Abstract

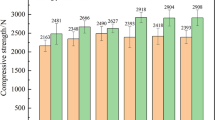

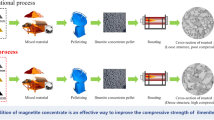

For improving the strength of pellets made of ultrafine and super-high-grade magnetite concentrates, the influence of basicity (CaO/SiO2 ratio) on the roasting and consolidation of pellets was investigated. The results showed that with the basicity of pellets increasing from 0.09 to 0.60, the compressive strength of both preheated and roasted pellets achieved an evident improvement from 502 and 2519 to 549 and 3096 N/pellet, respectively; meanwhile, the roasting time decreased from 15 to 9 min. The low-viscosity liquid phases were easily generated in fired pellets at the basicity range of 0.40–0.60 under the roasting temperature of 1240 °C, filled the voids between hematite particles and tightened the bonding among particles, effectively restraining the generation of concentric cracks and decreasing the porosity of fired pellets; low-viscosity liquid phases facilitated the solid diffusion of hematite, leading to the formation of coarse hematite crystals and thicker connecting necks.

Similar content being viewed by others

References

S. Dwarapudi, M. Ranjan, ISIJ Int. 50 (2010) 1581–1589.

D.Q. Zhu, F. Zhang, Z.Q. Guo, J. Pan, W. Yu, Int. J. Miner. Metall. Mater. 24 (2017) 473–485.

A.I. Arol, A. Aydogan, Colloids and Surfaces A: Physicochem. Eng. Aspects 232 (2004) 151–154.

X.H. Fan, X.L. Yuan, T. Jiang, L.S. Yuan, G.H. Li, J.M. Zhuang, Q.R. Tang, X.F. Yang, Chin. J. Nonferrous Met. 16 (2006) 1965–1970.

J.J. Fan, W.P. Zhang, C.G. Liu, G.D. Zhao, Y.M. Xi, Iron and Steel 49 (2014) No. 11, 20–24.

J.J. Fan, W.P. Zhang, C.G. Liu, G.D. Zhao, Y.M. Xi, Iron and Steel 48 (2013) No. 12, 20–24.

X.H. Fan, Z.Y. Tian, M. Gan, X.L. Chen, X.W. Zhou, G.J. Wang, Min. Met. Eng. 38 (2018) No. 1, 71–75.

D.Q. Zhu, M.J. Xu, J. Pan, C.C. Yang, H.Y. Tian, J. Iron Steel Res. 29 (2017) No. 9, 704–710.

C.C. Yang, D.Q. Zhu, J. Pan, B.Z. Zhou, X. Hu, J. Iron Steel Res. Int. 23 (2016) 924–932.

T. Umadevi, P. Kumar, N.F. Lobo, M. Prabhu, P.C. Mahapatra, M. Ranjan, ISIJ Int. 51 (2011) 14–20.

D.Q. Zhu, T.J. Chun, J. Pan, J.L. Zhang, Int. J. Miner. Process. 125 (2013) 51–60.

S. Dwarapudi, T.K. Ghosh, A. Shankar, V. Tathavadkar, D. Bhattacharjee, R. Venugopal, Int. J. Miner. Process. 99 (2011) 43–53.

X.H. Fan, M. Gan, T. Jiang, L.S. Yuan, X.L. Chen, J. Cent. South Univ. Technol. 17 (2010) 732–737.

J.D.G. Hamilton, Trans. Inst. Min. Metall. Sect. C 85 (1976) 30–39.

S.C. Panigrahy, B.C. Jena, M. Rigaud, Metall. Trans. B 21 (1990) 463–474.

F.W. Frazer, H. Westenberger, K.H. Boss, W. Thumm, Int. J. Miner. Process. 2 (1975) 353–365.

Y.S. Yusfin, T.Y. Malysheva, S.V. Plotnikov, Steel in Translation 39 (2009) 375–378.

J.Y. Fu, T. Jiang, D.Q. Zhu, Principle of sintering and pelletizing, Central South University of Technology Press, Changsha, China, 1996.

J.R. Wynnyckyj, W.A. McCurdy, Metall. Trans. 5 (1974) 2207–2215.

S.P.E. Forsmo, S.E. Forsmo, P.O. Samskog, B.M.T. Björkman, Powder Technol. 183 (2008) 247–259.

S.P.E. Forsmo, A. Hägglund, Int. J. Miner. Process. 70 (2003) 109–122.

J.C. Ruiz Sierra, J.M. Badie, F. Chejne Janna, Ironmak. Steelmak. 21 (1994) 114–117.

Acknowledgements

The authors want to express their gratitude for the financial support from the National Natural Science Foundation of China (No. 51474161) and would like to thank the Hunan Provincial Co-innovation Center for Clean and Efficient Utilization of Strategic Metal Mineral Resources, which supplied us the facilities and funds to complete the experiments.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhang, F., Zhu, Dq., Pan, J. et al. Improving roasting performance and consolidation of pellets made of ultrafine and super-high-grade magnetite concentrates by modifying basicity. J. Iron Steel Res. Int. 27, 770–781 (2020). https://doi.org/10.1007/s42243-020-00388-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-020-00388-y