Abstract

Periodic wavy patterns emerge and align in a transverse direction once a viscous fluid is coated onto a surface moving above a critical speed. In this study, we examine how this flow instability, which is usually referred to as ribbing, is triggered or damped on a moving topographic surface. To examine the transient flow behavior, the liquid first came into contact with a smooth surface, followed by a downstream surface with small-scale V-shaped grooves. Flow visualizations revealed a topography-induced flow stabilization and a matching of rib frequencies with the underlying groove patterns, depending on the groove geometry and capillary number.

Similar content being viewed by others

Introduction

Thin liquid film flowing over a topography is common in coating processes such as photolithographic steps in the fabrication of microelectronics,1 painting or printing on textiles,2 and cosmetics coating on human skin that involves groove-shaped sulcus cutis of submillimeters in depth. A wavy pattern evolves when a thin layer of viscous fluid is coated onto a surface that is moving above a critical speed. Generally, this pattern consists of crests and troughs, which run in the coating direction and periodically align in the transverse direction. This three-dimensional flow instability is often referred to as ribbing, which has garnered considerable attention in fluid dynamics over the decades.3,4,5,6,7 The flow becomes unstable against infinitesimal disturbances when the pressure gradient in the downstream direction is positive and exceeds a critical value.8 Viscous forces tend to increase the pressure gradient and destabilize the flow, whereas capillary pressure under a curved free surface contributes to decrease such instability. The competition between these two forces is characterized by the capillary number Ca = μU/σ, where μ is the shear viscosity, U is the speed of the moving surface, and σ is the surface tension of the fluid. Previous studies demonstrated that the ribbing frequency is determined by Ca and geometries of the flow channel.9,10 However, most of the previous studies were limited to the flow instability on smooth surfaces.

Consider a laminar flow confined between a stationary solid surface and a moving surface with topographic patterns. When the characteristic pattern depth (D) is much larger than the gap between the two surfaces (h0) (i.e., D/h0 ≫ 1), the flow would stabilize as the local pressure gradient dumps in the engraved pattern.11 In contrast, when D/h0 ≪ 1, flow instability is triggered just as it would be for a smooth surface. When a fluid flows along multiple patterns (grooves or cavities), the pressure gradient of the fluid decreases over concave patterns but grows over un-patterned surfaces in a sequential manner, leading to show a locally destabilized transient flow behavior that differs from the one across a smooth surface. Although extensive studies exist on ribbing instabilities in journal bearing,12 forward-roll coatings,10,13,14,15,16 reverse-roll coatings,17,18,19,20 deformable-roll coatings,21,22,23 slot-die coatings,24,25 and slide coatings,26 little attention has been paid to instabilities of free surface flows on topographic surfaces.

In this study, we examined the ribbing instability of a nonvolatile Newtonian fluid coated on a moving isothermal solid surface with a series of V-shaped grooves. The fluid was first destabilized on a smooth surface and subsequently moved onto a topographic surface, enabling comparison of flow stabilities across the two surfaces. The results revealed a topography-induced stabilization of the flow and a matching of rib frequencies with the underlying groove patterns. The ribbing patterns on topographic features were summarized into the flow regime map, which enables prediction of operable parameters for flow stabilization.

Experimental

We used Newtonian silicone oils (Shin-Etsu Silicone Co. Ltd.) with shear viscosities of 0.98 and 2.91 Pa·s, as well as 21.1 mN/m of static surface tension. The shear viscosity and the surface tension were measured with a stress-controlled shear rheometer (Mars II, Haake) and Wilhelmy plate (CBVP-A3, Kyowa), respectively. The liquid was coated on an aluminum plate with a flat 170-mm-long upstream surface and a 60-mm-long topographic downstream surface (Fig. 1). The latter was built by knurling a series of triangular grooves with a certain depth (D) that ranged between 33.3 and 1000 μm. The groove angle (θ) with respect to the longitudinal direction of the plate was varied between 30 and 90°. The width-to-depth ratio was fixed at 3.0, whereas the width of nongrooved area (i.e., land) between neighboring grooves (S) was fixed at 450 μm. The fluid was first spread onto the plate using a blade coater (Spiral Film Applicator Model 358, Erichsen) to cover both the groove and land surfaces and then confined between the plate and a cylindrical glass with a radius (R) of 63.9 or 201.1 mm. The minimum gap (h0) between the two surfaces was adjusted and maintained at 10 μm using a feeler gauge. To create a pressure gradient in the fluid, the cylindrical glass was fixed, whereas the coated plate was horizontally moved at a certain speed (U) between 2.1 and 90 mm/s using a variable-speed electric motor (SGSP33-200, Sigma-Koki). The flow became unstable as the fluid passed through the diverging channel between the stationary cylinder and moving plate. Once the speed exceeded a critical value, ribs appeared, wandered transversely, and coalesced to grow further in length. Finger-like capillary ridges with curved tips are developed in the upstream of crests on a wet film, demonstrating the same appearance reported in the literature.12 The ribbing instability of the fluid was visualized from the top using a digital video camera (Ditect, HAS-L1C) at 200 frames/s. To quantify the inter-rib spacing (λ) and rib length (l), profiles of 3–10 ribs were extracted from each 30-mm-wide image with a resolution of 252 × 189 pixels using image analysis.

