Abstract

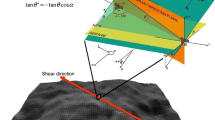

The area ratio content of the asperities with different apparent dip angles is studied based on Grasselli’s apparent dip angle distribution function. An approximate expression of the minimum dip angle of the asperities in contact is further obtained according to the contact theory. For regular joints, the peak dilation angle is the average dip angle of all asperities on the contact part. Extending the above idea to the peak dilation angle of rough joints, the peak dilation angle model is derived based on the apparent dip angle distribution of the real contact asperities. In the derivation process, the peak dilation angle of an arbitrary stress state is directly obtained, instead of obtaining the initial dilation angle first and then defining the relation between the peak dilation angle and the initial dilation angle. The more important innovation is that all the parameters in the new model are of physical significance and easy to obtain; furthermore, they are not obtained by fitting test results. Based on 89 sets of test data, the predicted values of the new model are compared with those of the other 4 existing models. The results show that the prediction accuracy of the new model is the best. Besides, the mesh scales of rock joint are discussed, and the size range of the triangle mesh is obtained. It is proposed to remove the isolated points with a large apparent dip angle when processing test data. The shear mechanism of rough joints is further clarified in this study: the dilation is regarded as the average apparent dip angle of the asperities in contact at a certain stress level. This view is easy to understand and follow. It is as simple and beautiful as many natural principles.

Similar content being viewed by others

Abbreviations

- JRC:

-

Joint roughness coefficient

- JCS:

-

Joint wall compressive strength (MPa)

- JMC:

-

Joint matching coefficient

- 3D:

-

Three-dimensional

- Max:

-

Maximum value

- θ :

-

Dip angle (°)

- θ * :

-

Apparent dip angle (°)

- t :

-

Shear direction

- n :

-

External vector of the triangle element

- n 1 :

-

Projection vector of n

- α :

-

Azimuth

- n 0 :

-

External vector of the shear plane

- \(\theta_{ \text{max} }^{*}\) :

-

Maximum apparent dip angle (°)

- A 0 :

-

Maximum possible contact area ratio

- C :

-

A fitting coefficient to describe the distribution of the apparent dip angles

- τ p :

-

Peak shear strength (MPa)

- ϕ b :

-

Basic friction angle (°)

- i p :

-

Peak dilation angle (°)

- σ n :

-

Normal stress (MPa)

- σ c :

-

Compression strength (MPa)

- i 0 :

-

Dilation angle under zero normal stress (°)

- α :

-

Azimuth (°)

- \(A_{{\theta^{*} }}\) :

-

Ratio between the area of the triangle elements with an effective dip angle greater than θ* and the total area of the joint surface

- A 0 :

-

Ratio between the area of the triangle elements with an effective dip angle greater than 0 and the total area of the joint surface

- \(x_{{\theta^{*} }}\) :

-

Area ratio content of the asperities

- \(\theta_{\text{big}}^{*}\) :

-

Large effective dip angle of triangle elements (°)

- \(\theta_{\text{small}}^{*}\) :

-

Small effective dip angle of triangle elements (°)

- x big :

-

Area ratio content of the asperities when the apparent dip angle is steep

- x small :

-

Area ratio content of the asperities when the apparent dip angle is smooth

- C big :

-

Extreme value of C when the apparent dip angle is steep

- C small :

-

Extreme value of C when the apparent dip angle is smooth

- ϕ (z):

-

Height probability density of the asperities

- z :

-

Peak height of the asperities

- m :

-

Root mean square of the asperities height

- E * :

-

Equivalent elastic modulus (GPa)

- R :

-

Curvature radius of the asperity

- θ ave :

-

Roughness parameter \({{\theta_{\text{max} }^{*} }/ {\left( {C + 1} \right)}}\)

- \(\theta_{\text{cr}}^{*}\) :

-

Minimum apparent dip angle of the asperities in contact at a certain stress level (°)

- δ :

-

Average relative error

- i pt :

-

Test peak dilation angle (°)

- i pe :

-

Estimated peak dilation angle (°)

References

Ban L, Qi C, Chen H et al (2019a) A new criterion for peak shear strength of rock joints with a 3D roughness parameter. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-019-02007-z

Ban L, Zhu C, Qi C, Tao Z (2019b) New roughness parameters for 3D roughness of rock joints. Bull Eng Geol Environ 78:4505–4517

Barton N (1973) Review of a new shear-strength criterion for rock joints. Eng Geol 7:287–332

Barton N, Choubey V (1977) The shear strength of rock joints in theory and practice. Rock Mech 10:1–54

Bertacchi P, Zaninetti A, Barla G, Forlati F (1988) Laboratory tests on the shear behaviour of filled discontinuities. In: Proceedings of the international symposium on engineering in complex rock formations. Elsevier, pp 262–270

Bowden FP, Tabor D (2001) The friction and lubrication of solids. Oxford University Press, Oxford

Chen X, Zeng Y, Sun H, Liu W (2019) A new model of the initial dilatancy angle of rock joints based on Grasselli′s morphological parameters. Chin J Rock Mech Eng 38:133–152

Fardin N, Feng Q, Stephansson O (2004) Application of a new in situ 3D laser scanner to study the scale effect on the rock joint surface roughness. Int J Rock Mech Min Sci 41:329–335

Ghazvinian AH, Taghichian A, Hashemi M, Mar’Ashi SA (2010) The shear behavior of bedding planes of weakness between two different rock types with high strength difference. Rock Mech Rock Eng 43:69–87

Grasselli G (2001) Shear strength of rock joints based on quantified surface description. EPFL, Lausanne

Grasselli GÃ (2005) 3D Behaviour of bolted rock joints: experimental and numerical study. Int J Rock Mech Min Sci 42:13–24

