Abstract

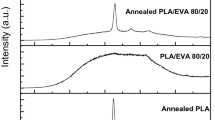

As far as we know, to enhance the toughness of poly(L-lactide) (PLLA) without compromising its inherent biodegradability, melt blending PLLA with flexible biodegradable polymers is the most effective and universal method. However, most of research results show a slight improvement in impact toughness due to the amorphous PLLA matrix. In other words, effective impact toughness can be achieved only if PLLA blend is in a highly crystalline state. In this work, blend of PLLA with 20 wt% PCL was prepared and then samples made by injection molding were applied to thermal annealing at different temperatures for 2 h to increase the crystallinity of PLLA matrix. The results show that the crystallinity of PLLA/PCL blend annealing at 80 °C is exceeding 40% and impact strength of the samples increases from 5.92 KJ/m2 of unannealed neat PLLA to 26.81 KJ/m2. At the same time, the thermal properties are also improved by a large margin.

Similar content being viewed by others

References

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9(2):63–84

Anders S, Mikael S (2002) Properties of lactic acid based polymers and their correlation with composition. Prog Polym Sci 27(6):1123–1163

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33(8):820–852

Baimark Y, Pasee S, Rungseesantivanon W, Prakymoramas N (2019) Flexible and high heat-resistant stereocomplex PLLA-PEG-PLLA/PDLA blends prepared by melt process: effect of chain extension. J Polym Res 26(9):218

Dorgan JR, Williams JS, Lewis DN (1999) Melt rheology of poly(lactic acid): entanglement and chain architecture effects. J Rheol 43(5):1141–1155

Rasal RM, Janorkar AV, Hirt DE (2010) Poly(lactic acid) modifications. Prog Polym Sci 35(3):338–356

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4(9):835–864

Drumright RE, Gruber PR, Henton DE (2000) Polylactic acid technology. Adv Mater 12(23):1841–1846

Li H, Michel AH (2007) Effect of nucleation and plasticization on the crystallization of poly(lactic acid). Polymer 48(23):6855–6866

Menczel JD, Prime RB (2009) Thermal analysis of polymers: fundamentals and applications. Macromol Chem Phys 12(6):131–142

Zhang J, Tashiro K, Tsuji H, Domb AJ (2008) Disorder-to-order phase transition and multiple melting behavior of poly(l-lactide) investigated by simultaneous measurements of WAXD and DSC. Macromolecules 41(4):1352–1357

Jose-Ramon Sarasua PHR-E, Muriel W et al (1998) Crystallization and melting behavior of Polylactides. Macromolecules 31(12):3895–3905

Martin O, Avérous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42(14):6209–6219

Deng L, Xu C, Wang X, Wang Z (2017) Supertoughened Polylactide binary blend with high heat deflection temperature achieved by thermal annealing above the glass transition temperature. ACS Sustain Chem Eng 6(1):480–490

Oyama HT (2009) Super-tough poly(lactic acid) materials: reactive blending with ethylene copolymer. Polymer 50(3):747–751

Sang ZH, Xie X-L, Zhou S-Y, Li Y, Yan Z, Xu L, Zhong G-J, Li Z-M (2017) Gradient structure of crystalline morphology in injection-molded Polylactide parts tuned by oscillation shear flow and its influence on Thermomechanical performance. Ind Eng Chem Res 56(21):6295–6306

Zhang J, Zhu J, Lei Y, Zeng T, Shen K, Fu Q (2008) Mechanical property, thermal property and crystal structure of isotactic polypropylene samples prepared by vibration injection molding. Polym Bull 59(6):855–864

Zheng L, Geng Z, Zhen W (2019) Preparation, characterization, and reaction kinetics of poly (lactic acid)/amidated graphene oxide nanocomposites based on reactive extrusion process. J Polym Res 26(3):78

Broz ME, VanderHart DL, Washburn NR (2003) Structure and mechanical properties of poly(D,L-lactic acid)/poly(epsilon-caprolactone) blends. Biomaterials 24(23):4181–4190

