a dual-phase steel. Int. J. Fatigue 7, 107–115 (1985). https://doi.org/10.1016/0142-1123(85)90041-6

S.K. Paul, N. Stanford, T. Hilditch, Effect of martensite volume fraction on low cycle fatigue behaviour of dual phase steels: experimental and microstructural investigation. Mater. Sci. Eng. A 638, 296–304 (2015). https://doi.org/10.1016/j.msea.2015.04.059

K. Nakajima, T. Urabe, Y. Hosoya, S. Kamiishi, T. Miyata, N. Takeda, Influence of microstructural morphology and prestraining on short fatigue crack propagation in dual-phase steels. ISIJ Int. 41, 298–305 (2001). https://doi.org/10.2355/isijinternational.41.298

M. Guan, H. Yu, Fatigue crack growth behaviors in hot-rolled low carbon steels: a comparison between ferrite–pearlite and ferrite–bainite microstructures. Mater. Sci. Eng. A 559, 875–881 (2013). https://doi.org/10.1016/j.msea.2012.09.036

S.K. Paul, N. Stanford, T. Hilditch, Effect of martensite morphology on low cycle fatigue behaviour of dual phase steels: experimental and microstructural investigation. Mater. Sci. Eng. A 644, 53–60 (2015). https://doi.org/10.1016/j.msea.2015.07.044

N. Stanford, J. Wang, T. Hilditch, Quantification of strain partitioning during low cycle fatigue of multi-phase steels containing a bainite matrix. Int. J. Fatigue 129, 105218 (2019). https://doi.org/10.1016/j.ijfatigue.2019.105218

ASTM E606/E606M-12. Standard test method for strain-controlled fatigue testing. ASTM Int 2012. https://doi.org/10.1520/E0606_E0606M-12.

P.B. Hirsch, Electron Microscopy of Thin Crystals (Krieger Publishing Company, Second. R. E, 1977)

T. Malis, S.C. Cheng, R.F. Egerton, EELS log-ratio technique for specimen-thickness measurement in the TEM. J. Electron. Microsc. Tech. 8, 193–200 (1988). https://doi.org/10.1002/jemt.1060080206

M. Calcagnotto, D. Ponge, E. Demir, D. Raabe, Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 527, 2738–2746 (2010). https://doi.org/10.1016/j.msea.2010.01.004

S. Majumdar, S. Roy, K.K. Ray, Fatigue performance of dual-phase steels for automotive wheel application. Fatigue Fract. Eng. Mater. Struct. 40, 315–332 (2017). https://doi.org/10.1111/ffe.12491

C.W. Shao, P. Zhang, R. Liu, Z.J. Zhang, J.C. Pang, Z.F. Zhang, Low-cycle and extremely-low-cycle fatigue behaviors of high-Mn austenitic TRIP/TWIP alloys: property evaluation, damage mechanisms and life prediction. Acta Mater. 103, 781–795 (2016). https://doi.org/10.1016/j.actamat.2015.11.015

Y.J. Park, D.H. Stone, Cyclic behavior of class u wheel steel. Am. Soc. Mech. Eng. 103, 113–118 (1980)

A. Ramazani, K. Mukherjee, A. Schwedt, P. Goravanchi, U. Prahl, W. Bleck, Quantification of the effect of transformation-induced geometrically necessary dislocations on the flow-curve modelling of dual-phase steels. Int. J. Plast. 43, 128–152 (2013). https://doi.org/10.1016/j.ijplas.2012.11.003

Z.Y. Li, X.L. Liu, G.Q. Wu, Z. Huang, Fretting fatigue behavior of Ti–6Al–4V and Ti–10V–2Fe–3Al alloys. Met. Mater. Int. 25, 64–70 (2019). https://doi.org/10.1007/s12540-018-0158-8

B.B. He, K. Zhu, M.X. Huang, On the nanoindentation behaviour of complex ferritic phases. Philos. Mag. Lett. 94, 439–446 (2014). https://doi.org/10.1080/09500839.2014.921348

Acknowledgments

This work was financially supported by POSCO. The authors are thankful for the support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Noh, K., Shams, S.A.A., Kim, W. et al. Influence of Microstructure on Low-Cycle and Extremely-Low-Cycle Fatigue Resistance of Low-Carbon Steels. Met. Mater. Int. 27, 3862–3874 (2021). https://doi.org/10.1007/s12540-020-00819-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00819-1