Abstract

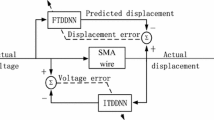

Hysteresis is a nonlinear phenomenon which may cause inaccuracies and delay in control applications. Shape memory alloys (SMAs) have an asymmetric saturated hysteresis. In addition, the excitation frequency changes the hysteresis behavior of SMA-driven systems and makes them challenging to track reference inputs at different frequencies. In this study, a rate-dependent Prandtl–Ishlinskii model coupled with a deadband function is proposed to characterize the asymmetric and saturated hysteresis behavior as well as its rate-dependency. Unknown parameters of the model are identified using genetic optimization algorithm in MATLAB Toolbox based on measured data. The identified model is validated to consider the excitation frequency effect with a different measured data set. The inverse model is also proposed as a compensator to mitigate hysteresis nonlinearity effects especially the frequency effect in tracking control. Although the proposed compensator cannot fully compensate for hysteresis effects, it can reduce the input–output hysteresis. The proposed rate-dependent compensator as a feedforward controller combined with a proportional–integral–derivative (PID) controller as a feedback mitigates hysteresis effects. The PID controller is used to improve the accuracy of compensated system and remove the steady-state error. Experimental results illustrate that the proposed controller has a great accuracy in tracking control to consider the excitation frequency effect as well as the asymmetric saturated hysteresis.

Graphic abstract

Similar content being viewed by others

References

Evangeliou N, Tzes A (2017) Design and control of a robotic platform for dexterous minimally invasive surgical applications. Int Rev Autom Control 10(5):443–450

Park SJ, Park CH (2019) Suit-type wearable robot powered by shape-memory-alloy-based fabric muscle. Sci Rep 9(1):9157

Mirzakhani F, Ayati S, Fahimi P, Baghani M (2019) Online force control of a shape-memory-alloy-based 2 degree-of-freedom human finger via inverse model and proportional–integral–derivative compensator. J Intell Mater Syst Struct 30(10):1538–1548

Basaeri H, Zakerzadeh MR, Yousefi Koma A, Mohtasebi SS (2015) Design and aerodynamic analysis of a morphing wing with shape memory alloy actuator. Modares Mech Eng 15(5):60–70

Williams EA, Shaw G, Elahinia M (2010) Control of an automotive shape memory alloy mirror actuator. Mechatronics 20(5):527–534

Shakiba S, Abedi M, Vedadi A (2020) Behavioral modeling and experimental verification of a smart servomotor used in a thermal control louver of a satellite using dynamic neural network-based NARX. AUT J Mech Eng. https://doi.org/10.22060/ajme.2020.16517.5822

de Abreu GLCM, Maesta MF, Junior VL, Junior CDM, Faria CT, Inman DJ (2015) Active angular control of a sectioned airfoil using shape memory alloys and fuzzy controller. J Braz Soc Mech Sci Eng 37(5):1555–1567

Copaci D-S, Blanco D, Martin-Clemente A, Moreno L (2020) Flexible shape memory alloy actuators for soft robotics: modelling and control. Int J Adv Rob Syst 17(1):1729881419886747

Borges JM et al (2018) On the active control of a rotor-bearing system using shape memory alloy actuators: an experimental analysis. J Braz Soc Mech Sci Eng 40(5):269

Choudhary N, Kaur D (2016) Shape memory alloy thin films and heterostructures for MEMS applications: a review. Sens Actuators A 242:162–181

Lan C-C, Fan C-H (2010) An accurate self-sensing method for the control of shape memory alloy actuated flexures. Sens Actuators A 163(1):323–332

Gédouin P-A, Delaleau E, Bourgeot J-M, Join C, Arbab Chirani S, Calloch S (2011) Experimental comparison of classical PID and model-free control: Position control of a shape memory alloy active spring. Control Eng Pract 19(5):433–441

Lee J, Jin M, Ahn KK (2013) Precise tracking control of shape memory alloy actuator systems using hyperbolic tangential sliding mode control with time delay estimation. Mechatronics 23(3):310–317

Moghadam MH, Zakerzadeh MR, Ayati M (2019) Development of a cascade position control system for an SMA-actuated rotary actuator with improved experimental tracking results. J Braz Soc Mech Sci Eng 41(10):407

Elahinia MH, Seigler TM, Leo DJ, Ahmadian M (2004) Nonlinear stress-based control of a rotary SMA-actuated manipulator. J Intell Mater Syst Struct 15(6):495–508

