Abstract

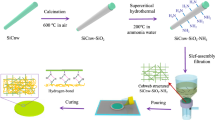

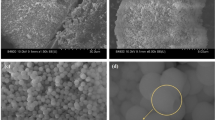

As a matrix resin of silica/epoxy hybrid encapsulation material with high heat resistance and low coefficient of thermal expansion, a tri-functional triglycidyl p-aminophenol (TGPAP) epoxy was successfully synthesized with the desired chemical structure by reacting epichlorohydrin with p-aminophenol using sodium hydroxide catalyst. In order to produce highly pure TGPAP with lower viscosity, a physical thin film vacuum distillation was carried out after synthesis, resulting in 97% purity with the viscosity of 700 cps at room temperature. Silica/TGPAP hybrid was fabricated using two kinds of ground fumed silica with different sizes of 20 μm and 9 μm. Glass transition temperature of the hybrid was found to be as high as 185 °C. Viscosity of the hybrid was 30,000 cps at room temperature before curing, implying good processability. When two different sizes of silica were used with 1 to 1 weight ratio, very low coefficient of thermal expansion of 22.79 ppm/°C was obtained. From thermal shock test, no cracks were observed even after 1,000 cycles of thermal shock between −40 °C and 125 °C when 67 wt% (45.8 vol%) of silica was involved in the hybrid. In conclusion, silica/TGPAP hybrid with improved processability, superior thermal shock resistance and low thermal expansion coefficient could be fabricated as electronic device encapsulation.

Similar content being viewed by others

References

Z. Chen, Proc. of the 5th International Conference on Environment, Materials, Chemistry and Power Electronics, Zhengzhou, 2016, p 21.

D. H. Schramm, J. of Renewable Energy and Sustainable Development, 1, 233 (2015).

H. Casier, Proceesings of the 5th International Conference on Thermal and Mechanical Simulation and Experiments in Microelectronics and Microsystems, 7 (2004).

W. Hollstein, Proc. Inductica (2012).

L. Gang, J. Experiment Science & Technology, 8, 20 (2010).

E. M. Johansson, Thesis, Controlling the Pore Size and Morphology of Mesoporous Silica, Linköping Univ. Electronic Press, Linköping, 2010.

I. Baylakoglu, C. Hillman, and M. Pecht, Proc. of the International IEEE Conference on the Business of Electronic Product Reliability and Liability, Hong Kong, 2003.

J. Tarrío-Saavedra, J. López-Beceiro, S. Naya, C. Gracia, and R. Artiaga, Express Polym. Lett., 4, 382 (2010).

Y. Wang, H. Liu, W. Li, and R. Ding, Macromol. Res., 27, 310 (2019).

H. T. Han and C. S. Wang, Eur. Polym. J., 37.2, 267 (2001).

T. Braun, K. F. Becker, M. Koch, V. Bader, R. Aschenbrenner, and H. Reichl, 8thInternational Advanced Packaging Materials Symposium IEEE., 2002, pp 151–159.

R. Mustafa, M. B. H. Othman, H. Ismail, and Z. Ahmad, Malaysian Polym. J., 4, 68 (2009).

B. E. Neves, R. B. Snyder, and T. A. Estes, Proc. of IPC Printed Circuit EXPO, Long Beach, 2003.

C. S. Wang and Z. K. Liao, Polym. Bulletin, 25, 559 (1991).

C. Asada, S. Basnet, M. Otsuka, C. Sasaki, and Y. Nakamura, Int. J. Biol. Macromol, 74, 413 (2015).

A. D. Nguyen and F. Le Goffic, Chem. Eng. Sci., 52, 2661 (1997).

J. Cvengroš, Š. Pollák, M. Micov, and J. Lutišan, Chem. Eng. J., 81, 9 (2001).

J. Cvengroš, Chem. Eng. Technol., 18, 49 (1995).

ASTM D 1652-97, American Society for Testing Materials International (1997).

ISO 2127-1, International Organization for Standardization (2019).

ISO 2555, International Organization for Standardization (2018).

T. H. Huh, S. Y. Lee, S. K. Park, J. H. Chang, Y. Lee, and Y. J. Kwark, Macromol. Res., 26, 187 (2018).

S. E. Lehman Jr., U.S. Patent 7,351,784 (2008).

JESD22-A104B, Joint Electron Device Engineering Council Standard (2000).

JESD22-A106B, Joint Electron Device Engineering Council Standard (2004).

AEC-Q200 Grade 1, Automotive Electronics Council Component Technical Committee (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Acknowledgments: This research was financially supported by National Research Foundation of Korea (NRF) grant (2010-0027955) and Korea Institute of Industrial Technology as “Development of smart textronic products based on electronic fibers and textiles (kitech JA-20-0001).”

Rights and permissions

About this article

Cite this article

Lee, S.B., Lee, H.S., Son, C.B. et al. Silica/Epoxy Hybrid Encapsulation with High Heat-Resistance and Low Coefficient of Thermal Expansion. Macromol. Res. 28, 1040–1045 (2020). https://doi.org/10.1007/s13233-020-8135-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-020-8135-8