Takayama T, Mitsugu T, Hideto T (2011) Effect of annealing on the mechanical properties of PLA/PCL and PLA/PCL/LTI polymer blends. J Mech Behav Biomed Mater 4(3):255–260

Takeshi S, Kazuo K, Umaru Semo I, Hiroyuki H (2010) The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends. J Appl Polym Sci 101(3):1816–1825

Nagarajan V, Mohanty AK, Misra M (2016) Perspective on Polylactic acid (PLA) based sustainable materials for durable applications: focus on toughness and heat resistance. ACS Sustain Chem Eng 4(6):2899–2916

Chen Y, Fan Q, Yang S, Zhang Q, Li Z (2018) Greatly improved toughness of isotactic polypropylene blends with traces of carbon nanotubes. Polym Eng Sci 59(4):757–764

Pan Y, Liu X, Shi S, Liu C, Dai K, Yin R, Schubert DW, Zheng G, Shen C (2016) Annealing induced mechanical reinforcement of injection molded iPP parts. Macromol Mater Eng 301(12):1468–1472

Nagarajan V, Mohanty AK, Misra M (2016) Crystallization behavior and morphology of polylactic acid (PLA) with aromatic sulfonate derivative. J Appl Polym Sci 133(28):43673

Wang F, Xia C, Jin M, Du H, Zhang J (2015) Influences of nucleating agent TMB-5 on crystallization properties of poly(lactic-acid). China Synthetic Resin Plastics 32(6):4–7

Mi D, Liu H, Zhang L, Wang T, Zhang X, Zhang J (2015) The changes of microstructure and physical properties of isotactic polypropylene/β nucleation agent/polyolefin elastomer induced by annealing following processing. J Macromolec Sci Part B 54(11):1376–1390

Yanhui C, Zhiqiang W, Qian F, Song Y, Erchao S, Qiuyu Z (2018) Great toughness reinforcement of isotactic polypropylene/elastomer blends with quasi-cocontinuous phase morphology by traces of β-nucleating agents and carbon nanotubes. Compos Sci Technol 167:277–284

Liu Z, Zheng G, Dai K, Liu C, Shen C (2019) Simultaneously improving tensile strength and toughness of melt-spun -nucleated isotactic polypropylene fibers. J Appl Polym Sci 133(21):43454

Battegazzore D, Bocchini S, Frache A (2011) Crystallization kinetics of poly(lactic acid)-talc composites. Express Polym Lett 5(10):849–858

Liang JZ, Zhou L, Tang CY, Tsui CP (2013) Crystalline properties of poly(L-lactic acid) composites filled with nanometer calcium carbonate. Compos Pt B-Eng 45(1):1646–1650

Liang JZ, Duan DR, Tang CY, Tsui CP, Chen DZ, Zhang SD (2015) Mechanical properties and morphology of poly(l-lactic acid)/Nano-CaCO3Composites. J Polym Environ 23(1):21–29

Frone AN, Berlioz S, Chailan J-F (2013) O.; Panaitescu, D. M., morphology and thermal properties of PLA–cellulose nanofibers composites. Carbohydr Polym 91(1):377–384

Kowalczyk M, Piorkowska E, Kulpinski P, Pracella M (2011) Mechanical and thermal properties of PLA composites with cellulose nanofibers and standard size fibers. Compos Part A Appl Sci Manufact 42(10):1509–1514

Suchaiya V, Aht-Ong D (2013) Evaluation of mechanical and thermal properties of MCC/PLA composite Compatibilized with modified cellulose. Adv Mater Res 747:698–702

Bai HW, Zhang WY, Deng H, Zhang Q, Fu QA (2011) Control of crystal morphology in poly(L-lactide) by adding nucleating agent. Macromolecules 44(6):1233–1237

Simmons H, Tiwary P, Colwell JE, Kontopoulou M (2019) Improvements in the crystallinity and mechanical properties of PLA by nucleation and annealing. Polym Degrad Stab 166:248–257