(a) Schematic diagram of ribbing instability of fluid confined between a cylindrical glass and a planar moving solid. Finger-like capillary ridges are developed on the moving surface, leaving crests in the downstream direction. The figure depicts the characteristic rib spacing (λ) defined as the transverse distance between the neighboring tips and the characteristic length (l) of ribs defined as the longitudinal distance between the tip and the neck. (b) Geometries of solid surface consisting of 170-mm flat surface and 60-mm grooved surface. (c) Cross-sectional view of triangular grooves with the depth D, the width W, and the land width S

Results and discussion

First, we demonstrated the flow transition when a fluid sequentially coated the smooth and topographic surfaces. Figure 2 shows time-lapsed snapshots of deforming air–liquid interfaces at Ca = 0.288. The substrate moved downward, as indicated by the arrow. The well-ordered crests were aligned in the transverse direction on the smooth plate (Fig. 2a). The free surface was stretched in the downstream direction and curved at the tips (white spots in the figure) of each crest. As the fluid moved onto the 45° angled grooves, the interface curvature relaxed at the tip, showing a near-sinusoidal profile with a wider rib spacing (Fig. 2b). Figs. 2a′ and 2b′ show schematics that highlight the groove geometries and free surface profiles corresponding to 2a and 2b, respectively.

Time-elapsed snapshots of deforming air–liquid interface on (a) flat and (b) grooved surface at Ca = 0.288. The substrate moves downward as indicated by the arrow. Ordered wavy patterns align in the transverse direction, and show a wider inter-rib spacing on the topographic surface with 45°-angled grooves. (a′) and (b′) show schematics that highlight the groove geometries and free surface profiles corresponding to (a) and (b), respectively

To examine the transient flow in detail, we tracked the tip positions to determine the rib length (l), which is defined as the distance between the tip and the neck (see Fig. 1a). Typical examples of time evolutions in ribbing patterns are illustrated in Fig. 3.

Time evolutions in tip position at different capillary number and groove angle of (a) Ca = 0.21, θ = 30°, and (c), (e) Ca = 2.46, θ = 45°, respectively. The circles show the tip positions moving along the smooth and grooved surface. The groove widths and cylinder radii (R) were of (a), (c) W = 1000 μm, R = 63.9 mm and (e) W = 500 μm, R = 201.1 mm. The time evolutions of rib length (l) are shown in (b), (d), and (f) under the same condition corresponding to (a), (c), and (e), respectively. Ribs decayed and eventually disappeared on the groove pattern in (a). The neighboring ribs merge to leave wider-spaced ribs in (c), whereas ribs maintained their spacing either on the flat or patterned surfaces in (e)

At low Ca values, the ribs on the topographic surface decayed in length while maintaining frequency and eventually disappeared in a finite length, showing a topography-induced flow stabilization (Figs. 3a and 3b).

In contrast, neighboring ribs approached one another and merged, leaving wider-spaced ribs at high Ca (Figs. 3c and 3d). In the case of finer groove patterns, ribs maintained their spacing and length for either the smooth or grooved surfaces (Figs. 3e and 3f). These different features of transient coating flows show rich physics of ribbing instability on topographic surfaces.

