Abstract

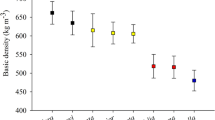

Several studies have highlighted the importance of the chemical composition of Eucalyptus woods in the generation of thermal energy and charcoal production. However, the influence of wood chemical constituents on the pyrolysis mass balance is still not sufficiently clear. This paper brings new insights about the influence of extractives and guaiacyl (G) to syringyl (S) ratio of lignin macromolecule in the carbon, hydrogen, and oxygen balances of the pyrolysis process. Thus, the aim of this research was to investigate the effect of the wood quality of genotypes of Eucalyptus on the carbonization mass balances. Ultimate analysis, structural chemical constituents, and lignin composition analyses were carried out in 14 clonal materials of Eucalyptus spp. at 81 months of age. After pyrolysis, the ultimate analysis of charcoal and the carbonization mass balance was also investigated. The findings show a positive relationship between the percentages of carbon and hydrogen retained in the charcoal with the lignin content and its composition. E. camaldulensis (clone 1025) and E. grandis hybrids (clone 1039) presented better wood quality for charcoal production, due to the results of gravimetric yield (35.7%), retained carbon (59.6%), and retained hydrogen (20.2%) after pyrolysis. In addition, these genetic materials stood out for the high values of lignin (32.0%), extractives soluble in acetone (2.4%), and mass of guaiacyl per kg of dry wood (27.2 g kg-1) associated with the low S/G ratio (2.5). The extractives content and lignin composition must be simultaneously analyzed to improve the Eucalyptus clones classification for charcoal production.

Similar content being viewed by others

References

Uzoejinwa BB, He X, Wang S, el-Fatah Abomohra A, Hu Y, Wang Q (2018) Co-pyrolysis of biomass and waste plastics as a thermochemical conversion technology for high-grade biofuel production: recent progress and future directions elsewhere worldwide. Energy Convers Manag 163:468–492. https://doi.org/10.1016/j.enconman.2018.02.004

Edrisi SA, Abhilash PC (2016) Exploring marginal and degraded lands for biomass and bioenergy production: an Indian scenario. Renew Sust Energ Rev 54:1537–1551. https://doi.org/10.1016/j.rser.2015.10.050

He Z-X, Xu S-C, Li Q-B, Zhao B (2018) Factors that influence renewable energy technological innovation in China: a dynamic panel approach. Sustainability 10:124. https://doi.org/10.3390/su10010124

Uddin MN, Taweekun J, Techato K, Rahman MA, Mofijur M, Rasul MG (2019) Sustainable biomass as an alternative energy source: Bangladesh perspective. Energy Procedia 160:648–654. https://doi.org/10.1016/j.egypro.2019.02.217

Dalólio FS, Silva JN, Oliveira ACC et al (2017) Poultry litter as biomass energy: a review and future perspectives. Renew Sust Energ Rev 76:941–949. https://doi.org/10.1016/j.rser.2017.03.104

IBÁ (2019) Brazilian Tree Industry. Report 2019. IBÁ, São Paulo

Silva FTM, Ataíde CH (2019) Valorization of Eucalyptus urograndis wood via carbonization: product yields and characterization. Energy 172:509–516. https://doi.org/10.1016/j.energy.2019.01.159

Couto AM, Trugilho PF, Napoli A, Lima JT, Silva JRM, Protásio TP (2015) Quality of charcoal from Corymbia and Eucalyptus produced at different final carbonization temperatures. Sci For 43:817–831. https://doi.org/10.18671/scifor.v43n108.7

Simetti R, Bonduelle GM, Silva DA et al (2018) Production of biomass and energy stock for five Eucalyptus species. Rev Ciência da Madeira 9:30–36. https://doi.org/10.12953/2177-6830/rcm.v9n1p30-36

Ignacio LHS, Santos PEA, Duarte CAR (2019) An experimental assessment of Eucalyptus urosemente energy potential for biomass production in Brazil. Renew Sust Energ Rev 103:361–369. https://doi.org/10.1016/j.rser.2018.12.053

Protásio TP, Trugilho PF, de Araújo ACC et al (2017) Classification of Eucalyptus clones by the ratio syringyl/guaiacyl and growth characteristics for energy use. Sci For 45:327–341. https://doi.org/10.18671/scifor.v45n114.09

Dufourny A, Van De Steene L, Humbert G et al (2019) Influence of pyrolysis conditions and the nature of the wood on the quality of charcoal as a reducing agent. J Anal Appl Pyrolysis 137:1–13. https://doi.org/10.1016/j.jaap.2018.10.013

