Abstract

To consider the effect of crack closure on the mechanical properties of metals, the fatigue life of metal specimens is predicted based on energy dissipation model. The main feature of the model consists in considering the relationship between the total failure energy and the energy density increment. The total failure energy model considers the fatigue crack size and stress amplitude. It is assumed the energy density increment gradually decreases and tends to be stable. The influence of crack closure effect is considered. According to the law of metal fatigue characteristics, a new mathematical model for predicting fatigue life is established.

Similar content being viewed by others

Abbreviations

- \( b \) :

-

Fatigue strength exponent

- \( c \) :

-

The fatigue ductility exponent

- \( \Delta \sigma \) :

-

Stress range

- \( \sigma_{a} \) :

-

Maximum tensile stress

- \( a_{\text{c}} \) :

-

Critical crack size

- \( a{}_{0} \) :

-

Initial crack size

- \( n \) :

-

Strain hardening exponent

- \( n^{\prime } \) :

-

Cyclic strain hardening exponent

- \( \varepsilon_{\text{f}} \) :

-

Fracture ductility

- \( \varepsilon_{\text{f}}^{{\prime }} \) :

-

Cyclic fatigue ductility coefficient

- \( \Delta \varepsilon_{\text{p}} \) :

-

Plastic strain range

- \( \Delta \varepsilon_{{{\text{p}}Z}} \) :

-

Plastic strain increment under equivalent stress increment

- \( \alpha \) :

-

Equivalent strain increment parameter

- \( W_{\text{p}} \) :

-

Plastic strain energy

- \( \sigma_{\text{f}}^{\prime } \) :

-

Cyclic fatigue strength coefficient

- \( \delta {\text{W}} \) :

-

One-cycle plastic strain energy increment

- \( K^{\prime } \) :

-

Cyclic stress intensity coefficient

- \( W_{\text{pf}} \) :

-

Total failure energy

- \( \sigma_{b} \) :

-

Ultimate tensile strength

- \( K_{\text{theff}} \) :

-

Effective initial stress intensity factor

- \( K_{I} \) :

-

Stress intensity factor

- \( \sigma_{\text{f}} \) :

-

Fracture strength

- \( N_{\text{f}} \) :

-

Fatigue life

References

Zhu SP, Hao YZ, de Oliveira Correia JA, Lesiuk G, de Jesus AM (2019) Nonlinear fatigue damage accumulation and life prediction of metals: a comparative study. Fatigue Fract Eng Mater Struct 42(6):1271–1282

Feng L (2016) Fiber metal layer board fatigue property analysis based on strain energy density method. Mech Eng Autom 6:129–131

Wu JN, Yan SZ, Li JL, Gu YX (2016) Mechanism reliability of bistable compliant mechanisms considering degradation and uncertainties: modeling and evaluation method. Appl Math Model 40(23–24):10377–10388

Liu XT, Zhang MH, Wang HJ, Luo J, Tong JC, Wang XL (2020) Fatigue life analysis of automotive key parts based on improved peak‐over‐threshold method. Fatigue Fract Eng Mater Struct 43(8):1824–1836

He JC, Zhu SP, Liao D, Niu XP (2020) Probabilistic fatigue assessment of notched components under size effect using critical distance theory. Eng Fract Mech 235:107150

Liu XT, Kan FH, Wang HJ, Xin XF, Wang ZQ, Huang H (2020) Fatigue life prediction of clutch sleeve based on abrasion mathematical model in service period. Fatigue Fract Eng Mater Struct 43(3):488–501

Geng SL, Liu XT, Liang ZQ, Wang YS, Wang XL (2020) Tolerance analysis and evaluation of uncertain automatic battery replacement system. Struct Multidiscip Optim 61(1):239–252

Wang ML, Liu XT, Wang XL, Wang YS (2018) Probabilistic modeling of unified S-N curves for mechanical parts. Int J Damage Mech 27(7):979–999

Wang HJ, Liu XT, Zhang MH, Wang YS, Wang XL (2019) Prediction of material fatigue parameters for low alloy forged steels considering error circle. Int J Fatigue 121:135–145

Esin A (1968) The microplastic strain energy criterion applied to fatigue. Basic Eng 90(1):28–31

Esin A, Jones WJD (1966) A theory of fatigue based on the microstructural accumulation of strain energy*1. Nucl Eng Des 4(3):292–298

Tchankov DS, Vesselinov KV (1998) Fatigue life prediction under random loading using total hysteresis energy. Inc J Pressure Vessel Pi 75(13):955–962

Xiao T, De W, Hao X (1989) Investigation of cyclic hysteresis energy in fatigue failure process. Int J Fatigue 11(5):353–359

Liakat M, Khonsari MM (2014) Rapid estimation of fatigue entropy and toughness in metals. Mater Des 62:149–157

Huffman P, Ferreira J, Correia JAFO, Jesus AMPD, Glinka G (2017) Fatigue crack propagation prediction of a pressure vessel mild steel based on a strain energy density model. Frat Ed Integr Strut 42:170–180

Lesiuk G, Szata M, Rozumek D, Marciniak Z, Correia J, De Jesus A (2018) Energy response of s355 and 41cr4 steel during fatigue crack growth process. J Strain Anal Eng Des 53(8):663–675

Correia JAFO, Huffman PJ, De Jesus AMP (2018) Probabilistic fatigue crack initiation and propagation fields using the strain energy density. Strength Mater 2018(50):620–635

