Abstract

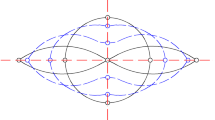

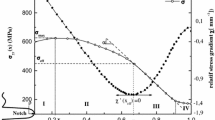

The purpose of this work is to assess the circumferential mechanical characteristics and the mechanical strength of industrial PVC pipes, especially under pressure loading. The investigation and the prediction of the resistance to deformation or failure of PVC pipes under internal pressure are essential to develop their potential application. To this end, two approaches are retained in this paper. The first one consists of developing an experimental apparatus devoted to study the mechanical properties of PVC pipes at laboratory scale. A split disk tensile (SDT) apparatus was developed according to the tensile test machine available in our laboratory. Such developed apparatus permits to characterize successfully more than one pipe diameter. The second approach consists of building a successful finite element (FE) model which will be able to predict the mechanical response of the pipes when submitted to pressure loading in radial direction. The obtained experimental and numerical results were firstly evaluated and then, their correlation was discussed. The robustness and efficiency of the FE model is assessed on the basis of the experimental/numerical correlation analysis. From the main results, the established model is shown to well predict the mechanical properties of polymeric pipes when will be exposed to mechanical loadings and other factors.

Similar content being viewed by others

References

Laiarinandrasana L, Gaudichet E, Oberti S, Devilliers C (2011) Effects of aging on the creep behaviour and residual lifetime assessment of polyvinyl chloride (PVC) pipes. Int J Press Vessel Pip 88(2–3):99–108

Guermazi N, Haddar N, Elleuch K, Ayedi HF (2016) Effect of filler addition and weathering conditions on the performance of PVC/CaCO3 composites. Polym Compos 37(7):2171–2183

Benyahia H, Tarfaoui M, El Moumen A, Ouinas D, Hassoon OH (2018) Mechanical properties of offshoring polymer composite pipes at various temperatures. Compos Part B 152:231–240

Peres FM, Schön CG (2007) An alternative approach to the evaluation of the slow crack growth resistance of polyethylene resins used for water pipe extrusion. J Polym Res 14(3):181–189

Han R, Nie M, Wang Q (2017) Continuously enhanced hoop strength of rotation-extruded polypropylene pipe via self-assembly β nucleating agent with different aspect ratio. J Polym Res 24(11):204

Zhang J, Xiao Y, Liang Z (2018) Mechanical behaviors and failure mechanisms of buried polyethylene pipes crossing active strike-slip faults. Compos Part B 154:449–466

Krishnaswamy RK (2005) Analysis of ductile and brittle failures from creep rupture testing of high-density polyethylene (HDPE) pipes. Polymer 46(25):11664–11672

ASTM. 22900e12 Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe

D-2290-00, Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe by Split Disk Method”, American Society for Testing Materials (ASTM) designation: D2290–00, 2003

ASTM, “Standard test method for apparent tensile strength of plastic or reinforced plastic pipe by split disk method,” D 2290, West Conshohocken, PA, 2010

Lam L, Teng JG (2002) Strength Models for Fiber-Reinforced Plastic-Confined Concrete. Jl. of Struct. Engg. 128(5):612–623

Tamuzs V, Tepfers R, You C-S, Rousakis T, Repelis I, Skruls V, Vilks U (2006) Behavior of concrete cylinders confined by carbon-composite tapes and prestressed yarns 1. Experimental data. Mech. and Compo. Mat. 42(1):13–32

Chen JF, Li SQ, Bisby LA, Ai J (2011) FRP rupture strains in the split disk test. Compos Part B 42:962–972

Kaynak C, Salim Erdiller E, Parnas L, Senel F (2005) Use of split-disk tests for the process parameters of filament wound epoxy composite tubes. Polym Test 24(5):648–655

Shlitsa RP, Novikova EA (1983) Characteristics of the use of the split-disk method for investigating modern winding composites. Mech Compos Mater 18(4):502–508

Ellyin F, Maser R (2004) Environmental effects on the mechanical properties of glass-fiber epoxy composite tubular specimens. Compos Sci Technol 64(12):1863–1874

Zhang, J., Xiao, Y., & Liang, Z. (2018). Mechanical behaviors and failure mechanisms of buried polyethylene pipes crossing active strike-slip faults. Composites Part B: Engineering

Bahri A, Guermazi N, Bargui M, Elleuch K (2016) Estimation of the elastic modulus of the alumina coated AA1050 aluminum: modeling and experiments. Mater Sci Eng A 670:188–195

Jemii, H., Boubakri, A., Hammiche, D., Bahri, A., Guermazi, N., Elleuch K., On the friction and wear behavior of virgin and hydrothermally aged PVC/CaCO3 composites, submitted for publication, 2020

Perillo G, Vacher R, Grytten F, Sørbø S, Delhaye V (2014) Material characterisation and failure envelope evaluation of filament wound GFRP and CFRP composite tubes. Polym Test 40:54–62

d’Almeida JRM, de Almeida RC, De Lima WR (2008) Effect of water absorption of the mechanical behavior of fiberglass pipes used for offshore service waters. Compos Struct 83(2):221–225

Kara M, Kirici M, Cagan SC (2019) Effects of the number of fatigue cycles on the hoop tensile strength of glass Fiber/epoxy composite pipes. J Fail Anal Prev 19(4):1181–1186

Acknowledgements

The material samples were supplied from the Tuyauplast industry situated in Gafsa, Tunisia. For this, the authors would like to thank Mr. Jamel LACHKHEM, the Head of the company, for his help and contribution to this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jemii, H., Bahri, A., Boubakri, A. et al. On the mechanical behaviour of industrial PVC pipes under pressure loading: experimental and numerical studies. J Polym Res 27, 240 (2020). https://doi.org/10.1007/s10965-020-02222-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02222-1