Abstract

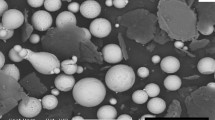

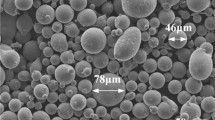

The tribo-mechanical properties of NiMoAl-Cr2AlC MAX phase composite coatings on stainless steel substrate have been investigated. NiMoAl with different amounts of Cr2AlC (10, 20, 50 and 100 wt.%) were prepared by turbo-mixing and deposited by High-Velocity Oxy-Fuel (HVOF) method on stainless steel substrate. The phase composition, microstructure, chemical composition, tribological and mechanical properties of the coatings were analyzed using x-Ray Diffraction (XRD), Field Emission Scanning Electron Microscope (FESEM), Energy-Dispersive x-ray analysis (EDAX), pin-on-disk wear testing rig and nanohardness tester, respectively. The worn surfaces were analyzed by metallurgical optical microscope, FESEM and three-dimensional surface profiler to understand the wear behavior in detail. The addition of the Cr2AlC MAX phase in NiMoAl enhances the mechanical properties and reduces the surface roughness and porosity. NiMoAl-20 wt.% Cr2AlC and Cr2AlC coatings containing equal amounts of oxygen and carbon in the tribofilm show the low coefficient of friction (COF) and wear rate. The addition of the Cr2AlC MAX phase in the NiMoAl matrix up to 20 wt.% reduces the wear rate by one order of magnitude and enhances the coating life by 7000 twist fatigue cycles.

Similar content being viewed by others

References

C.M. Taylor, Automobile Engine Tribology—Design Considerations for Efficiency and Durability, Wear, 1998, 221(1), p 1-8

B.K. Prasad, Sliding Wear Response of a Grey Cast Iron: Effects of Some Experimental Parameters, Tribol. Int., 2011, 44(5), p 660-667

V. Goyal, S.K. Sharma, and B.V. Kumar, Effect of Lubrication on Tribological Behaviour of Martensitic Stainless Steel, Mater. Today Proc., 2015, 2(4-5), p 1082-1091

D.S. Codd, Automotive Mass Reduction with Martensitic Stainless Steel. SAE Technical Paper; 2011

D.J. Young, High Temperature Oxidation and Corrosion of Metals, Vol 1, Elsevier, Amsterdam, 2008

Metals, Special. “High-Performance Alloys for Resistance to Aqueous Corrosion,” SM Aqueous Corrosion Book, 2000, p. 28

J.R. Davis, Ed., Nickel, Cobalt, and Their Alloys, ASM international, 2000

P. Andersson, J. Tamminen, and C.E. Sandström, Piston Ring Tribology: A Literature Survey, VTT, Espoo, 2002

M.L. Parucker, A.N. Klein, C. Binder, W. Ristow Junior, and R. Binder, Development of Self-Lubricating Composite Materials of Nickel with Molybdenum Disulfide, Graphite and Hexagonal Boron Nitride Processed by Powder Metallurgy: Preliminary Study, Mater. Res., 2014, 17, p 180-185

H.E. Sliney, Solid Lubricant Materials for High Temperatures—A Review, Tribol. Int., 1982, 15(5), p 303-315

S. Gupta, D. Filimonov, T. Palanisamy, T. El-Raghy, and M.W. Barsoum, Ta2AlC and Cr2AlC Ag-Based Composites—New Solid Lubricant Materials for Use Over a Wide Temperature Range Against Ni-Based Superalloys and Alumina, Wear, 2007, 262(11–12), p 1479-1489

M.W. Barsoum, A New Class of Solids: Thermodynamically Stable Nanolaminates, Prog. Solid State Chem., 2000, 28, p 201

J.D. Hettinger, S.E. Lofland, P. Finkel, T. Meehan, J. Palma, K. Harrell, S. Gupta, A. Ganguly, T. El-Raghy, and M.W. Barsoum, Electrical Transport, Thermal Transport, and Elastic Properties of M2AlC (M = Ti, Cr, Nb, and V), Phys. Rev. B, 2005, 72(11), p 115120

