Abstract

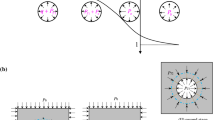

Ductile linings have been proved to be highly effective for tunnelling in heavy squeezing grounds. But there still has not been a well-established design method for them. In this paper, an investigation on an analytical design method for ductile tunnel linings is performed. Firstly, a solution in closed form for ground response of a circular tunnel within Burgers viscoelastic rocks is derived, accounting for the displacement release effect. Then based on the principle of equivalent deformation, the mechanical model of segmental shotcrete linings with yielding elements is established using the homogenization approach. Analytical prediction for behaviour of ductile tunnel linings is provided. Furthermore, the proposed design method for ductile tunnel linings is applied in Saint Martin La Porte access tunnel and the analytical prediction is in good agreement with field monitoring data. Finally, a parametric investigation on the influence of yielding elements on performance of ductile tunnel linings is conducted. Results show that the length of yielding elements poses a great influence on linings. It is feasible and effective to increase the length of yielding elements to obtain the pressure within the bearing capacity of linings. However, yield stress of yielding elements does not significantly affect the performance of the lining. It is suggested to apply yielding elements with relatively higher yield stress in linings for higher stability.

Similar content being viewed by others

Abbreviations

- \(\sigma ,\sigma_{r} ,\sigma_{\theta }\) :

-

Compression stress, radial and tangential stresses, respectively

- \(\overline{{\sigma_{\theta } }}\) :

-

Mean tangential stress

- \(\sigma_{y}\) :

-

Yield stress of yielding element

- \(\varepsilon ,\varepsilon_{lim}\) :

-

Strain and limit strain of yielding element, respectively

- \(s_{ij}\) :

-

Tensor of stress deviator

- \(e_{ij}\) :

-

Tensor of strain deviator

- \(G_{1} ,G_{2}\) :

-

Elastic constants of Hookean spring

- \(\eta_{1} ,\eta_{2}\) :

-

Viscous coefficients of Newtonian dashpot

- \(\lambda\) :

-

Lateral pressure coefficient

- \(A_{k} ,B_{k}\) :

-

Coefficients in Burgers constitutive equation, respectively

- \(A,A_{1} ,A_{2}\) :

-

Cross-sectional area, cross-sectional areas of segmental lining and steel pipes, respectively

- \(C_{1} ,C_{2} ,D_{1} ,D_{2}\) :

-

Coefficients related with Poisson’s ratio of rock

- \(E_{1} ,E_{2} ,E^{*}\) :

-

Elastic moduli of shotcrete, yielding element and homogenized lining, respectively

- \(\nu_{1} ,\nu_{2} ,\nu^{*} ,\nu_{r}\) :

-

Poisson’s ratios of shotcrete, yielding element, homogenized lining and rock, respectively

- \(F,F_{\theta }\) :

-

Axial force and tangential axial force in lining, respectively

- \(k\) :

-

Ratio of cross-sectional areas of steel pipes to segmental lining

- \(K_{s}^{\left( i \right)}\) :

-

Stiffness of lining

- \(l_{1i} ,l_{2i}\) :

-

Lengths of each segmental lining and yielding element, respectively

- \(M,N,Q\) :

-

Bending moment, axial force and shear force, respectively

- \(P,Q\) :

-

Differential time operators

- \(p_{i}\) :

-

Internal pressure at tunnel wall or lining pressure

- \(p_{0}\) :

-

Initial ground stress

- \(R_{0}\) :

-

Tunnel radius

- \(r\) :

-

Distance between element and tunnel centre

- \(t_{s}\) :

-

Thickness of lining

- \(t\) :

-

Time

- \(u^{*}\) :

-

Displacement release coefficient

- \(u_{R}\) :

-

Tunnel radial displacement or lining displacement

- \(u_{\max }\) :

-

Maximum unlined tunnel radial displacement

- \(u_{0}\) :

-

Tunnel radial displacement with X* = 0

- \(u_{1} ,u_{2}\) :

-

Lining displacements responding to beginning time and finishing time of plastic strain of yielding elements

- \(X^{*}\) :

-

Ratio of distance from tunnel face to tunnel radius

References

Wu K, Shao Z, Qin S, Li B. Determination of deformation mechanism and countermeasures in silty clay tunnel. J Perform Constr Fac. 2020;34(1):04019095.

Paraskevopoulou C, Diederichs M. Analysis of time-dependent deformation in tunnels using the Convergence-Confinement Method. Tunn Under Space Tech. 2018;71:62–80.

Hoek E. Big tunnels in bad rock. J Geotech Geoenviron Eng. 2001;127(9):726–40.

Qiu J, Lu Y, Lai J, Zhang Y, Yang T, Wang K. Experimental study on the effect of water gushing on loess metro tunnel. Environ Earth Sci. 2020;79:261.

Cantieni L, Anagnostou G. The interaction between yielding supports and squeezing ground. Tunn Under Space Tech. 2009;24:309–22.

Wu K, Shao Z, Qin S. A solution for squeezing deformation control in tunnels using foamed concrete: a review. Constr Build Mater. 2020;257:119539.

Lackner R, Macht J, Hellmich C, Mang HA. Hybrid method for analysis of segmented shotcrete tunnel linings. J Geotech Geoenviron Eng. 2002;128(4):298–308.

Pöttler R. Shotcrete lining with longitudinal gaps. Felsbau. 1997;15(6):422–9.

Barla G, Bonini M, Semeraro M. Analysis of the behaviour of a yield-control support system in squeezing rock. Tunn Under Space Tech. 2011;26(1):146–54.

Moritz B. Yielding elements-requirements, overview and comparison. Geomech Tunn. 2011;4(3):221–36.

