Abstract

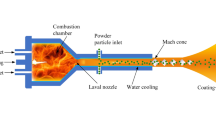

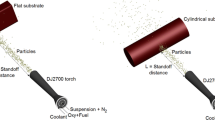

Shot peening was induced by utilizing the particles that flow out of the nozzle in a WPPA-HVOF process. For investigation of the peening particles, a model was built to simulate the HVOF spraying process including the temperature, velocity, pressure field of the flame, and the reaction of kerosene oxidation. The effect of incident velocity, incident position, and the diameter on the in-flight particle was presented. Incident velocity is an important factor for the synchronization of shot peening and coating deposition. The critical velocity was introduced to describe the particle state after hitting onto the substrate. The velocity and temperature of small particles injected in the barrel were measured experimentally to verify the model reliability. Experimental results reveal that the particle injected in the barrel deposited onto the substrate and the particle injected out of the nozzle rebounded, which agrees well with the predicted result.

Similar content being viewed by others

References

H.W. Sheng, Y.Q. Cheng, P.L. Lee, S.D. Shastri, and E. Ma, Atomic Packing in Multicomponent Aluminum-Based Metallic Glasses, Acta Mater., 2008, 56(20), p 6264-6272

S. Hong, Y. Wu, W. Gao, B. Wang, W. Guo, and J. Lin, Microstructural Characterisation and Microhardness Distribution of HVOF Sprayed WC-10Co-4Cr Coating, Surf. Eng., 2014, 30(1), p 53-58

M. Xie, S. Zhang, and M. Li, Comparative Investigation on HVOF Sprayed Carbide-Based Coatings, Appl. Surf. Sci., 2013, 273, p 799-805

W. Luo, U. Selvadurai, and W. Tillmann, Effect of Residual Stress on the Wear Resistance of Thermal Spray Coatings, J. Therm. Spray Technol., 2015, 25(1-2), p 321-330

H.J.C. Voorwald, P.C.F. Rocha, M.O.H. Cioffi, and M.Y.P. Costa, Residual Stress Influence on Fatigue Lifetimes of Electroplated AISI, 4340 High Strength Steel, Fatigue Fract. Eng. Mater. Struct., 2010, 30(11), p 1084-1097

P. Bansal, P.H. Shipway, and S.B. Leen, Residual Stresses in High-Velocity Oxy-Fuel Thermally Sprayed Coatings—Modelling the Effect of Particle Velocity and Temperature During the Spraying Process, Acta Mater., 2007, 55(15), p 5089-5101

S. Sampath, X.Y. Jiang, J. Matejicek, L. Prchlik, A. Kulkarni, and A. Vaidya, Role of Thermal Spray Processing Method on the Microstructure, Residual Stress and Properties of Coatings: An Integrated Study for Ni-5 wt%Al Bond Coats, Mater. Sci. Eng. A, 2004, 364(1-2), p 216-231

J. Stokes and L. Looney, Residual Stress in HVOF Thermally Sprayed Thick Deposits, Surf. Coat. Technol., 2004, 177, p 18-23

S. Amirhaghi, H.S. Reehal, R.J.K. Wood, and D.W. Wheeler, Diamond Coatings on Tungsten Carbide and Their Erosive Wear Properties, Surf. Coat. Technol., 2001, 135(2), p 126-138

G. Bolelli, L. Lusvarghi, T. Varis, E. Turunen, M. Leoni, P. Scardi, C.L. Azanza-Ricardo, and M. Barletta, Residual Stresses in HVOF-Sprayed Ceramic Coatings, Surf. Coat. Technol., 2008, 202(19), p 4810-4819

T. Suhonen, T. Varis, S. Dosta, M. Torrell, and J.M. Guilemany, Residual Stress Development in Cold Sprayed Al, Cu and Ti Coatings, Acta Mater., 2013, 61(17), p 6329-6337

