Abstract

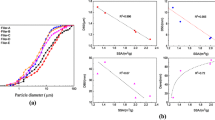

This study aims at examining the performance of asphalt mastics in the Linear Viscoelastic (LVE) domain incorporating three Indian and three Austrian fillers. The various physical, morphological, and chemical properties of the fillers were analyzed with the help of respective characterization tests. In addition to the particle size distribution curve and fineness modulus, a new parameter called Filler Grain Coefficient (FGC) has been introduced in this study to quantify the distribution of particles in the system. This paper also attempts to find a correlation between various physical parameters. There are two variables i.e., \(\left| {G^{*} } \right|_{\text{LVE}}\) and \(\left| {G^{*} } \right|_{\text{ratio}}\) in order to quantify the Linear Viscoelastic complex modulus. The effects of both volume and surface area of fillers have been manifested by three ratios denoted as V/FM, V/FGC, and V/RV. To compare the outcome of the study, the Strategic Highway Research Program Linear Viscoelastic strain criteria is also included, which examines the applicability of the criteria to the asphalt mastics. The research incorporates a wide range of fillers with variable properties, as confirmed by the test results. Filler parameters Rigden Voids and Filler Grain Coefficient were found to be strongly correlated with almost all physical properties. On the grounds of variation in LVEM with volume concentration of filler, the highest rank can be attributed to Red Mud and LimeStone, respectively, followed by other fillers with Marble Dust being the lowest. The reinforcing effect of fillers and higher surface area contributed to the exponential increase in \(\left| {G^{*} } \right|_{\text{LVE}}\), with an increase in volumetric concentration. The variation of both variables: \(\left| {G^{*} } \right|_{\text{LVE}}\) and \(\left| {G^{*} } \right|_{\text{ratio}}\), presented V/FM as the most worthy parameter, as it illustrated variation at different temperatures. The Linear Viscoelastic limits obtained from the study were relatively conservative compared to those from the SHRP study, this confirms the unsuitability of applying SHRP equations to the asphalt mastics. Moreover, the relationship instigated in the study can be used to reckon the LVE strain limit and to further analyse asphalt mastics.

Similar content being viewed by others

Availability of data and material

Not applicable.

References

Chen JS, Kuo PH, Lin PS et al (2008) Experimental and theoretical characterization of the engineering behavior of bitumen mixed with mineral filler. Mater Struct Constr 41:1015–1024. https://doi.org/10.1617/s11527-007-9302-5

Miró Recasens R, Martínez A, Pérez Jiménez F (2005) Effect of filler on the aging potential of asphalt mixtures. Transp Res Rec 1901:10–17

Lackner R, Spiegl M, Blab R, Eberhardsteiner J (2005) Is low-temperature creep of asphalt mastic independent of filler shape and mineralogy?—arguments from multiscale analysis. J Mater Civ Eng 17:485–491. https://doi.org/10.1061/(ASCE)0899-1561(2005)17:5(485)

Chen JS, Peng CH (1998) Analyses of tensile failure properties of asphalt-mineral filler mastics. J Mater Civ Eng 10:256–262. https://doi.org/10.1061/(ASCE)0899-1561(1998)10:4(256)

Hesami E, Birgisson B, Kringos N (2014) Numerical and experimental evaluation of the influence of the filler-bitumen interface in mastics. Mater Struct Constr 47:1325–1337. https://doi.org/10.1617/s11527-013-0237-8

Huang SC, Zeng M (2007) Characterization of aging effect on rheological properties of asphalt-filler systems. Int J Pavement Eng 8:213–223. https://doi.org/10.1080/10298430601135477

Johansson L, Isacsson U (1998) Effect of filler on low temperature physical hardening of bitumen. Constr Build Mater 12:463–470

Shenoy A, Stuart K, Mogawer W (2003) Do asphalt mixtures correlate better with mastics or binders in evaluating permanent deformation? In: Transportation research record. National Research Council, pp 16–25

Aljassar AH, Metwali S, Ali MA (2004) Effect of filler types on Marshall stability and retained strength of asphalt concrete. Int J Pavement Eng 5:47–51. https://doi.org/10.1080/10298430410001733491

Miró R, Martínez AH, Pérez-Jiménez FE et al (2017) Effect of filler nature and content on the bituminous mastic behaviour under cyclic loads. Constr Build Mater 132:33–42. https://doi.org/10.1016/j.conbuildmat.2016.11.114

Pereira L, Freire AC, Sá da Costa M et al (2018) Experimental study of the effect of filler on the ductility of filler-bitumen mastics. Constr Build Mater 189:1045–1053. https://doi.org/10.1016/j.conbuildmat.2018.09.063

Kallas BF, Puzinauskas VP (1961) A study of Mineral fillers in asphalt paving mixtures. In: Association of asphalt paving technologists proceedings. (with discussion)

Anderson DA, Goetz WH Mechanical behavior and reinforcement of mineral filler-asphalt mixtures: technical paper

