Abstract

Rhodospirillum rubrum is a gram-negative bacterium that naturally takes advantage of CO and which, in the presence of acetate, accumulates carbon and energy units as polyhydroxybutyrate (PHB). Since the conversion of CO depends on a large protein membrane complex that is expressed after the exposure to carbon monoxide, this study presents the effects of a CO-based acclimation in R. rubrum on the growth trend and on the production of PHB. The strain was cultured in two consecutive fermentation cycles on 15% of CO, and the behaviour of this species, in the presence of acetate or a reducing sugar, such as fructose, was compared. The exposure of R. rubrum to CO during the first adaptation phase led to the development of a metabolically active population characterised by a greater biomass growth. The supply of fructose ensured a shorter lag-phase and a higher biomass titre, but it also determined a decrease in the biopolymer accumulation. However, R. rubrum showed the best carbon utilisation in the absence of fructose, with a growth molar yield of 48 mg mol−1, compared to the 12 mg mol−1 obtained for fructose feeding.

Similar content being viewed by others

1 Introduction

The next few decades will be characterised by a radical change in the economy, which will evolve from the current linear type to the new concept of circular economy. This change in perspective requires a substantial evolution of the supply chain network, in which by-products should be designed to take part in new production cycles as secondary raw materials. Carbon monoxide is a harmful molecule for most living beings and a greenhouse gas that affects climate change. In this scenario, anthropogenic activities play a crucial role, contributing by around 70% to the global CO emissions in the atmosphere [1]. However, carbon monoxide can be used for a broad spectrum of applications in the microbial fermentation field, where it can be fed as a carbon source for all those microorganisms that can take advantage of it. Furthermore, even though this kind of technology has already been launched at an industrial scale, there is still a wide margin for improvement [2, 3].

The current environmental issues evidence the urgent need to substitute conventional fossil-based plastics materials with biodegradable polymers originating from renewable feedstock [4, 5]. Polyhydroxybutyrate (PHB) is a biodegradable and biocompostable thermoplastic that is naturally synthesised, by several microbial species, as a carbon store and energy source for famine periods [6, 7]. One of these species is Rhodospirillum rubrum, a gram-negative facultative aerobe that belongs to the Rhodospirillaceae family, which can rely on carbon monoxide for its growth and promote the production of PHB in the presence of acetate at the same time [8,9,10,11,12]. Hence, it is a suitable candidate to produce PHB on a CO-based feeding.

Even though the CO conversion mechanism is not yet fully understood, genetic and biochemistry studies have demonstrated that the CO conversion of R. rubrum is mediated by a membrane protein complex, which orchestrates the biological water-gas shift (WGS) reaction (CO + H2O ➔ CO2 + H2) [13] (Fig. 1). The oxidation of CO into CO2 is guaranteed by carbon monoxide dehydrogenase (CODH), a membrane protein that contains a nickel-based binding site and an iron-sulphur centre which coordinate CO and catalyses its oxidation at the expenses of one water molecule, with a consequent release of a couple of protons and a couple of electrons. In this context, the formation of a chemiosmotic gradient across the cell membrane, that is, a transmembrane proton gradient derived from the water-gas-shift reaction, leads to the production of molecular hydrogen and the phosphorylation of ADP molecules [14]. Therefore, it is supposed that a large membrane-bound protein complex composed of CODH, an accessory electron transport protein equipped with an Fe-S centre (CooF), a membrane CO-tolerant [NiFe]-hydrogenase (which is also called CO-linked hydrogenase) and an ATP-synthase can promote (i) proton pumping and (ii) proton reduction coupled with ATP synthesis activity [15,16,17,18,19]. The cell within this mechanism is able to dissipate electrons in excess and to provide ATP during dark fermentation.

The principal metabolic pathways of R. rubrum on fructose and CO with acetate. The metabolites and enzymes in the scheme are addressed as follows: F: fructose; F1P: fructose-1-phosphate; 6-PFK: 6-phosphofructokinase; FBP-aldolase: fructose-1,6-bisphosphate aldolase; G3AP: glyceraldehyde-3-phosphate; GA3P-DH: glyceraldehyde-3-phosphate dehydrogenase; 1,3-PG: 1,3-bisphosphoglycerate; PGK: phosphoglycerate kinase; PGM: phosphoglycerate mutase; PEP: phosphoenolpyruvate; PYR: pyruvate; PFOR: pyruvate synthase; PFL: pyruvate-formate lyase; FDHH: formate-hydrogen lyase; ACS: acetyl-CoA synthase; TCA: tricarboxylic acid cycle; PhaA: 3-ketotiolase; PhaB: acetoacetyl-CoA reductase; PhaC: PHB synthase; CODH: carbon monoxide dehydrogenase, CooF: electron transfer protein; CooH: CO-induced hydrogenase; ATPase: ATP-synthase; e-: electron; CooA: CO-dependent transcription factor. The figure was created with BioRender.com

This large membrane-bound complex in R. rubrum is induced by the presence of CO. In fact, it is only once the cells are exposed to carbon monoxide, that a CO-sensor transcriptional activator, CooA, can bind CO and turn on the expression of those genes involved in the oxidation of CO [15, 20,21,22]. It has been demonstrated that these transcriptional events present an accumulation profile, with an amount of produced proteins that grows as exposure to carbon monoxide increases [23]. However, even though CO is the preferred substrate in the absence of other carbon sources, an increase in the partial pressure of CO can also determine inhibition events on CO uptake, which results into a slower CO conversion [24, 25].