X. Zhang, M. Watanabe, and S. Kuroda, Effects of Processing Conditions on the Mechanical Properties and Deformation Behaviors of Plasma-Sprayed Thermal Barrier Coatings: Evaluation of Residual Stresses and Mechanical Properties of Thermal Barrier Coatings on the Basis of In Situ Curvature Measurement Under a Wide Range of Spray Parameters, Acta Mater., 2013, 61(4), p 1037-1047

R. Ghelichi, S. Bagherifard, D. MacDonald, I. Fernandez-Pariente, B. Jodoin, and M. Guagliano, Experimental and Numerical Study of Residual Stress Evolution in Cold Spray Coating, Appl. Surf. Sci., 2014, 288, p 26-33

S. Wang, Y. Li, M. Yao, and R. Wang, Compressive Residual Stress Introduced by Shot Peening, J. Mater. Process. Technol., 1998, 73(1-3), p 64-73

S. Khameneh Asl, M.H. Sohi, and S.M.M. Hadavi, The Effect of the Heat Treatment on Residual Stresses in HVOF Sprayed WC-Co Coating, Mater. Sci. Forum, 2004, 465, p 427-432

M.S. Zoei, M.H. Sadeghi, and M. Salehi, Effect of Grinding Parameters on the Wear Resistance and Residual Stress of HVOF-Deposited WC-10Co-4Cr Coating, Surf. Coat. Technol., 2016, 307, p 886-891

M. Hasan, J. Stokes, L. Looney, and M.S.J. Hashmi, Effect of Spray Parameters on Residual Stress Build-Up of HVOF Sprayed Aluminium/Tool-Steel Functionally Graded Coatings, Surf. Coat. Technol., 2008, 202(16), p 4006-4010

U. Selvadurai, P. Hollingsworth, I. Baumann, B. Hussong, W. Tillmann, S. Rausch, and D. Biermann, Influence of the Handling Parameters on Residual Stresses of HVOF-Sprayed WC-12Co Coatings, Surf. Coat. Technol., 2015, 268, p 30-35

A.G.M. Pukasiewicz, H.E. de Boer, G.B. Sucharski, R.F. Vaz, and L.A.J. Procopiak, The Influence of HVOF Spraying Parameters on the Microstructure, Residual Stress and Cavitation Resistance of FeMnCrSi Coatings, Surf. Coat. Technol., 2017, 327, p 158-166

A.R.E. Singer, Simultaneous Spray Deposition and Peening of Metals (SSP), Met. Sci. J., 1984, 11(1), p 99-104

X.B. Liang, J.C. Shang, Y.X. Chen, Z.D. Zhou, Z.B. Zhang, and B.S. Xu, Influence of Ceramic Particles and Process Parameters on Residual Stress of Flame-Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2018, 354, p 10-17

O. Unal and R. Varol, Surface Severe Plastic Deformation of AISI, 304 Via Conventional Shot Peening, Severe Shot Peening and Repeening, Appl. Surf. Sci., 2015, 351, p 289-295

G.S. Junior, H.J.C. Voorwald, L.F.S. Vieira, M.O.H. Cioffi, and R.G. Bonora, Evaluation of WC-10Ni Thermal Spray Coating with Shot Peening on the Fatigue Strength of AISI, 4340 Steel, Proc. Eng., 2010, 2(1), p 649-656

Y. Chen, J. Shang, X. Liang, H. Wang, and Z. Zhou, Warm-Particle Peening Assisted HVOF Spraying: A New Process to Improve the Coating Performances, Surf. Coat. Technol., 2019, 367, p 135-147

E. Dongmo, M. Wenzelburger, and R. Gadow, Analysis and Optimization of the HVOF Process by Combined Experimental and Numerical Approaches, Surf. Coat. Technol., 2008, 202(18), p 4470-4478

M. Li and P.D. Christofides, Modeling and Analysis of HVOF Thermal Spray Process Accounting for Powder Size Distribution, Chem. Eng. Sci., 2003, 58(3), p 849-857

