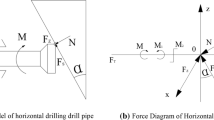

The non-interference uniform speed rope drilling coring device is a tool for investigating samples of submarine underground leakage hydrate rock formations. In the process of coring, the penetration resistance of the shoe is large, and the rock stratum is disturbed, which results in disturbance of the rock sample's original state. In order to solve this problem, the standard core diameter is ∅72 mm and the length is the length of a single cylinder. For example, a drilling coring device with a working outer diameter d not more than 90 mm is used to optimize the size and structure of the shoe. To ensure the strength of the tube shoe, the related dimensions of the shoe were optimized using finite element analysis software, and the structure of the shoe was improved based on the optimized dimensions. The results of the size optimization are: á = 20 °, 11 = 13mm, and ä = 1.5mm: the structural improvement results are: the front cone surface at the lower end of the rube shoe is changed to a regular mesa, and the number of regular mesa sides is 32. The LS-DYNA dynamic simulation results show that the penetration resistance of the tube shoe after size optimization and structure improvement is significantly reduced, so the disturbance of the drilling and coring device to the rock formation is also reduced, and the quality of the sample is improved.

Similar content being viewed by others

References

“China’s first sea area gas hydrate trial and test success,” China Today: Chinese version, (66), 8 (2017).

D. Wang and J.Q. Chen, “Current status of research and development of submarine gas hydrate resources,” Energy Res. Uttl., 6, 36-39 (2004).

Y.M. Zhou, X.Y. Song, J. Wang, et al., “Submarine gas hydrate mining device,” Sci. Technol. Vision, 9, (2017).

Y.X. Fang, X.L. Jin, and M.B. Li, “Exploration and Development Technology of Natural Gas Hydrate,” China Ocean Platform, 17(2), 11-15 (2002).

M. Wu and L.H. Xie, Finite Element Analysis and Simulation of ANSYS Workbench, Publishing House of Electronics Industry (2014).

W. Liu, D.C. Li, Z.M. Jin, et al., “Structural design criteria for flexible titanium mandible substitutes based on finite element method,” Chin. J. Rehab. Med., 23(9), 836-838 (2008).

H. Ren, X.L. Pei, Z.H. Wu, G.Q. Zhou, Q.Z. Yang, and J.L. Xu, “Development and field test of gas hydrate insulation and pressure-reducing tools,” Oil Drill. Technol., 46 (03), 44-48 (2018).

H.L. Ruan, Y.L. Chen, J.P. Cai, et al., “Optimization and application of sampling and drilling tools for Nanhai ultra-deep water drilling” China Offshore Oil Gas, 1, 105-109 (2017).

T.J. Yan, M.X. Jiang, Y. Zhang, et al., “Law of particle impact rock breaking under confining pressure based on ANSYS-LSDYNA,” Fault Block Oil Gas Field, 02, 108-111 (2012).

Q.X. Sun, J. Yang, et al., “Simulation research on stamping forming of electronic components based on LS-DYNA,” Mecn. Sci. Technol., 32(1), 146-149 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 2, pp. 66 — 71, March—April, 2020.

Rights and permissions

About this article

Cite this article

Yang, Z., Jiawei, L., Hong, R. et al. Research on Optimizing the Size and Structure of Tube Shoes of Undisturbed Uniform Rope Drilling Coring Tools. Chem Technol Fuels Oils 56, 226–235 (2020). https://doi.org/10.1007/s10553-020-01133-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-020-01133-7