In similar carboxytrophs species, an acclimation to CO is a culturing procedure that allows the most efficient cultures to be [26]. For instance, in the acetogen Clostridium ljungdahlii, it has been demonstrated that an adaptation phase, reached by exposing the pre-cultures to CO, could enhance CO stress tolerance. Moreover, in the same study, it was also demonstrated that the combination of CO and a reducing sugar could positively affect the accumulation of both the biomass and the end products, such as ethanol or acetate, due to a higher accumulation of energy (e.g., ATP and GTP), and to the reducing equivalents (e.g., NADH) provided by the sugar metabolism [27].

In the studies dedicated to PHB biosynthesis with CO as the main carbon and energy feedstock, R. rubrum is generally cultivated using syngas as the source of CO and acetate as the main liquid carbon source. Under these standard culturing conditions, R. rubrum presents a linear growth trend because it is mainly limited by CO mass transfer events from the gas to the liquid phase, with a biomass accumulation yield that is affected by the amount of supplied syngas [10,11,12]. It has also been demonstrated that the presence of acetate induces the accumulation of PHB [10].

Fructose is a fermentable sugar which can lead to high-density cultures being achieved in darkness fermentations [28, 29]. However, no information regarding a co-feeding of CO and sugars has been presented so far. Such a feeding strategy can be identified as mixotrophic fermentation, in order to distinguish it from the standard CO-based fermentation conditions that is carried out on CO and acetate.

For these reasons, this work has focused on the effects of an adaptation step made with CO in the wild-type strain of R. rubrum and has compared them with the contribution of fructose in the presence of carbon monoxide. The strain was exposed to 15% of CO in 160-mL serum bottles filled to 20% with the liquid medium for the acclimation and the successive growth cycle. R. rubrum was cultured in two consecutive growth cycles, in which the accumulated biomass from the first fermentation run was inoculated into fresh media for a subsequent cultivation cycle. During the experiments, the CO was restored every 24 h, and the effects of the adaptation on the biomass growth efficiency, the substrate conversion and PHB production were evaluated.

2 Materials and methods

2.1 Bacterial strain and cultivation

Rhodospirillum rubrum (ATCC 11170) was pre-cultured in a 160-mL serum bottle which was closed with a rubber stop-cap (Fig. 2). The growth was carried out under darkness in 80 mL of Rhodospirillum rubrum no-light CO (RRNCO) medium [9, 10], with 15 mM of fructose used as liquid carbon source. The preculture was grown for 48 h until it reached an optical density of 1.5 at 600 nm (OD660) and it consumed all the fructose present in the medium [12].

The experimental culturing strategy adopted to test a CO-based adaptation in R. rubrum. Each condition tested is represented by a culturing bottle followed by a description of the carbon source used, where “Fruct.” stands for fructose and “Ac.” stands for acetate. The figure was created with BioRender.com

The adaptation and culture cycles were run in 160-mL serum bottles filled with 30 mL of the RNNCO medium and different carbon sources (3 mM of acetate and 5 or 15 mM of fructose for the mixotrophic condition). The biomass growth started at an initial OD660 of 0.08. The headspace in the bottle, which corresponded to 130 mL, was filled with 15% of CO and 85% of N2. During biomass growth, the bacteria were fed with the following procedure: the headspace in the bottle was purged for 30 s using a vacuum pump, washed with N2, purged again for another 30 s and filled with a fresh aliquot of CO and N2. This procedure was repeated every 24 h. The experiments were carried out in biological triplicate. All the cultures were conducted at 200 rpm at 30 °C. The experimental strategy consisted in culturing the biomass in a first growth cycle, carried out on CO and 3 mM of acetate (standard CO-based fermentation), or on 5 or 15 mM of fructose (mixotrophic fermentation) for the adaptation cycle. Hence, the cells adapted under the standard CO-based fermentation were seeded in a fresh medium with the same amount of acetate, while the cells grown on 5 mM of fructose were inoculated on a fresh mixotrophic medium with 5 mM of fructose or in an RRNCO medium on 3 mM of acetate. Moreover, the cells that underwent an adaptation cycle on fructose were also inoculated in a mixotrophic medium that was supplied with 5 mM of fructose every 24 h. During the adaptation phase, the growth was stopped before the stationary phase was reached to allow propagation in the second growth cycle.

