The structure of retained austenite in wear-resistant steels 150KhNML and Kh12MFL of pearlitic and ledeburitic classes is studied under the conditions of abrasive wear after different variants of heat treatment. The working surfaces of the steels are subjected to electron microscope transmission analysis. It is shown that the retained austenite formed as a result of high-temperature quenching (1100 – 1170°C) is metastable and transforms in the wear process into fine- and nanocrystalline strain martensite with regular periodic arrangement of crystals in addition to slip and twinning. This provides a high capacity of the working surface for friction hardening. The optimum mode of heat treatment for formation of a dissipative structure with high abrasive wear resistance is chosen.

Similar content being viewed by others

References

V. M. Schastlivtsev and M. A. Filippov, “Role of the Bogachev–Mints principle of metastability of austenite in selection of wear-resistant materials,” Metalloved. Term. Obrab. Met., No. 1(595), 6 – 9 (2005).

A. V. Makarov, L. G. Korshunov, V. B. Vykhodets, et al., “Effect of hardening friction treatment on the chemical composition, structure and tribological properties of high-carbon steel,” Fiz. Met. Metalloved., 110(5), 530 – 544 (2010).

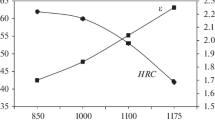

M. A. Filippov, M. A. Gervas’ev, Yu. V. Khudorozhkova, and V. V. Legchilo, “Effect of quenching temperature on the phase composition, structure and wear resistance of steel 150KhNM,” Izv. Vysh. Uchebn. Zaved., Chern. Metall., 11, 14 – 16 (2013).

M. A. Filippov, M. A. Gervas’ev, G. N. Plotnikov, et al., “Formation of structure of wear-resistant steels 150KhNML and Kh12MFL under quenching,” Metalloved. Term. Obrab. Met., No. 11(725), 5 – 9 (2015).

V. S. Ivanova, “Synergy in the science of metals,” Metalloved. Term. Obrab. Met., No. 2, 12 – 19 (2005).

I. Schmidt, “Reibungsinduzierter Martensit in austenitischen Fe – Mn – C – Stahlen,” Zeitschrift fur Metallkude, 75(10), 747 – 754 (1984).

Yu. A. Geller, Tool Steels [in Russian], Metallurgiya, Moscow (1983), 584 p.

M. A. Gervas’ev, Yu. V. Khudorozhkova, and M. A. Filippov, “Structure and wear resistance of roll steels with 5% chromium,” Metalloved. Term. Obrab. Met., No. 10, 16 – 20 (2010).

M. A. Filippov, V. S. Litvinov, and Yu. R. Nemirovskii, Steels with Metastable Austenite [in Russian], Metallurgiya, Moscow (1988), 257 p.

M. L. Bernshtein, V. A. Zaimovskii, and L. M. Kaputkina, Thermomechanical Treatment of Steel [in Russian], Metallurgiya, Moscow (1983), 480 p.

I. N. Bogachev, L. G. Korshunov, M. S. Khadyev, et al., “A study of the hardening and structural transformations in steel 110G13 under friction,” Fiz. Met. Metalloved., 43(2), 380 – 387 (1977).

V. M. Schastlivtsev and V. I. Zeldovich, Physical Fundamentals of the Science of Metals [in Russian], URO RAN, Ekaterinburg (2015), 224 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 3, pp. 30 – 39, March, 2020.

Rights and permissions

About this article

Cite this article

Filippov, M.A., Khadyev, M.S., Ozerets, N.N. et al. Formation of Dissipative Structure of Metastable Austenite for Raising the Abrasive Wear Resistance of Steels of Pearlitic and Ledeburitic Classes. Met Sci Heat Treat 62, 210–219 (2020). https://doi.org/10.1007/s11041-020-00537-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00537-w