Lesiuk G, Szata M, Rozumek D, Marciniak Z, Jesus AMPD (2017) Energy description of fatigue crack growth process-theoretical and experimental approach. Procedia Struct Integr 5:904–911

Yang B, Liaw PK, Morrison M, Liu CT, Buchanan RA, Huang JY (2005) Temperature evolution during fatigue damage. Intermetallics 13(3):419–428

Risitano A, Risitano G (2013) Cumulative damage evaluation in multiple cycle fatigue tests taking into account energy parameters. Int J Fatigue 48:214–222

Meneghetti G (2007) Analysis of the fatigue strength of a stainless steel based on the energy dissipation. Int J Fatigue 29(1):81–94

Meneghetti G, Ricotta M (2012) The use of the specific heat loss to analyse the low-and high-cycle fatigue behaviour of plain and notched specimens made of a stainless steel. Eng Fract Mech 81:2–16

Ye DY, Wang ZL (2001) A new approach to low-cycle fatigue damage based on exhaustion of static toughness and dissipation of cyclic plastic strain energy during fatigue. Int J Fatigue 23(8):679–687

Wang HJ, Liu XT, Wang XL, Wang YS (2019) Numerical method for estimating fatigue crack initiation size using elastic-plastic fracture mechanics method. Appl Math Model 73:365–377

Meneghetti G, Ricott M (2017) Evaluating the heat energy dissipated in a small volume surrounding the tip of a fatigue crack. Int J Fatigue 3:424–431

Stowell E (1966) A study of the energy criterion for fatigue. Nucl Eng Des 3:32–40

Correia JAFO, Blasón S, De Jesus AMP, Canteli AF, Moreira PMGP, Tavares PJ (2016) Fatigue life prediction based on an equivalent initial flaw size approach and a new normalized fatigue crack growth model. Eng Fail Anal 69:15–28

Vshivkov AN, Iziumova AY, Panteleev IA, Ilinykh AV, Wildemann VE, Plekhov OA (2019) The study of a fatigue crack propagation in titanium Grade 2 using analysis of energy dissipation and acoustic emission data. Eng Fract Mech 210:312–319

Wojciech M, Tadeusz L, Norbert M (2018) Energy-based fatigue failure characteristics of materials under random bending loading in elastic-plastic range. Fatigue Fract Eng Mater Struct 41(2):249–259

Guo Q, Zairi F, Guo XL (2018) An intrinsic dissipation model for high-cycle fatigue life prediction. Int J Mech Sci 140:163–171

Wang RZ, Zhang XC, Tu ST, Zhu SP, Zhang CC (2016) A modified strain energy density exhaustion model for creep-fatigue life prediction. Int J Fatigue 90:12–22

Zhu SP, Liu Y, Liu Q (2018) Strain energy gradient-based LCF life prediction of turbine discs using critical distance concept. Int J Fatigue 113:33–42

Socie DF, Morrow J, Chen WC (1979) A procedure for estimating the total fatigue life of notched and cracked members. Eng Fract Mech 11(4):851–859

Mahtabi MJ, Shamsaei N (2016) A modified energy-based approach for fatigue life prediction of superelastic NiTi in presence of tensile mean strain and stress. Int J Mech Sci 117:321–333

Sedighi M, Monshi P, Joudaki J (2017) Investigation of mechanical properties and fatigue life of ECARed AA5083 aluminium alloy. Fatigue Fract Eng Mater Struct 40(3):412–422

Liao D, Zhu SP (2019) Energy field intensity approach for notch fatigue analysis. Int J Fatigue 127:190–202

Liao D, Zhu SP, Keshtegar B, Qian G, Wang QY (2020) Probabilistic framework for fatigue life assessment of notched components under size effects. Int J Mech Sci 181:105685

Liu HL, Liu HJ, Bocher P, Zhu CC, Sun ZD (2018) Effects of case hardening properties on the contact fatigue of a wind turbine gear pair. Int J Mech Sci 141:520–527

Elber W (1970) Fatigue crack closure under cyclic tension. Eng Fract Mech 2(1):37–45

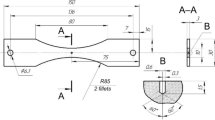

Schijve J (1998) Fatigue specimens for sheet and plate material. Fatigue Fract Eng Mater Struct 21(3):347–357

Manson SS, Hrischberg MH (1963) Fatigue behavior in strain cycling in low-and intermediate-cycle range. In: Proceedings of the 10th Sagamore army materials research confidence

Zheng XL, Wang H, Yan JH, Ding XW (2013) Material fatigue theory and engineering application. Science Press, Beijing

Wang XG, Crupi V, Jiang C (2017) Energy-based approach for fatigue life prediction of pure copper. Int J Fatigue 104:243–250

Budynas RG, Nisbett JK (2006) Shigley’s mechanical engineering design, 8th edn. McGraw-Hill Primis, New York

Mischke CR (1987) Prediction of stochastic endurance strength. J Vib Acoust Stress Reliab Des 109(1):113

Ling J, Pan J (1997) A maximum likelihood method for estimating P-S-N curves. Int J Fatigue 19:415–419

Tong XY, Jun WD, Hao X (1989) Investigation of cyclic hysteresis energy in fatigue failure process. Int J Fatigue 11:353–359

Acknowledgement

This work is supported by the National Natural Science Foundation of China (51675324).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Q., Liu, X., Liang, Z. et al. Fatigue life prediction model of metallic materials considering crack propagation and closure effect. J Braz. Soc. Mech. Sci. Eng. 42, 424 (2020). https://doi.org/10.1007/s40430-020-02512-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02512-1