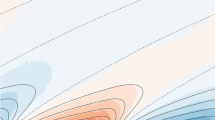

Next, we discuss the fully developed ribs that complete coalescence or decay over a finite distance on the moving substrate. Based on Lopez et al.,12 the rib spacing was scaled in units of (h0R)1/2 as shown in Fig. 4 for (a) smooth and (b) grooved surfaces. The rib spacing decreased with increasing capillary numbers and reached a constant value at high Ca, showing good qualitative consistency with the previous experiments.3 In the case of the smooth surface, the nondimensional rib spaces matched at two different radii of the cylindrical surface, R, and collapsed into a single band with respect to the capillary number (Fig. 4a). However, the scaling differed for the ribs on the topographic surface. A decrease in the curvature radius led to an increase in the dimensionless rib spacing as well as the critical capillary number (Cac) below which the ribs disappear (Fig. 4b). Although it has been previously known that flow on a smooth surface becomes more stable when the fluid contacts a surface with a smaller curvature radius,9,10 the larger rib spacing at a smaller radius on the topographic surface demonstrated an opposite trend from the flow on a smooth surface.

Variations in rib spacing with capillary number for (a) smooth and (b) patterned surfaces. The dimensionless spacing data collapse into a single band with respect to Ca on the flat surface, whereas the scaling no longer holds for the ribs on the topographic surface. The ribs disappear below a critical capillary number. The groove angle was θ = 45°

To further examine the effects of groove geometry on the ribbing instability, we calculated the dimensionless inter-rib spacing (λ/λ0) for different groove widths, where λ0 denotes the rib spacing on the smooth surface at each Ca. When the groove is angled at θ, the center-to-center distance between neighboring grooves in the transverse direction is expressed as (W + S)/cosθ, where S represents land width. The broken curve in Fig. 5a represents the rib spacing that matches the groove distance as λ = (W + S)/cosθ. For large groove widths, the rib spacing almost matched the center-to-center groove distance at Ca = 2.46, indicating that the rib evolution was guided by surface topography. The rib spacing at smaller widths of W < 0.5 mm was longer than both the groove distance and λ0. In contrast, the rib spacing at low capillary numbers of Ca = 0.41 agreed with that on the smooth surface, i.e., λ/λ0 = 1. The spacing of the ribs increased with the increase in the width of grooves; however, they disappeared beyond the critical width of W > 3 mm.

Variations in rib spacing ratio (λ/λ0) with (a) width and (b) angle of grooves. The broken curves denote the rib spacings that match the center-to-center groove distance as λ = (W + S)/cosθ. The rib spacing at Ca = 2.46 first decreased, approached the groove distance to reach a minimum, and then increased with increasing the groove width, showing the rib evolution guided by the series of grooves. The radius of curvature of stationary surface was fixed at R = 63.9 mm

In the second series of experiments, the groove inclination angle was varied, while the groove width was kept constant. As shown in Fig. 5b, the rib spacing agreed well with the center-to-center distance of grooves at low angles (θ < 45°), whereas it was no longer guided by the grooves at larger angles.

We systematically collected similar measurements for different groove depths and inclination angles to determine critical conditions, beyond/below which different flow instabilities emerge. Figure 6 illustrates the flow regime map within the capillary number/groove-geometry parameter space. In a single groove inclined at angle θ with respect to the longitudinal direction, the apparent depth of the groove was given by D/sinθ, which was derived by integrating the triangular surface profile in the moving direction of the substrate and dividing by the width W. We considered the effective clearance of h0 + D/sinθ and used the clearance-to-radius ratio (h0 + D/sinθ)/R as the characteristic geometric factor of the flow channel. When the groove depth (D) was much smaller than the minimum gap between the stationary and moving surfaces (h0) (i.e., D/h0 ≪ 1), the geometric factor was reduced to h0/R, which agreed with the geometrical factor that dominates a forward-roll coating flow confined between two cylindrical rolls of radius R with a gap h0.10,13

Flow regime map for ribbing instability of fluids confined between the curved surface with the radius of curvature, R, and the engraved surface with the groove depth, D, the angle, θ, with the minimum clearance of h0. A variety of flow regimes are identified, including (i) steady ribs, (ii) coalescing ribs, (iii) ribs guided by the groove, and (iv) stable flow with no ribbing. The groove angles were 30° (orange), 45° (white), respectively. The groove depths were varied between 33 and 1000 μm. R = 63.9 mm, and h0 = 0.01 mm

The four different flows were identified in their corresponding operating regimes. The flow was stable for low capillary numbers and high clearance/radius ratios, exhibiting the same trend as in smooth-roll coating flows.10 The flow became unstable against infinitesimal disturbances and the ribbing instability onsets for the geometrical factors below a critical value. At low geometrical factors of (h0 + D/sinθ)/R < 5 × 10−3 and low capillary numbers below a critical value of Cac ~ 1, ribs became robust against changes in surface topographies and exhibited almost the same spacing as they do on the flat surface of λ/λ0 = 1.0 ± 0.2 (illustrated as circles in Fig. 6). This is hereafter referred to as steady ribbing. On the other hand, the neighboring ribs wandered transversely and eventually coalesced for an intermediate range of the geometric factors (square symbols in Fig. 6), which was located between the stable and steady flow regimes at Ca < Cac. The existence of this coalesce regime is possibly because the local pressure gradient dumps in the engraved topographies to weaken the flow instability, leading to a wider rib spacing than that on a flat surface.