Moghadam MH, Zakerzadeh MR, Ayati M (2019) Robust sliding mode position control of a fast response SMA-actuated rotary actuator using temperature and strain feedback. Sens Actuators A 292:158–168

Li J, Tian H (2018) Position control of SMA actuator based on inverse empirical model and SMC-RBF compensation. Mech Syst Signal Process 108:203–215

Sayyaadi H, Zakerzadeh MR (2012) Position control of shape memory alloy actuator based on the generalized Prandtl–Ishlinskii inverse model. Mechatronics 22(7):945–957

Zakerzadeh MR, Sayyaadi H (2013) Precise position control of shape memory alloy actuator using inverse hysteresis model and model reference adaptive control system. Mechatronics 23(8):1150–1162

Janaideh MA, Su C-Y, Rakheja S (2008) Development of the rate-dependent Prandtl–Ishlinskii model for smart actuators. Smart Mater Struct 17(3):035026

Al Janaideh M (2013) A time-dependent stop operator for modeling a class of singular hysteresis loops in a piezoceramic actuator. Physica B Condens Matter 413:100–104

Al Janaideh M, Krejci P (2013) Inverse rate-dependent Prandtl-Ishlinskii model for feedforward compensation of hysteresis in a piezomicropositioning actuator. IEEE/ASME Trans Mechatron 18(5):1498–1507

Aljanaideh O, Rakheja S, Su C-Y (2014) Experimental characterization and modeling of rate-dependent asymmetric hysteresis of magnetostrictive actuators. Smart Mater Struct 23(3):035002

Shakiba S, Yousefi-Koma A, Jokar M, Zakerzadeh MR, Basaeri H (2020) Modeling and characterization of the shape memory alloy–based morphing wing behavior using proposed rate-dependent Prandtl–Ishlinskii models. Proc Inst Mech Eng Part I J Syst Control Eng 234(4):550–565

Al Janaideh M, Aljanaideh O (2018) Further results on open-loop compensation of rate-dependent hysteresis in a magnetostrictive actuator with the Prandtl-Ishlinskii model. Mech Syst Signal Process 104:835–850

Aljanaideh O, Al-Tahat MD, Al Janaideh M (2016) Rate-bias-dependent hysteresis modeling of a magnetostrictive transducer. Microsyst Technol 22:883–892

Aljanaideh O, Al Janaideh M, Rakheja S, Su C-Y (2013) Compensation of rate-dependent hysteresis nonlinearities in a magnetostrictive actuator using an inverse Prandtl-Ishlinskii model. Smart Mater Struct 22(2):025027

Ang WT, Khosla PK, Riviere CN (2007) Feedforward controller with inverse rate-dependent model for piezoelectric actuators in trajectory-tracking applications. IEEE/ASME Trans Mechatron 12(2):134–142

Shakiba S, Zakerzadeh MR, Ayati M (2018) Experimental characterization and control of a magnetic shape memory alloy actuator using the modified generalized rate-dependent Prandtl–Ishlinskii hysteresis model. Proc Inst Mech Eng Part I J Syst Control Eng 232(5):506–518

Riccardi L, Naso D, Turchiano B, Janocha H, Palagachev DK (2012) On PID control of dynamic systems with hysteresis using a Prandtl–Ishlinskii model. In: 2012 American control conference (ACC). IEEE, pp 1670–1675

Al Janaideh M, Feng Y, Rakheja S, Tan Y, Su C-Y (2009) Generalized Prandtl–Ishlinskii hysteresis: modeling and robust control for smart actuators. In: Proceedings of the 48th IEEE conference on decision and control (CDC) held jointly with 2009 28th Chinese control conference. IEEE, pp 7279–7284

Al Janaideh M, Feng Y, Rakheja S, Su C-Y, Rabbath CA (2009) Hysteresis compensation for smart actuators using inverse generalized Prandtl–Ishlinskii model. In: 2009 American control conference. IEEE, pp 307–312

Funding

Funding was provided by Iran National Science Foundation (Grant No. 97018481).

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Pedro Manuel Calas Lopes Pacheco, D.Sc.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shakiba, S., Yousefi-Koma, A. & Ayati, M. Tracking control of an SMA-driven actuator with rate-dependent behavior using an inverse model of hysteresis. J Braz. Soc. Mech. Sci. Eng. 42, 418 (2020). https://doi.org/10.1007/s40430-020-02486-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02486-0