2.2 Growth characterisation

Biomass growth was evaluated measuring the absorbance at 660 nm. Aliquots of 1 mL were taken from the culture bottles and analysed in a spectrophotometer (Thermo Fisher Scientific), with appropriate dilutions, when necessary. Cell dry weight measurements were determined gravimetrically. Biomass samples were centrifuged at 10,000 rpm for 5 min, washed twice and air-dried at 80 °C for 12 h in an oven.

Acetate, fructose and formate were detected by means of HPLC analysis (Shimatzu). After sampling the culture, the medium was filtered using a 0.2-μm cellulose nitrate filter and was analysed using an ROA-Organic Acid H+ (8%) column (Phenomenex), with an isocratic flux of 0.7 mL min−1 of 5 mM of H2SO4 and a temperature of 50 °C. Acetate, fructose and formic acid were detected after 13.59 min, 9.17 min and 12.3 min of retention time, respectively. Acetate and fructose were identified by means of a RID detector, while formate was detected using a PDA detector at 206 nm.

2.3 PHB quantification

Biomass samples were centrifuged at 10,000 rpm for 5 min, washed twice and dried at 80 °C for 12 h in an oven. Once the biomass concentration had been estimated (g L−1), the dry biomasses were hydrolysed with 1 mL of 96% H2SO4 under stirring at 800 rpm, in an agitated oil bath at 90 °C for 1 h. At the end of the reaction, a 1:125 dilution was prepared, and the samples were analysed by means of HPLC (Shimatzu) using an ROA-Organic Acid H+ (8%) column (Phenomenex), with an isocratic flux of 0.7 mL min−1 of 5 mM of H2SO4 and a temperature of 50 °C. The related PHB signal appeared at 210 nm after 23.09 min from the injection of the sample, a signal that corresponds to the crotonic acid, the monomer that comes from hydrolysed PHB [30].

2.4 Gas composition analysis

In order to perform the analysis of the composition of the gas present in the headspace of the bottle, a gasbag, previously purged and put under vacuum using a vacuum pump, was connected, by a needle, to the serum bottle hosting the R. rubrum cultures, and the gas was sampled. The procedure was improved by the presence of an overpressure, which was developed as a result of the performed water gas shift reaction after 24 h of cultivation. The collected gas was analysed by means of SRA micro-GC, equipped with a Molsive 5A column at a temperature of 100 °C with argon as the carrier gas (for the quantification of H2), and with a PoraPLOT U column at 85 °C, using helium as the carrier gas (for CO2 analysis).

2.5 Calculations

The molar growth yield (Ymol) was calculated after complete depletion of the consumed substrate. It was calculated on the basis of the work of Schultz [31], considering the total carbon atoms present as the substrate (acetate or fructose), as follows: mg of collected biomass on mmol of consumed substrate per atom of C of the substrate.

3 Results and discussion

3.1 Effect of CO adaptation on biomass accumulation

R. rubrum was grown under darkness in two successive culture cycles, which are an adaptation run and a cultivation run, respectively (Fig. 3). R. rubrum was fed with 15% of CO during both fermentation runs, and its growth trend supported by CO and acetate was compared with that obtained when CO and fructose were used as co-substrates. Two different concentrations of fructose, corresponding to 5 and 15 mM, were investigated in the adaptation phase to verify its effect on biomass growth. The headspace composition was restored every 24 h with a fresh mix of CO and N2 at concentrations of 15 and 85%, respectively. At the end of the first culture cycle (I cycle), the biomass samples were transferred to fresh culture media (II cycle), and the effects of adaptation, as a result of exposure to CO exposure in the presence of fructose or acetate, were analysed on the growth rate.

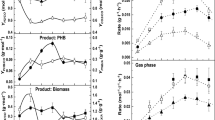

Adaptation and growth cycles of R. rubrum in the presence of CO under standard CO-based fermentation conditions and mixotrophic growth conditions under darkness. a Adaptation phase of R. rubrum on 15% of CO and 5 mM of fructose (∆), 15 mM (□) of fructose, or 3 mM of acetate (○) into the liquid phase. b Second growth cycle of pre-adapted cultures A. Pre-adapted cultures on 5 mM of fructose were transferred to a fresh liquid medium containing 5 mM of fructose (∆) or 3 mM of acetate (◊), while pre-adapted cultures on acetate were seeded in a fresh medium containing 3 mM of acetate (○). All the experiments were made in biological triplicate

During the first growth cycle, the biomass showed an exponential improvement, characterised by a specific growth rate, μ1, of 0.8 h−1 on 5 and 15 mM of fructose, respectively (Fig. 3a). The strain doubled the accumulated biomass, which peaked at an OD660 of 0.62 as a result of the highest tested sugar concentration. A diauxic growth trend was observed, probably due to a metabolic adaptation from sugar-dependent growth to CO-based fermentation, as the evolution of the CO2/H2 couple from CO oxidation indicates (Fig. 4). The intermediate lag phase lasted around 24 h on 5 mM of sugar, after which R. rubrum restarted to grow with a μ2 of 0.01 h−1. On the other hand, the diauxic trend was not observed for cultures fed with 15 mM of fructose.

