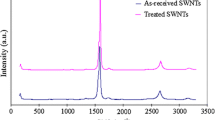

In this work, transmission electron microscopy (TEM) and Raman spectroscopy were used to assess the dispersion quality of carbon nanotubes (CNTs) in an epoxy matrix. Its ultimate tensile strength (UTS), engineering strain, local strain, and the elastic tensile modulus were determined experimentally. The effect of CNT sonication time in an ethanol medium was also evaluated. A statistical analysis using the t-test approach was employed to clarify how the use of CNTs affects the mechanical properties of the matrix. An increase in the UTS by 10 and 7% was observed in the cases of 0.1 wt.% single-walled carbon nanotubes (SWCNTs) and multiwalled carbon nanotubes (MWCNTs), respectively, but the elastic modulus increased significantly when using MWCNTs. A TEM analysis indicated that the dispersion quality was proportional to the content of CNTs. It is concluded that a CNT-reinforced epoxy matrix is highly sensitive to the amount of CNTs, which can explain the conflicting properties reported for such matrices in the literature.

Similar content being viewed by others

References

M. Bourchak, A. Algarni, A. Khan, and U. Khashaba, “Effect of SWCNTs and graphene on the fatigue behavior of antisymmetric GFRP laminate,” Compos. Sci. Technol., 167, 164–173 (2018).

A. Kausar, I. Rafique, and B. Muhammad, “Review of applications of polymer/carbon nanotubes and epoxy/cnt composites,” Polym–Plast. Technol., 55, No. 11, 1167–1191 (2016).

W. Khan, R. Sharma, and P. Saini, in : M. Berber and I. H. Hafez (eds.), Carbon Nanotubes – Current Progress of their Polymer Composites, Ch. 1, InTech, Rijeka, Croatia (2016).

Y. Jiang, H. Song, and R. Xu, “Research on the dispersion of carbon nanotubes by ultrasonic oscillation, surfactant and centrifugation respectively and fiscal policies for its industrial development,” Ultrason. Sonochem., 48, 30–38 (2018).

K. Almuhammadi, M. Alfano, Y. Yang, and G. Lubineau, “Analysis of interlaminar fracture toughness and damage mechanisms in composite laminates reinforced with sprayed multi–walled carbon nanotubes,” Mater. Des., 53, 921–927 (2014).

A. Montazeri, J. Javadpour, A. Khavandi, A. Tcharkhtchi, and A. Mohajeri, “Mechanical properties of multi–walled carbon nanotube/epoxy composites,” Mater. Des., 31, No. 9, 4202–4208 (2010).

U. Khan, K. Ryan, W. J. Blau, and J. N. Coleman, “The effect of solvent choice on the mechanical properties of carbon nanotube–polymer composites,” Compos. Sci. Technol., 67, No. 15–16, 3158–3167 (2007).

I. Alig, P. Pötschke, D. Lellinger, T. Skipa, S. Pegel, G. R. Kasaliwal, and T. Villmow, “Establishment, morphology and properties of carbon nanotube networks in polymer melts,” Polymer, 53, No. 1, 4–28 (2012).

A. Algarni, “Enhancing the mechanical properties of aerospace fiber reinforced polymer composite materials using nanoparticles,” PhD Thesis, King Abdulaziz University, KSA (2018).

P.–C. Ma, N. A. Siddiqui, G. Marom, and J.–K. Kim, “Dispersion and functionalization of carbon nanotubes for polymer–based nanocomposites: A review,” Compos. Part A–Appl. S., 41, No. 10, 1345–1367 (2010).

S. Bose, R.A. Khare, and P. Moldenaers, “Assessing the strengths and weaknesses of various types of pre–treatments of carbon nanotubes on the properties of polymer/carbon nanotubes composites: a critical review,” Polymer, 51, No. 5, 975–993 (2010).

L.–J. Cui, Y.–B. Wang, W.–J. Xiu, W.–Y. Wang, L.–H. Xu, X.–B. Xu, Y. Meng, L.–Y. Li, J. Gao, L.–T. Chen, and H.–Z. Geng, “Effect of functionalization of multi–walled carbon nanotube on the curing behavior and mechanical property of multi–walled carbon nanotube/epoxy composites,” Mater. Des., 49, 279–284 (2013).

A. Tugrul Seyhan, M. Tanoglu, and K. Schulte, “Mode I and mode II fracture toughness of e–glass non–crimp fabric/ carbon nanotube (CNT) modified polymer based composites,” Eng. Fract. Mech., 75, No. 18, 5151–5162 (2008).

S. Rahmanian, A. R. Suraya, M. A Shazed, R. Zahari, and E. S. Zainudin, “Mechanical characterization of epoxy composite with multiscale reinforcements: carbon nanotubes and short carbon fibers,” Mater. Des., 60, 34–40 (2014).

I. O’Connor, H. Hayden, S. O’Connor , J. N. Coleman, and Y. K. Gun’ko, “Polymer reinforcement with kevlar–coated carbon nanotubes,” J. Phys. Chem. C., 113, No. 47, 20184–20192 (2009)

K. J . Green, D. R. Dean, U. K. Vaidya, and E. Nyairo, “Multiscale fiber reinforced composites based on a carbon nanofiber/epoxy nanophased polymer matrix: synthesis, mechanical, and thermomechanical behavior,” Compos. Part A–Appl. S., 40, No. 9, 1470–1475 (2009).

E. N. Ganesh, “Single walled and multi walled carbon nanotube structure, synthesis and applications,” IJITEE, 2, No. 4, 2278–3075 (2013).