On the other hand, the topography-guided ribbing instability emerged at Ca > Cac and (h0 + D/sinθ)/R > 5 × 10−3. The rib spacing in this flow regime agreed with the center-to-center distance of the grooves, λ/{(W + S)/cosθ} = 1.0 ± 0.2. The guided ribbing at high Ca showed a good consistency with the qualitative operating map of forward patterned roll coating.27 The flow exhibits a transition from the guided to coalesce regimes as the critical geometrical factor decreases at a given Ca.

Although the physical origin of the guided ribbing is not immediately clear, we address the flow mechanism by focusing on a local pressure gradient in the downstream direction at high capillary numbers. As the capillary number increases, the positive pressure gradient increases in the diverging flow channel between the moving and stationary solid surfaces.34 The resultant low fluid pressure sucks the free surface into an upstream position, giving rise to a decrease in the effective length of the diverging flow. With a further increase in Ca above a critical value, further growth of the pressure gradient can be suppressed9 because a geometrical constraint limits the shrinkage of the diverging flow section, leading to a flow behavior that is insensitive to Ca. This is consistent with the fact that the measured rib spacing approaches a constant value and varied solely with the geometrical parameters of the system3 at high capillary numbers (Fig. 4). When a viscous flow at high Ca is destabilized on a solid surface with a series of grooves, the flow responds to a periodic transverse variation in the pressure gradient originating from a local pressure dumping in the engraved patterns. As a result, the growth of three-dimensional disturbances varies in the transverse direction, leading to unique matching of rib frequencies with the underlying groove patterns. As the groove depth decreases at a given Ca, the local pressure gradient no longer dumps and its transverse variation reduces in magnitude, leading to an unguided ribbing instability. This is consistent with the flow transition from topography-guided to coalescence flow regimes at low geometrical factors (Fig. 6).

The development of topography-guided ribs can also be examined by considering a pressure-driven flow along the groove axis. The flow visualizations revealed that the rib tips tilted along the groove inclination when the fluid contacted the topographic surface (not shown), indicating that a capillary action pulled the liquid out of the rib crests toward the engraved topographies. For a fluid-filled groove with a concave free surface profile, the negative capillary pressure is given by Δp ~ − σ/r, where σ is the surface tension of fluid and r is the free surface curvature radius. The pressure gradient caused a flow in the groove with a total flow rate of Q ~ D4Δp. Assuming the scaling between the radius and groove depth as r ~ D,28 the magnitude of the capillary pressure and the flow rate were scaled as Δp ~ D−1 and Q ~ D3, respectively, implying that more fluids direct toward deeper grooves. This physical picture is also consistent with the frequency matching at large groove depths (Fig. 5b). In addition, previous theoretical studies demonstrated that a free surface of thin film flow develops a capillary ridge located just upstream of a step-down topography.29,30,31,32,33 This ridge formation may also enhance the pressure-driven flow along the groove and hence assist the topography-guided ribbing instabilities.

In various coating applications, the fluid inertia,35 evaporation,36 and thermo-capillary flow37,38 can affect the liquid motion imparted by the topography, though the present study is restricted to isothermal, nonvolatile, and low Reynolds number flows. Nevertheless, the flow regime map in Fig. 6 provides the first quantitative basis for optimizing the design of topographic surfaces to coat defect-free uniform liquid layers, or to coat patterned liquid films with periodic ribs, if preferred, at a given substrate speed.

More theoretical studies are needed to investigate the inherent three-dimensional natures of ribbing instability on topographic surfaces. On the topography-induced flow stabilization observed in the present experiment (Figs. 3a and 3b), for instance, a linear stability analysis of thin-film flow confined between a smooth and a patterned surface would provide quantitative information on how growth rates of infinitesimal disturbances vary with topographic features of the patterned surface. Such analysis is also a conceptually straightforward but mathematically complex extension of the previous stability analyses of film-splitting flow between rigid cylinders10 and deformable rolls.21 Furthermore, computational tracking of three-dimensional free surface positions at different Ca would allow us to verify the present hypothesis that the topography-induced frequency matching emerges in a particular case when the meniscus position becomes independent on Ca. From experimental viewpoints, the extensions of the flow regime map into different topographies, such as rectangular, pyramidal, and semicircular cavities,39 or into other fluids with different surface tensions and viscoelastic natures,40 and would give us further physical insight into flow instabilities on patterned surfaces, which is beyond the scope of this study.