CO2 and H2 production profiles measured in the two successive fermentation cycles. a CO2 (○, ●) and H2 (∆, ▲) productions of cultures adapted on 15% of CO and 5 mM of fructose. b CO2 (○, ●) and H2 (∆, ▲) profiles of the standard CO-based fermentation of 15% CO and 3 mM of acetate. The adaptation cycle (open symbols) and the second cultivation run (black symbols) are shown in the graph

During the standard CO-based fermentation conditions (CO and acetate), 72 h of adaptation was necessary before the growth phase began at a μ2 of 0.03 h−1. This longer lag phase could be a consequence of the time required for R. rubrum to activate the protein complex responsible for the CO metabolism.

Both feeding strategies were investigated in the second culture cycle (Fig. 3b). The cultures grown in the presence of fructose were transferred to fresh media supplemented with fructose or acetate, respectively, while the cultures adapted under acetate were moved to a medium with an identical composition. Moreover, since the samples that underwent the adaptation on 15 mM of fructose showed a decreasing biomass trend, they were not propagated.

The first adaptation cycle had two main effects on the second culture run: it diminished the lag phase and promoted biomass growth efficiency. The diauxic growth on 5 mM of fructose showed an intermediate lag phase, which was less than halved with respect to the adaptation cycle, while it diminished by one-third in the case of the standard CO-based fermentation condition. Parallelly, the adaptation to CO guaranteed a higher biomass yield, and at the end of the observation, the growth efficiency was three-fold higher than the first CO-based fermentation, with a maximum biomass accumulation of 0.5 g L−1 for both fermentation strategies. Therefore, once R. rubrum shifted to a metabolism sustained by CO, no effect of fructose presence was detectable on the biomass trend. This similar biomass concentration reached at the end of both fermentation strategies is evidence of the biomass growth principally being sustained by the presence of CO, once the sugar had been depleted. Indeed, the CO-based feeding lasted 4 days, while fructose-assisted growth lasted less than 1 day.

3.2 Analysis of the headspace gas composition

During the first and the second fermentation cycles, the gas phase was restored with 15% of CO every 24 h. Before the restoration, the amounts of evolved CO2 and H2 were measured under each tested condition. CO2 was the first gas species to be observed in the adaptation phase with 5 mM of fructose (Fig. 4A), as it originates from fructose oxidation, while H2 appeared after the lag phase, thus suggesting a shift to CO-dependent growth. A similar gas profile appeared during the second fermentation cycle in the presence of 5 mM of fructose. However, in this case, the H2/CO2 couple presented a shift on the time axis. Under the standard CO-based fermentation conditions (Fig. 3B), the CO2 and H2 production profiles followed the same growth trend as the biomass. However, a similar shift was observed on the time axis.

The production profile of CO2 and H2 in 1:1 ratio, measured during standard CO-based fermentation or in the presence of fructose, is evidence of the strain growing under a CO-limited condition. Indeed, this is the typical WGS reaction ratio [13]. Even though R. rubrum has other ways of producing hydrogen, they were inactivated under the experimental conditions that were applied. R. rubrum can, in fact, produce H2 in another three ways: through the reduction of N2 by nitrogenases, as a product of formate oxidation mediated by a formate–hydrogen lyase complex, and, when it is cultivated with light, by a membrane-bound uptake hydrogenase enzyme (that shows both H2 oxidation and evolution activity). Nevertheless, the presence of ammonium and CO, in the liquid medium and headspace, respectively, ensured the inactivation of both nitrogenases and formate lyase, while the application of darkness prevented the transcription of the H2-uptake hydrogenase [32,33,34,35,36].

3.3 Growth substrate utilisation and PHB production

Once the cultures had adapted to the presence of CO in the first culture cycle, the substrate consumption and product formation were measured in the liquid phase of the second fermentation run by means of HPLC analysis (Fig. 5). The data confirmed that the fructose was depleted in 24 h, in the presence of 5 mM of fructose. The fructose consumption was followed by a release of 4.6 ± 0.3 mM of acetate, a value that remained stable throughout the fermentation period. The fructose metabolism in R. rubrum proceeds via the Embden–Meyerhof–Parnas (EMP) pathway, which, in the absence of oxygen or any other reducing agents, such as dimethyl sulfoxide, is mainly metabolised as formate, succinate, acetate and CO2 [31]. Under this condition, the tricarboxylic acid (TCA) cycle partially operates in reductive mode, causing a contraction of the available reducing equivalents [31, 37, 38]. Accordingly, the consumption of acetate, which occurs when the TCA operates in oxidative mode or when the cell produces PHB, was not observed, while an increase in organic acids was verified, as the formate profile demonstrated.