Pereira BLC, Carneiro ACO, Carvalho AMML et al (2013) Influence of chemical composition of Eucalyptus wood on gravimetric yield and charcoal properties. BioResources 8:4574–4592. https://doi.org/10.15376/biores.8.3.4574-4592

Gouvêa AFG, Trugilho PF, Assis CO, Assis MR, Colodette JL, Gomes CM (2015) Evaluation of syringyl/guaiacyl ratio of eucalypt lignin in the charcoal production. Braz J Wood Sci 6:71–78. https://doi.org/10.12953/2177-6830/rcm.v6n2p71-78

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86. https://doi.org/10.1016/j.pecs.2017.05.004

Castro AFNM, Castro RVO, Carneiro ACO et al (2016) Correlations between age, wood quality and charcoal quality of Eucalyptus clones. J Braz For Sci 40:551–560. https://doi.org/10.1590/0100-67622016000300019

Santos RC, Carneiro ACO, Vital BR et al (2016) Effect of properties chemical and siringil/guaiacil relation wood clones of Eucalyptus in the production of charcoal. Ciência Florest 26:657–669. https://doi.org/10.5902/1980509822765

Araújo ACC, Trugilho PF, Napoli A et al (2016) Effects of the syringyl/guaiacyl ratio and of lignin-derived phenols on the wood and charcoal characteristics in Eucalyptus spp. Sci For 44:405–414. https://doi.org/10.18671/scifor.v44n110.13

Castro AFNM, Castro RVO, Carneiro ACO et al (2013) Multivariate analysis for the selection of eucalyptus clones destined for charcoal production. Pesqui Agropecuária Bras 48:627–635. https://doi.org/10.1590/S0100-204X2013000600008

Protásio TP, Scatolino MV, Araújo ACC et al (2019) Assessing proximate composition, extractive concentration, and lignin quality to determine appropriate parameters for selection of superior Eucalyptus firewood. BioEnergy Res 12:626–641. https://doi.org/10.1007/s12155-019-10004-x

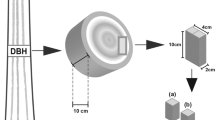

Downes GM, Hudson IL, Raymond CA et al (1997) Sampling plantation eucalypts for wood and fibre properties. CSIRO, Melbourne

Gomide JL, Demuner BJ (1986) Determination of lignin in woody material: Modified Klason method. O Pap 47:36–38

Goldschmid O (1971) Ultraviolet spectra. In: Lignins: occurrence, formation, structure and reactions. Wiley Interscience, New York, pp 241–266

Chen LC (1992) Determination of total and aliphatic hydroxyl groups. In: Methods in lignin chemistry. Springer-Verlag, New York, pp 408–422

TAPPI (1999) Technical Association of the Pulp and Paper Industry. T 280 pm-99: acetone extractives of wood and pulp. TAPPI, Atlanta

ASTM (2007) American Society for Testing Materials. D1762 - 84: standard test method for chemical analysis of wood charcoal. ASTM International, Philadelphia

Protásio TP, Guimarães Neto RM, de Santana JDP et al (2014) Canonical correlation analysis of the characteristics of charcoal from Qualea parviflora Mart. Cerne 20:81–88. https://doi.org/10.1590/S0104-77602014000100011

R Core Team (2018) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Viena. Austria

Fox J, Weisberg S (2011) An R companion to applied regression. SAGE Publications

Zeileis A, Hothorn T (2002) Diagnostic checking in regression relationships. R News 2:7–10

González I, Déjean ST (2012) Canonical correlation analysis. R package version 1.2

Menzel U (2012) Significance tests for canonical correlation analysis (CCA)

Butts CT (2018) Yet another canonical correlation analysis package

Menucelli JR, Amorim EP, Freitas MLM, et al (2019) Potential of Hevea brasiliensis clones, Eucalyptus pellita and Eucalyptus tereticornis wood as raw materials for bioenergy based on higher heating value. BioEnergy Res 1–8. https://doi.org/10.1007/s12155-019-10041-6

Mészáros E, Jakab E, Várhegyi G (2007) TG/MS, Py-GC/MS and THM-GC/MS study of the composition and thermal behavior of extractive components of Robinia pseudoacacia. J Anal Appl Pyrolysis 79:61–70. https://doi.org/10.1016/j.jaap.2006.12.007

Choi HL, Sudiarto SIA, Renggaman A (2014) Prediction of livestock manure and mixture higher heating value based on fundamental analysis. Fuel 116:772–780. https://doi.org/10.1016/j.fuel.2013.08.064