M. Li, D. Shi, and P.D. Christofides, Feedback Control of HVOF Thermal Spray Process: A Study of the Effect of Process Disturbances on Closed-Loop Performance, Comput. Aided Chem. Eng., 2003, 15, p 1193-1198

M. Li, D. Shi, and P.D. Christofides, Diamond Jet Hybrid HVOF Thermal Spray: Gas-Phase and Particle Behavior Modeling and Feedback Control Design, Ind. Eng. Chem. Res., 2004, 43(14), p 3632-3652

D. Cheng, Q. Xu, G. Tapaga, and E.J. Lavernia, A Numerical Study of High-Velocity Oxygen Fuel Thermal Spraying Process, Part I: Gas Phase Dynamics, Metall. Mater. Trans. A, 2001, 32(7), p 1609-1620

T. Shamim, C. Xia, and P. Mohanty, Modeling and Analysis of Combustion Assisted Thermal Spray Processes, Int. J. Therm. Sci., 2007, 46(8), p 755-767

S. Kamnis, S. Gu, T.J. Lu, and C. Chen, Computational Simulation of Thermally Sprayed WC-Co Powder, Comput. Mater. Sci., 2008, 43(4), p 1172-1182

X. Wang, Q. Song, and Z. Yu, Numerical Investigation of Combustion and Flow Dynamics in a High Velocity Oxygen-Fuel Thermal Spray Gun, J. Therm. Spray Technol., 2016, 25(3), p 1-10

M. Li and P.D. Christofides, Computational Study of Particle in-Flight Behavior in the HVOF Thermal Spray Process, Chem. Eng. Sci., 2006, 61(19), p 6540-6552

J. Pan, S. Hu, L. Yang, K. Ding, and B. Ma, Numerical Analysis of Flame and Particle Behavior in an HVOF Thermal Spray Process, Mater Des., 2016, 96, p 370-376

Z. Zhou, X. Liang, Y. Chen, B. Shen, J. Shang, and Z. Cai, Effects of Al Addition on Microstructure and Wear Resistance of High-Velocity-Oxygen-Fuel-Sprayed FeCoNiCrMn High Entropy Alloy Coating, Sci. Adv. Mater., 2019, 11(5), p 685-693

J.M. Park, J. Moon, J.W. Bae, J.J. Min, J. Park, S. Lee, and H.S. Kim, Strain Rate Effects of Dynamic Compressive Deformation on Mechanical Properties and Microstructure of CoCrFeMnNi High-Entropy Alloy, Mater. Sci. Eng. A, 2018, 719, p 155-163

J.I. Lee, H.S. Oh, J.H. Kim, and E.S. Park, Effect of Configurational Entropy of Mixing on Thermophysical Properties in Single Phase FCC Solid Solutions with Multi-Principal Elements, Korean J. Met. Mater., 2017, 55(1), p 1-9

S. Emami, H. Jafari, and Y. Mahmoudi, Effects of Combustion Model and Chemical Kinetics in Numerical Modeling of Hydrogen-Fueled Dual-Stage HVOF System, J. Therm. Spray Technol., 2019, 28(3), p 333-345

S. Kamnis and S. Gu, Numerical Modelling of Propane Combustion in a High Velocity Oxygen-Fuel Thermal Spray Gun, Chem. Eng. Process., 2006, 45(4), p 246-253

S. Kamnis and S. Gu, 3-D Modelling of Kerosene-Fuelled HVOF Thermal Spray Gun, Chem. Eng. Sci., 2006, 61(16), p 5427-5439

A. Dolatabadi, J. Mostaghimi, and V. Pershin, Effect of a Cylindrical Shroud on Particle Conditions in High Velocity Oxy-Fuel Spray Process, Sci. Technol. Adv. Mater., 2002, 137(1), p 214-224

X. Yang and S. Eidelman, Numerical Analysis of a High-Velocity Oxygen-Fuel Thermal Spray System, J. Therm. Spray Technol., 1996, 5(2), p 175-184