Fructose and acetate conversion. After the adaptation phase, the variation in the fructose concentration (□) and the relative production of acetate (○) and formate (◊) were evaluated by means of HPLC analysis in cultures grown on 15% of CO and 5 mM of fructose. In the same way, the acetate (●) and formate (♦) trends were analysed in samples grown on 15% of CO and 3 mM of acetate

Formate is the second end-product obtained from the decarboxylation of pyruvate mediated by pyruvate-formate lyase (Fig. 1). Moreover, because of the presence of CO, its further oxidation into CO2 and H2 was prevented [34, 35, 39, 40]. Thus, in the presence of 5 mM of fructose, the concentration of formate peaked at a value of 8 ± 0.4 mM under the mixotrophic condition, while it stayed under 2 ± 0.2 mM under the standard CO-based fermentation feeding.

In order to confirm whether fructose consumption resulted in an accumulation of formate, a control experiment was carried out in which an adapted R. rubrum biomass was cultured with a daily supply of 5 mM of fructose and CO. Figure 6 shows the biomass accumulation, the substrate consumption and the relative acetate and formate evolution. As expected, repetitive fructose-based feeding favoured the accumulation of the biomass, which reached a maximum OD660 of 1.5. Fructose was depleted during biomass accumulation, and 0.58 ± 0.05 g L−1 of biomass, 5.1 ± 0.1 mM of acetate and 11 ± 2 mM of formate were achieved, thereby confirming a higher formate accumulation.

The effect of organic acid accumulation on repetitive fructose-based feeding. A control culture of adapted R. rubrum on 15% of CO was cultured on 15% of CO and 5 mM of fructose, which were supplied every 24 h. The biomass (∆), acetate (○), formate (◊) and fructose (□) were monitored during the fermentation

On the other hand, the acetate was gradually depleted under standard CO-based fermentation conditions (Fig. 5). In this case, the primary electron source for the cell is that of the oxidation of carbon monoxide, and the biomass, therefore, consumed acetate as a building block for biomass and PHB production [10]. A tiny increase in acetate concentration was observed during the first hours of culturing under the standard CO-based fermentation conditions. Such a variation was also observed in similar experiments that are not reported in this work. It could be the result of some products metabolised from the yeast extract, which was present in the medium.

The final amount of produced PHB was measured after the adaptation phase, on the last day in which the fermentation was carried out. As reported in Table 1, a similar amount of PHB was found for the mixotrophic and standard CO-based fermentations, where it peaked at about 8% with respect to the cellular dry weight. However, the PHB concentration in the control culture, which was exposed to repetitive fructose feeding, showed a PHB accumulation of 3%. In accordance with the trend of formate and acetate, the decrease in PHB accumulation could have been derived from a shift in the electrons and carbon units from the biosynthetic biopolymer pathway to the residual biomass and organic acid production. Hence, the daily supply of reducing sugar could have blocked the restoration of reducing equivalents, caused by a lack of reducing agents, thereby preventing the accumulation of PHB.

On the other hand, the presence of the high acetate concentrations found in the samples fed with CO and fructose suggests that the small amount of the corresponding PHB was not a consequence of a previous polymer consumption mediated by the biomass itself.

Calculations of the carbon molar growth yield on the liquid carbon sources confirmed that the acetate source resulted in a better investment of carbon resources for the biomass, which showed a yield of 48.33 mg mmol−1 C as a result of CO and acetate-based feeding (Table 1). Instead, under mixotrophic conditions, the same index corresponded to 12 and 4 mg mmol−1 C mol−1, respectively, for single and repetitive fructose supplies. Similar values were also reported in the work of Schultz, where R. rubrum was cultured in an anaerobic environment with a fructose supply [31].

The pH was also measured for each tested condition. In the case of the standard CO-based fermentation condition, and in the presence of 5 mM of fructose, its value was almost stable at around 7.5 throughout the entire fermentation. In samples in which fructose was added every 24 h, it instead dropped day by day, passing from 7.5 to 4.9, because of the higher amount of formate in the media.

3.4 The CO adaptation mechanism

The substrate adaptation on 15% of carbon monoxide resulted in a decrease in the time necessary to metabolise CO, as reported in Fig. 2, and in turn caused a reduction in the lag phase. In the presence of carbon monoxide, the production of energy relies on the formation of a chemiosmotic H+ gradient across the membrane [19]. As previously reported in the literature, the CODH complex shows a rapid response to CO, once this molecule has entered the cells [23]. However, its transcription depends on the CooA transcriptional factor, which is activated by CO [41].

The results have demonstrated that the first exposure to CO determined the generation of a metabolically active population ready to take advantage of CO in the successive cultures, which may have relied on a higher availability of the CO oxidation protein complexes from the adapted cells. As anticipated, the CO oxidation complex is arranged in order to connect the CODH with a membrane ATPase, and efficiently ensure the synthesis of ATP, which is the only energy source of CO-based feeding [18, 19]. The possibility of promptly taking advantage of CO, after the first exposure to CO, could render the ATP more available to the cells, thus resulting in a reduced lag-phase. Hence, H2 evolved earlier in the adapted cultures during the second culturing round, thus pointing out a parallel ATP production.