Cocca M, Di Lorenzo ML, Mario M, Vincenzo F (2011) Influence of crystal polymorphism on mechanical and barrier properties of poly(l-lactic acid). Eur Polym J 47(5):1073–1080

Gu X, Zhou M, Wang Y, Zhang J (2019) Influence of annealing on the morphology and mechanical properties of iPP/HDPE blend with tailored oriented crystalline structures. J Polym Res 26(8):194

Eling B, Gogolewski S, Pennings AJ (1982) Biodegradable materials of poly(l-lactic acid): 1. Melt-spun and solution-spun fibres. Polymer 23(11):1587–1593

Liu M, Hong R, Gu X, Fu Q, Zhang J (2019) Remarkably improved impact fracture toughness of isotactic polypropylene via combining the effects of shear layer-Spherulites layer alternated structure and thermal annealing. Ind Eng Chem Res 58(32):15069–15078

Puiggali J, Ikada Y, Tsuji H, Cartier L, Okihara T, Lotz B (2000) The frustrated structure of poly(L-lactide). Polymer 41(25):8921–8930

Mi D, Hou F, Zhou M, Zhang J (2018) Improving the mechanical and thermal properties of shish-kebab via partial melting and re-crystallization. Eur Polym J 101:1–11

Bai H, Xiu H, Gao J, Deng H, Zhang Q, Yang M, Fu Q (2012) Tailoring impact toughness of poly(L-lactide)/poly(epsilon-caprolactone) (PLLA/PCL) blends by controlling crystallization of PLLA matrix. ACS Appl Mater Interfaces 4(2):897–905

Liu H, Chen F, Liu B, Estep G, Zhang J (2010) Super toughened poly(lactic acid) ternary blends by simultaneous dynamic vulcanization and interfacial Compatibilization. Macromolecules 43(14):6058–6066

Pan P, Kai W, Zhu B, Dong T, Inoue YY (2007) Polymorphous crystallization and multiple melting behavior of poly(l-lactide): molecular weight dependence. Macromolecules 40(19):6898–6905

Jalali A, Shahbikian S, Huneault MA, Elkoun S d (2017) Effect of molecular weight on the shear-induced crystallization of poly(lactic acid). Polymer 112:393–401

Nagarajan V, Zhang K, Misra M, Mohanty AK (2015) Overcoming the fundamental challenges in improving the impact strength and Crystallinity of PLA biocomposites: influence of nucleating agent and Mold temperature. ACS Appl Mater Interfaces 7(21):11203–11214

Sakai F, Nishikawa K, Inoue Y, Yazawa K (2009) Nucleation enhancement effect in poly(L-lactide) (PLLA)/poly(epsilon-caprolactone) (PCL) blend induced by locally activated chain mobility resulting from limited miscibility. Macromolecules 42(21):8335–8342

Lauritzen JI (1973) Extension of theory of growth of chain-folded polymer crystals to large undercoolings. J Appl Phys 44(10):4340–4352

Bai H, Huang C, Xiu H, Gao Y, Zhang Q, Fu Q (2013) Toughening of poly(l-lactide) with poly(ε-caprolactone): combined effects of matrix crystallization and impact modifier particle size. Polymer 54(19):5257–5266

Zhang X, Meng L, Li G, Liang N, Rui W (2016) Effect of nucleating agents on the crystallization behavior and heat resistance of poly(L-lactide). J Appl Polym Sci 133(8):42999

Ran XH, Jia ZY, Yang YM, Dong LS (2010) Flexible plasticized PLA with high crystallinity obtained by controlling the annealing temperature. e-Polymers 10(1):7

Acknowledgments

The authors genuinely appreciate the financial supports of the National Natural Science Foundation of China (No. 21627804) and State Key Laboratory of Polymer Materials Engineering (No. sklpme2019-2-18).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Deng, C., Hong, R. et al. Effect of thermal annealing on crystal structure and properties of PLLA/PCL blend. J Polym Res 27, 221 (2020). https://doi.org/10.1007/s10965-020-02206-1

Published:

DOI: https://doi.org/10.1007/s10965-020-02206-1