H. Tabbara, S. Gu, and D.G. McCartney, Computational Modelling of Titanium Particles in Warm Spray, Comput. Fluids, 2011, 44(1), p 358-368

M.N. Khan and T. Shamim, Effect of Operating Parameters on a Dual-Stage High Velocity Oxygen Fuel Thermal Spray System, J. Therm. Spray Technol., 2014, 23(6), p 910-918

M.N. Khan and T. Shamim, Investigation of a Dual-Stage High Velocity Oxygen Fuel Thermal Spray System, Appl. Energy, 2014, 130, p 853-862

M. Li and P.D. Christofides, Modeling and Control of High-Velocity Oxygen-Fuel (HVOF) Thermal Spray: A Tutorial Review, J. Therm. Spray Technol., 2009, 18(5-6), p 753-768

D. Cheng, Q. Xu, E. Lavernia, and G. Trapaga, The Effect of Particle Size and Morphology on the In-Flight Behavior of Particles During High-Velocity Oxyfuel Thermal Spraying, Metall. Mater. Trans. B, 2001, 32(3), p 525-535

H. Jafari, S. Emami, and Y. Mahmoudi, Numerical Investigation of Dual-Stage High Velocity Oxy-Fuel (HVOF) Thermal Spray Process: A Study on Nozzle Geometrical Parameters, Appl. Therm. Eng., 2017, 111, p 745-758

A. Haider and O. Levenspiel, Drag Coefficient and Terminal Velocity of Spherical and Nonspherical Particles, Powder Technol., 1989, 58(1), p 63-70

W. Ranz and W.R. Marshall, Evaporation from Drops, Chem. Eng. Prog., 1952, 48(3), p 141-146

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

J.Y. He, C. Zhu, D.Q. Zhou, W.H. Liu, T.G. Nieh, and Z.P. Lu, Steady State Flow of the FeCoNiCrMn High Entropy Alloy at Elevated Temperatures, Intermetallics, 2014, 55, p 9-14

S. Zimmermann, E. Vogli, M. Kauffeldt, M. Abdulgader, B. Krebs, B. Rüther, K. Landes, J. Schein, and W. Tillmann, Supervision and Measuring of Particle Parameters During the Wire-Arc Spraying Process with the Diagnostic Systems Accuraspray-g3 and LDA (Laser-Doppler-Anemometry), J. Therm. Spray Technol., 2010, 19(4), p 745-755

H. Kobatake, Y. Kurokawa, H. Fukuyama, N. Sasajima, Y. Yamaguchi, and Y. Yamada, Dual-Wavelength Reflectance-Ratio (DWR) Method Applied to High-Temperature Metals, Proc. SICE Annu. Conf., 2017, 2017, p 427-428

H. Tabbara and S. Gu, A Study of Liquid Droplet Disintegration for the Development of Nanostructured Coatings, AlChE J., 2012, 58(11), p 3533-3544

Z. Zhou, J. Shang, Y. Chen, X. Liang, B. Shen, and Z. Zhang, Synchronous Shot Peening Applied on HVOF for Improvement on Wear Resistance of Fe-Based Amorphous Coating, Coatings, 2020, 10(187), p 2-14

E. Sadeghimeresht, N. Markocsan, and P. Nylen, Microstructural Characteristics and Corrosion behavior of HVAF-and HVOF-Sprayed Fe-Based Coatings, Surf. Coat. Technol., 2017, 318, p 365-373

Acknowledgments

This project is supported by the National Key R&D Program of China (Grant No. 2018YFC1902400), National Natural Science Foundation of China (Grant No. 51975582) and the program of China Scholarships Council (No. 201906420072)

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Z., Chen, Y., Hu, Z. et al. Numerical Investigation of Particles in Warm-Particle Peening-Assisted High-Velocity Oxygen Fuel (WPPA-HVOF) Spraying. J Therm Spray Tech 29, 1682–1694 (2020). https://doi.org/10.1007/s11666-020-01063-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01063-0