In the same way, in another carboxytrophs species, that is, Citrobacter amalonaticus Y19, the over-expression of the transcriptional factor CooA was shown to lead to an improvement of the whole CO oxidation protein complexes, as demonstrated by the increased activities of CODH and CO-tolerant hydrogenase [42].

In our experiments, a similar effect of the influence of the energy balance on the growth was recognised in those cultures supplied with 5 mM of fructose, which did not show a detectable lag phase maybe because of the higher ATP/NAD(P)H supply that was ensured by the sugar. As proof of this effect, it is necessary to note that such behaviour has also been identified in Thermoanaerobacter kivui, which, once adapted to carbon monoxide, presented a rise in the growth efficiency, as could be seen from the measured higher activity of CODH; moreover, CO-resistant hydrogenase improved the production of measured ATP [43].

4 Conclusion

The application of exhaust fumes produced by industrial activities as a feed for microbial fermentation is an example of how different production processes can interact with each other in respect of a circular economy strategy. In this scenario, this study has focused on the effects that an adaptation phase on CO can have on R. rubrum.

The exposure to CO determined the generation of a metabolically active biomass, which was promptly able to activate the oxidation of CO during the subsequent cultivation run. The adaptation phase could act in favour of the biomass energy balance derived from the CO metabolism and, consequently, reduce the lag phase and improve the accumulation of biomass.

Moreover, the supply of fructose showed positive effects during the first steps of R. rubrum growth, even in the presence of carbon monoxide. However, unlike what was observed for Clostridium ljungdahlii, in which ethanol production increased by 20% after an adaptation made with fructose and CO, the addition of a reducing sugar did not lead to any improvement in PHB accumulation.

The PHB accumulation capacity decreased as a result of repeated fructose feeding, and the carbon units could be preferentially spent on the biosynthesis of residual biomass or were released as either organic acids and CO2. In this way, it has been demonstrated that the feeding of a reducing sugar, in combination with CO, is useful to trigger the biomass growth. However, once the cells have adapted to the presence of CO, it becomes the preferred electron donor for the PHB biosynthesis and biomass growth.

Data availability

Not applicable.

References

Zhong Q, Huang Y, Shen H, Chen Y, Chen H, Huang T, Zeng EY, Tao S (2017) Global estimates of carbon monoxide emissions from 1960 to 2013. Environ Sci Pollut Res 24:864–873. https://doi.org/10.1007/s11356-016-7896-2

Zhu Q (2019) Developments on CO2-utilization technologies. Clean Energy 3:85–100. https://doi.org/10.1093/ce/zkz008

Almeida Benalcázar E, Noorman H, Maciel Filho R, Posada JA (2020) Modeling ethanol production through gas fermentation: a biothermodynamics and mass transfer-based hybrid model for microbial growth in a large-scale bubble column bioreactor. Biotechnol Biofuels 13:1–19. https://doi.org/10.1186/s13068-020-01695-y

Bátori V, Åkesson D, Zamani A, Taherzadeh MJ, Sárvári Horváth I (2018) Anaerobic degradation of bioplastics: a review. Waste Manag 80:406–413. https://doi.org/10.1016/j.wasman.2018.09.040

Jambeck JR, Geyer R, Wilcox C et al (2015) Plastic waste inputs from land into the ocean. Science (80- ) 347:768–771

Georgios K, Silva A, Furtado S (2016) Applications of green composite materials. Biodegrad Green Compos 312–337. https://doi.org/10.1002/9781118911068.ch10

Oliveira CS, Silva C, Carvalho GRMA (2016) Strategies for efficiently selecting PHA producing mixed microbial cultures using complex feedstocks: feast and famine regime and uncoupled carbon and nitrogen availabilities. New Biotechnol 37:69–79. https://doi.org/10.1016/j.nbt.2016.10.008

Munk AC, Copeland A, Lucas S, Lapidus A, del Rio TG, Barry K, Detter JC, Hammon N, Israni S, Pitluck S, Brettin T, Bruce D, Han C, Tapia R, Gilna P, Schmutz J, Larimer F, Land M, Kyrpides NC, Mavromatis K, Richardson P, Rohde M, Göker M, Klenk HP, Zhang Y, Roberts GP, Reslewic S, Schwartz DC (2011) Complete genome sequence of Rhodospirillum rubrum type strain (S1). Stand Genomic Sci 4:293–302. https://doi.org/10.4056/sigs.1804360

Kerby RL, Ludden PW, Roberts GP (1995) Carbon monoxide-dependent growth of Rhodospirillum rubrum. J Bacteriol 177:2241–2244. https://doi.org/10.1128/JB.177.8.2241-2244.1995

Revelles O, Tarazona N, García JL, Prieto MA (2016) Carbon roadmap from syngas to polyhydroxyalkanoates in Rhodospirillum rubrum. Environ Microbiol 18:708–720. https://doi.org/10.1111/1462-2920.13087

