Abstract

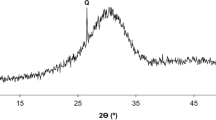

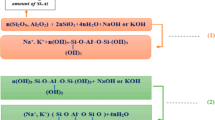

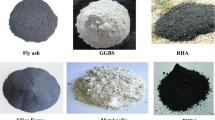

The main objective of this paper focuses on the changes that occur in the strength and microstructural properties of sodium silicate activated fly ash based geopolymer due to varying the sulfate salt and water content. A series of tests including X-ray diffraction, Fourier transform infrared spectroscopy, scanning electron microscopy, physical adsorption and unconfined compressive strength were used to investigate this effect. The results indicate that the higher water content has an adverse effect on the alkali activation and microstructural properties of geopolymer, so the optimum mass ratio of sodium sulfate in alkali-activated geopolymer under different water-to-binder ratios shows a “peak shifting” phenomenon, i.e., the higher the water-to-binder ratio, the higher the optimum mass ratio. Lower presence of sodium sulfate has no significant effect on the alkali-activated geopolymer systems; higher addition of sodium sulfate, however, could cause the symmetrical stretching vibration of Si-O and the symmetrical stretching vibration of Si-O-Si and Al-O-Si, and promote the formation of N-A-S-H gels. Furthermore, the cement effect of the gel and sodium sulfate aggregate could improve the integrity of pore structure obviously. The maximum strength of geopolymer curing at ambient temperature was 52 MPa. This study obtains the rule that the strength properties of alkali-activated geopolymers vary with the water-to-binder ratio and sodium sulfate content. The feasibility of geopolymer co-activated by sodium sulfate and sodium silicate was investigated, and reference for engineering application of alkali-activated geopolymer in salt-bearing areas was provided.

摘要

本文主要研究了水玻璃激发粉煤灰基地质聚物的强度和微观结构随硫酸盐和水胶比的变化. 通过 X 射线衍射、 傅立叶红外光谱、 扫描电镜、 物理吸附和无侧限抗压强度等一系列试验研究了该变化. 结果表明, 高水胶比对地聚物的强度及微观结构有不利影响; 在不同水胶比条件下, 碱激发粉煤灰基地聚物中硫酸钠的最佳质量比表现出“峰移”现象, 即水胶比越高, 最佳质量比越高; 硫酸钠的加入量越低, 对碱激发粉煤灰基地聚合物体系的影响越小; 硫酸钠的加入量增加, 会引起 Si-O 的对称拉伸 振动及 Si-O-Si 和 Al-O-Si 的对称拉伸振动, 促进 N-A-S-H 凝胶的形成. 凝胶和硫酸钠集料的胶结作用能明显改善孔隙结构的完整性. 常温养护地聚物的最大强度为 52 MPa. 本文得出了碱激发粉煤灰基地聚物的强度特性随水胶比和硫酸钠含量的变化规律, 研究了硫酸钠和硅酸钠共同激发地质聚合物的可行性, 能够为碱激发粉煤灰基地聚物在含盐地区的工程应用提供参考.

Similar content being viewed by others

References

KOLEŻYŃSKI A, KRÓL M, ŻYCHOWICZ M. The structure of geopolymers-Theoretical studies [J]. Journal of Molecular Structure, 2018, 1163: 465–471. DOI: https://doi.org/10.1016/j.molstruc.2018.03.033.

FAN Feng-hong, LIU Zhen, XU Guo-ji, PENG Hui, CAI C S. Mechanical and thermal properties of fly ash based geopolymers [J]. Construction and Building Materials, 2018, 160: 66–81. DOI: https://doi.org/10.1016/j.conbuildmat.2017.11.023.

NATH S K, MAITRA S, MUKHERJEE S. Microstructural and morphological evolution of fly ash based geopolymers [J]. Construction and Building Materials, 2016, 111: 758–765. DOI: https://doi.org/10.1016/j.conbuildmat.2016.02.106.

PEYNE J, JOUSSEIN E, GAUTRON J, DOUDEAU J, ROSSIGNOL S. Feasibility of producing geopolymer binder based on a brick clay mixture [J]. Ceramics International, 2017, 43: 9860–9871. DOI: https://doi.org/10.1016/j.ceramint.2017.04.169.

NMIRI A, DUC M, HAMDI N, MARZOUK O Y, SRASRA E. Replacement of alkali silicate solution with silica fume in metakaolin-based geopolymers [J]. International Journal of Minerals Metallurgy and Materials, 2019, 26(5): 555–564. DOI: https://doi.org/10.1007/s12613-019-1764-2.

GHOSH P, KUMAR H, BISWAS K. Fly ash and kaolinite-based geopolymers: Processing and assessment of some geotechnical properties [J]. International Journal of Geotechnical Engineering, 2016, 10(4): 1–10. DOI: https://doi.org/10.1080/19386362.2016.1151621.