F. Cverna, Ed., ASM Ready Reference: Thermal Properties of Metals, ASM International, Cleveland, 2002

D. Davis, M. Srivastava, M. Malathi, B.B. Panigrahi, and S. Singh, Effect of Cr2AlC Max Phase Addition on Strengthening of Ni-Mo-Al Alloy Coating on Piston Ring: Tribological and Twist-Fatigue Life Assessment, Appl. Surf. Sci., 2018, 15(449), p 295-303

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Studies on the Properties of High-Velocity Oxy-Fuel Thermal Spray Coatings for Higher Temperature Applications, Mater. Sci., 2005, 41(6), p 805-823

V. Vishnyakov, O. Crisan, P. Dobrosz, and J.S. Colligon, Ion Sputter-Deposition and In-Air Crystallisation of Cr2AlC Films, Vacuum, 2014, 1(100), p 61-65

H.P. Komsa and A.V. Krasheninnikov, Effects of Confinement and Environment on the Electronic Structure and Exciton Binding Energy of MoS2 from First Principles, Phys. Rev. B, 2012, 86(24), p 241201

R. Saggar, H. Porwal, P. Tatarko, I. Dlouhý, and M.J. Reece, Boron Nitride Nanosheets Reinforced Glass Matrix Composites, Adv. Appl. Ceram., 2015, 114(sup1), p S26-S33

R.W. Bruce, Handbook of Lubrication and Tribology, Volume II: Theory and Design, CRC Press, Boca Raton, 2012

R.P. Chakradhar, G. Prasad, K. Venkateswarlu, and M. Srivastava, An Investigation on the Wear and Corrosion Behavior of HVOF-Sprayed WC-12Co-Al2O3 Cermet Coating, J. Mater. Eng. Perform., 2018, 27(3), p 1241-1248

Ch Verdon, A. Karimi, and J.-L. Martin, A Study of High Velocity Oxy-Fuel Thermally Sprayed Tungsten Carbide Based Coatings. Part 1: Microstructures, Mater. Sci. Eng. A, 1998, 246(1–2), p 11-24

J.R. Davis, Ed., Handbook of Thermal Spray Technology, ASM International, Cleveland, 2004

M.S. Mahdipoor, F. Tarasi, C. Moreau, A. Dolatabadi, and M. Medraj, HVOF Sprayed Coatings of Nano-Agglomerated Tungsten-Carbide/Cobalt Powders for Water Droplet Erosion Application, Wear, 2015, 1(330), p 338-347

Š. Houdková, Z. Pala, E. Smazalová, M. Vostřák, and Z. Česánek, Microstructure and Sliding Wear Properties of HVOF Sprayed, Laser Remelted and Laser Clad Stellite 6 Coatings, Surf. Coat. Technol., 2017, 25(318), p 129-141

P. Mi, T. Wang, and F. Ye, Influences of the Compositions and Mechanical Properties of HVOF Sprayed Bimodal WC-Co Coating on Its High Temperature Wear Performance, Int. J. Refract Metal Hard Mater., 2017, 1(69), p 158-163

Y. Rajkumar, B.M. Rahul, P. Ananth Akash, and B.B. Panigrahi, Nonisothermal Sintering of Cr2AlC Powder, Int. J. Appl. Ceram. Technol., 2017, 14(1), p 63-67

A. Ganvir, N. Curry, S. Björklund, N. Markocsan, and P. Nylén, Characterization of Microstructure and Thermal Properties of YSZ Coatings Obtained by Axial Suspension Plasma Spraying (ASPS), J. Therm. Spray Technol., 2015, 24(7), p 1195-1204

Y. Gao, J. Xiong, D. Gong, J. Li, and M. Ding, Improvement of Solar Absorbing Property of Ni-Mo Based Thermal Spray Coatings by Laser Surface Treatment, Vacuum, 2015, 1(121), p 64-69

M. Farber and R.D. Srivastava. The Dissociation Energy of NiO and Vaporization and Sublimation Enthalpies of Ni, Analytical Calorimetry, R.S. Porter and J.F. Johnson, Ed., Springer, Boston, 1974, pp. 731–741