Velázquez-Martí B, Sajdak M, López-Cortés I, Callejón-Ferre AJ (2014) Wood characterization for energy application proceeding from pruning Morus alba L., Platanus hispanica Münchh. and Sophora japonica L. in urban areas. Renew Energy 62:478–483. https://doi.org/10.1016/j.renene.2013.08.010

Soares VC, Bianchi ML, Trugilho PF, Pereira AJ, Höfler J (2014) Correlations between the properties of Eucalyptus hybrids wood and charcoal. J Brazilian For Sci 38:543–549. https://doi.org/10.1590/S0100-67622014000300017

Leite ERS, Protásio TP, Rosado SCS et al (2015) Elemental chemical composition of wood and charcoal from Coffea arabica for bioenergy use. Coffee Sci 10:537–547. https://doi.org/10.25186/cs.v10i4.992

Ren X, Sun R, Meng X, Vorobiev N, Schiemann M, Levendis YA (2017) Carbon, sulfur and nitrogen oxide emissions from combustion of pulverized raw and torrefied biomass. Fuel 188:310–323. https://doi.org/10.1016/j.fuel.2016.10.017

Yi L, Feng J, Qin Y-H, Li W-Y (2017) Prediction of elemental composition of coal using proximate analysis. Fuel 193:315–321. https://doi.org/10.1016/j.fuel.2016.12.044

Yang H, Yan R, Chen H, Lee DH, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788. https://doi.org/10.1016/j.fuel.2006.12.013

Liu C, Hu J, Zhang H, Xiao R (2016) Thermal conversion of lignin to phenols: relevance between chemical structure and pyrolysis behaviors. Fuel 182:864–870. https://doi.org/10.1016/j.fuel.2016.05.104

Wang S, Wang K, Liu Q, Gu Y, Luo Z, Cen K, Fransson T (2009) Comparison of the pyrolysis behavior of lignins from different tree species. Biotechnol Adv 27:562–567. https://doi.org/10.1016/j.biotechadv.2009.04.010

Guo G, Liu X, Li R, Li Q, Yu HB, Li MJ (2019) Characterization of tobacco stalk lignin using nuclear magnetic resonance spectrometry and its pyrolysis behavior at different temperatures. J Anal Appl Pyrolysis 142:104665. https://doi.org/10.1016/j.jaap.2019.104665

Zhang X, Jiang W, Ma H, Wu S (2020) Relationship between the formation of oligomers and monophenols and lignin structure during pyrolysis process. Fuel 276:118048. https://doi.org/10.1016/j.fuel.2020.118048

Garcia DP, Caraschi JC, Ventorim G, Vieira FHA, de Paula PT (2019) Assessment of plant biomass for pellet production using multivariate statistics (PCA and HCA). Renew Energy 139:796–805. https://doi.org/10.1016/j.renene.2019.02.103

Leite ERS, Protásio TP, Rosado SCS et al (2015) Quality of charcoal produced from coffee wood for bioenergy use. Coffee Sci 10:251–261

Hair Junior JF, Black WC, Babin BJ et al (2009) Multivariate data analysis. Bookman, Porto Alegre

Acknowledgment

The authors appreciate the National Council for Scientific and Technological Development (CNPq/Brazil – processes no. 141439/2014-9 and no. 306793/2019-9), the Coordination for the Improvement of Higher Education Personnel (CAPES/Brazil–financing code 001), the Research Support Foundation of Minas Gerais state (FAPEMIG), and the Plantar Group for the financial support of the project. We would also like to thank the anonymous reviewers whose comments and suggestions have made this study scientifically fit.

Author information

Authors and Affiliations

Contributions

Thiago de Paula Protásio and Michael Douglas Roque Lima: conceptualization, methodology, investigation, roles/writing—original draft; Roberthi Alef Costa Teixeira, Fábio Silva do Rosário, Ana Clara Caxito de Araújo, and Maíra Reis de Assis: writing—review and editing; Paulo Ricardo Gherardi Hein: validation, supervision, and writing—review and editing; Paulo Fernando Trugilho: writing—review and editing, funding acquisition and project administration.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Paula Protásio, T., Lima, M.D.R., Teixeira, R.A.C. et al. Influence of Extractives Content and Lignin Quality of Eucalyptus Wood in the Mass Balance of Pyrolysis Process. Bioenerg. Res. 14, 175–189 (2021). https://doi.org/10.1007/s12155-020-10166-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10166-z