M. R. Ayatollahi, S. Shadlou, M. M. Shokrieh, and M. Chitsazzadeh, “Effect of multi–walled carbon nanotube aspect ratio on mechanical and electrical properties of epoxy–based nanocomposites,” Polym. Test., 30, No. 5, 548–556 (2011).

M. Kumar and Y. Ando, “Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production,” J. Nanosci. Nanotechno., 10, No. 6, 3739–3758 (2010).

R. Xiang, E. Einarsson, J. Okawa, Y. Miyauchi, and S. Maruyama, “Acetylene–accelerated alcohol catalytic chemical vapor deposition growth of vertically aligned single–walled carbon nanotubes,” J. Phys. Chem. C, 113, No. 18, 7511–7515 (2009).

D.–J. Yun, K. Hong, S. hyun Kim, W.–M. Yun, J. Jang, W.–S. Kwon, C.–E. Park, and S.–W. Rhee, “Multiwall carbon nanotube and poly(3,4–ethylenedioxythiophene): polystyrene sulfonate (PEDOT:PSS) composite films for transistor and inverter devices,” ACS. Appl. Mater. Inter., 3, No. 1, 43–49 (2011).

Q. Zhang, J. Wu, L. Gao, T. Liu, W. Zhong, G. Sui, G. Zheng, W. Fang, and X. Yang, “Dispersion stability of functionalized MWCNT in the epoxy–amine system and its effects on mechanical and interfacial properties of carbon fiber composites,” Mater. Des., 94, 392–402 (2016).

K. Jagadish, S. Srikantaswamy, K. Byrappa, L. Shruthi, and M. R. Abhilash, “Dispersion of multiwall carbon nanotubes in organic solvents through hydrothermal supercritical condition,” J. Nanomater., 2015, 1–6 (2015).

J. Zhou, J. Cheiftz, R. Li, F. Wang, X. Zhou, T.–K. Sham, X. Sun, and Z. Ding, “Tailoring multi–wall carbon nanotubes for smaller nanostructures,” Carbon, 47, No. 3, 829–838 (2009).

C.–X. Liu and J.–W. Choi, “Improved dispersion of carbon nanotubes in polymers at high concentrations,” Nanomaterials, 2, No. 4, 329–347 (2012).

S. Manivannan, I. O. Jeong, J. H. Ryu, C. S. Lee, K. S. Kim, J. Jang, and K. C. Park, “Dispersion of single–walled carbon nanotubes in aqueous and organic solvents through a polymer wrapping functionalization, “ J. Mater. Sci. Mater. Electron., 20, No. 3, 223–229 (2009).

Q. Li, M. Zaiser, and V. Koutsos, “Carbon nanotube/epoxy resin composites using a block copolymer as a dispersing agent,” Phys. Status. Solidi., 201, No. 13, R89–91 (2004).

X. C. Zhang, H. X. Peng, A. P. Limmack, and F. Scarpa, “Viscoelastic damping behaviour of cup stacked carbon nanotube modified epoxy nanocomposites with tailored interfacial condition and re–agglomeration,” Compos. Sci. Technol., 105, 66–72 (2014).

F. H. Gojny, M. H. G. Wichmann, B. Fiedler, and K. Schulte, “Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites – a comparative study,” Compos. Sci. Technol., 65, No. 15–16, 2300–2313 (2005).

M. Kim, Y.–B. Park, O. I. Okoli, and C. Zhang, “Processing, characterization, and modeling of carbon nanotube–reinforced multiscale composites,” Compos. Sci. Technol., 69, No. 3–4, 335–342 (2009).

M. Jamal–Omidi and M. ShayanMehr, “Improving the dispersion of SWNT in epoxy resin through a simple Multi–Stage method,” J. King Saud Univ. – Sci., 31, No. 2, 202–208 (2019).

M. Yourdkhani and P. Hubert, “A systematic study on dispersion stability of carbon nanotube–modified epoxy resins,” Carbon, 81, No. 1, 251–259 (2015).

L. Bokobza and J. Zhang, “Raman spectroscopic characterization of multiwall carbon nanotubes and of composites,” Express Polym. Lett., 6, No. 7, 601–608 (2012).

C. Vix–Guterl, M. Couzi, J. Dentzer, M. Trinquecoste, and P. Delhaes, “Surface characterizations of carbon multiwall nanotubes: comparison between surface active sites and raman spectroscopy,” J. Phys. Chem. B, 108, No. 50, 19361–19367 (2004).

ASTM, D638–02a. Standard Test Method for Tensile Properties of Plastics. ASTM International, West Conshohocken, PA, USA (2002).

D. Ren, “Understanding statistical hypothesis testing,” J. Emerg. Nurs., 35, No. 1, 57–59 (2009).

S. M. C. Pereira and G. Leslie, “Hypothesis testing,” Aust. Crit. Care, 22, No. 4, 187–191 (2009).

Acknowledgment

This project was funded by the Deanship of Scientific Research (DSR), at King Abdulaziz University, Jeddah, under grant No. G–511–135–36. The authors, with thanks, acknowledge DSR for the technical and financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 56, No. 2, pp. 321-336, March-April, 2020.

Rights and permissions

About this article

Cite this article

Bourchak, M., Juhany, K.A., Salah, N. et al. Determining the Tensile Properties and Dispersion Characterization of CNTs in Epoxy Using Tem and Raman Spectroscopy. Mech Compos Mater 56, 215–226 (2020). https://doi.org/10.1007/s11029-020-09874-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-020-09874-6