Tunnicliff D (1962) A review of mineral filler. J Assoc Asph Paving Technol 31:118–150

Antunes V, Freire AC, Quaresma L, Micaelo R (2015) Influence of the geometrical and physical properties of filler in the filler-bitumen interaction. Constr Build Mater 76:322–329. https://doi.org/10.1016/j.conbuildmat.2014.12.008

Clopotel C, Velasquez R, Bahia H (2012) Measuring physico-chemical interaction in mastics using glass transition. Road Mater Pavement Des 13:304–320. https://doi.org/10.1080/14680629.2012.657095

Qiu H, Tan X, Shi S, Zhang H (2013) Influence of filler-bitumen ratio on performance of modified asphalt mortar by additive. J Mod Transp. https://doi.org/10.1007/s40534-013-0002-2

Liu Y, Huang Y, Sun W et al (2017) Effect of coarse aggregate morphology on the mechanical properties of stone matrix asphalt. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.06.062

Cosme RL, Teixeira JESL, Calmon JL (2016) Use of frequency sweep and MSCR tests to characterize asphalt mastics containing ornamental stone residues and LD steel slag. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2016.06.126

Yan KZ, Bin X, Zhang HL (2013) Effect of mineral filler on properties of warm asphalt mastic containing Sasobit. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2013.07.085

Grabowski W, Wilanowicz J (2008) The structure of mineral fillers and their stiffening properties in filler-bitumen mastics. Mater Struct Constr 41:793–804. https://doi.org/10.1617/s11527-007-9283-4

Hospodka M, Hofko B, Blab R (2018) Introducing a new specimen shape to assess the fatigue performance of asphalt mastic by dynamic shear rheometer testing. Mater Struct Constr 51:1–11. https://doi.org/10.1617/s11527-018-1171-6

Prowell BD, Zhang J, Brown ER (2005) Aggregate properties and the performance of superpave designed hot mix asphalt. NCHRP 539 Final Report, Transport Research Board, Washington DC

Anderson DA, Bahia HU, Dongre R (1992) Rheological properties of mineral filler asphalt mastic and its importance to pavement performance. ASTM STP 1147: 131–153

Al-Suhaibani A, Al-Mudaiheem J (1992) Effect of filler type and content on properties of asphalt concrete mixes. ASTM Int, West Conshohocken

Zhang J, Liu S, Yao Z et al (2018) Environmental aspects and pavement properties of red mud waste as the replacement of mineral filler in asphalt mixture. Constr Build Mater 180:605–613. https://doi.org/10.1016/j.conbuildmat.2018.05.268

Tugrul Tunc E (2019) Recycling of marble waste: a review based on strength of concrete containing marble waste. J Environ Manag 231:86–97. https://doi.org/10.1016/j.jenvman.2018.10.034

Rana A, Kalla P, Csetenyi LJ (2017) Recycling of dimension limestone industry waste in concrete. Int J Min Reclam Environ 31:231–250. https://doi.org/10.1080/17480930.2016.1138571

Lokeshwari M, Jagadish KS (2016) Eco-friendly use of granite fines waste in building blocks. Proc Environ Sci 35:618–623. https://doi.org/10.1016/j.proenv.2016.07.049

Kurańska M, Barczewski M, Uram K et al (2019) Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym Test 76:90–100. https://doi.org/10.1016/j.polymertesting.2019.02.008

Kim Y-R, Little DN, Song I (2007) Effect of mineral fillers on fatigue resistance and fundamental material characteristics: mechanistic evaluation. Transp Res Rec J Transp Res Board 1832:1–8. https://doi.org/10.3141/1832-01

Huang B, Shu X, Dong Q, Shen J (2010) Laboratory evaluation of moisture susceptibility of hot-mix asphalt containing cementitious fillers. J Mater Civ Eng 22:667–673. https://doi.org/10.1061/(ASCE)MT.1943-5533.0000064

Rochlani M, Leischner S, Falla GC et al (2019) Influence of filler properties on the rheological, cryogenic, fatigue and rutting performance of mastics. Constr Build Mater 227:116974. https://doi.org/10.1016/j.conbuildmat.2019.116974

Delaporte B, Di Benedetto H, Chaverot P, Gauthier G (2007) Linear viscoelastic properties of bituminous materials: from binders to mastics. J Assoc Asphalt Paving Technol 76: 455–494

Roberts FL, Kandhal PS, Brown ER, Lee DY, Kennedy TW (1996) Hot mix asphalt materials, mixture design, and construction. NAPA Education Foundation, Lanham

ASTM (2000) D854—standard test methods for specific gravity of soil solids by water pycnometer. ASTM D854 2458000, West Conshohocken, pp 1–7. https://doi.org/10.1520/D0854-10.2

ASTM D7928–17 (2017) Standard test method for particle-size distribution (gradation) of fine-grained soils using the sedimentation (hydrometer) analysis. ASTM Int, West Conshohocken, pp 1–25. https://doi.org/10.1520/D7928-17