Conclusions

We examined the ribbing instability of Newtonian fluids coated on a moving solid with both flat and topographic surfaces. On the flat surface, the fluid exhibited a ribbing pattern with a well-defined spatial order in the transverse direction. In contrast, the pattern changed when the fluid reached the downstream topography, which was a series of inclined, V-shaped grooves. Flow visualization revealed four distinct regimes characterizing the flow instability. The flow remained stable when the capillary number was sufficiently small. Beyond the critical capillary number, the ribs were: (1) easily merged with neighbors, (2) guided by groove frequency, or (3) robust against surface topography. A flow regime map was newly presented within the capillary number/groove-geometry operating window, which allowed us to identify the critical conditions, beyond or below which different flow instabilities emerge. The proposed flow regime map provides an initial quantitative basis for the optimum design of topographic surfaces that will limit instability at higher surface speeds.

References

Gupta, SA, Gupta, RK, “A Parametric Study of Spin Coating over Topography.” Ind. Eng. Chem. Res., 37 2223–2227 (1998)

Liu, J, Li, Y, Li, M, Arumugam, S, Beeby, SP, “Processing of Printed Dye Sensitized Solar Cells on Woven Textiles.” IEEE J. Photovolt., 9 (8721081) 1020–1024 (2019)

Mill, CC, South, GR, “Formation of Ribs on Rotating Rollers.” J. Fluid Mech., 28 523–529 (1967)

Higgins, BG, Scriven, LE, “Ribbing Instabilities of a Two-Roller Coater: Newtonian Fluids.” Chem. Eng. Sci., 35 459–466 (1980)

Bauman, T, Sullivan, T, Middleman, S, “Ribbing Instability in Coating Flows-Effect of Polymer Additives.” Chem. Eng. Commun., 14 35–46 (1982)

Savage, M, “Mathematical Model for the Onset of Ribbing.” AIChE J., 30 999–1002 (1984)

Ruschak, KJ, “Coating Flows.” Annu. Rev. Fluid Mech., 17 65–89 (1985)

Pitts, E, Greiller, J, “The Flow of Thin Liquid Films Between Rollers.” J. Fluid Mech., 11 33–50 (1961)

Adachi, K, Tamura, T, Nakamura, R, “Coating Flows in a Nip Region and Various Critical Phenomena.” AIChE J., 34 456–464 (1988)

Coyle, DJ, Macosko, CW, Scriven, LE, “Stability of Symmetric Film-Splitting Between Counter-Rotating Cylinders.” J. Fluid Mech., 216 437–458 (1990)

Yin, X, Kumar, S, “Lubrication Flow Between a Cavity and a Flexible Wall.” Phys. Fluids, 17 063101 (2005)

Lopez, FV, Pauchard, L, Rosen, M, Rabaud, M, “Non-Newtonian Effects on Ribbing Instability Threshold.” J. Non-Newtonian Fluid Mech., 103 123–139 (2002)

Hasegawa, T, Sorimachi, K, “Wavelength and Depth of Ribbing in Roll Coating and Its Elimination.” AIChE J., 39 935–945 (1993)

Decré, M, Gailly, E, Buchlin, JM, “Meniscus Control by String in Roll Coating Experiment.” AIChE J., 42 1583–1589 (1996)

Castillo, MEG, Patera, AT, “Three-Dimensional Ribbing Instability in Symmetric Forward-Roll Film-Coating Processes.” J. Fluid Mech., 335 323–359 (1997)

Owens, MS, Vinjamur, M, Scriven, LE, Macosko, CW, “Misting of Newtonian Liquids in Forward Roll Coating.” Ind. Eng. Chem. Res., 50 3212–3219 (2011)

Coyle, DJ, Macosko, CW, Scriven, LE, “The Fluid Dynamics of Reverse Roll Coating.” AIChE J., 36 161–174 (1990)

Benkreira, H, Shibata, Y, Ito, K, “Thinnest Uniform Liquid Films Formed at the Highest Speeds with Reverse Roll Coating.” AIChE J., 59 3083–3091 (2013)

Sasaki, M, “Visualization Study of Two-Layer Reverse Roll Transfer.” ISIJ Int., 54 2868–2874 (2014)