A.R.C. Nascimento, F.B. Ettouil, C. Moreau, S. Savoie, and R. Schulz, Production of Babbitt Coatings by High Velocity Oxygen Fuel (HVOF) Spraying, J. Therm. Spray Technol., 2017, 26(7), p 1732-1740

L.L. Silveira, G.B. Sucharski, A.G.M. Pukasiewicz, and R.S.C. Paredes, Influence of Particle Size Distribution on the Morphology and Cavitation Resistance of High-Velocity Oxygen Fuel Coatings, J. Therm. Spray Technol., 2018, 27(4), p 695-709

C. Yang, C. Maoyou, W. Lijun, S. Zhixia, W. Xingming, and Z. Bitian. Microstructure and Performance of Cr2AlC Coatings Deposited by HVOF Spraying. Chinese Journal of Rare Metals. 2012, 4

S. Saber-Samandari, K. Alamara, S. Saber-Samandari, and K.A. Gross, Micro-Raman Spectroscopy Shows How the Coating Process Affects the Characteristics of Hydroxylapatite, Acta Biomater., 2013, 9(12), p 9538-9546

J. Chen, X. Zhao, H. Zhou, J. Chen, Y. An, and F. Yan, Microstructure and Tribological Property of HVOF-Sprayed Adaptive NiMoAl-Cr3C2-Ag composite coating from 20 C to 800 C, Surf. Coat. Technol., 2014, 15(258), p 1183-1190

J. Chen, X. Zhao, H. Zhou, J. Chen, Y. An, and F. Yan, HVOF-Sprayed Adaptive Low Friction NiMoAl-Ag Coating for Tribological Application from 20 to 800 C, Tribol. Lett., 2014, 56(1), p 55-66

M.S. Ali, A.H.M. Ariff, C.N.A. Jaafar, S.M. Tahir, N. Mazlan, K.A. Maori, and H. Naser, Factors Affecting the Porosity and Mechanical Properties of Porous Ceramic Composite Materials, Reference Module in Materials Science and Materials Engineering, 2017. https://doi.org/10.1016/b978-0-12-803581-8.10131-6

D.B. Lee and Thuan Dinh Nguyen, Cyclic Oxidation of Cr2AlC Between 1000 and 1300 C in Air, J. Alloys Compd., 2008, 464(1–2), p 434-439

G. Frommeyer, R. Rablbauer, and H.J. Schäfer, Elastic Properties of B2-Ordered NiAl and NiAl-X (Cr, Mo, W) Alloys, Intermetallics, 2010, 18(3), p 299-305

W.B. Tian, P.L. Wang, G.J. Zhang, Y.M. Kan, and Y.X. Li, Mechanical Properties of Cr2AlC Ceramics, J. Am. Ceram. Soc., 2007, 90(5), p 1663-1666

S.M. Hashemi, N. Parvin, and Z. Valefi, Effect of Microstructure and Mechanical Properties on Wear Behavior of Plasma-Sprayed Cr2O3-YSZ-SiC Coatings, Ceram. Int., 2019, 45(5), p 5284-5296

A. Souchet, J. Fontaine, J.L. Loubet, Z. Hassan, M. Belin, and M.W. Barsoum, The Role of Tribofilm Evolution on Tribological Behaviour of Ti3SiC2 Ceramic. in Proceeding of World Tribology Congress III 2005 Jan 1.

S. Gupta and M.W. Barsoum, On the Tribology of the MAX Phases and Their Composites During Dry Sliding: A Review, Wear, 2011, 271(9–10), p 1878-1894

X.S. Wang, Z.L. Lu, G.T. Lin, L. Jia, and J.X. Chen, Effect of Cr2AlC Content on the Properties of a Cu-Cr2AlC Composite, Results Phys., 2016, 1(6), p 789-795

G.V. Kumar, C.S. Rao, and N. Selvaraj, Mechanical and Tribological Behavior of Particulate Reinforced Aluminum Metal Matrix Composites—A Review, J. Miner. Mater. Charact. Eng., 2011, 10(01), p 59