Grasselli G, Wirth J, Egger P (2002) Quantitative three-dimensional description of a rough surface and parameter evolution with shearing. Int J Rock Mech Min Sci 39:789–800

Greenwood JA, Tripp JH (1970) The contact of two nominally flat rough surfaces. Proc Inst Mech Eng 185:625–633

Greenwood JA, Williamson JBP (1966) Contact of nominally flat surfaces. Proc R Soc Lond Ser A Math Phys Sci 295:300–319

Hsiung SM, Ghosh A, Ahola MP, Chowdhury AH (1993) Assessment of conventional methodologies for joint roughness coefficient determination. In: The 34th US Symposium on Rock Mechanics (USRMS). American Rock Mechanics Association

Jing L (1990) Numerical modelling of jointed rock masses by distinct element method for two-and three-dimensional problems. Luleå tekniska universitet, Luleå

Johansson F (2015) Influence of scale and matedness on the peak shear strength of fresh, unweathered rock joints. Int J Rock Mech Min Sci 82:36–47

Johansson F, Stille H (2014) A conceptual model for the peak shear strength of fresh and unweathered rock joints. Int J Rock Mech Min Sci 69:31–38

Kulatilake P, Shou G, Huang TH, Morgan RM (1995) New peak shear strength criteria for anisotropic rock joints. In: International Journal of rock mechanics and mining sciences & geomechanics abstracts. Elsevier, pp 673–697

Ladanyi B, Archambault G (1969) Simulation of shear behavior of a jointed rock mass. In: The 11th US symposium on rock mechanics (USRMS). American Rock Mechanics Association

Lee Y-H, Carr JR, Barr DJ, Haas CJ (1990) The fractal dimension as a measure of the roughness of rock discontinuity profiles. In: International journal of rock mechanics and mining sciences & geomechanics abstracts. Elsevier, pp 453–464

Li J, Ma G (2010) Analysis of blast wave interaction with a rock joint. Rock Mech Rock Eng 43:777–787

Li JC, Li NN, Li HB, Zhao J (2017a) An SHPB test study on wave propagation across rock masses with different contact area ratios of joint. Int J Impact Eng 105:109–116

Li Y, Oh J, Mitra R, Canbulat I (2017b) A fractal model for the shear behaviour of large-scale opened rock joints. Rock Mech Rock Eng 50:67–79

Maksimović M (1992) New description of the shear strength for rock joints. Rock Mech Rock Eng 25:275–284

Pariseau WG, Puri S, Schmelter SC (2008) A new model for effects of impersistent joint sets on rock slope stability. Int J Rock Mech Min Sci 45:122–131

Patton FD (1966) Multiple modes of shear failure in rock. In: Proceedings of the first congress of ISRM. Lisbone. pp 509–513

Plesha ME (1987) Constitutive models for rock discontinuities with dilatancy and surface degradation. Int J Numer Anal Methods Geomech 11:345–362

Prudencio M, Jan MVS (2007) Strength and failure modes of rock mass models with non-persistent joints. Int J Rock Mech Min Sci 44:890–902

Reeves MJ (1985) Rock surface roughness and frictional strength. In: International journal of rock mechanics and mining sciences & geomechanics abstracts. Elsevier, pp 429–442

Schneider HJ (1976) The friction and deformation behaviour of rock joints. Rock Mech 8:169–184

Swan G (1983) Determination of stiffness and other joint properties from roughness measurements. Rock Mech Rock Eng 16:19–38

Tang ZC, Wong LNY (2016) New criterion for evaluating the peak shear strength of rock joints under different contact states. Rock Mech Rock Eng 49:1191–1199

Tang ZC, Liu QS, Liu XY (2014) Shear behavior of rock joints and comparative study on shear strength criteria with three-dimensional morphology parameters. Chin J Geotech Eng 36:873–879

Tatone BSA (2009) Quantitative characterization of natural rock discontinuity roughness in situ and in the laboratory. University of Toronto, Toronto

Tian Y, Liu Q, Liu D et al (2018) Updates to Grasselli’s peak shear strength model. Rock Mech Rock Eng 51:2115–2133

Turk N, Greig M, Dearman W, Amin F (1987) Characterization of rock joint surfaces by fractal dimension. In: Proc U.S. Symp. on Rock Mech. Tuscon, pp 1223–1236

Valentin LP (2018) Contact mechanics and friction: physical principles and applications. Springer, Berlin

von Terzaghi C (1925) Erdbaumechanik auf bodenphysikalischer Grundlage. Deuticke, Vienna

Xia CC, Tang ZC, Xiao WM, Song YL (2014) New peak shear strength criterion of rock joints based on quantified surface description. Rock Mech Rock Eng 47:387–400

Xie H (1995) Fractal estimation of joint roughness coefficients. Chin Sci Abstr Ser B 2:55

Yang J, Rong G, Hou D et al (2016) Experimental study on peak shear strength criterion for rock joints. Rock Mech Rock Eng 49:821–835

Zhang X, Jiang Q, Chen N et al (2016) Laboratory investigation on shear behavior of rock joints and a new peak shear strength criterion. Rock Mech Rock Eng 49:3495–3512

Zhao J (1997) Joint surface matching and shear strength part B: JRC-JMC shear strength criterion. Int J Rock Mech Min Sci 34:179–185

Acknowledgements

This study is supported by National Key R&D Programs of China (No. 802015CB575), National Natural Science Foundation of China (Nos. 51478027, 51174012, 41502323) and Beijing Postdoctoral Research Foundation.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ban, L., Du, W. & Qi, C. A Peak Dilation Angle Model Considering the Real Contact Area for Rock Joints. Rock Mech Rock Eng 53, 4909–4923 (2020). https://doi.org/10.1007/s00603-020-02193-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02193-1