Radončić N, Schubert W, Moritz B. Ductile support design. Geomech Tunn. 2009;2(5):561–77.

Wu K, Shao Z, Qin S, Zhao N, Hu H. Analytical-based assessment of effect of highly deformable elements on tunnel lining within viscoelastic rocks. Int J Appl Mech. 2020;12(3):2050030.

Button EA, Schubert W, Moritz B. The application of ductile support methods in Alpine tunnels. In: 10th ISRM Congress, International Society for Rock Mechanics and Rock Engineering, South Africa; 2003.

Schubert W. Dealing with squeezing conditions in Alpine tunnels. Rock Mech Rock Eng. 1996;29:145–53.

Qiu W, Wang G, Gong L, Shen Z, Li C, Dang J. Research and application of resistance-limiting and energy-dissipating support in large deformation tunnel. Chinese J Rock Mech Eng. 2018;37(8):1785–95.

Moritz B. Ductile support system for tunnels in squeezing rock. PhD thesis, Graz University of Technology, Graz, Austria; 1999.

Bonini M, Barla G. The Saint Martin La Porte access adit (Lyon-Turin Base Tunnel) revisited. Tunn Under Space Tech. 2012;30:38–54.

Mezger F, Ramoni M, Anagnostou G. Options for deformable segmental lining systems for tunnelling in squeezing rock. Tunn Under Space Tech. 2018;76:64–75.

Kovári K. Design methods with yielding support in squeezing and swelling rocks. In: Proceedings of the World Tunnel Congress, Budapest, Hungary; 2009.

Hammer AL, Hasanpour R, Hoffmann C, Thewes M. Numerical analysis of interaction behavior of yielding supports in squeezing ground. Numerical methods in geotechnical engineering IX. Boca Raton: CRC Press; 2018.

Tian H, Chen W, Yang D, Wu G, Tan X. Numerical analysis on the interaction of shotcrete liner with rock for yielding supports. Tunn Under Space Tech. 2016;2016(54):20–8.

Nomikos P, Rahmannejad R, Sofianos A. Supported axisymmetric tunnels within linear viscoelastic Burgers rocks. Rock Mech Rock Eng. 2011;44:553–64.

Birchall TJ, Osman AS. Response of a tunnel deeply embedded in a viscoelastic medium. Int J Num Anal Meth Geomech. 2012;36(15):1717–40.

Wu K, Shao Z. Visco-elastic analysis on the effect of flexible layer on mechanical behavior of tunnels. Int J Appl Mech. 2019;11(3):1950027.

Wu K, Shao Z. Study on the effect of flexible layer on support structures of tunnel excavated in viscoelastic rocks. J Eng Mech. 2019;145(10):04019077

Vlachopoulos N, Diederichs MS. Improved longitudinal displacement profiles for convergence confinement analysis of deep tunnels. Rock Mech Rock Eng. 2009;42(2):131–46.

Chu Z, Wu Z, Liu Q, Liu B. Analytical solutions for deep-buried lined tunnels considering longitudinal discontinuous excavation in rheological rock mass. J Eng Mec. 2020;146(6):04020047

Panet M, Guenot A. Analysis of convergence behind the face of a tunnel. In: Proceedings of the International Symposium Tunnelling, 1982; IMM, London

Panet M. Calcul des Tunnels par la Me’thode de Convergence-Confinement. Paris: Presses de l’Ecole Nationale des Ponts et Chausse’es; 1995.

Unlu T, Gercek H. Effect of Poisson's ratio on the normalized radial displacements occurring around the face of a circular tunnel. Tunn Under Space Tech. 2003;18(5):547–53.

Goodman RE. Introduction to rock mechanics. 2nd ed. New York: Wiley; 1989.

Lei SX, Zhao W. Study on the mechanism of circumferential yielding support for soft rock tunnel with large deformation. Rock Soil Mech. 2020;41(3):1–8.

Barla G, Debernardi D, Sterpi D. Time-dependent modeling of tunnels in squeezing conditions. Int J Geomech. 2012;12(6):697–710.

Chu Z, Wu Z, Liu B, Liu Q. Coupled analytical solutions for deep-buried circular lined tunnels considering tunnel face advancement and soft rock rheology effects. Tunn Under Space Tech. 2019;94:103111.

Yang CY, Xu MX, Chen WF. Reliability analysis of shotcrete lining during tunnel construction. J Constr Eng M. 2007;133(12):975–81.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 11872287), and the Fund of Shaanxi Key Research and Development Program (No. 2019ZDLGY01-10).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that they have no conflicts of interest for this work.

Ethical statement

The authors state that the work was conducted according to ethical standards.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendix

Appendix

As previously mentioned, for steel pipes acting as yielding elements, there is a reduction in their stiffness. We define that

where A1 denotes the cross-sectional area of the segmental linings and A2 represents the actual cross-sectional area of steel pipes.

There is a relationship between compression stress and elastic modulus of material that

where σ and ε are compression stress and strain, respectively. F denotes the axial force. E and A are the elastic modulus and cross-sectional area of the material.

Considering the stress state of steel pipes in the lining, Eq. (35) can be rewritten as

where Fθ represents the tangential axial force in the lining.

Substituting Eq. (34) into (36) provides

The right part of Eq. (37) is the calculation formula for elastic modulus of normal yielding elements where a reduction in stiffness is not considered. Then, replacing E2 in Eq. (21) with kE2 can provide the elastic modulus of homogenized lining where a reduction in stiffness of steel pipes is estimated.

Rights and permissions

About this article

Cite this article

Wu, K., Shao, Z. & Qin, S. An analytical design method for ductile support structures in squeezing tunnels. Archiv.Civ.Mech.Eng 20, 91 (2020). https://doi.org/10.1007/s43452-020-00096-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-020-00096-0