Abstract

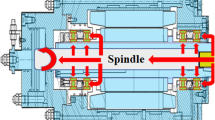

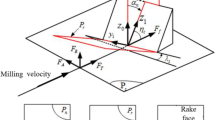

Wellbore trajectory control tool is a sort of point-the-bit drilling tool to achieve the steering function while drilling. In complex conditions, the spindle bears the acting force of the bit pressure, the torque, the force of biasing mechanism and so on. So the force is very complex. Basing on the early research of our group, the further research of spindle deflecting reliability of prototype has been carried out. Based on the contact analysis between the tool spindle and the inner eccentric ring, the variation law of contact stress between the inner ring of the eccentric mechanism and the spindle is studied. Based on Palmgren-Miner and the fatigue life experiment of the spindle material, the cumulative damage calculation model of the spindle is established, and the fatigue life of spindle is solved. The result shows that the deflecting reliability of the spindle can be guaranteed.

Similar content being viewed by others

References

D. Feng et al., Development status and trend of well trajectory control tool, China Petroleum Machinery, 39 (3) (2011) 70–73.

H. Zhang, Y. Feng, Z. Xiang and D. Feng, Study on deformation motion and mechanical model of the shaft of the wellbore trajectory control tool, Journal of Applied Science and Engineering, 20 (4) (2017) 435–443.

H. Zhang et al., A new predicting method of build-up rate of steering tools based on Kriging surrogate model, Arab. J. Sci. Eng., 43 (2018) 4949–4956.

H. Zhang et al., Research on the correlation between the spindle load and the deflecting capacity of the wellbore trajectory control tool, Mechanics in Engineering, 39 (2017) 134, 152–157.

Q. Sun et al., Failure analysis of cantilever bearing in wellbore trajectory control tool with high build-up rate, Engineering Failure Analysis, 104 (10) (2019) 1040–1052.

K. Iyer, Solution for contact in pinned connections, International Journal of Solids and Structures, 38 (2001) 9133–9148.

M. A. Miner, Cumulative damage in fatigue, Journal of Applied Mechanics, 12 (1945) 159–164.

S. R. Prasad and A. S. Sekhar, Life estimation of shafts using vibration based fatigue analysis, Journal of Mechanical Science and Technology, 32 (9) (2018) 4071–4078.

S. H. Baek, S. S. Cho, H. S. Kim and W. S. Joo, Reliability design of preventive maintenance scheduling for cumulative fatigue damage, Journal of Mechanical Science & Technology, 23 (5) (2009) 1225–1233.

V. C. Tong and S. W. Hong, Statistical investigation into the effects of distributed roller diameter error on the fatigue life of tapered roller bearings, Journal of Mechanical Science and Technology, 31 (12) (2017) 5977–5985.

E. Suhir, R. Ghaffarian and S. Yi, Probabilistic Palmgren — Miner rule, with application to solder materials experiencing elastic deformations, Journal of Materials Science: Materials in Electronics, 28 (3) (2017) 2680–2685.

A. Palmgren, Die Lebensdauer von Kugellagern, Zeitschrift des Vereins Deutscher Ingenieure, 68 (1924) 339–341.

S. R. Prasad and A. S. Sekhar, Life estimation of shafts using vibration based fatigue analysis, Journal of Mechanical Science and Technology, 32 (9) (2018) 4071–4078.

M. Yakout, A. Elkhatib and M. G. A. Nassef, Rolling element bearings absolute life prediction using modal analysis, Journal of Mechanical Science and Technology, 32 (1) (2018) 91–99.

Acknowledgments

This work was supported by the National Science and Technology Major Project of China under Grant No. 2016ZX05038-002-LH001, the National Natural Science Foundation of China under Grant No. 51275057 and 51704034, and the Postgraduate education and teaching research project of Yangtze University No. YJY2019024.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Guest Editor Seung Jin Song.

Hong Zhang was born in Shandong Province, P.R. China in 1982. She received her B.S. degree from China University of Petroleum, M.S. degree from Shandong University and Ph.D. degree from Yangtze University, and currently is a Vice Professor at the School of Mechanical Engineering of Yangtze University. Her research interests are in the design, development and simulation of oil and gas equipment and downhole tools and the study of pipe string mechanics.

Ding Feng was born in Anhui Province, P. R. China in 1963. He received his Ph.D. degree from China University of Petroleum(Beijing) in 2012, and currently is a Professor of Yangtze University. His research interests are in the design of oil and gas equipment and downhole tools, diagnosis and the dynamic simulation theory and technology application.

Rights and permissions

About this article

Cite this article

Zhang, H., Shi, L., Liu, X. et al. Research on the spindle deflecting reliability of the wellbore trajectory control tool based on Palmgren-Miner. J Mech Sci Technol 34, 4925–4931 (2020). https://doi.org/10.1007/s12206-020-2105-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-020-2105-0