Do YS, Smeenk J, Broer KM, Kisting CJ, Brown R, Heindel TJ, Bobik TA, DiSpirito AA (2007) Growth of Rhodospirillum rubrum on synthesis gas: conversion of CO to H2 and poly-beta-hydroxyalkanoate. Biotechnol Bioeng 97:279–286. https://doi.org/10.1002/bit.21226

Karmann S, Panke S, Zinn M (2019) Fed-batch cultivations of Rhodospirillum rubrum under multiple nutrient-limited growth conditions on syngas as a novel option to produce poly(3-hydroxybutyrate) (PHB). Front Bioeng Biotechnol 7:1–11. https://doi.org/10.3389/fbioe.2019.00059

Dadak A, Aghbashlo M, Tabatabaei M, Najafpour G, Younesi H (2016) Sustainability assessment of photobiological hydrogen production using anaerobic bacteria (Rhodospirillum rubrum) via exergy concept: effect of substrate concentrations. Environ Prog Sustain Energy 35:1166–1176. https://doi.org/10.1002/ep.12296

Maness PC, Huang J, Smolinski S, Tek V, Vanzin G (2005) Energy generation from the CO oxidation-hydrogen production pathway in Rubrivivax gelatinosus. Appl Environ Microbiol 71:2870–2874. https://doi.org/10.1128/AEM.71.6.2870-2874.2005

Fox JD, Kerby RL, Roberts GP, Ludden PW (1996) Characterization of the CO-induced, CO-tolerant hydrogenase from Rhodospirillum rubrum and the gene encoding the large subunit of the enzyme. J Bacteriol 178:1515–1524

Ensign SA, Ludden PW (1991) Characterization of the CO oxidation/H2 evolution system of Rhodospirillum rubrum: role of a 22-kDa iron-sulfur protein in mediating electron transfer between carbon monoxide dehydrogenase and hydrogenase. J Biol Chem 266:18395–18403

Drennan CL, Heo J, Sintchak MD, Schreiter E, Ludden PW (2001) Life on carbon monoxide: X-ray structure of Rhodospirillum rubrum Ni-Fe-S carbon monoxide dehydrogenase. Proc Natl Acad Sci U S A 98:11973–11978. https://doi.org/10.1073/pnas.211429998

Maness PC, Smolinski S, Dillon AC, Heben MJ, Weaver PF (2002) Characterization of the oxygen tolerance of a hydrogenase linked to a carbon monoxide oxidation pathway in Rubrivivax gelatinosus. Appl Environ Microbiol 68:2633–2636. https://doi.org/10.1128/AEM.68.6.2633-2636.2002

Singer SW, Hirst MB, Ludden PW (2006) CO-dependent H2 evolution by Rhodospirillum rubrum: role of CODH:CooF complex. Biochim Biophys Acta Bioenerg 1757:1582–1591. https://doi.org/10.1016/j.bbabio.2006.10.003

Wawrousek K, Noble S, Korlach J, Chen J, Eckert C, Yu J, Maness PC (2014) Genome annotation provides insight into carbon monoxide and hydrogen metabolism in Rubrivivax gelatinosus. PLoS One 9:1–18. https://doi.org/10.1371/journal.pone.0114551

Shelver D, Kerby RL, He Y, Roberts GP (1995) Carbon monoxide-induced activation of gene expression in Rhodospirillum rubrum requires the product of cooA, a member of the cyclic AMP receptor protein family of transcriptional regulators. J Bacteriol 177:2157–2163. https://doi.org/10.1128/jb.177.8.2157-2163.1995

Roberts GP, Youn H, Kerby RL (2004) CO-sensing mechanisms. Microbiol Mol Biol Rev 68:453–473. https://doi.org/10.1128/MMBR.68.3.453

Bonam D, Lehman L, Roberts GP, Ludden PW (1989) Regulation of carbon monoxide dehydrogenase and hydrogenase in Rhodospirillum rubrum: effects of CO and oxygen on synthesis and activity. J Bacteriol 171:3102–3107. https://doi.org/10.1128/jb.171.6.3102-3107.1989

Klasson KT, Gupta A, Clausen EC, Gaddy JL (1993) Evaluation of mass-transfer and kinetic parameters for Rhodospirillum rubrum in a continuous stirred tank reactor. Appl Biochem Biotechnol 39:549–557

Cowger JP, Klasson KT, Ackerson MD, Clausen E, Caddy JL (1992) Mass-transfer and kinetic aspects in continuous bioreactors using Rhodospirillum rubrum. Appl Biochem Biotechnol 34–35:613–624. https://doi.org/10.1007/BF02920582

Esquivel-Elizondo S, Delgado AG, Krajmalnik-Brown R (2017) Evolution of microbial communities growing with carbon monoxide, hydrogen, and carbon dioxide. FEMS Microbiol Ecol 93:1–12. https://doi.org/10.1093/femsec/fix076