BS 812 (1975) Methods for sampling and testing of mineral aggregate part 1

International Slurry Seal Association (1989) Test method for determination of methylene blue absorption value (MBV) of mineral aggregate fillers and fines. ISSA Bull 145

BS EN 933-9 (1999) Tests for geometrical properties of aggregates, Assessment of fines. Methylene blue test, British Standard Institute, London

Ana Walt JDH, Rinn HW, Frevel LK (1938) Chemical analysis by x-ray diffraction: classification and use of x-ray diffraction patterns. Ind Eng Chem Anal Ed 10:457–512. https://doi.org/10.1021/ac50125a001

Airey GD, Rahimzadeh B (2004) Combined bituminous binder and mixture linear rheological properties. Constr Build Mater 18:535–548. https://doi.org/10.1016/j.conbuildmat.2004.04.008

Fu H, Xie L, Dou D et al (2007) Storage stability and compatibility of asphalt binder modified by SBS graft copolymer. Constr Build Mater 21:1528–1533. https://doi.org/10.1016/j.conbuildmat.2006.03.008

Saboo N, Kumar P (2015) Optimum blending requirements for EVA modified binder. Int J Pavement Res Technol 8:172–178. https://doi.org/10.6135/ijprt.org.tw/2015.8(3).172

Pink HS, Merz RE, Bosniack DS (1980) Asphalt rheology: experimental determination of dynamic moduli at low temperature. In: Assoc asph paving technol proc, vol 49

Goodrich JL (1988) Asphalt and polymer modified asphalt properties related to the performance of asphalt concrete mixes. In: Assoc asph paving technol proc, vol 57. (with discussion)

Goos D, Carre D (1996) Rheological modelling of bituminous binders—a global approach to road technologies. In: Eurasphalt and Eurobitume congress, Strasbourg

Bahia HU, Huachun Z, Bonnetti K, Kose S (1999) Non-linear viscoelastic and fatigue properties of asphalt binders. In: A pap submitt present 1999 annu meet assoc asph paving technol sess asph modif asph prop

Bahia HU, Hislop WP, Zhai H, Rangel A (1998) Classification of asphalt binders into simple and complex binders. J Assoc Asphalt Pav 67:1–41

Airey GD (2002) Rheological evaluation of ethylene vinyl acetate polymer modified bitumens. Constr Build Mater 16:473–487

Petersen JC, Robertson RE, Branthaver JF, Harnsberger PM, Duvall JJ, Kim SS et al. (1994) Binder characterization and evaluation, Test methods, vol. 4. Strategic highway research program, SHRP-A-370. National Research Council, Washington

Cheung CY, Cebon D (1997) Deformation mechanisms of pure bitumen. J Mater Civ Eng 9:117–129. https://doi.org/10.1061/(ASCE)0899-1561(1997)9:3(117)

Anderson DA, Le HY, Marasteanu MO et al (2001) Evaluation of fatigue criteria for asphalt binders. Transp Res Rec 1766:48–56

Anderson DA, Christensen DW, Bahia HU, Dongre R, Sharma M, Antle CE, Button J (1994) Binder characterization and evaluation, vol 3: physical characterization, SHRP-A-369. Strategic Highway Research Program, National Research Council, Washington DC

MoRTH (Ministry of Road Transport and Highways) (2013) Specifications for road and bridge works (fifth revision). Indian Road Congress

Faheem AF, Bahia HU (2010) Modelling of asphalt mastic in terms of filler-bitumen interaction. Road Mater Pavement Des 11:281–303. https://doi.org/10.1080/14680629.2010.9690335

Kandhal PS, Lynn CY, Parker F (1998) Characterization tests for mineral fillers related to performance of asphalt paving mixtures. Transp Res Rec. https://doi.org/10.3141/1638-12

Zhang H, Li H, Abdelhady A et al (2020) Fine solid wastes as a resource conserving filler and their infl uence on the performance of asphalt materials. J Clean Prod 252:119929. https://doi.org/10.1016/j.jclepro.2019.119929

Wang H, Al-Qadi IL, Faheem AF et al (2011) Effect of mineral filler characteristics on asphalt mastic and mixture rutting potential. Transp Res Rec. https://doi.org/10.3141/2208-05

Cheng Y, Tao J, Jiao Y et al (2016) Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr Build Mater 118:268–275. https://doi.org/10.1016/j.conbuildmat.2016.05.041

Faheem AF, Bahia HU (2009) Conceptual phenomenological model for interaction of asphalt binders with mineral fillers, vol 78. In: Association of asphalt paving technologists

Acknowledgements

This work is a part of the Indo-Austrian bilateral project. The authors would like to thank the Department of Science and Technology (DST), India and the Austrian Agency for International Cooperation in Education and Research (OeAD-GmbH) for their support.

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Code availability

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaudhary, M., Saboo, N., Gupta, A. et al. Assessing the effect of fillers on LVE properties of asphalt mastics at intermediate temperatures. Mater Struct 53, 96 (2020). https://doi.org/10.1617/s11527-020-01532-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1617/s11527-020-01532-6