Abstract

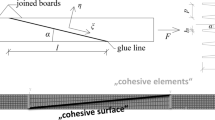

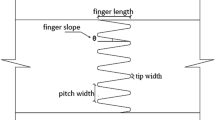

The aim of this study was to evaluate the structural performance of finger-joints made of Uruguayan Eucalyptus grandis and two types of adhesives. A numerical model for bending strength and stiffness prediction was developed. Model inputs were experimentally determined from tests on wooden specimens and from the literature. Finger-joints glued with two types of adhesives (one-component polyurethane -PUR- and emulsion polymer isocyanate-EPI-) were tested in bending and the failure modes were evaluated. Results show that adhesive type did not influence the stiffness of the finger-joint, but the bending strength. Specimens glued with PUR showed higher strength than those glued with EPI. A 3D model, using Comsol Multiphisic software, was developed to simulate the finger-joint behavior. Adhesive-wood interaction in the finger-joints was modelled using the Comsol Thin Elastic Layer module, defined by the elastic properties of the adhesives. The numerical results showed no differences on the stiffness of the joints regardless of adhesive type. Results agreed with those obtained from experimental tests, with a maximum error of 7%. Models predicted the bending strength with an error of 6% with respect to the experimental values. Different finger configurations were analysed, and the optimal geometry (20 mm-length, 6.2 mm-pitch and 1.0 mm-tip-thick) to attain the maximum strength for Uruguayan Eucalyptus was found.

Similar content being viewed by others

References

Ahmad Z, Lum WC, Lee SH et al (2017) Mechanical properties of finger jointed beams fabricated from eight Malaysian hardwood species. Constr Build Mater 145:464–473. https://doi.org/10.1016/j.conbuildmat.2017.04.016

Ayarkwa J, Sasaki HYY (2000a) Effect of finger geometry and end pressure on the flexural properties of finger-jointed tropical African hardwoods. For Prod J 50(11–12):53–63

Ayarkwa J, Hirashima Y, Sasaki Y, Ando K (2000b) Effect of glue type on flexural and tensile properties of finger-jointed tropical African hardwoods. For Prod J 50(10):59–68

Bourreau D, Aimene Y, Beauchene J, Thibaut B (2013) Feasibility of glued laminated timber beams with tropical hardwoods. Eur J Wood Prod 75:653–662

Bourscheid CB, Terezo RF, Stüpp AM, Vanzella DA (2015) Desempenho mecânico de madeira laminada colada de Eucalyptus spp. [Mechanical performance of Eucalyptus spp. glulam] In: Anais do I I Congresso Brasileiro de Ciencia e Tecnologia da Madeira - CBCTEM. Belo Horizonte, Brazil

Bustos C, Mohammad M, Hernández RE, Beauregard R (2003) Effects of curing time and end pressure on the tensile strength of finger-jointed black spruce lumber. For Prod J 53:85

Calil Neto C, Christoforo AL, Ribeiro Filho SM et al (2014) Evaluation of strength to shear and delamination in glued laminated wood. Ciência Florest 23:989–996

Camú CT, Aicher S (2018) A stochastic finite element model for glulam beams of hardwoods. In: World conference on timber engineering. Seoul, South Korea

CEN (2013) EN 14080. Timber structures. Glued laminated timber and glued solid timber. Requirements. CEN/TC 124/WG3. Brussels

CEN (2015) EN 16351. Timber structures. Cross laminated timber. Requirements. CEN/TC 124/WG 3, Brussels

CEN (2010) EN 408. Timber structures. Structural timber and glued laminated timber. Determination of some physical and mechanical properties. CEN/TC 124/WG1, Brussels

CEN (2016a) EN 384. Structural timber. Determination of characteristic values of mechanical properties and density. CEN/TC 124/WG2, Brussels

CEN (2016b) EN 338. Structural timber. Strength classes. CEN/TC 124/WG2. Brussels P

de Castro San Román J (2005) Experiments on Epoxy, Polyurethane and ADP adhesives: composite construction laboratory, Technical Report Nr. CCLab2000.1b/1

Dieste A (2012) Programa de promoción de exportaciones de productos de madera [Wood Products Export Promotion Program] Dirección Nacional de Industrias, Ministerio de Industrias, Energía y Minería, Consejo Sectorial Forestal-Madera [National Direction of Industries, Ministry of Industries, Energy and Minning, Forest-Wood Sectorial Council]. p 38

Franke B, Schusser A, Müller A (2014) Analysis of finger joints from beech wood. In: World conference on timber engineering. Quebec, Canada

Franke S, Marto J (2014) Investigation of Eucalyptus globulus wood for the use as engineered wood material. In: Proceedings of the world conference on timber engineering. Quebec, Canada

Milner HR, Yeoh E (1991) Finite element analysis of glued timber finger joints. J Struct Eng 117:755–766

IRAM (2013a) IRAM 9661:2013. Madera laminada encolada estructural. Requisitos de fabricación de los empalmes por unión dentada [Glued laminated timber. Requirements of manufacturing of the finger joints]. Instituto Argentino de Normalización y Certificación-IRAM- [Argentinean Institute of Standardization and Certification], Buenos Aires