Benkreira, H, Shibata, Y, Ito, K, “Reverse Roll Coating with a Deformable Roll Operating at Negative Gaps.” Chem. Eng. Sci., 165 204–215 (2017)

Carvalho, MS, Scriven, LE, “Deformable Roll Coating Flows: Steady State and Linear Perturbation Analysis.” J. Fluid Mech., 339 143–172 (1997)

Chong, YH, Gaskell, PH, Kapur, N, “Coating with Deformable Rolls: An Experimental Investigation of the Ribbing Instability.” Chem. Eng. Sci., 62 4138–4145 (2007)

Lee, JH, Han, SK, Lee, JS, Jung, HW, Hyun, JC, “Ribbing Instability in Rigid and Deformable Forward Roll Coating Flows.” Korea Aust. Rheol. J., 22 75–80 (2010)

Lin, YT, Chu, WB, Liu, TJ, “Slot Die Coating of Dilute Suspensions.” Asia Pacific J. Chem. Eng., 4 125–132 (2009)

Khandavalli, S, Rothstein, JP, “The Effect of Shear-Thickening on the Stability of Slot-Die Coating.” AIChE J., 62 4536–4547 (2016)

Tjiptowidjojo, K, Carvalho, MS, “Operability Limits of Slide Coating.” Chem. Eng. Sci., 66 5077–5083 (2011)

Hanumanthu, R, Scriven, LE, “Coating with Patterned Rolls and Rods.” Tappi Journal, 79 126–138 (1996)

Thomas, SK, Lykins, RC, Yerkes, KL, “Fully Developed Laminar Flow in Trapezoidal Grooves with Shear Stress at the Liquid-Vapor Interface.” Int. J. Heat Mass Transf., 44 3397–3412 (2001)

Kalliadasis, S, Bielarz, C, Homsy, GM, “Steady Free-Surface Thin Film Flows Over Topography.” Phys. Fluids, 12 1889–1898 (2000)

Kalliadasis, S, Homsy, GM, “Stability of Free-Surface Thin-Film Flows over Topography.” J. Fluid Mech., 448 387–410 (2001)

Mazouchi, A, Homsy, GM, “Free Surface Stokes Flow over Topography.” Phys. Fluids, 13 2751–2761 (2001)

Decré, MMJ, Baret, JC, “Gravity-Driven Flows of Viscous Liquids over Two-Dimensional Topographies.” J. Fluid Mech., 487 147–166 (2003)

Gaskell, PH, Jimack, PK, Sellier, M, Thompson, HM, Wilson, MCT, “Gravity-Driven Flow of Continuous Thin Liquid Films on Non-porous Substrates with Topography.” J. Fluid Mech., 509 253–280 (2004)

Ruschak, KJ, “Limiting Flow in a Pre-Metered Coating Device.” Chem. Eng. Sci., 31 1057–1060 (1976)

Bielarz, C, Kalliadasis, S, “Time-Dependent Free-Surface Thin Film Flows over Topography.” Phys. Fluids, 15 2512–2524 (2003)

Gaskell, PH, Jimack, PK, Sellier, M, Thompson, HM, “Flow of Evaporating, Gravity-Driven Thin Liquid Films over Topography.” Phys. Fluids, 18 013601 (2006)

Saprykin, S, Trevelyan, PMJ, Koopmans, RJ, Kalliadasis, S, “Free-Surface Thin-Film Flows over Uniformly Heated Topography.” Phys. Rev. E Stat. Nonlinear Soft Matter Phys., 75 026306 (2007)

Yoo, J, Nam, J, Ahn, KH, “Thermocapillary Flows on Heated Substrates with Sinusoidal Topography.” J. Fluid Mech., 859 992–1021 (2019)

Benkreira, H, Cohu, O, “Direct Forward Gravure Coating on Unsupported Web.” Chem. Eng. Sci., 53 1223–1231 (1998)

Pettas, D, Karapetsas, G, Dimakopoulos, Y, Tsamopoulos, J, “Viscoelastic Film Flows over an Inclined Substrate with Sinusoidal Topography. I. Steady State.” Phys. Rev. Fluids, 4 083303 (2019)

Acknowledgments

The authors would like to thank Tatsuya Kai for technical assistance with the experiments and Dr. Hidenobu Miura for helpful discussions. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamamura, M. Ribbing instability of Newtonian fluid coated on a topographic surface. J Coat Technol Res 17, 1447–1453 (2020). https://doi.org/10.1007/s11998-020-00375-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00375-8