CHEN Xiao, ZHU Guo-rui, ZHOU Ming-kai, WANG Jie, CHEN Qian. Effect of organic polymers on the properties of slag-based geopolymers [J]. Construction and Building Materials, 2018, 167: 216–224. DOI: https://doi.org/10.1016/j.conbuildmat.2018.02.031.

PROVIS J L. Alkali-activated materials [J]. Cement and Concrete Research, 2018, 114: 40–48. DOI: https://doi.org/10.1016/j.cemconres.2017.02.009.

PROVIS J L, BERNAL S A. Geopolymers and related alkali-activated materials [J]. Annual Review of Materials Research, 2014, 44(1): 299–327. DOI: https://doi.org/10.1146/annurevmatsci-070813-113515.

ABABNEH F A, ALAKHRAS A I, HEIKAL M, IBRAHIM S M. Stabilization of lead bearing sludge by utilization in fly ash-slag based geopolymer [J]. Construction and Building Materials, 2019, 227: 116694. DOI: https://doi.org/10.1016/j.conbuildmat.2019.116694.

HEIKAL M, NASSAR M Y, EL-SAYED G, IBRAHIM S M. Physico-chemical, mechanical, microstructure and durability characteristics of alkali activated Egyptian slag [J]. Construction and Building Materials, 2014, 69: 60–72. DOI: https://doi.org/10.1016/j.conbuildmat.2014.07.026.

ODERJI S Y, CHEN B, AHMAD M R, SHAH S F A. Fresh and hardened properties of one-part fly ash-based geopolymer binders cured at room temperature: Effect of slag and alkali activators [J]. Journal of Cleaner Production, 2019, 225: 1–10. DOI: https://doi.org/10.1016/j.jclepro.2019.03.290.

AHN J, KIM W S, UM W. Development of metakaolin-based geopolymer for solidification of sulfate-rich HyBRID sludge waste [J]. Journal of Nuclear Materials, 2019, 518: 247–255. DOI: https://doi.org/10.1016/j.jnucmat.2019.03.008.

PRASITTISOPIN L, SEREEWATTHANAWUT I. Effects of seeding nucleation agent on geopolymerization process of fly-ash geopolymer [J]. Frontiers of Structural and Civil Engineering, 2018, 12: 16–25. DOI: https://doi.org/10.1007/s11709-016-0373-7.

CHEQUER D L, FRIZON F. Impact of sulfate and nitrate incorporation on potassium- and sodium-based geopolymers: Geopolymerization and materials properties [J]. Journal of Materials Science, 2011, 46(17): 5657–5664. DOI: https://doi.org/10.1007/s10853-011-5516-6.

KOMNITSAS K, ZAHARAKI D, BARTZAS G. Effect of sulphate and nitrate anions on heavy metal immobilisation in ferronickel slag geopolymers [J]. Applied Clay Science, 2013, 73: 103–109. DOI: https://doi.org/10.1016/j.clay.2012.09.018.

CRIADO M, FERNANDEZ J A, PALOMO A. Effect of sodium sulfate on the alkali activation of fly ash [J]. Cement and Concrete Composites, 2010, 32: 589–594. DOI: https://doi.org/10.1016/j.cemconcomp.2010.05.002.

ISMAIL I, BERNAL S A, PROVIS J L, HANDAN S, van DEVENTER J S J. Microstructural changes in alkali activated fly ash/slag geopolymers with sulfate exposure [J]. Materials and Structures, 2013, 46: 361–373. DOI: https://doi.org/10.1617/s11527-012-9906-2.

ZHANG Yao-jun, CHAI Qian, YANG Meng-yang, FAN Bo-wen, LI Xin. Synthesis of bottom ash-based geopolymer co-activated by double salts [J]. Journal of Functional Materials, 2016, 47(9): 9176–9181. DOI: https://doi.org/10.3969/j.issn.1001-9731.2016.09.034. (in Chinese)

CUI Yong, WANG Dong-ming, WANG Yi-ren, SUN Rui, RUI Ya-feng. Effects of the n(H2O: Na2Oeq) ratio on the geopolymerization process and microstructures of fly ash-based geopolymers [J]. Journal of Non-Crystalline Solids, 2019, 511: 19–28. DOI: https://doi.org/10.1016/j.jnoncrysol.2018.12.033.

DUXSON P, A FERNÁNDEZ-JIMÉNEZ, PROVIS J L, LUKEY G C, PALOMO A, van DEVENTER J S J. Geopolymer technology: The current state of the art [J]. Journal of Materials Science, 2007, 42(9): 2917–2933. DOI: https://doi.org/10.1007/s10853-006-0637-z.