Tirado-Acevedo OL, Cotter J. S., Chinn M. M., Grunden A (2011) Influence of carbon source pre-adaptation on Clostridium ljungdahlii growth and product formation. J Bioprocess Biotech 01: https://doi.org/10.4172/2155-9821.s2-001

Ghosh R, Hardmeyer A, Thoenen I, Bachofen R (1994) Optimization of the Sistrom culture medium for large-scale batch cultivation of Rhodospirillum rubrum under semiaerobic conditions with maximal yield of photosynthetic membranes. Appl Environ Microbiol 60:1698–1700

Zeiger L, Grammel H (2010) Model-based high cell density cultivation of Rhodospirillum rubrum under respiratory dark conditions. Biotechnol Bioeng 105:729–739. https://doi.org/10.1002/bit.22589

Braunegg G (1978) A rapid gas chromatographic method for the determination of poly-β-hydroxybutyric acid in microbial biomass. Eur J Appl Microbiol Biotechnol 7:29–37

Schultz JE, Weaver PF (1982) Fermentation and anaerobic respiration by Rhodospirillum rubrum and Rhodopseudomonas capsulata. J Bacteriol 149:181–190. https://doi.org/10.1128/jb.149.1.181-190.1982

Kim EJ, Lee MK, Kim MS, Lee JK (2008) Molecular hydrogen production by nitrogenase of Rhodobacter sphaeroides and by Fe-only hydrogenase of Rhodospirillum rubrum. Int J Hydrog Energy 33:1516–1521. https://doi.org/10.1016/j.ijhydene.2007.09.044

Lehman LJ, Roberts GP (1991) Identification of an alternative nitrogenase system in Rhodospirillum rubrum. J Bacteriol 173:5705–5711. https://doi.org/10.1128/jb.173.18.5705-5711.1991

Voelskow H, Schön G (1980) H2 production of Rhodospirillum rubrum during adaptation to anaerobic dark conditions H. Voelskow & G Schön 125:245–249. https://doi.org/10.1007/BF00446884

McDowall JS, Murphy BJ, Haumann M et al (2014) Bacterial formate hydrogenlyase complex. Proc Natl Acad Sci U S A 111:E3948–E3956. https://doi.org/10.1073/pnas.1407927111

Maness PC, Weaver PF (2001) Evidence for three distinct hydrogenase activities in Rhodospirillum rubrum. Appl Microbiol Biotechnol 57:751–756. https://doi.org/10.1007/s00253-001-0828-0

Carius L, Carius AB, McIntosh M, Grammel H (2013) Quorum sensing influences growth and photosynthetic membrane production in high-cell-density cultivations of Rhodospirillum rubrum. BMC Microbiol 13:189. https://doi.org/10.1186/1471-2180-13-189

Hädicke O, Grammel H, Klamt S (2011) Metabolic network modeling of redox balancing and biohydrogen production in purple nonsulfur bacteria. BMC Syst Biol 5:150. https://doi.org/10.1186/1752-0509-5-150

Schon G, Voelskow H (1976) Pyruvate fermentation in Rhodospirillum rubrum and after transfer from aerobic to anaerobic conditions in the dark. 107:87–92. https://doi.org/10.1007/BF00427872

Jungermann K, Schön G (1974) Pyruvate formate lyase in Rhodospirillum rubrum Ha adapted to anaerobic dark conditions. Arch Microbiol 99:109–116. https://doi.org/10.1007/BF00696227

Roberts GP, Kerby RL, Youn H, Conrad M (2005) CooA, a paradigm for gas sensing regulatory proteins. J Inorg Biochem 99:280–292. https://doi.org/10.1016/j.jinorgbio.2004.10.032

Ainala SK, Seol E, Sekar BS, Park S (2014) Improvement of carbon monoxide-dependent hydrogen production activity in Citrobacter amalonaticus Y19 by over-expressing the CO-sensing transcriptional activator, CooA. Int J Hydrog Energy 39:10417–10425. https://doi.org/10.1016/j.ijhydene.2014.04.148

Weghoff MC, Müller V (2016) CO metabolism in the thermophilic acetogen Thermoanaerobacter kivui. Appl Environ Microbiol 82:2312–2319. https://doi.org/10.1128/AEM.00122-16

Acknowledgements

The author would like to thank Dr. Auxiliadora Prieto of the Centro de Investigaciones Bológicas of the National Research Council (CSIC-CIB) (Madrid, Spain) and her Polymer Biotechnology group, who kindly provided the bacteria strain used in this work. This work has been funded by the Horizon 2020 EU Framework Programme: CELBICON project, Grant agreement number: 679050.

Funding

Open access funding provided by Politecnico di Torino within the CRUI-CARE Agreement. This work has been funded by the Horizon 2020 EU Framework Programme: CELBICON project, Grant agreement number: 679050.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mongili, B., Fino, D. Carbon monoxide fermentation to bioplastic: the effect of substrate adaptation on Rhodospirillum rubrum. Biomass Conv. Bioref. 11, 705–714 (2021). https://doi.org/10.1007/s13399-020-00876-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00876-x