IRAM (2006) IRAM 9660–1:2006. Madera laminada encolada estructural. Parte 1. Clases de resistencia y requisitos de fabricación y control [Glued laminated timber. Part 1. Strength classes and manufacturing and control requirements]. Instituto Argentino de Normalización y Certificación-IRAM- [Argentinean Institute of Standardization and Certification], Buenos Aires

IRAM (2013b) IRAM 9662-2: 2013. Madera laminada encolada estructural. Clasificación visual de las tablas por resistencia. Parte 2. Tablas de Eucalyptus grandis [Glued laminated timber. Visual grading of boards by strength. Part 2. Boards of Eucalyptus grandis]. Instituto Argentino de Normalización y Certificación-IRAM- [Argentinean Institute of Standardization and Certification], Buenos Aires

Iwakiri S, Monteiro Matos JL, Prata JG et al (2014) Characteristics of glued laminated beams made of teak wood (Tectona grandis). Floresta e Ambient 21:269–275

Khelifa M, Auchet S, Méausoone PJ, Celzard A (2015) Finite element analysis of flexural strenghening of timber beams with Carbon Fibre-Reinforced Polymers. Eng Struct 101:364–375

Konnerth J, Gindl W, Müller U (2007) Elastic properties of adhesive polymers. I. Polymer films by means of electronic speckle pattern interferometry. J Appl Polym Sci 103:3936–3939. https://doi.org/10.1002/app.24434

Lara-Bocanegra AJ, Majano-Majano A, Crespo J, Guaita M (2017) Finger-jointed Eucalyptus globulus with 1C-PUR adhesive for high performance engineered laminated products. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.01.004

Moya L, Pérez-Gomar C, Vega A, Sánchez A, Torino I, Baño V (2019) Relationship between manufacturing parameters and structural properties of Eucalyptus grandis glued laminated timber. Maderas 21:21

Özçifçi AYF (2008) Structural performance of the finger-jointed strength of some wood species with different joint configurations. Constr Build Mater 22:1543–1550

Pereira MC, Calil Neto C, Icimoto FH, Calil Junior C (2016) Evaluation of tensile strength of a Eucalyptus grandis and Eucalyptus urophyla Hibrid in wood beams bonded together by means of finger joints and polyurethane-based glue. Mater Res 19:1270–1275

Piter JC, Cotrina AD, Sosa Zitto MA et al (2007) Determination of characteristic strength and stiffness values in glued laminated beams of Argentinean Eucalyptus grandis according to European standards. Holz Roh- Werkst 65:261–266. https://doi.org/10.1007/s00107-006-0161-5

Raknes E (1980) The influence of production conditions on the strength of finger-joints (of sawnwood in Norway). In: Transmitted by the Government of Norway in FAO, Geneva (Switzerland). Joint ECE/FAO Agriculture and Timber Div. Seminar on the PRoduction, Marketing and Use of Finger-Jointed Sawnwood. Hamar (Norway)

Sebera V, Muszyński L, Tippner J et al (2015) FE analysis of CLT panel subjected to torsion and verified by DIC. Mater Struct 48:451–459. https://doi.org/10.1617/s11527-013-0195-1

Serrano E, Gustafsson J, Larsen HJ (2001) Modeling of finger-joint failure in glued-laminated timber beams. J Struct Eng 127:914–921

Smardzewski J (1996) Distribution of stresses in finger joints. Wood Sci Technol 30:477–489

Stoeckel F, Konnerth J, Gindl-altmutter W (2013) Mechanical properties of adhesives for bonding wood—a review. Int J Adhes Adhes 45:32–41

Tran VD, Oudjene M, Méausoone PJ (2015) Experimental and numerical analysis of the structural response of adhesively reconstituted beech timber beams. Compos Struct 119:206–217

Tran VD, Oudjene M, Méausoone PJ (2014) FE analysis and geometrical optimization of timber beech finger-joint under bending test. Int J Adhes Adhes 52:40–47. https://doi.org/10.1016/j.ijadhadh.2014.03.007

Vassiliou V, Barboutis I, Karastergiou S (2006) Effect of PVA bonding on finger-joint strength of steamed and unsteamed beech wood (Fagus sylvatica). J Appl Polym Sci 103:1664–1669

Volkmer T, Schusser A, Franke B (2014) Analysis of the penetration of adhesives at finger-joints in beech wood. In: WCTE 2014 World Conference on Timber Engineering, Quebec, Canada. August 10-14 2014

Vrazel M, Sellers Jr T (2004) The effects of species, adhesive type and cure temperature on the strength and durability of a structural finger-joint. For Prod J 54:66–75

Acknowledgments

The authors thank the National Agency for Research and Innovation (ANII) of Uruguay for the funds for the execution of this project (PR FSA_1_2013_1_12897) and for the funds for the postdoctoral fellowship of Dr. Abel Vega in the Facultad de Ingeniería, Universidad de la República (PD_NAC_2014_1_102147).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vega, A., Baño, V., Cardoso, A. et al. Experimental and numerical evaluation of the structural performance of Uruguayan Eucalyptus grandis finger-joint. Eur. J. Wood Prod. 78, 923–932 (2020). https://doi.org/10.1007/s00107-020-01570-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01570-5