W. Gu, H.F. Wu, S.L. Kampe, and G.-Q. Lu, Volume Fraction Effects on Interfacial Adhesion Strength of Glass-Fiber-Reinforced Polymer Composites, Mater. Sci. Eng. A, 2000, 277(1–2), p 237-243

R. Mitra and Y.R. Mahajan, Interfaces in Discontinuously Reinforced Metal Matrix Composites: An Overview, Bull. Mater. Sci., 1995, 18(4), p 405-434

A. Kulkarni, J. Gutleber, S. Sampath, A. Goland, W.B. Lindquist, H. Herman, A.J. Allen, and B. Dowd, Studies of the Microstructure and Properties of Dense Ceramic Coatings Produced by High-Velocity Oxygen-Fuel Combustion Spraying, Mater. Sci. Eng. A, 2004, 369(1–2), p 124-137

J. Jie, L. Huan, and L. Xiaohan, Friction and Wear Behavior of Micro Arc Oxidation Coatings on Magnesium Alloy at High Temperature, Rare Met. Mater. Eng., 2017, 46(5), p 1202-1206

A. Ghosh and F. Sadeghi, A Novel Approach to Model Effects of Surface Roughness Parameters on Wear, Wear, 2015, 15(338), p 73-94

H. Chen, Y. Du, D. Wang, C. Zhang, G. Yang, B. Liu, Y. Gao, and S. Shi, TiC/Ti3AlC2-Co Plasma-Sprayed Coatings with Excellent High-Temperature Tribological Properties, Ceram. Int., 2018, 44(18), p 22520-22528

L. Gudmand-Høyer, A. Bach, G.T. Nielsen, and P. Morgen, Tribological Properties of Automotive Disc Brakes with Solid Lubricants, Wear, 1999, 232(2), p 168-175

E. Badisch, C. Mitterer, P.H. Mayrhofer, G. Mori, R.J. Bakker, J. Brenner, and H. Störi, Characterization of Tribo-Layers on Self-Lubricating Plasma-Assisted Chemical-Vapor-Deposited TiN Coatings, Thin Solid Films, 2004, 460(1–2), p 125-132

A.S. Rathaur, J.K. Katiyar, and V.K. Patel, Thermo-Mechanical and Tribological Properties of SU-8/h-BN Composite with SN150/perfluoropolyether Filler, Friction, 2020, 8(1), p 151-163

A. Shankara, P.L. Menezes, K.R. Simha, and S.V. Kailas, Study of Solid Lubrication with MoS2 Coating in the Presence of Additives Using Reciprocating Ball-on-Flat Scratch Tester, Sadhana, 2008, 33(3), p 207-220

M.R. Vazirisereshk, A. Martini, D.A. Strubbe, and M.Z. Baykara, Solid Lubrication with MoS2: A Review, Lubricants, 2019, 7(7), p 57

T.W. Scharf and S.V. Prasad, Solid Lubricants: A Review, J. Mater. Sci., 2013, 48(2), p 511-531

Acknowledgments

The authors would like to acknowledge the Director, CSIR-NAL and Head, Surface Engineering Division, CSIR-NAL, for permission to carry out the coating development at CSIR-National Aerospace Laboratories, Bengaluru, Karnataka, India. The authors are thankful to the technical staff of the division for their assistance rendered in the characterization of the coatings. Mr. Deepak Davis acknowledges the ‘Council of Scientific and Industrial Research’, Government of India, New Delhi, India for financial support through CSIR-SRF [CSIR-HRDG reference no. 09/1045(0030)2K19 EMR-I]. The authors also would like to acknowledge the SRM Institute of Science and Technology, Chennai, Tamil Nadu, India for the funding under Selective Excellence Initiative (PNT01) and micro-Raman facility. We acknowledge Nanotechnology Research Centre, SRM Institute of Science and Technology, Chennai, India, for providing FESEM facility.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Davis, D., Singh, S., Chakradhar, R.P.S. et al. Tribo–Mechanical Properties of HVOF-Sprayed NiMoAl-Cr2AlC Composite Coatings. J Therm Spray Tech 29, 1763–1783 (2020). https://doi.org/10.1007/s11666-020-01069-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01069-8