KUMAR S, KRISTALY F, MUCSI G. Geopolymerisation behaviour of size fractioned fly ash [J]. Advanced Powder Technology, 2015, 26(1): 24–30. DOI: https://doi.org/10.1016/j.apt.2014.05.002.

LI Xian-bo, YE Jun-jian, LIU Zhi-hong, QIU Yue-qin, LI Long-jiang, MAO Song, WANG Xiao-chen, ZHANG Qin. Microwave digestion and alkali fusion assisted hydrothermal synthesis of zeolite from coal fly ash for enhanced adsorption of Cd(II) in aqueous solution [J]. Journal of Central South University, 2018, 25(1): 9–20. DOI: https://doi.org/10.1007/s11771-018-3712-0.

LV Qing-feng, JIANG Lu-sha, MA Bo, ZHAO Ben-hai, HUO Zhen-sheng. A study on the effect of the salt content on the solidification of sulfate saline soil solidified with an alkali-activated geopolymer [J]. Construction and Building Materials, 2018, 176: 68–74. DOI: https://doi.org/10.1016/j.conbuildmat.2018.05.013.

PEYNE J, JOUSSEIN E, GAUTRON J, DOUDEAU J, ROSSIGNOL S. Feasibility of producing geopolymer binder based on a brick clay mixture [J]. Ceramics International, 2017, 43(13): 9860–9871. DOI: https://doi.org/10.1016/j.ceramint.2017.04.169.

KROL M, ROZEK P, CHLEBDA D, MOZGAWA W. Influence of alkali metal cations/type of activator on the structure of alkali-activated fly ash-ATR-FTIR studies [J]. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy, 2018, 198: 33–37. DOI: https://doi.org/10.1016/j.saa.2018.02.067.

RAKHIMOVA N R, RAKHIMOV R Z, MOROZOV V P, GAIFULLIN A R, POTAPOVA L I, GUBAIDULLINA A M, OSIN Y N. Marl-based geopolymers incorporated with limestone: A feasibility study [J]. Journal of Non-Crystalline Solids, 2018, 492: 1–10. DOI: https://doi.org/10.1016/j.jnoncrysol.2018.04.015.

KOTTA A B, KARAK S K, KUMAR M. Chemical, physical, thermal, textural and mineralogical studies of natural iron ores from Odisha and Chhattisgarh regions, India [J]. Journal of Central South University, 2018, 25(12): 2857–2870. DOI: https://doi.org/10.1007/s11771-018-3958-6

HAJIMOHAMMADI A, NGO T, KASHANI A. Glass waste versus sand as aggregates: The characteristics of the evolving geopolymer binders [J]. Journal of Cleaner Production, 2018, 193: 593–603. DOI: https://doi.org/10.1016/j.jclepro.2018.05.086.

LEE W K W, van DEVENTER J S J. The effects of inorganic salt contamination on the strength and durability of Geopolymers [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2002, 211: 115–126. DOI: https://doi.org/10.1016/S0927-7757(02)00239-X.

LV Qing-feng, JIA Meng-xue, WANG Sheng-xin, ZHOU Gang, WANG Qing-dong. Effect of salt content on compressive strength of solidified sulphate saline soil [J]. Journal of Central South University: Science and Technology, 2018, 49(3): 718–724. DOI: https://doi.org/10.11817/j.issn.1672-7207.2018.03.027. (in Chinese)

LI Qin, XU Hui, LI Fei-hu, SHEN Li-feng, ZHAI Jian-ping. Synthesis of geopolymer composites from blends of CFBC fly and bottom ashes [J]. Fuel, 2012, 97: 366–372. DOI: https://doi.org/10.1016/j.fuel.2012.02.059.

MAJIDI B. Geopolymer technology, from fundamentals to advanced applications: A review [J]. Materials Technology, 2009, 24(2): 79–87. DOI: https://doi.org/10.1179/175355509X449355.

HAJIMOHAMMADI A, van DEVENTER J S J. Characterisation of one-part geopolymer binders made from fly ash [J]. Waste and Biomass Valorization, 2017, 8(1): 225–233. DOI: https://doi.org/10.1007/s12649-016-9582-5.

LEONG H Y, ONG D E L, SANJAYAN J G, NAZARI A. The effect of different Na2O and K2O ratios of alkali activator on compressive strength of fly ash based-geopolymer [J]. Construction and Building Materials, 2016, 106: 500–511. DOI: https://doi.org/10.1016/j.conbuildmat.2015.12.141.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51878322) supported by the National Natural Science Foundation of China; Project(18YF1FA112) supported by Key Research and Development Program of Gansu Province, China

Rights and permissions

About this article

Cite this article

Lv, Qf., Wang, Zs., Gu, Ly. et al. Effect of sodium sulfate on strength and microstructure of alkali-activated fly ash based geopolymer. J. Cent. South Univ. 27, 1691–1702 (2020). https://doi.org/10.1007/s11771-020-4400-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4400-4